4

–

21205647

□

If exposure has occurred move to ventilated area or fresh air. If

breathing is difficult, supplement oxygen may be required. If not

breathing, give artificial respiration. SEEK IMMEDIATE MEDICAL

ATTENTION.

□

Contact with liquid nitrogen or uninsulated equipment containing

nitrogen can result in cold contact burns or tissue damage.

Nitrogen vapor can cause damage to skin or eyes.

□

In case of frostbite, warm area with warm water not exceeding 105°F

(40°C) and SEEK IMMEDIATE MEDICAL ATTENTION.

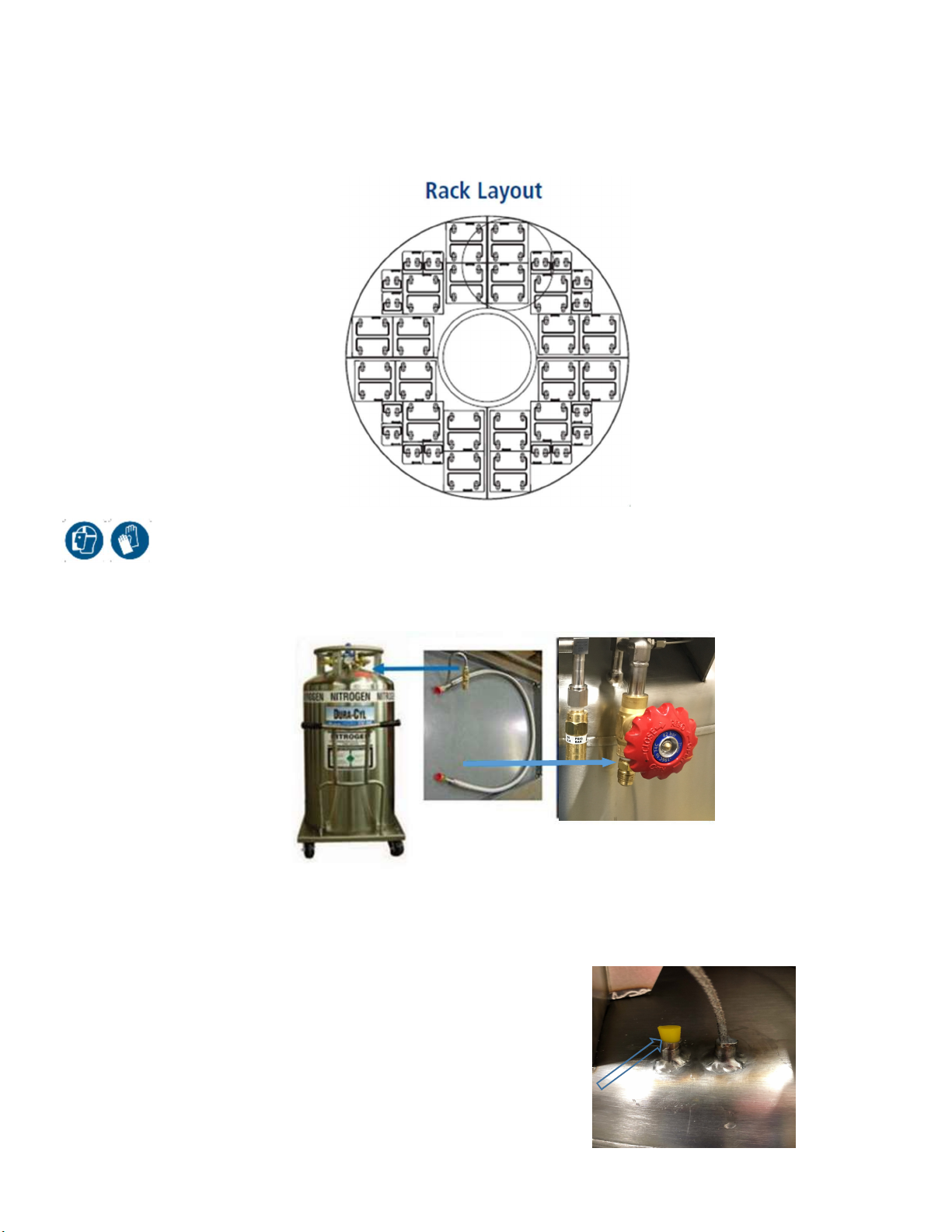

Never place LN2 in a sealed container without a pressure relief

device. The expansion ratio of liquid nitrogen to gaseous nitrogen

is 1 to 700 (1 cubic foot of liquid nitrogen becomes 700 cubic feet of

gaseous nitrogen when evaporated).

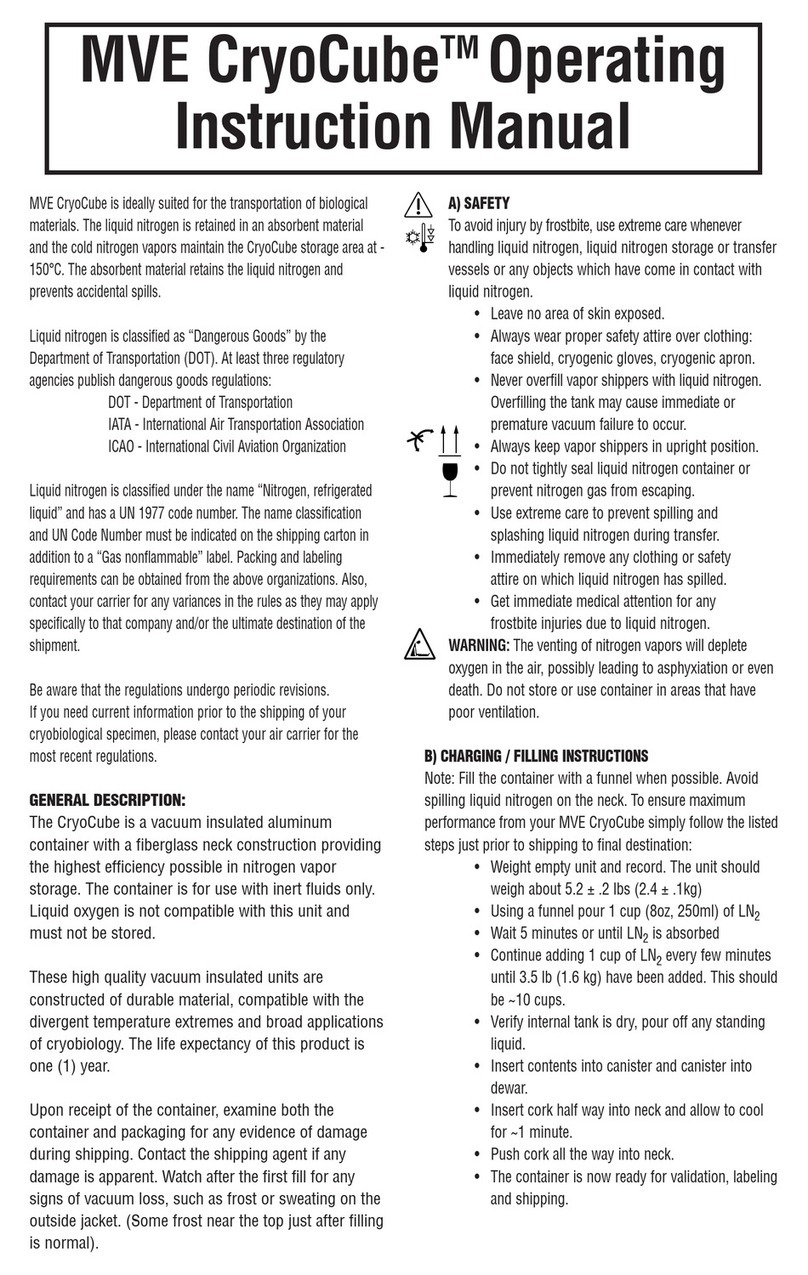

The two most important safety aspects to consider when handling LN2 are adequate ventilation

and eye and skin protection. Although nitrogen gas is non-toxic, it is dangerous in that the gas

will displace oxygen in a normal breathing atmosphere. Liquid products are of even greater threat

since a small amount of liquid evaporates into a large amount of gas. Therefore, it is imperative

that cryogenic supply and storage Dewars be stored and operated in well-ventilated areas.

Persons transferring LN2 should make every effort to protect the eyes and skin from accidental

contact with liquid or cold vapor. Chart MVE recommends the following protective clothing and

accessories when transferring LN2 or handling hoses, valves, and plumbing components:

Recommended protective clothing

□

Cryogenic gloves (loose fitting)

□

Full-face shield or chemical splash goggles

□

Cryogenic apron

□

Long sleeve shirt and cuffless pants

□

Closed toe shoes (no sandals)