Table of Contents

General Information.............................................................................................................................1

Description...........................................................................................................................1

Dimensions ..........................................................................................................................1

Range of the Snap-Switch....................................................................................................2

Test Feature.........................................................................................................................2

Thumb-ValveTM Operation....................................................................................................3

LM500 Series Flow Rates....................................................................................................3

Service Parts (Specify part number) ....................................................................................4

Hose Kit (P/N 15000355) .....................................................................................................4

Vent Fittings Kit (P/N 15000954)..........................................................................................4

Fittings Kit (P/N 15000943)..................................................................................................4

Bubble Lens Kit (P/N 15000532)..........................................................................................4

Typical Installation............................................................................................................................. 5

Mount the LM500.................................................................................................................5

Pipe Bracket Mount (PM) (P/N 15000518)...........................................................................5

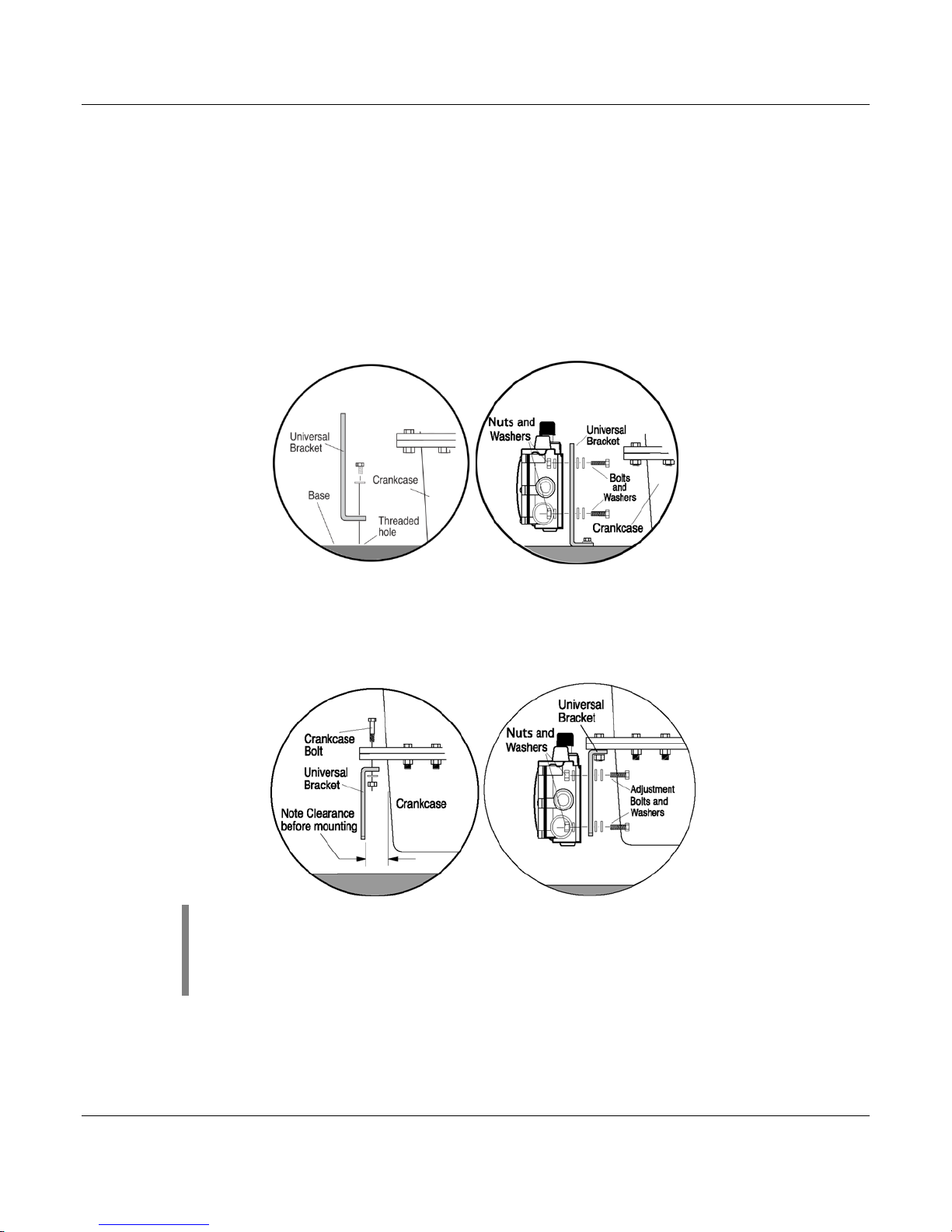

Universal Bracket Mount (UB) (P/N 15000519)....................................................................6

Base Mounting.................................................................................................................6

Crankcase (Oil Pan) Mounting.........................................................................................6

Connect Fittings and Hoses.................................................................................................7

Connect LM500 to Oil Supply Tank......................................................................................8

LM500 Typical Installation Shown........................................................................................8

Specifications..................................................................................................................................... 9