Murata GCM21BR72A223KA37 Series User manual

Other Murata Industrial Electrical manuals

Murata

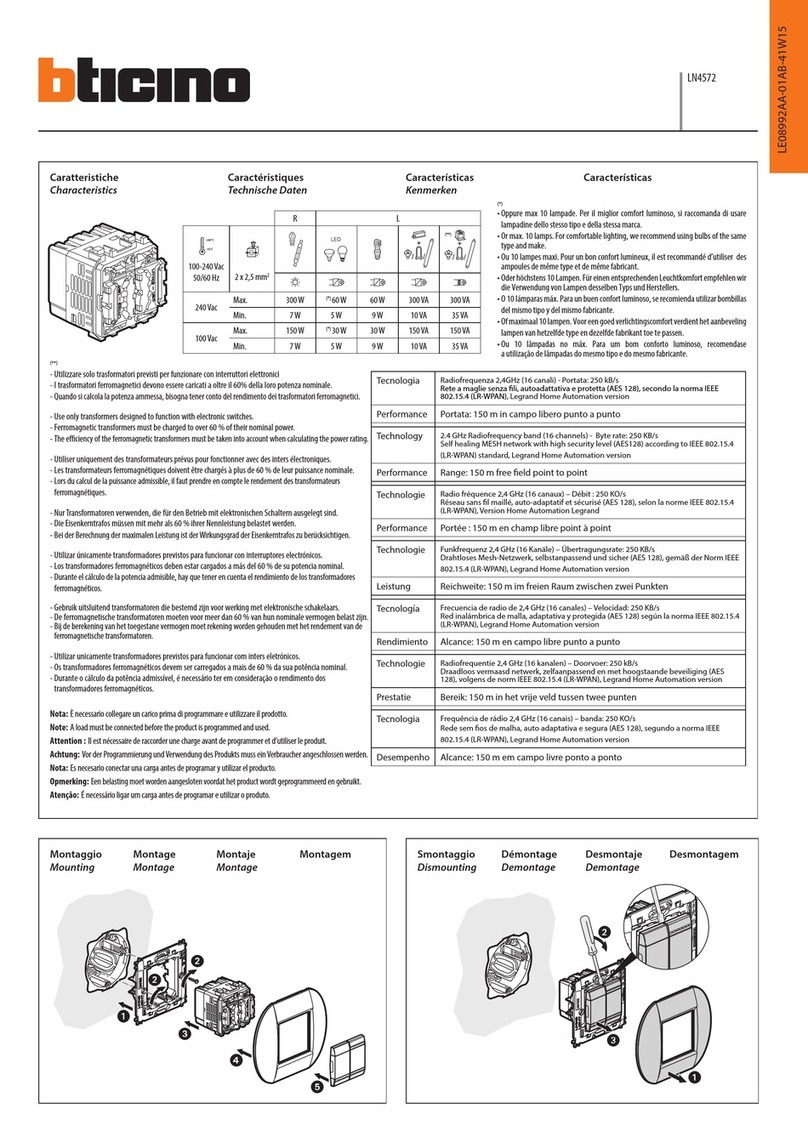

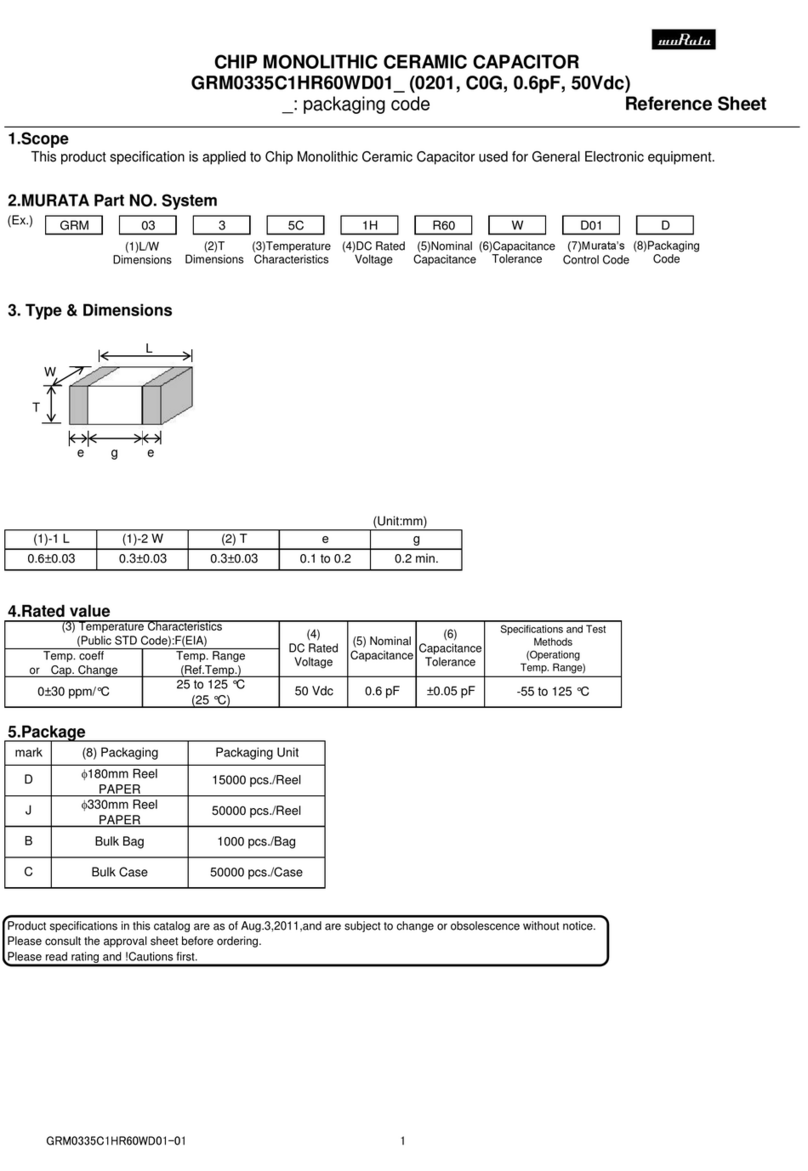

Murata GRM0335C1HR60WD01 Series User manual

Murata

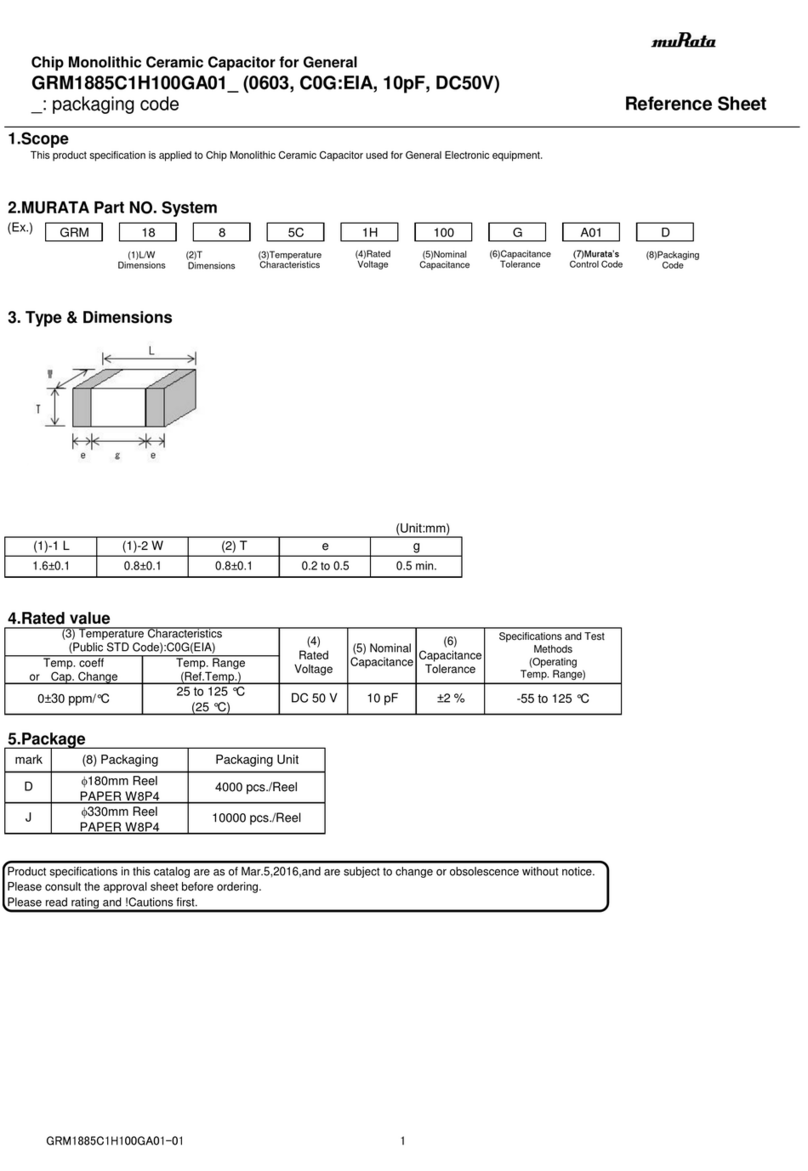

Murata GRM1885C1H100GA01 Series User manual

Murata

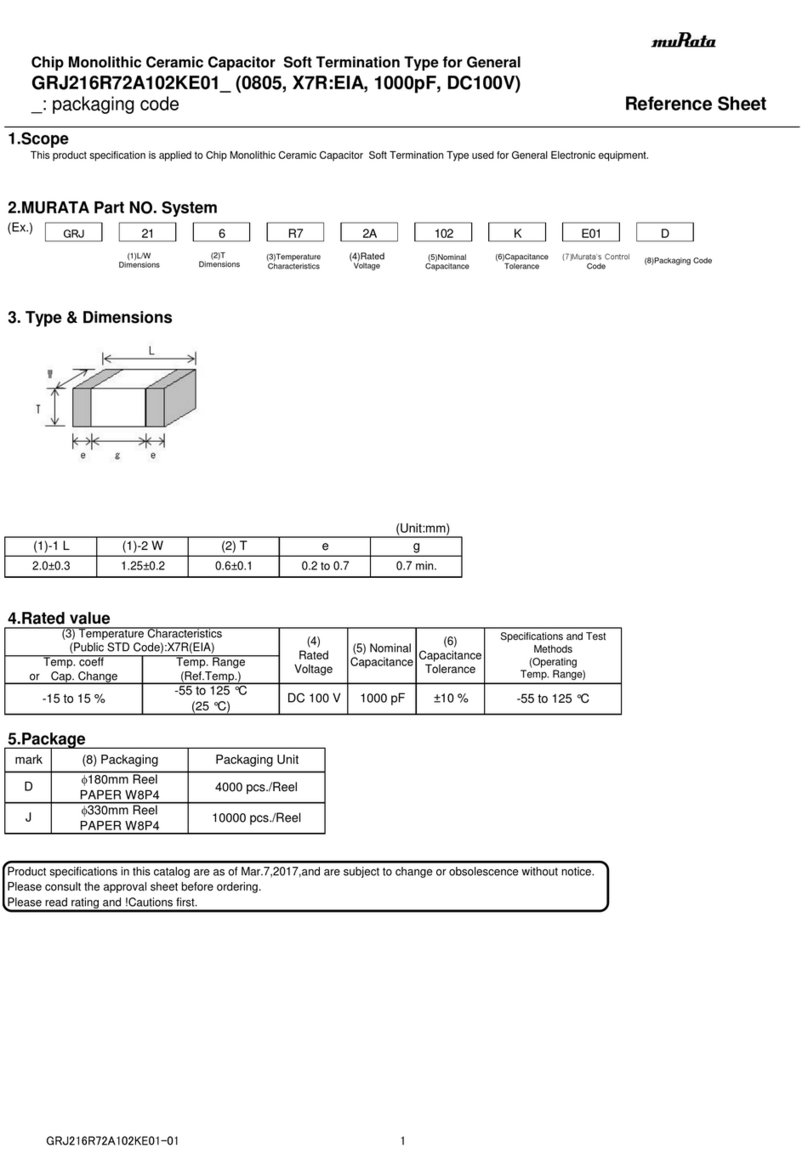

Murata GRJ216R72A102KE01 Series User manual

Murata

Murata GRM033R60J333KE01 Series User manual

Murata

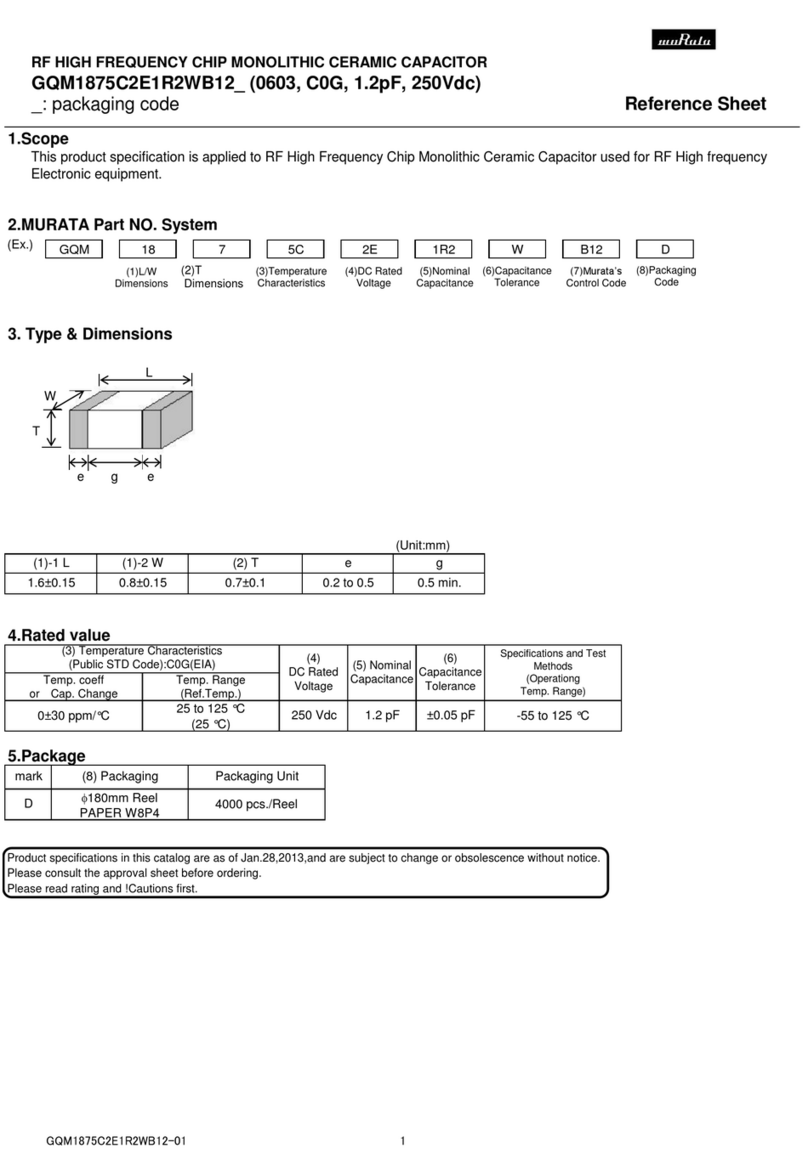

Murata GQM1875C2E1R2WB12 Series User manual

Murata

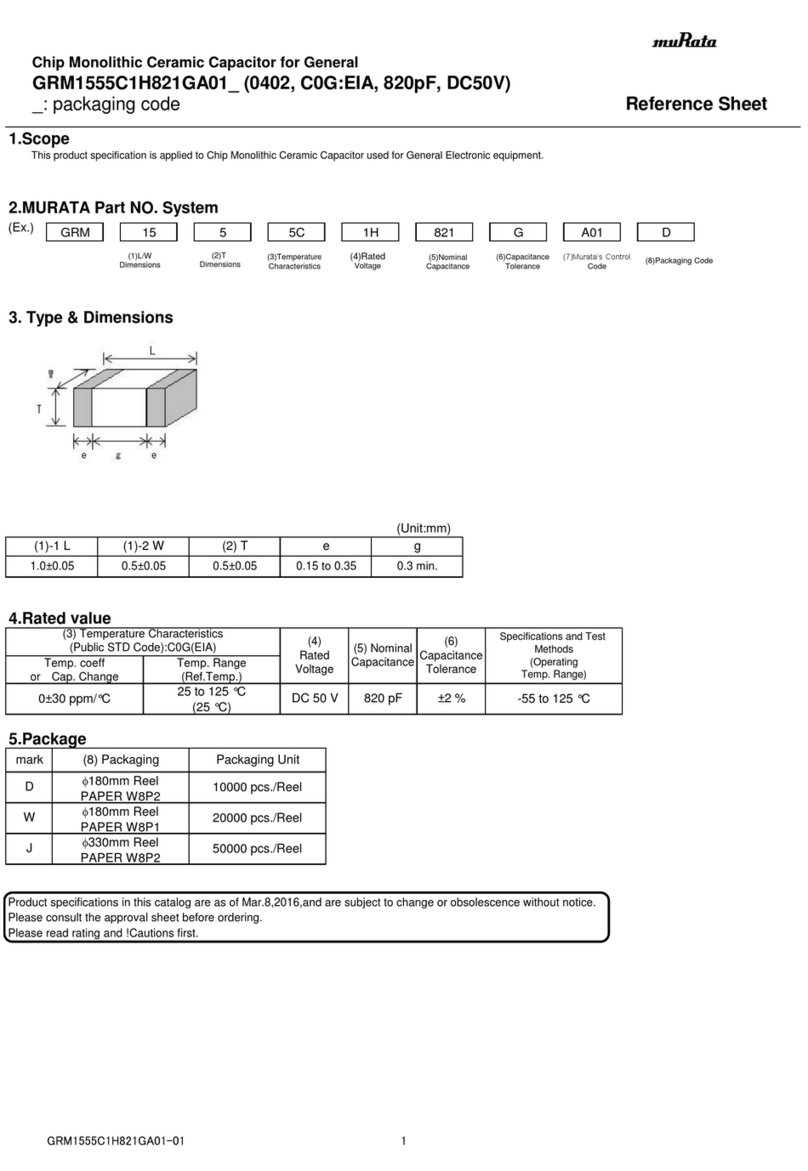

Murata GRM1555C1H821GA01 Series User manual

Murata

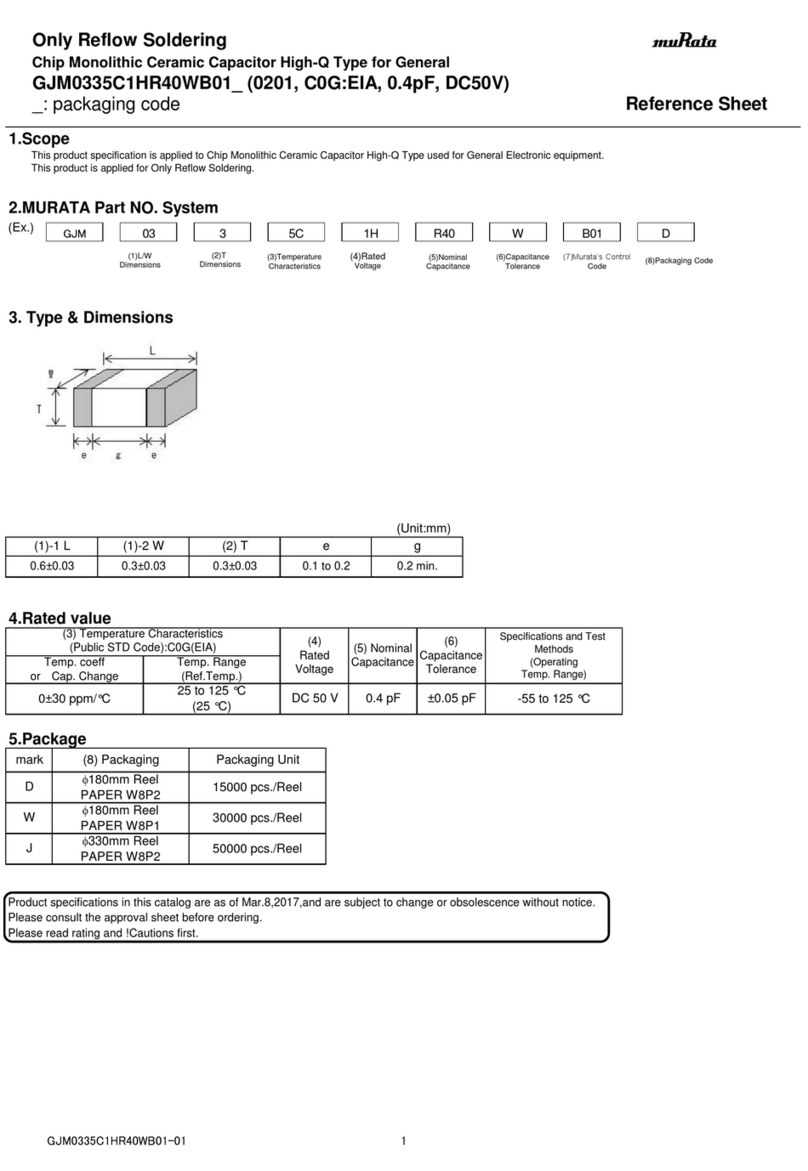

Murata GJM0335C1HR40WB01 Series User manual

Murata

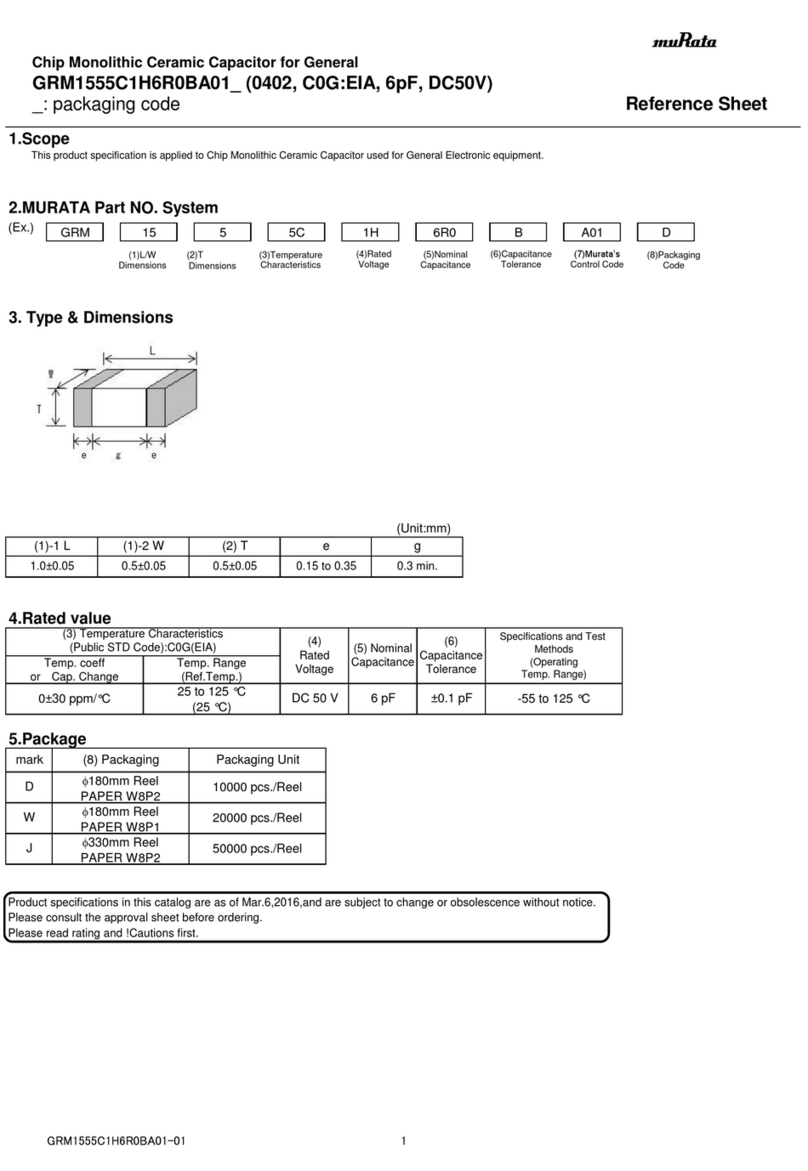

Murata GRM1555C1H6R0BA01 Series User manual

Murata

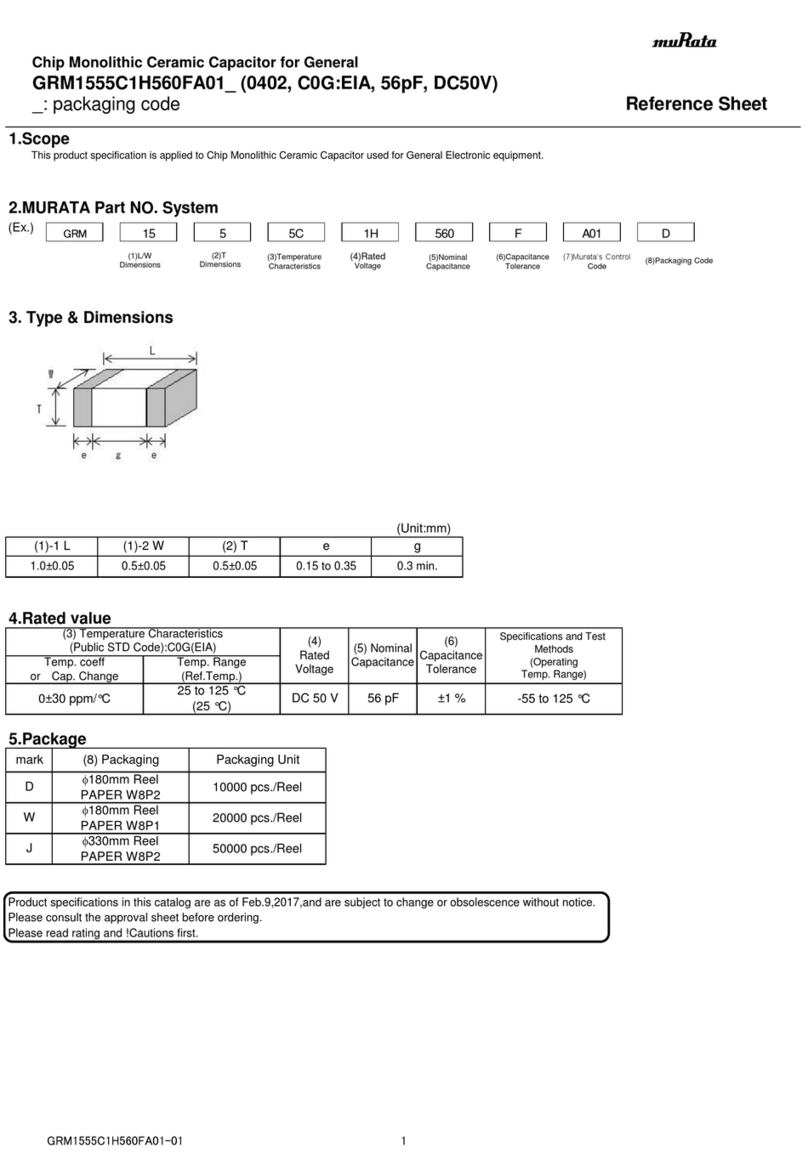

Murata GRM1555C1H560FA01 Series User manual

Murata

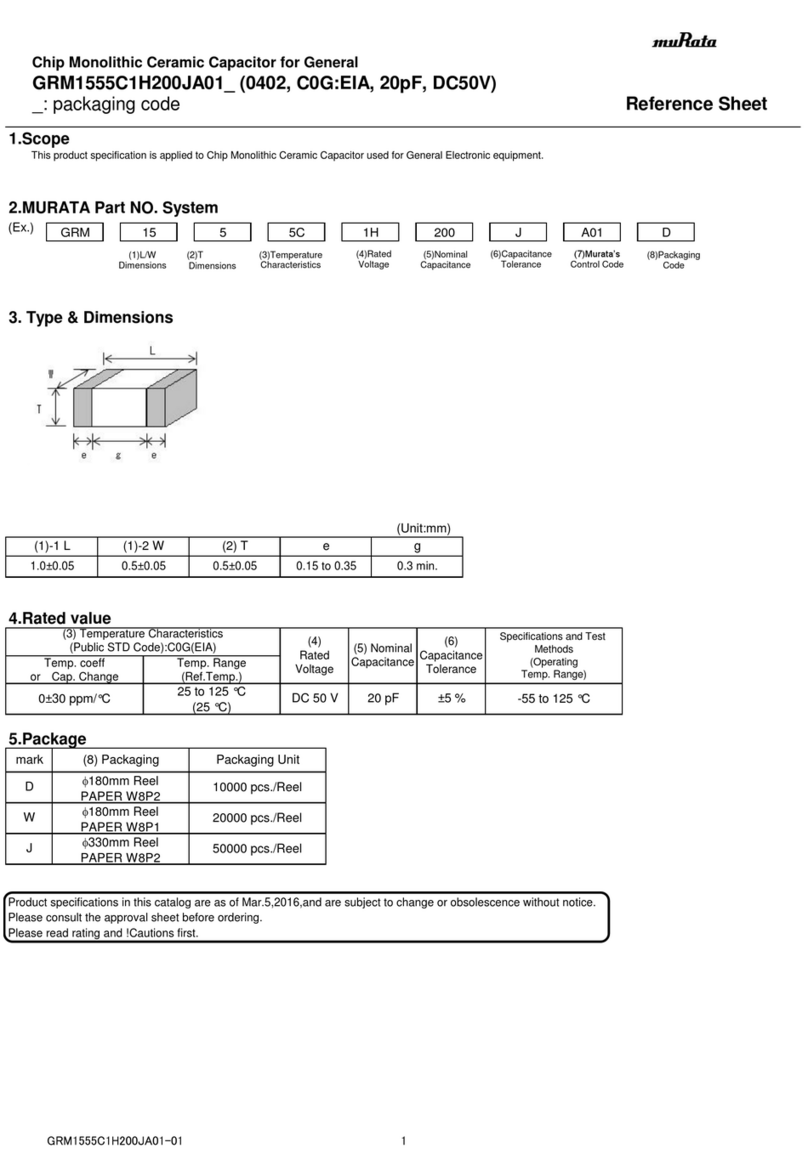

Murata GRM1555C1H200JA01 Series User manual

Murata

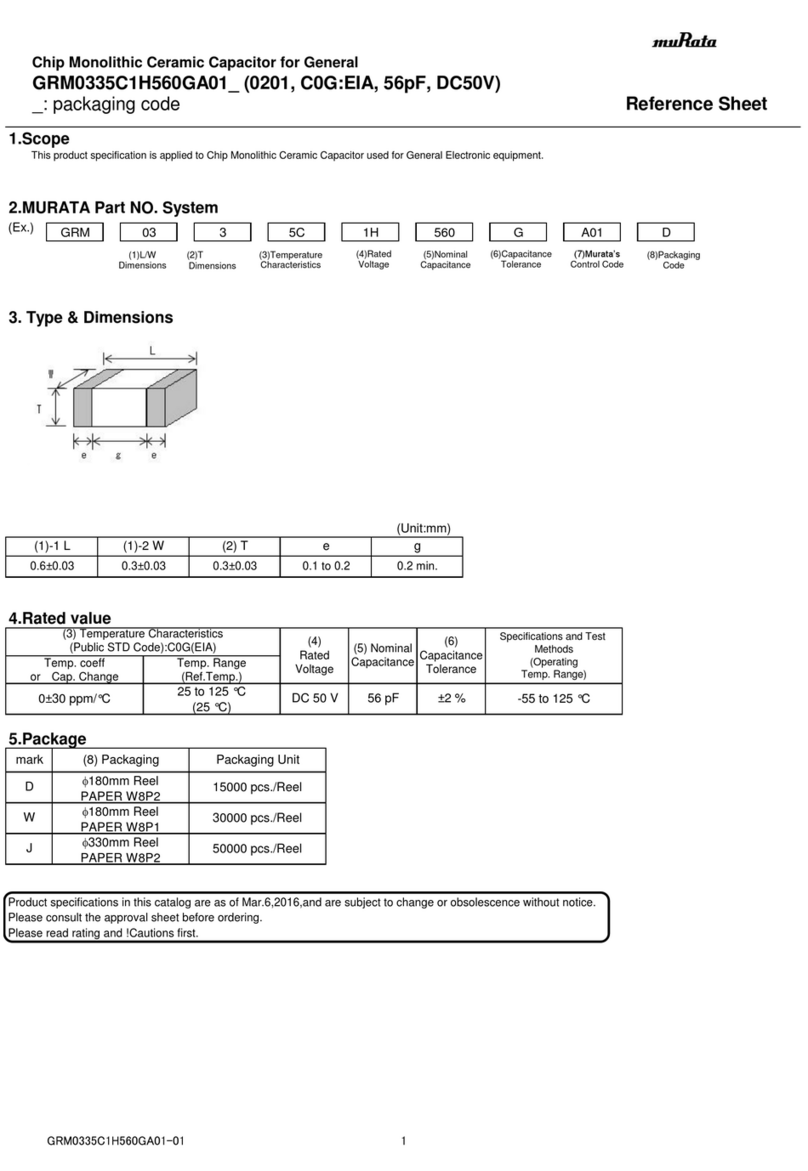

Murata GRM0335C1H560GA01 Series User manual

Murata

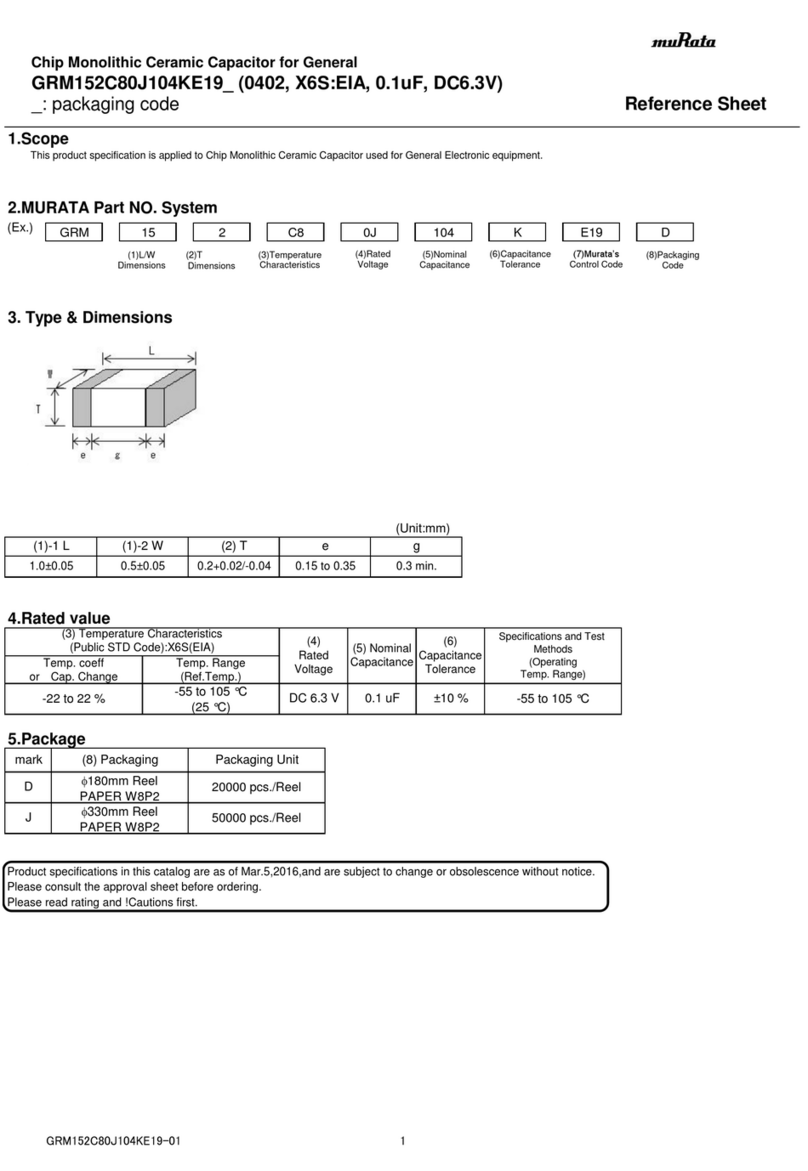

Murata GRM152C80J104KE19 Series User manual

Murata

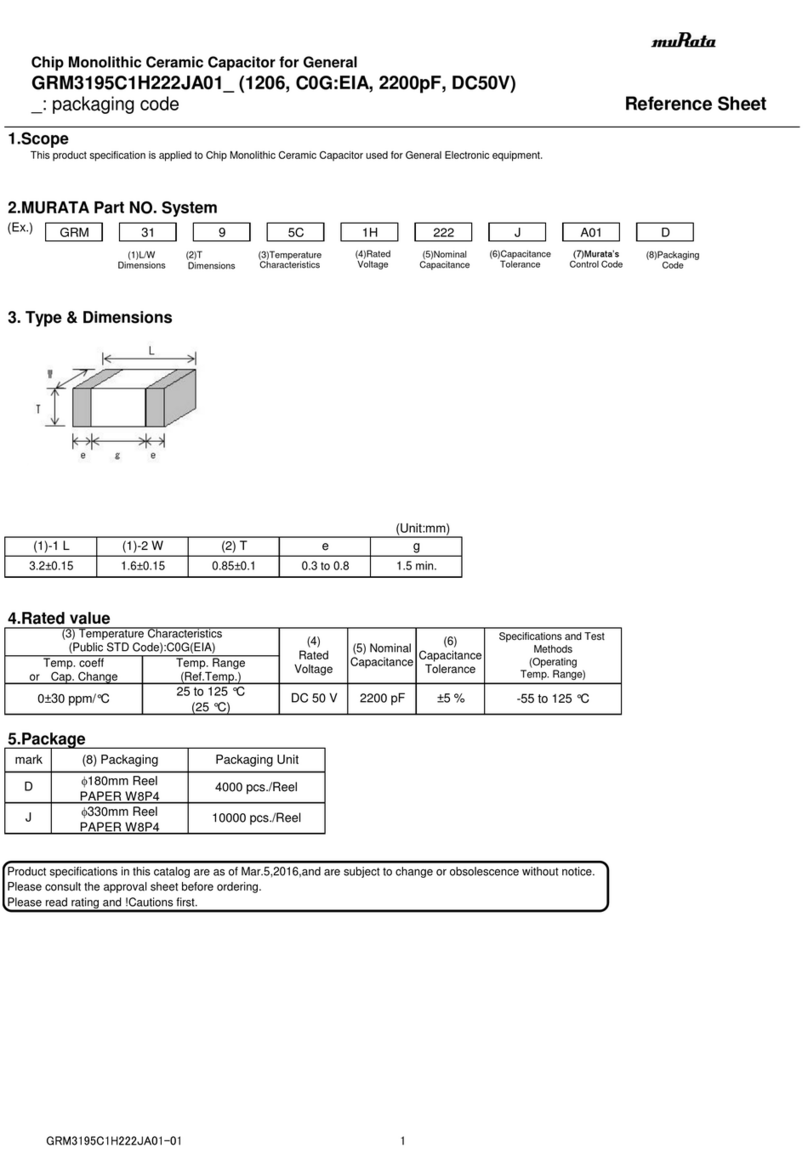

Murata GRM3195C1H222JA01 Series User manual

Murata

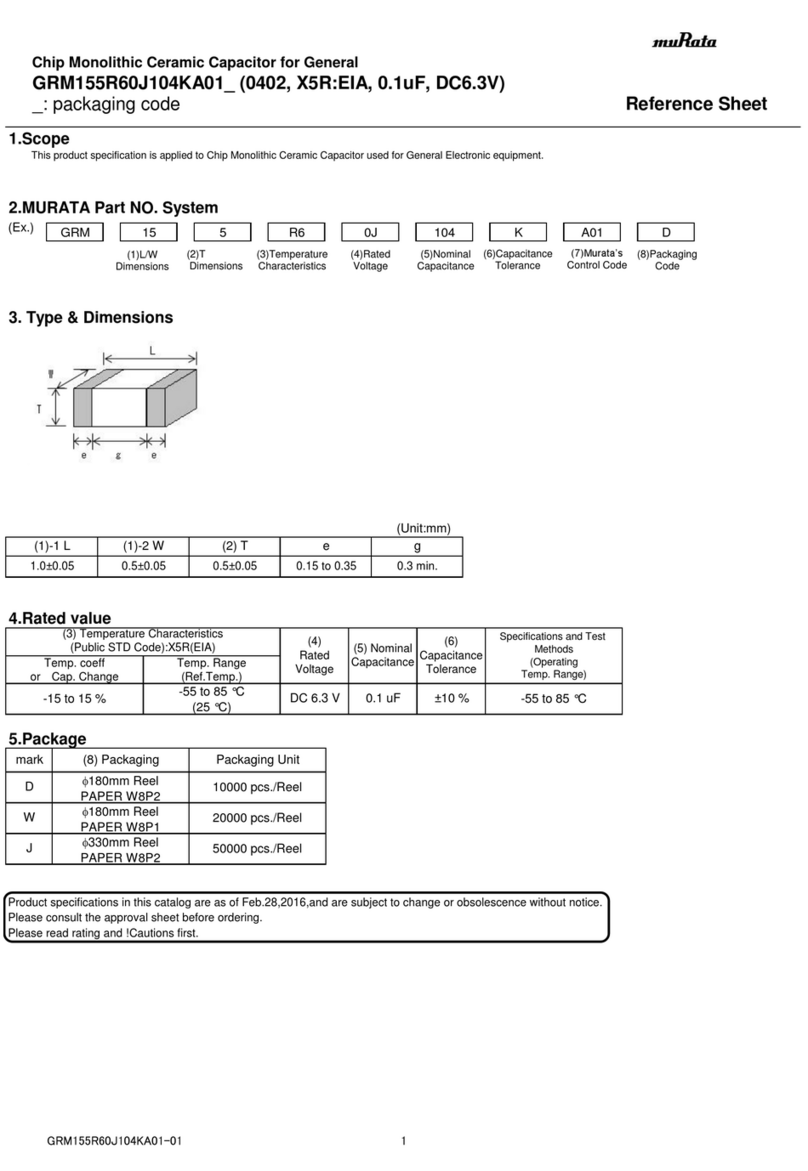

Murata GRM155R60J104KA01 Series User manual

Murata

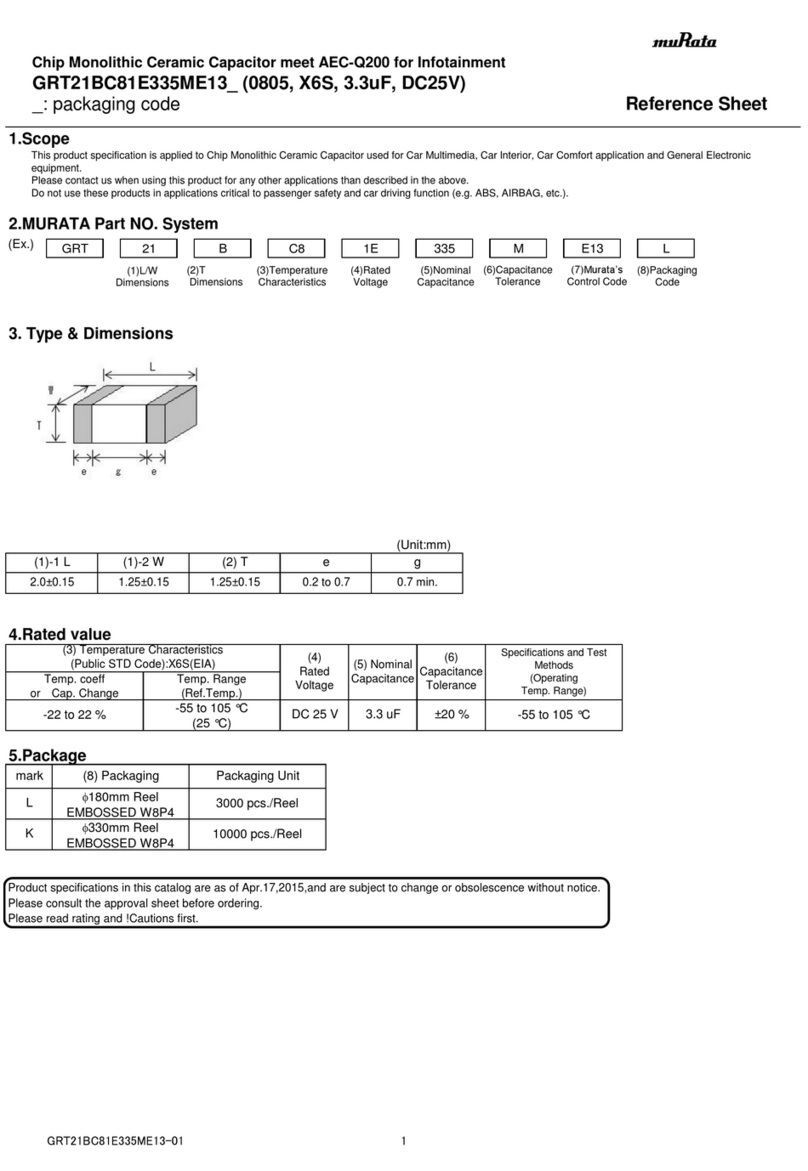

Murata GRT21BC81E335ME13 Series User manual

Murata

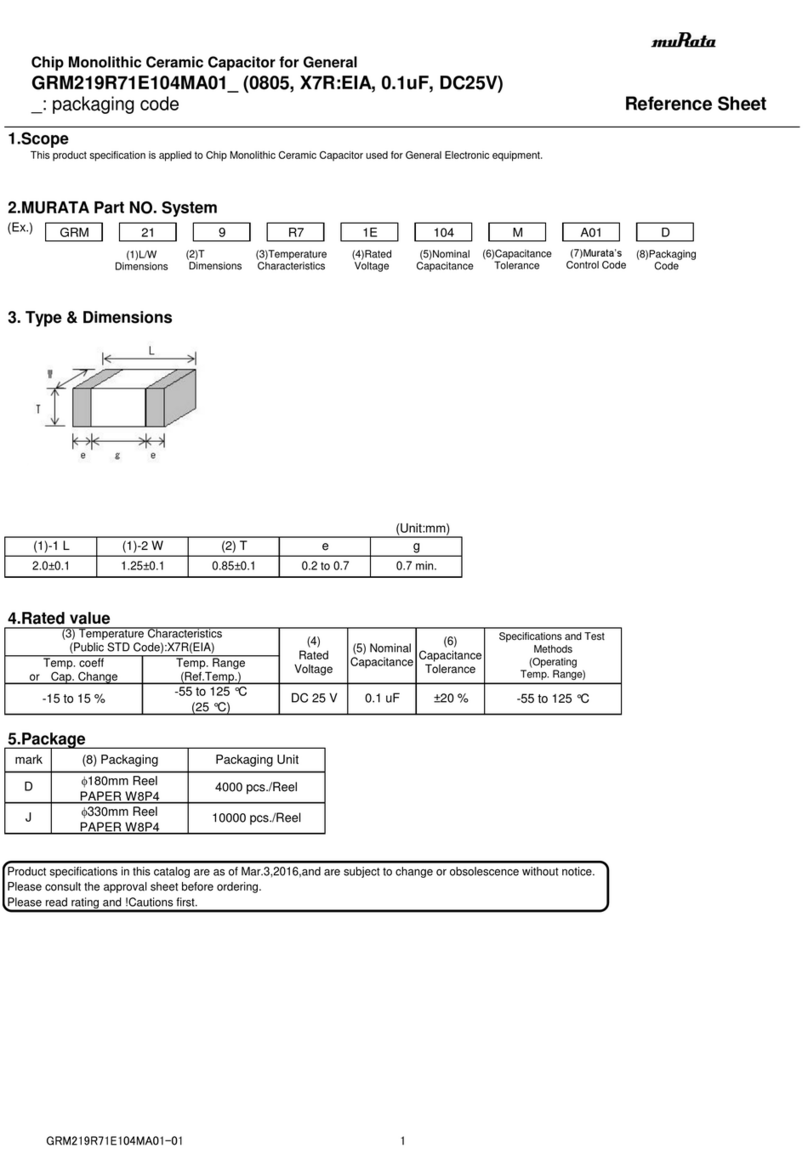

Murata GRM219R71E104MA01 Series User manual

Murata

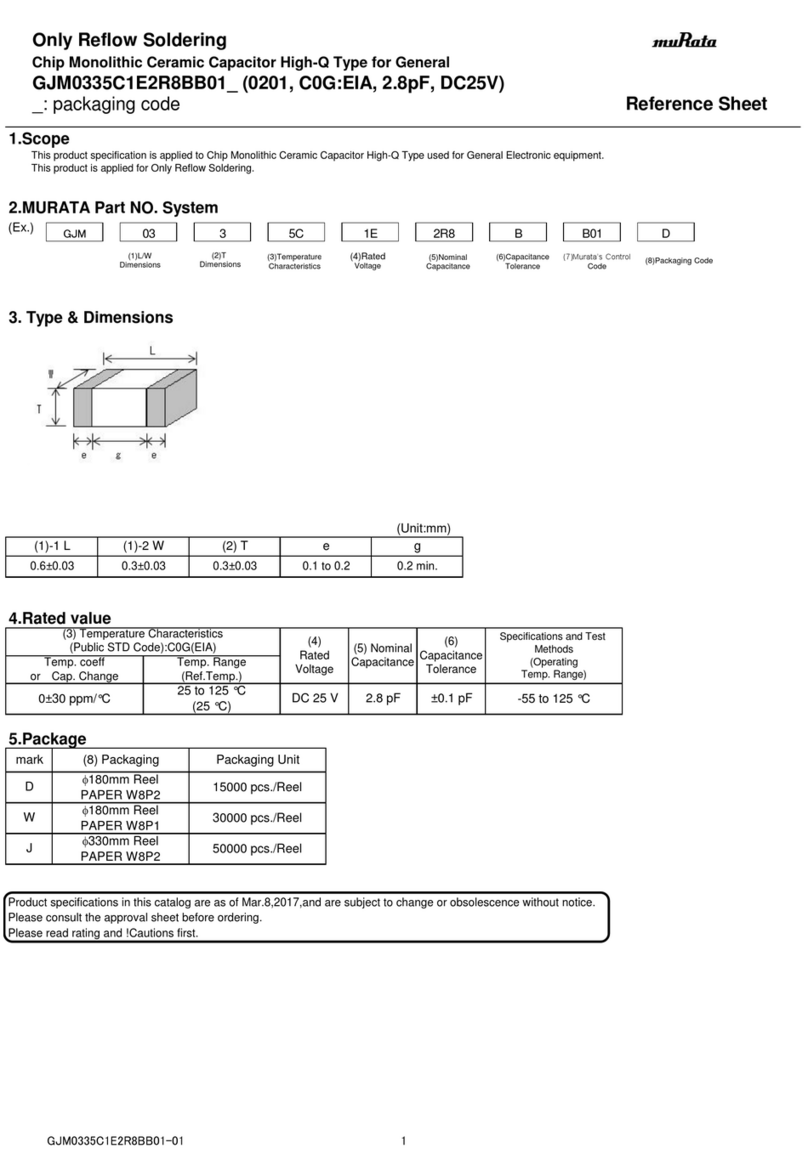

Murata GJM0335C1E2R8BB01 Series User manual

Murata

Murata GJM0225C1E7R2CB01 Series User manual

Murata

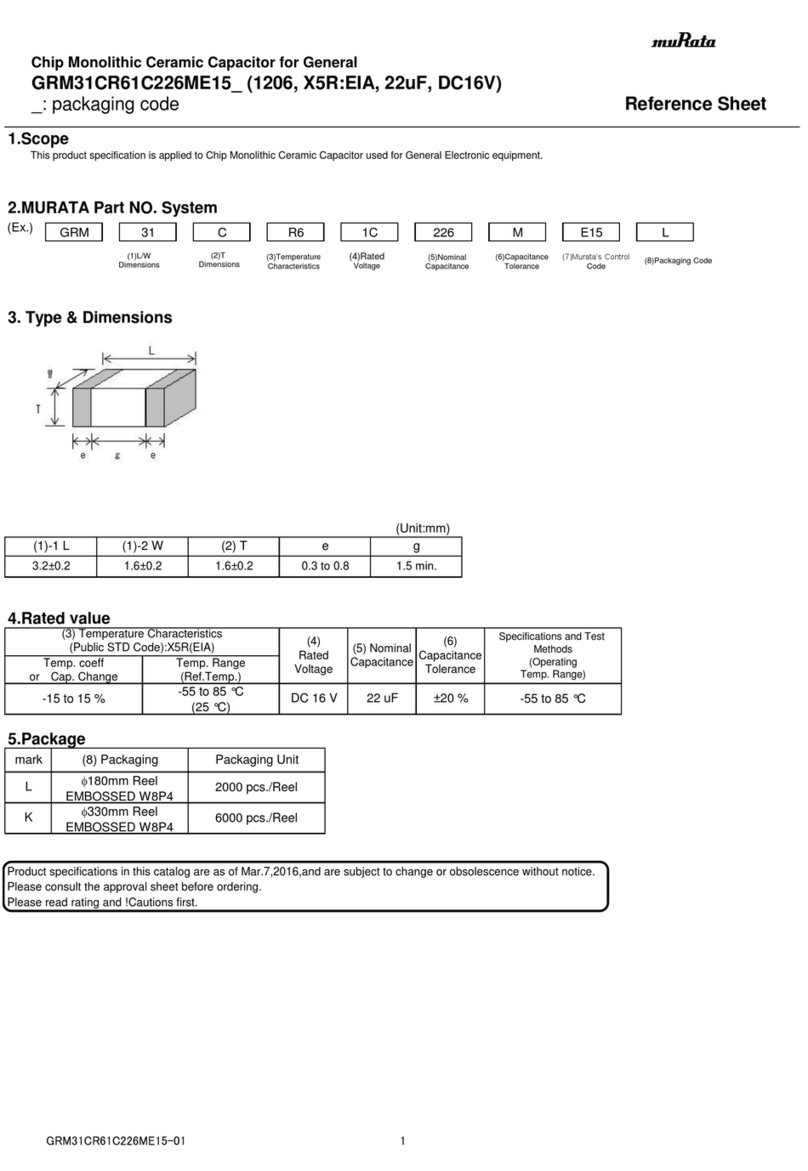

Murata GRM31CR61C226ME15 Series User manual

Murata

Murata GRM022R60J102ME19 Series User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

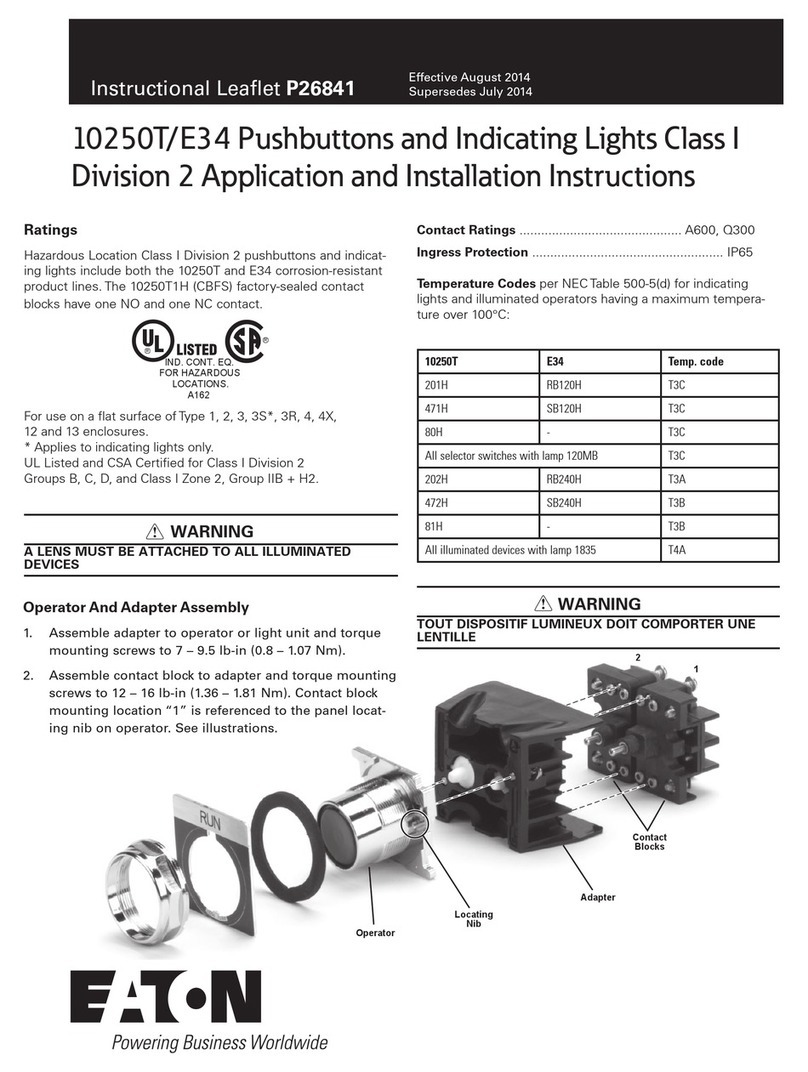

Eaton

Eaton Ulusoy HMH24-04 user manual

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

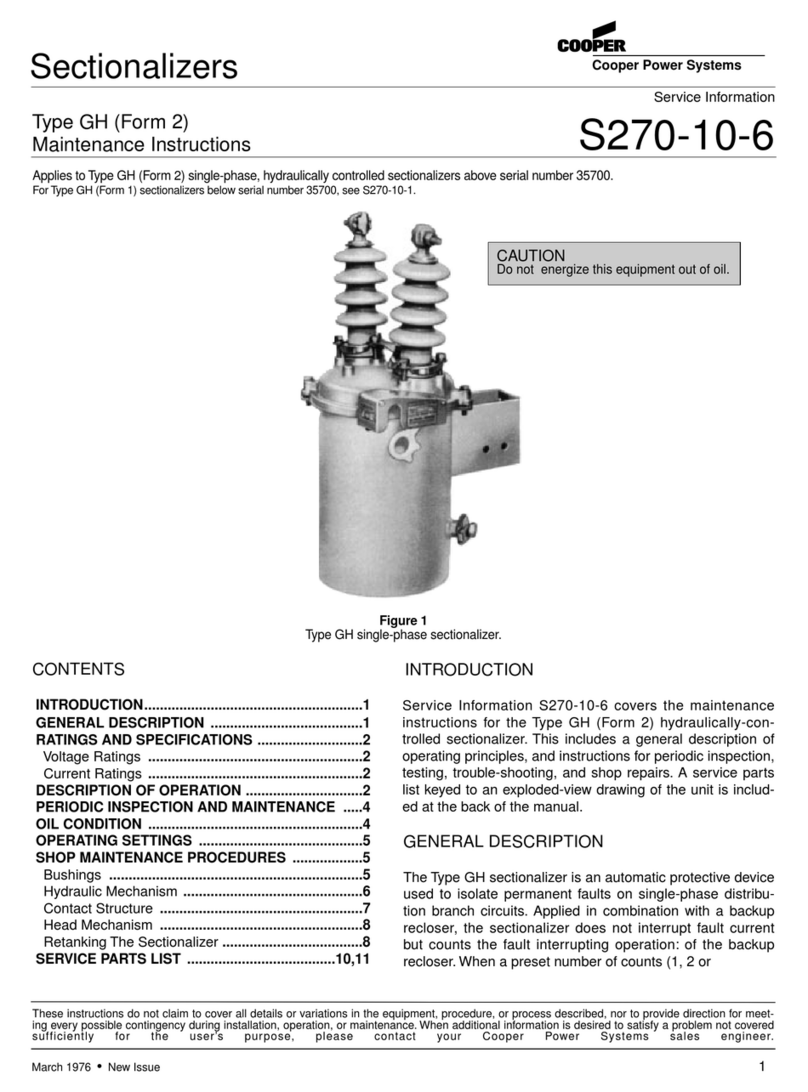

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions