2

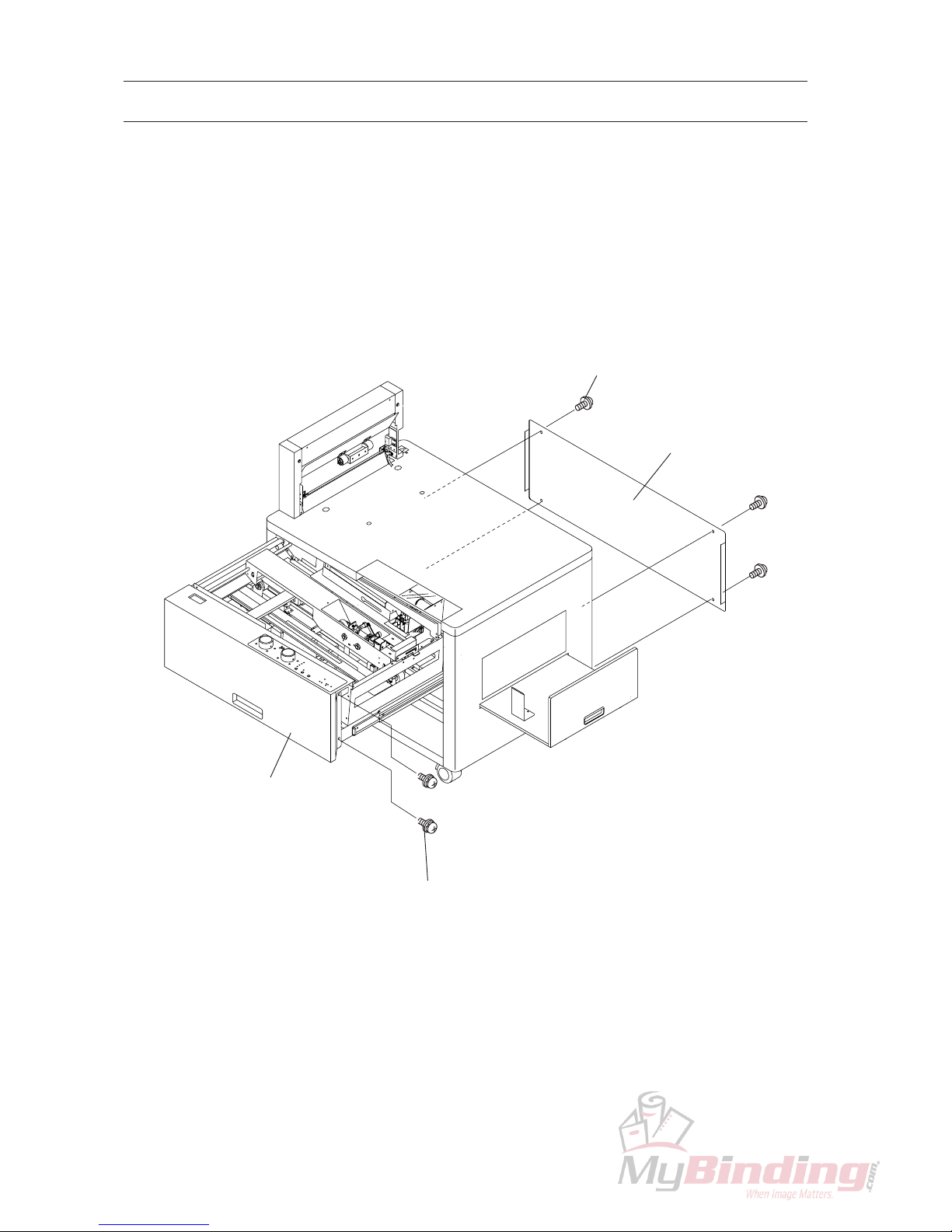

2. Operation Overview

1. Pile sheets into bins and turn on power switch.

- Staple unit will be reset if staple unit is not at home position before power is on.

- LED conditions of operation panel

Jog Guide Illuminates at the current position. Not illuminates when irregular

sheets are used.

Staple Mode Illuminates at the angled side staple position.

Punch Not illuminates.

Jog Time 1 time lamp illuminates.

2. Press option button on collator.

- Option LED illuminates.

- Gate in collator moves.

3. Set jog guides according to sheets.

- LED in the selected sheet size illuminates.

4. Select required mode with staple mode button.

- LED illuminates in different position as staple button is pressed.

Staple unit moves to set position a few seconds after staple mode is selected.

NOTE

- In the case of other side corner staple or top staple, staple mode cannot be selected

because of limited sheet size.

- In the case of staple with punch, staple mode cannot be selected because of limited

sheet size.

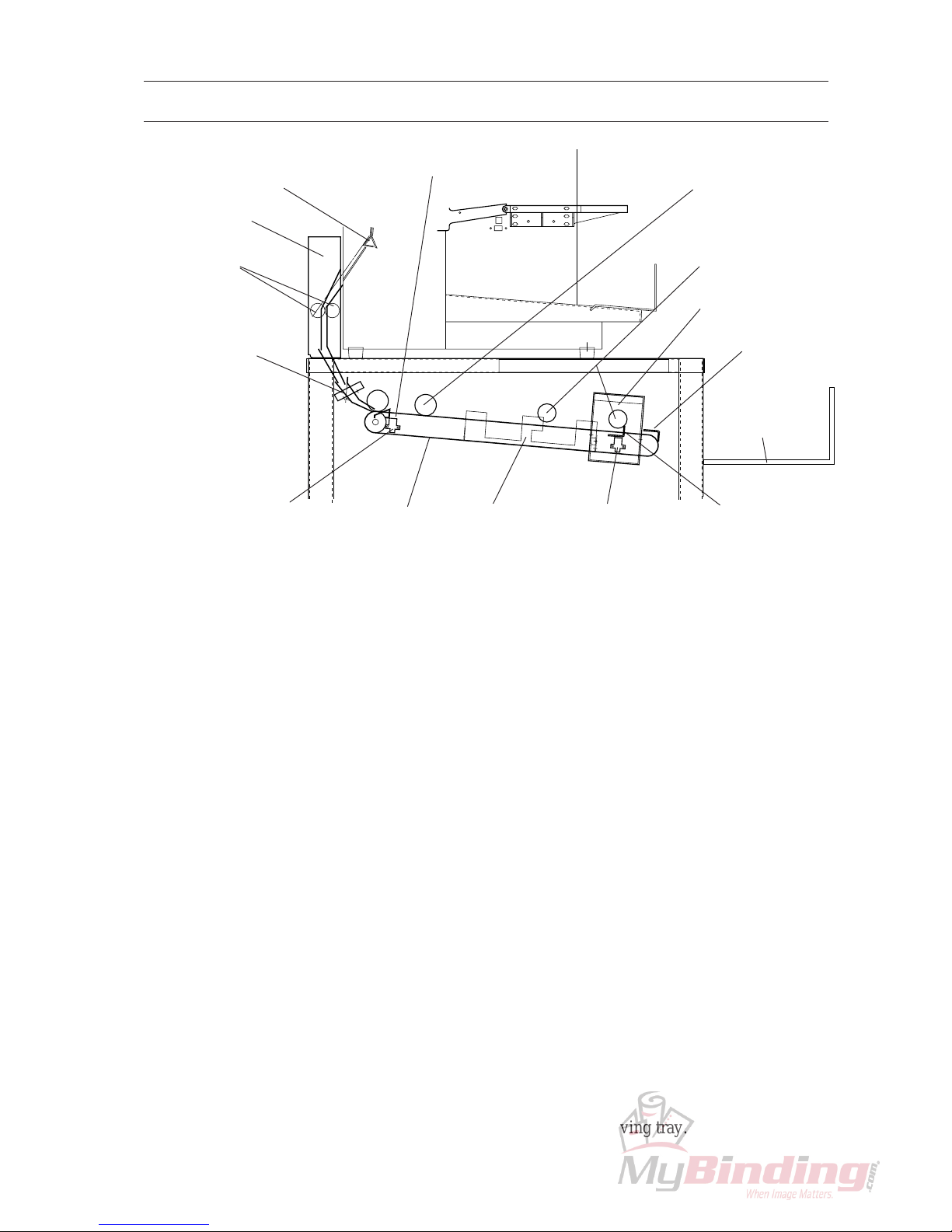

5. Set receiving tray and receiving tray guide according to sheet size.

6. Press check button of collator twice. As collator starts, transport unit will transport a set of

sheets. The set is stapled and/or punched and delivered to receiving tray.

7. Press start button of collator. Collator starts collating and sets of sheets are produced.

When miss/double or other troubles happen on collator, collating job stops with LED illumi-

nated.

Collator's Error : Sheet jam, misfeed, and double feed are indicated on panel of collator.

PS-P61's Error : QC-P10 : Option error message is indicated on collator.

QC-P8 : Receiving tray lamp illuminates on collator.

PS-P61 : Monitor lamp illuminates.

8. When preset counter reaches to set number, collating stops and then transport unit stops.

- In the case of the number of sets are not input in preset counter, collator stops because

sheets run out, or because receiving tray of PS-P61 is full.