5C : -55℃to 125℃Reference Temperature : 25℃

Temperature Range

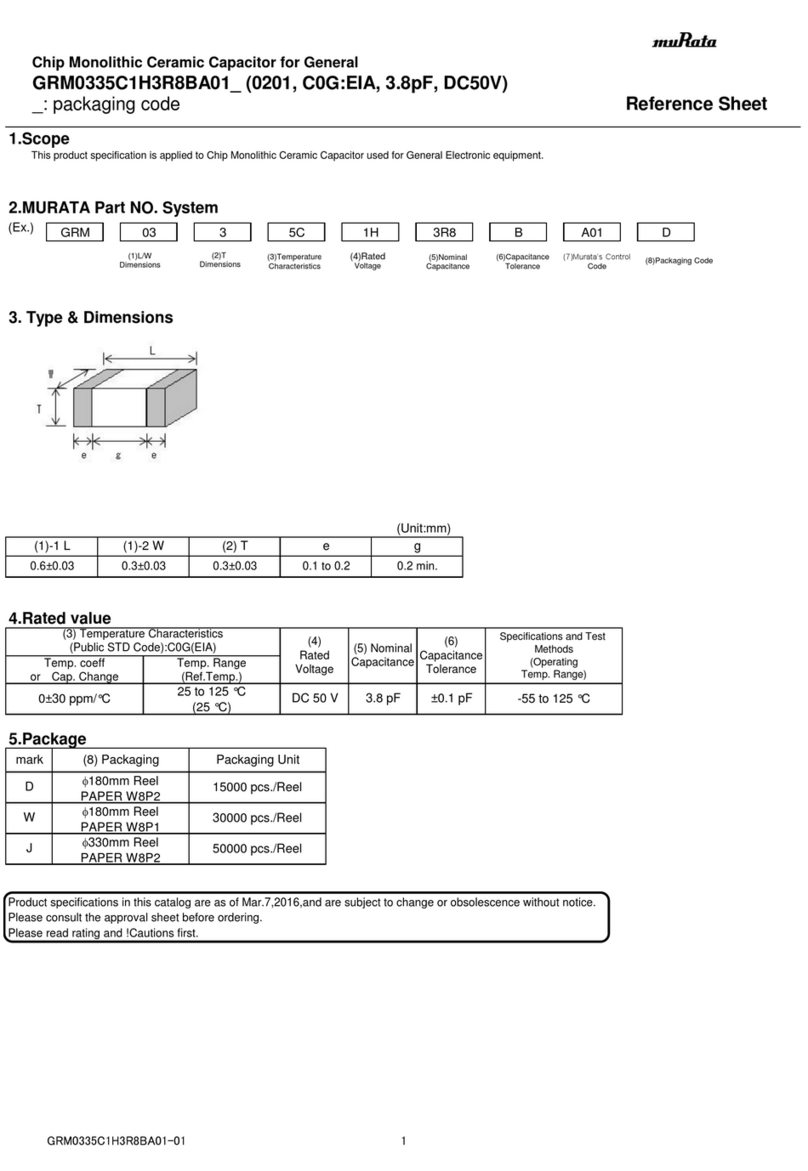

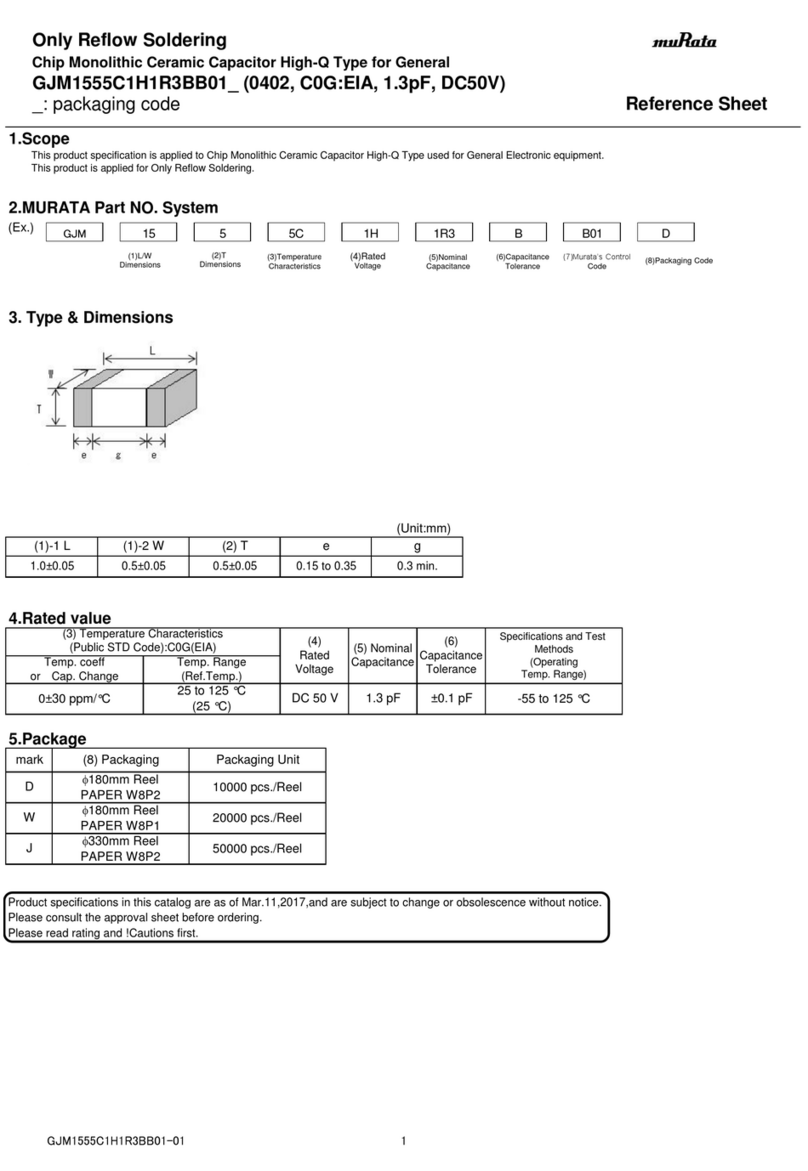

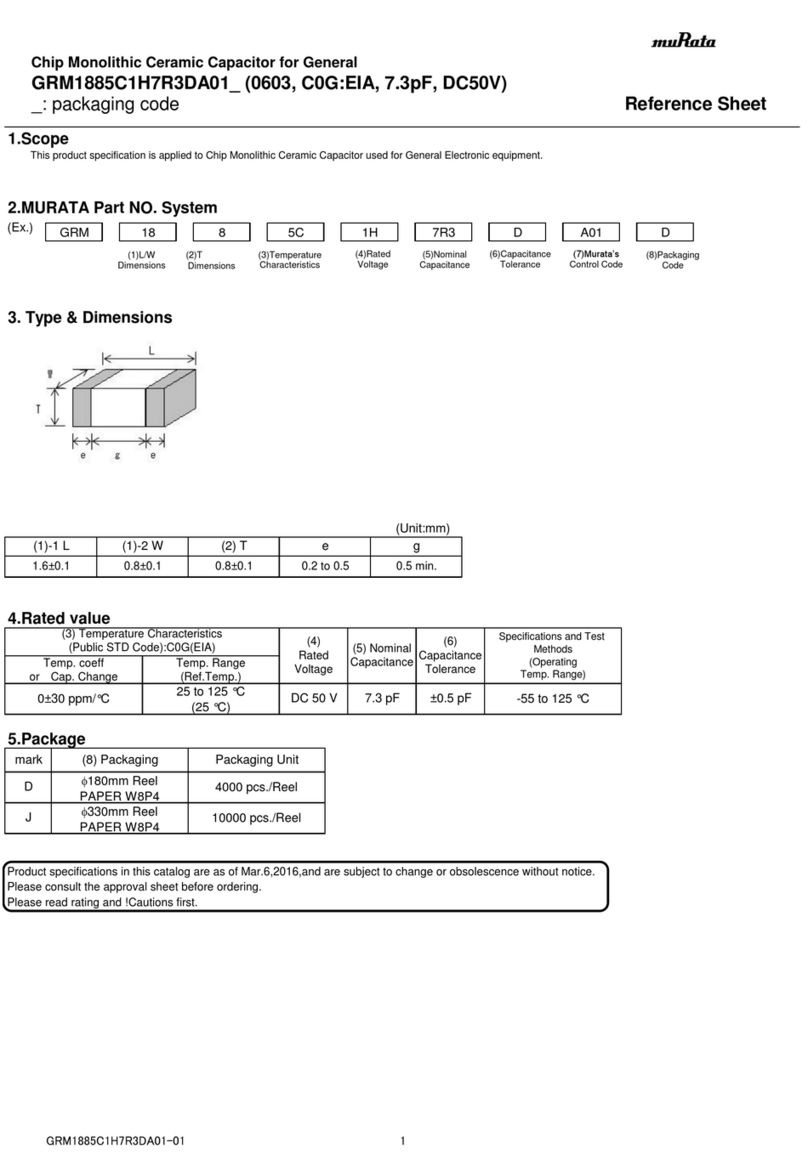

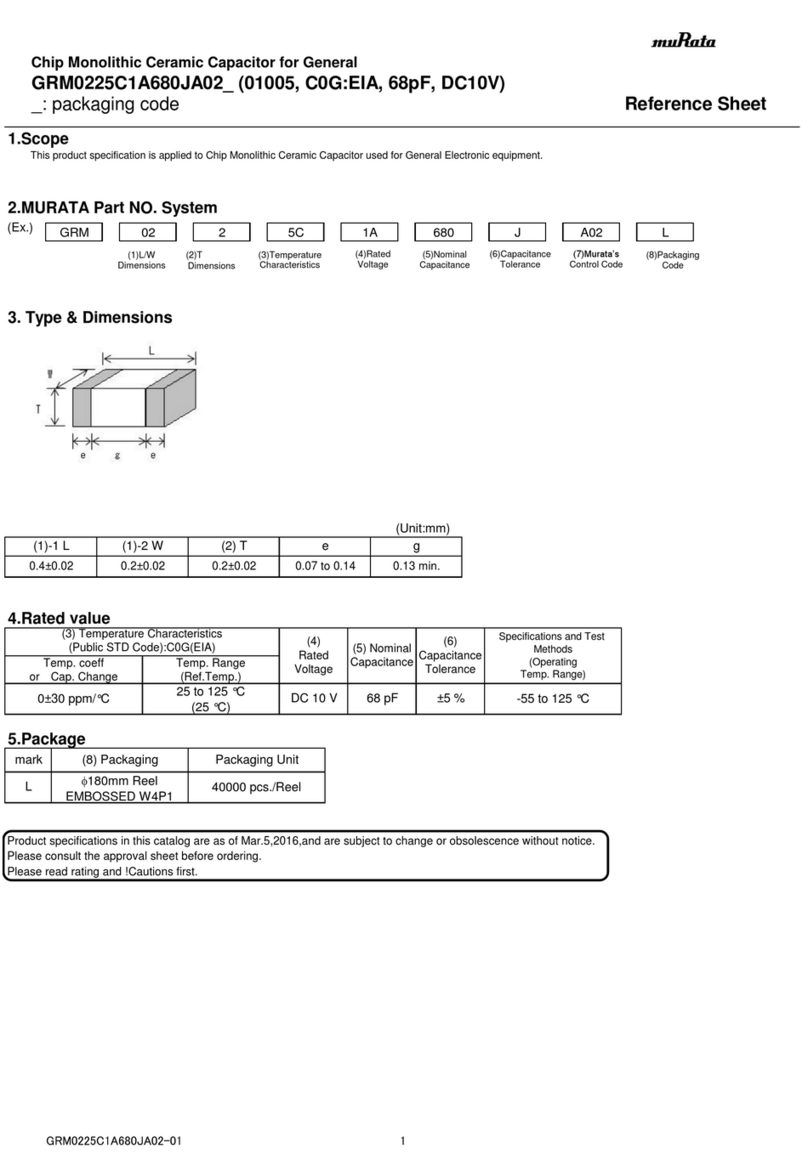

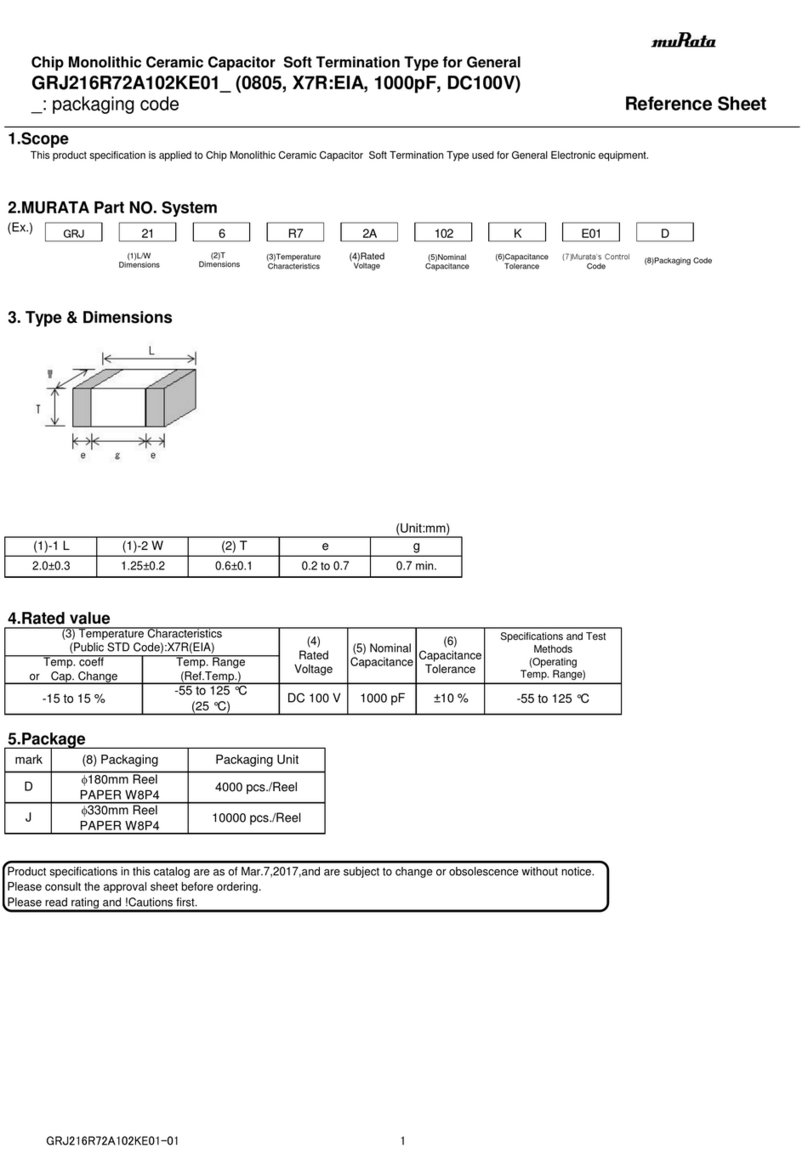

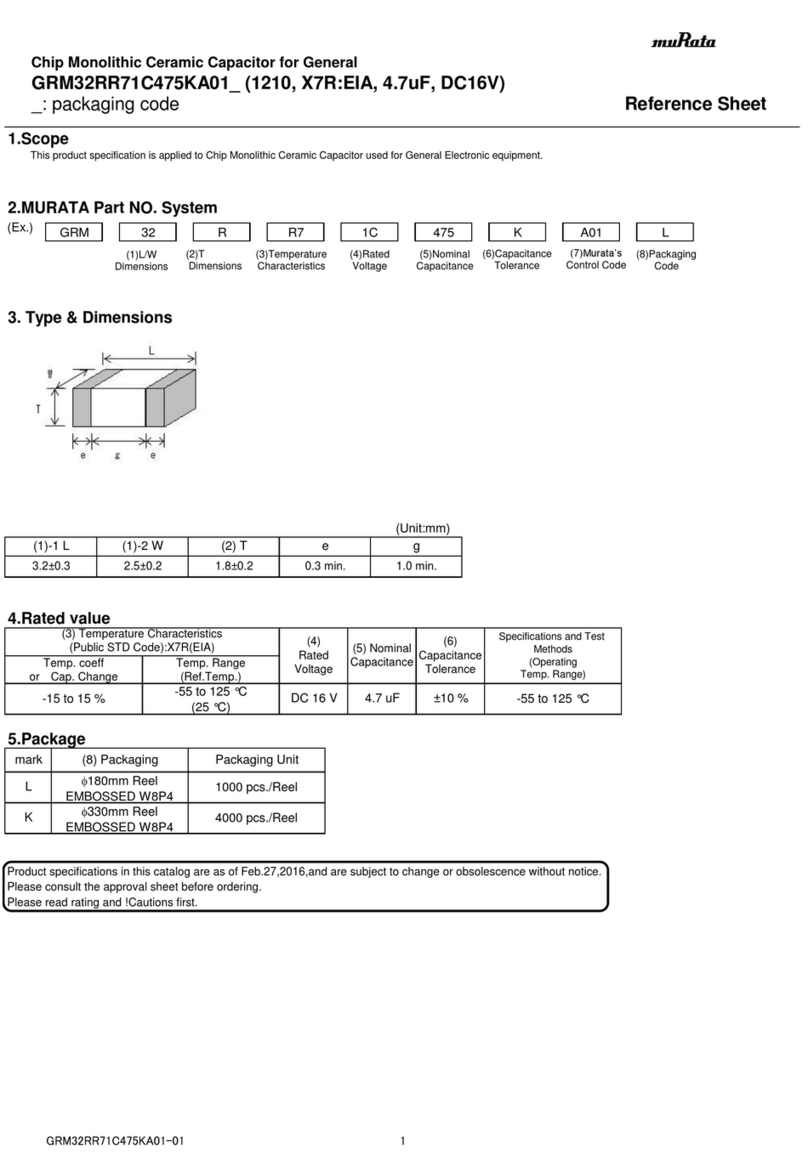

2 Rated Voltage See the previous pages. The rated voltage is defined as the maximum voltage which may

be applied continuously to the capacitor.

When AC voltage is superimposed on DC voltage, VP-P or VO-P,

whichever is larger, should be maintained within the rated voltage

range.

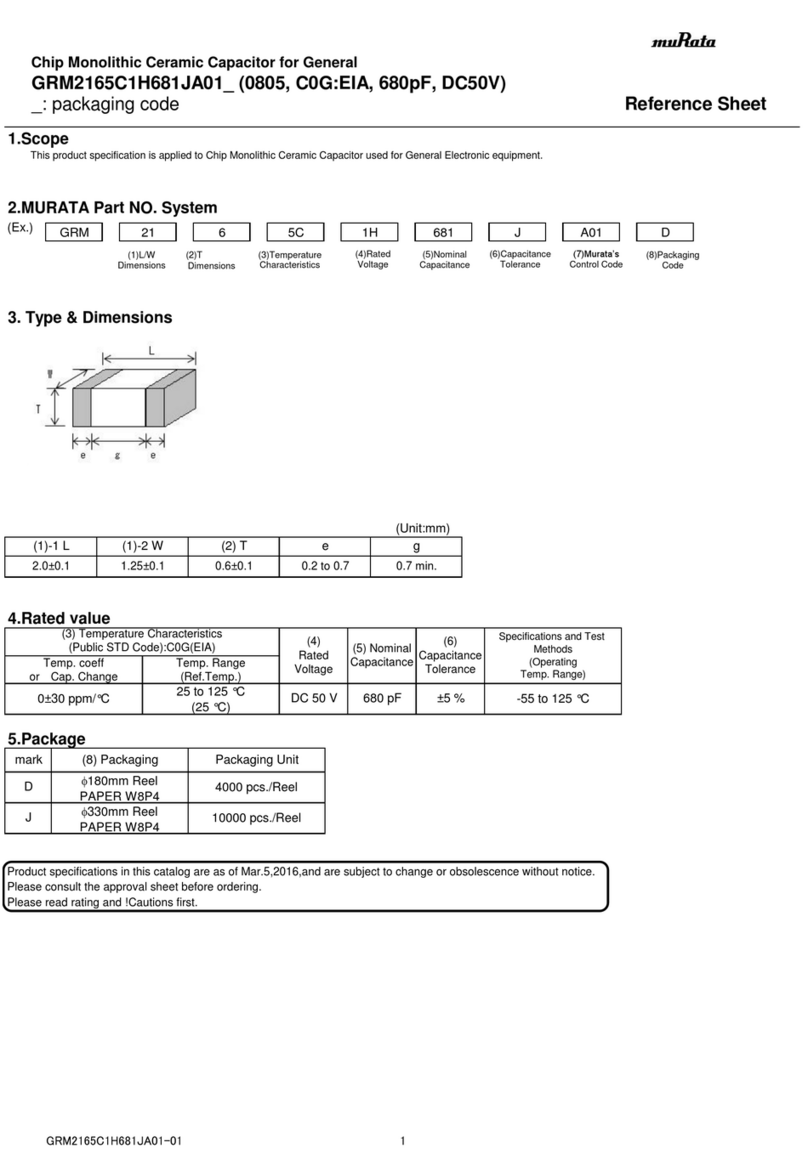

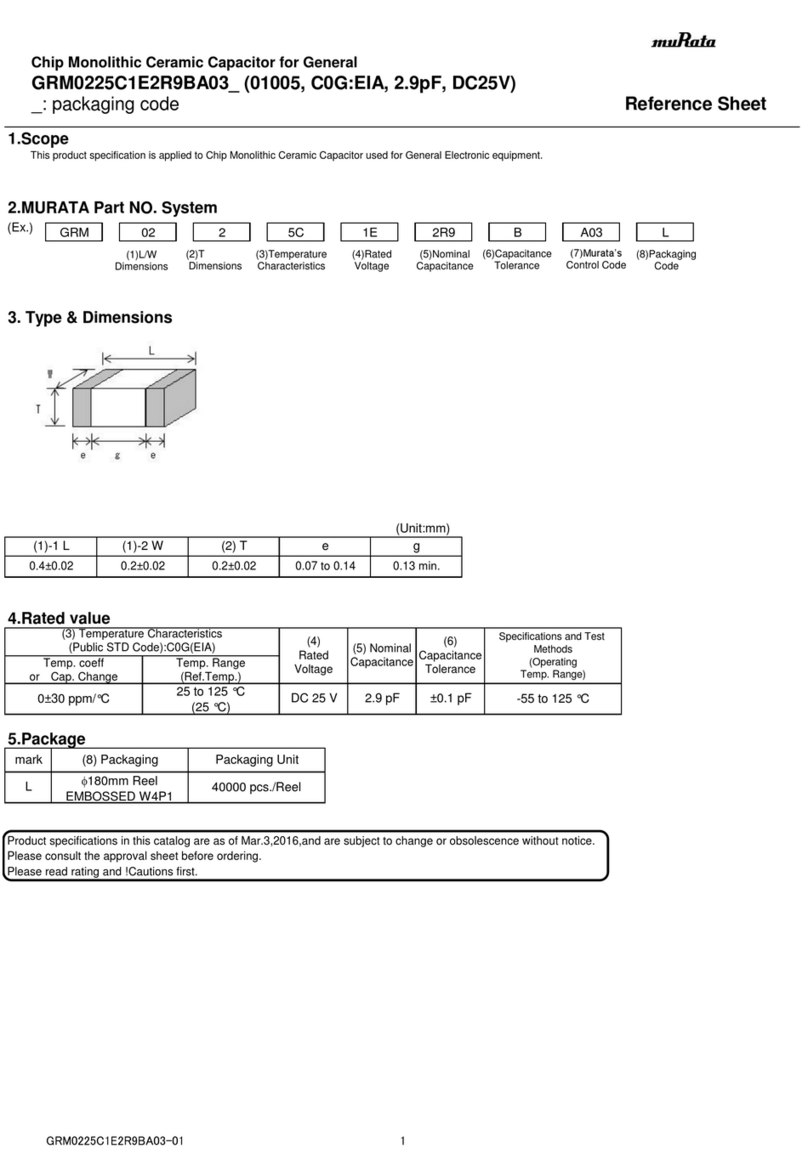

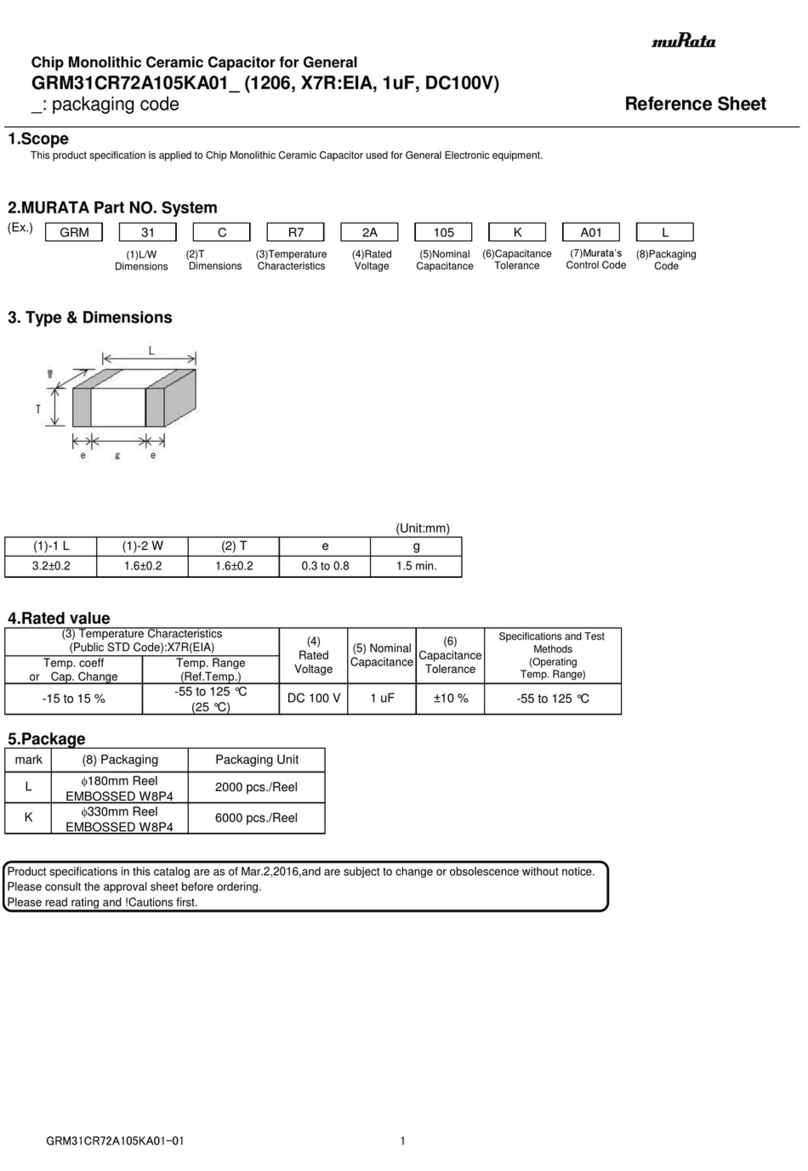

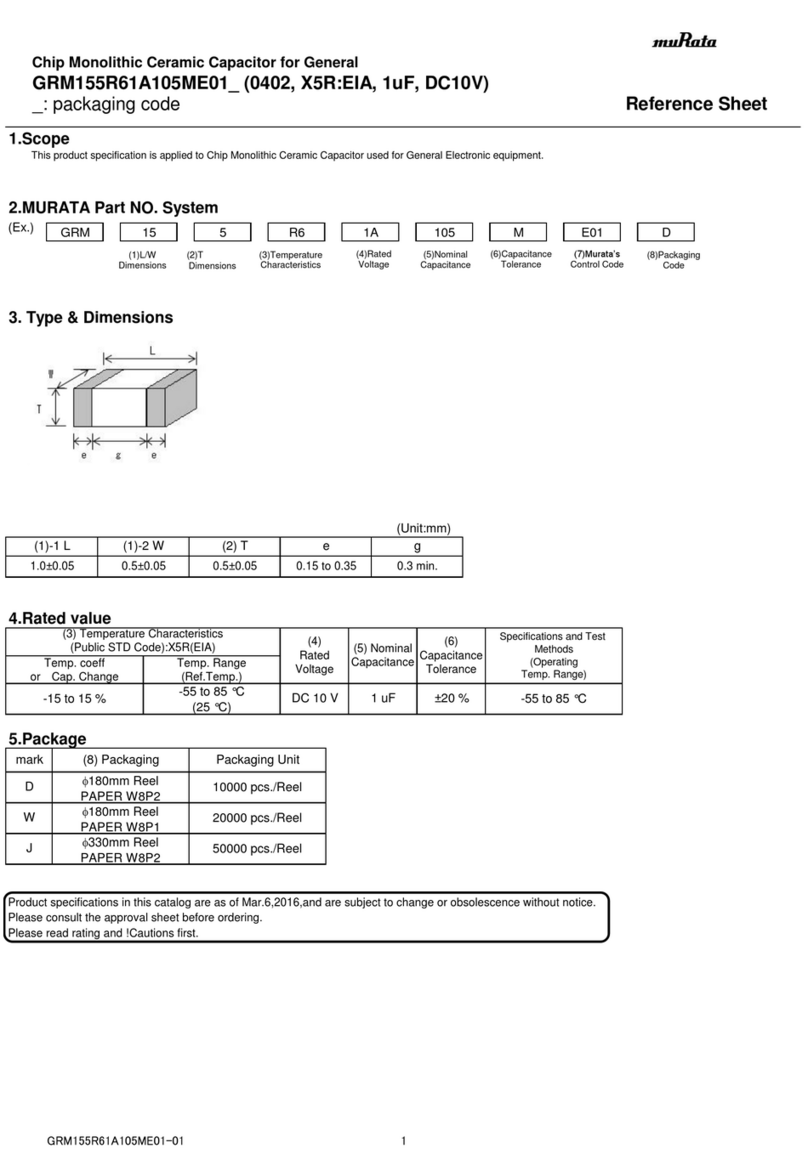

3 Appearance No defects or abnormalities. Visual inspection.

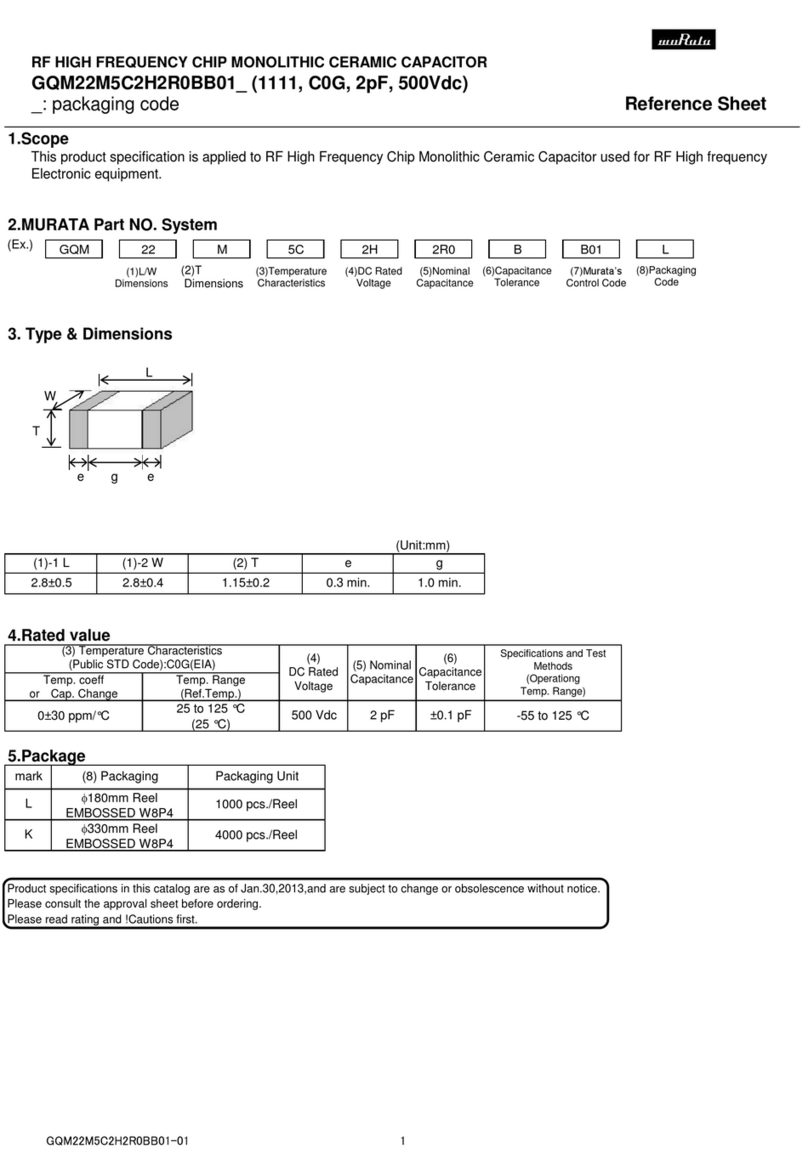

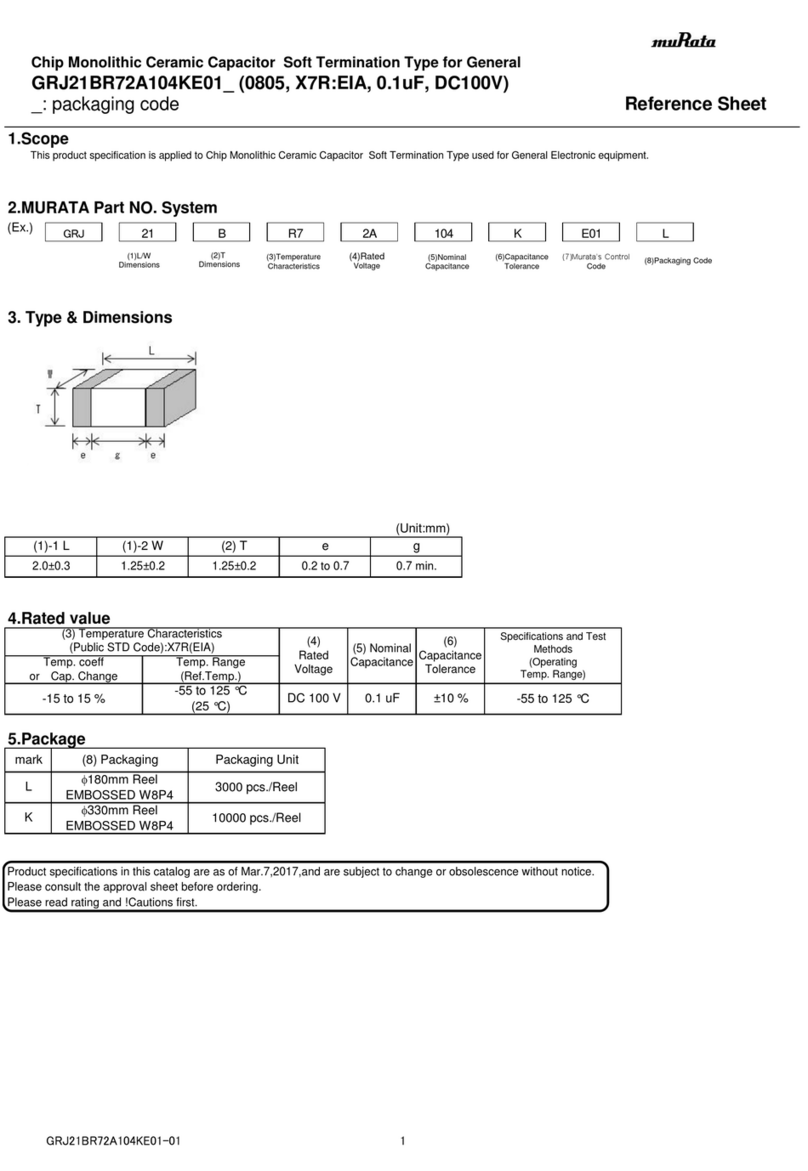

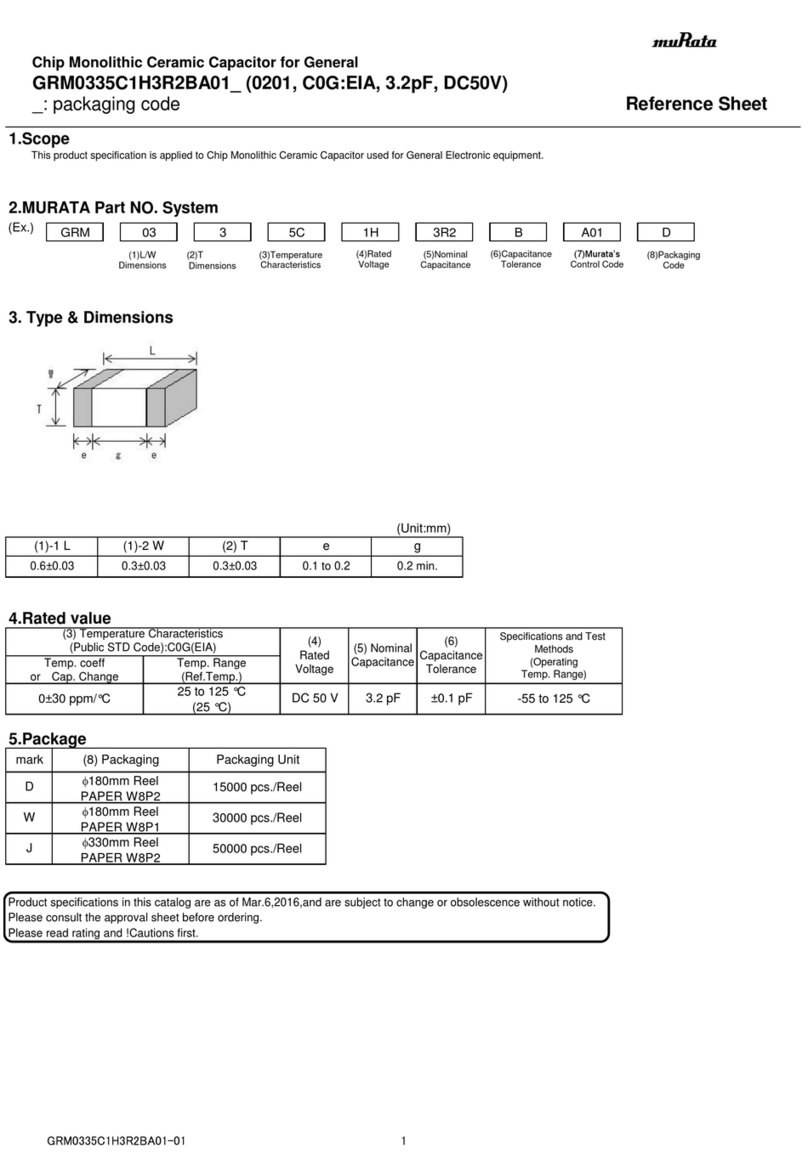

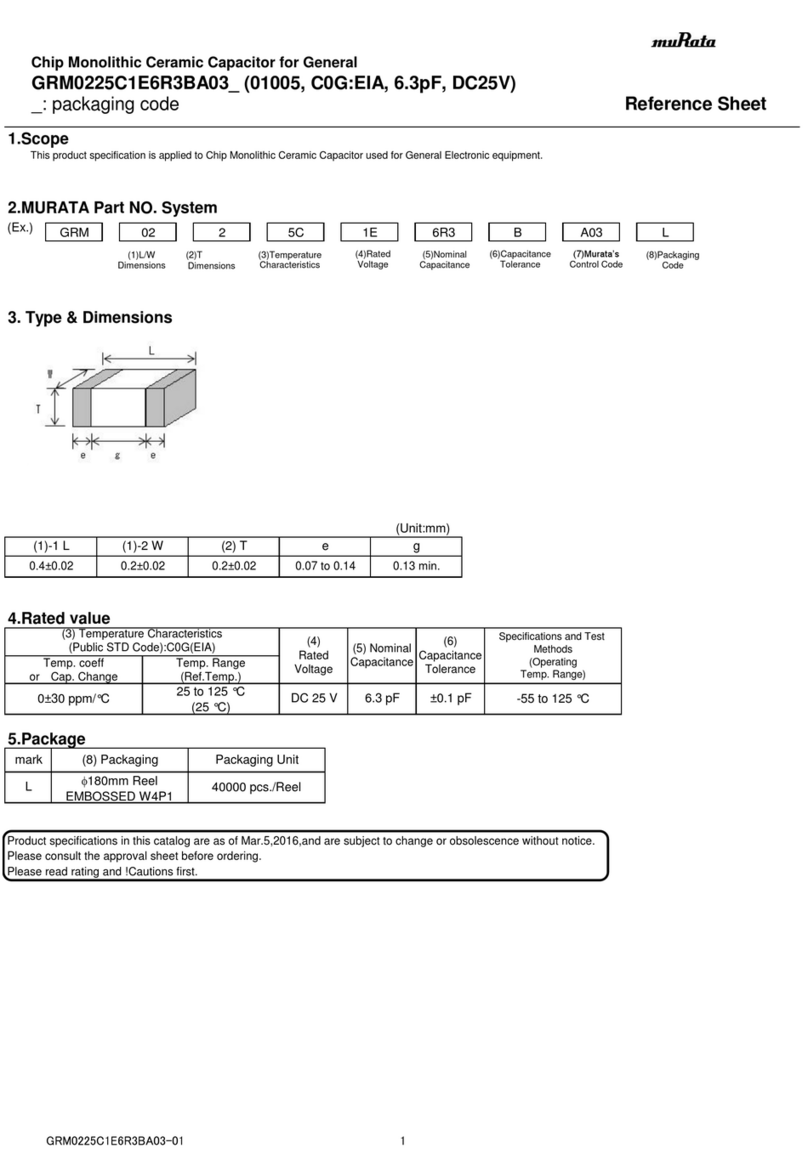

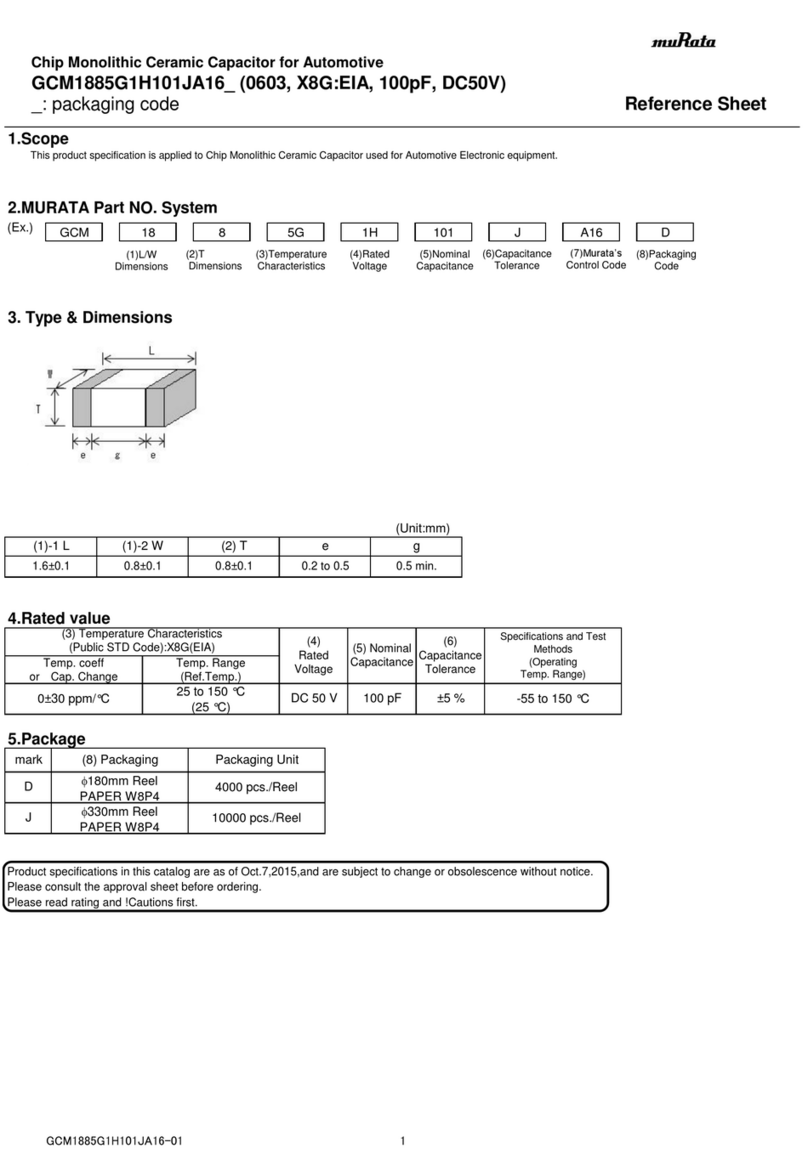

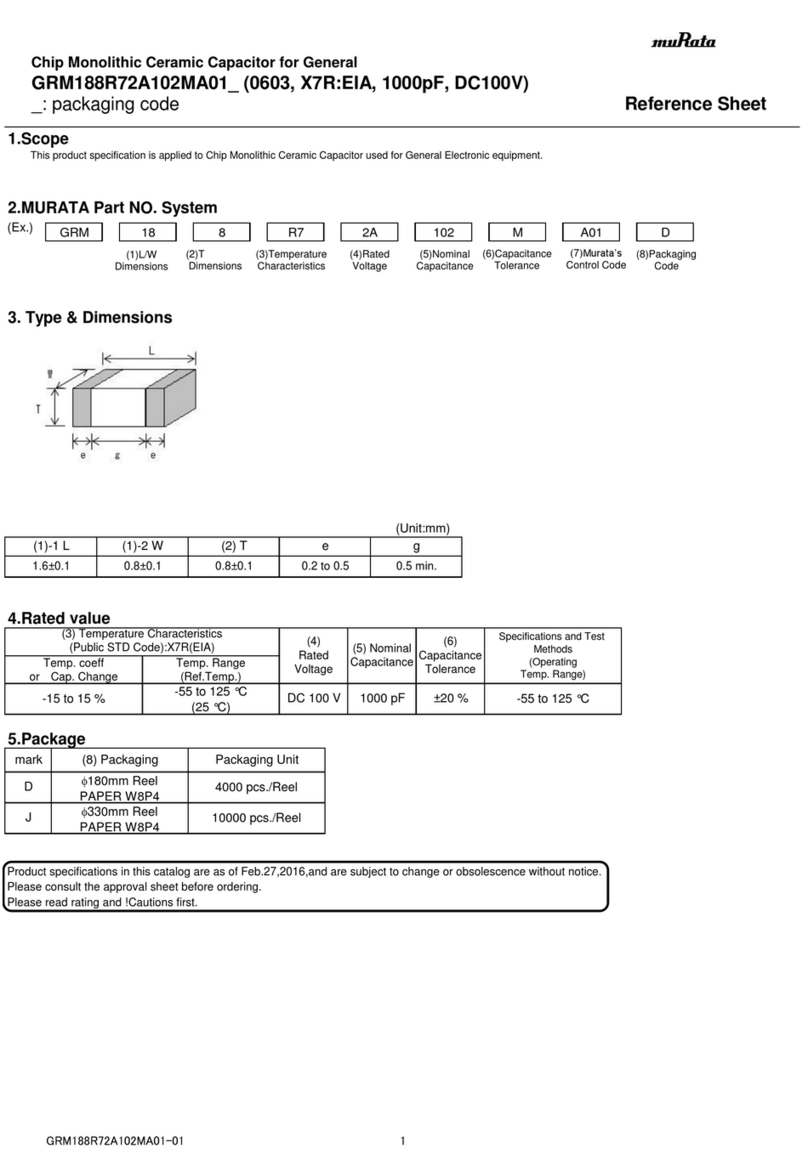

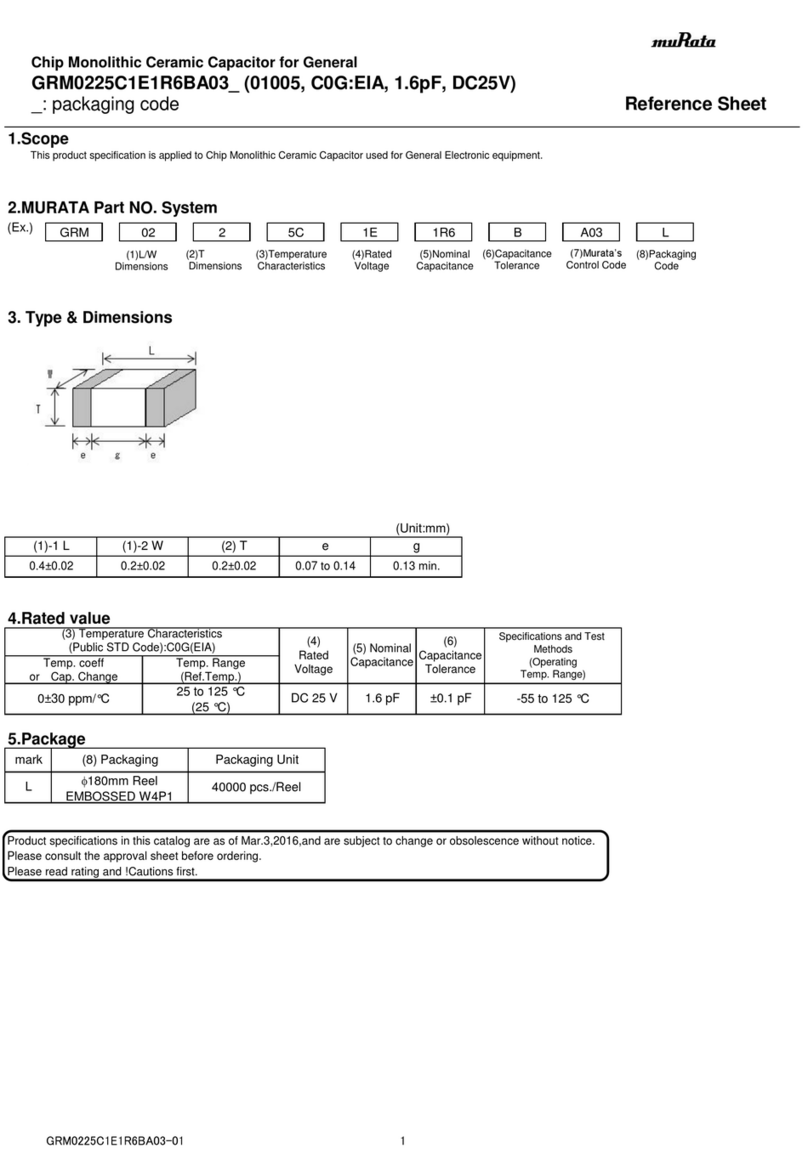

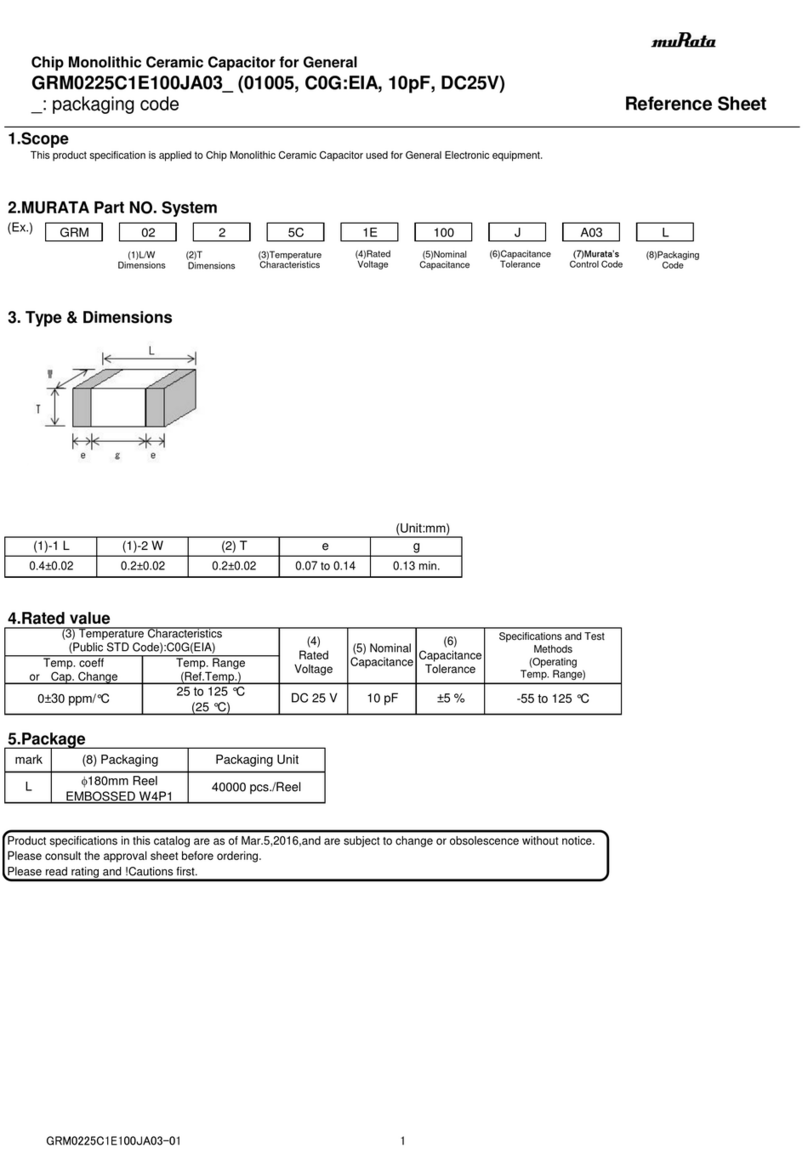

4 Dimension Within the specified dimensions. Using calipers.

5 Dielectric Strength No defects or abnormalities. No failure should be observed when test voltage*

is applied between the terminations for 1 to 5 seconds,

provided the charge/discharge current is less than 50mA.

6 Insulation More than 10,000MΩ The insulation resistance should be measured with a DC voltage

Resistance

not exceeding the rated voltage at 25℃and 75%RH max.

and within 2 minutes of charging, provided the charge/discharge

current is less than 50mA.

7 Capacitance Within the specified tolerance.

The capacitance/Q should be measured at 25℃at the frequency

and voltage shown in the table.

8 Q

C:NominalCapacitance (pF)

9Capacitance Temperature Within the specified tolerance.(Table A-1) The capacitance change should be measured after 5 min. at

Temperature Coefficient each specified temp. stage.

Characteristics The temperature coefficient is determined using the capacitance

measured in step 3 as a reference.

When cycling the temperature sequentially from step 1 through 5

the capacitance should be within the specified tolerance for the

Capacitance Within ±0.2% or ±0.05pF temperature coefficient and capacitance change as Table A-1.

Drift (Whichever is larger.) The capacitance drift is calculated by dividing the differences

between the maximum and minimum measured values in the

step 1,3 and 5 by the cap. value in step 3.

10 Adhesive Strength of No removal of the terminations or other defect Solder the capacitor on the test jig (glass epoxy board) shown

Termination should occur. in Fig.3 using an eutectic solder.

Then apply 5N force in parallel with the test jig for 10±1seconds.

The soldering should be done either with an iron or using the

reflow method and should be conducted with care so that the

soldering is uniform and free of defects such as heat shock.

11 Vibration Appearance No defects or abnormalities. Solder the capacitor on the test jig (glass epoxy board) shown

Resistance in Fig.3 using an eutectic solder.

Capacitance Within the specified tolerance. The capacitor should be subjected to a simple harmonic motion

having a total amplitude of 1.5mm, the frequency being varied

Q

30pFmin. : Q≧1400 uniformly between the approximate limits of 10 and 55Hz.

30pFmax.: Q≧800+20C The frequency range, from 10 to 55Hz and return to 10Hz,

should be traversed in approximately 1 minute.

C:NominalCapacitance (pF)

This motion should be applied for a period of 2 hours in each 3

mutually perpendicular directions(total of 6 hours).

12 Deflection Appearance No defects or abnormalities.

Solder the capacitor on the test jig (glass epoxy board) shown

in Fig.1 using an eutectic solder.

Capacitance Within ±5% or ±0.5pF

Then apply a force in the direction shown in Fig 2 for 5±1seconds.

Change (Whichever is larger) The soldering should be done by the reflow method and should

be conducted with care so that the soldering is uniform and

free of defects such as heat shock.

13 Solderability 75% of the terminations is to be soldered Immerse the capacitor in a solution of ethanol (JIS-K-8101)

of Termination evenly and continuously. and rosin (JIS-K-5902) (25% rosin in weight proportion).

Preheat at 80 to 120℃for 10 to 30 seconds.

After preheating, immerse in an eutectic solder solution for

2±0.5 seconds at 230±5℃or Sn-3.0Ag-0.5Cu solder solution

for 2±0.5 seconds at 245±5℃

■SPECIFICATIONS AND TEST METHODS

*test voltage

rated voltage test voltage

100V 300% of rated voltage

200V 250% of rated voltage