INDEX

1. INTRODUCTION .............................................................................................3

2. TECHNICAL CHARACTERISTICS......................................................................4

2.1. Main characteristics ................................................................................................. 4

3. GENERAL SAFETY AND ACCIDENT PREVENTION REGULATIONS ..................7

3.1. Personnel responsible for using the equipment.................................................. 7

3.2. Electrical hazard ....................................................................................................... 7

3.3. Thermal hazard......................................................................................................... 7

4. RECEPTION, TRANSPORT AND POSITIONING ...............................................8

4.1. Reception.................................................................................................................. 8

4.2. Transport................................................................................................................... 8

4.3. Positioning ................................................................................................................ 9

5. INSTALLATION .............................................................................................10

5.1. Electrical connection ............................................................................................. 10

5.1.1. Evoline three-phase models ...................................................................... 10

5.1.2. Evoline single-phase models ..................................................................... 11

5.2. Water connection (appliances with humidity) .................................................... 12

5.2.1. Water input .................................................................................................. 12

5.2.2. Drain (appliances with humidity)............................................................... 12

6. USE...............................................................................................................13

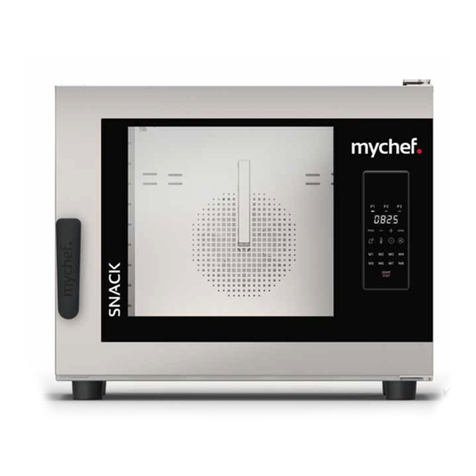

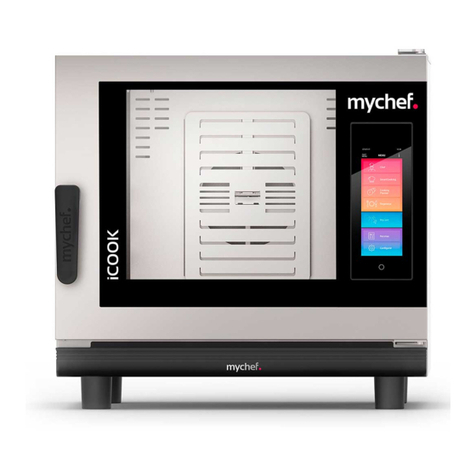

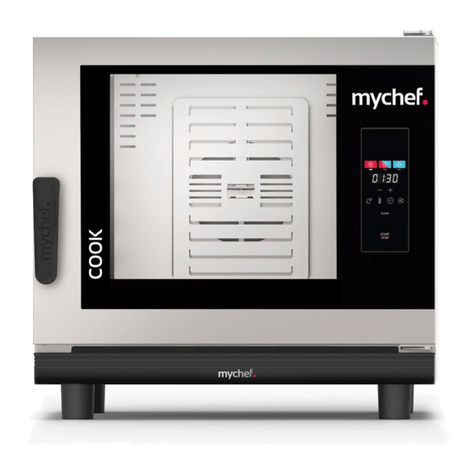

6.1. Control panel.......................................................................................................... 13

6.2. Operation................................................................................................................ 14

6.2.1. Turning on the appliance ........................................................................... 14

6.2.2. Regeneration ............................................................................................... 14

6.2.3. End of cycle.................................................................................................. 14

6.2.4. Door open.................................................................................................... 15

6.2.5. Errors and faults........................................................................................... 15

7. MAINTENANCE ............................................................................................17

7.1. Cleaning.................................................................................................................. 17

7.1.1. Door gasket.................................................................................................. 18

7.1.2. Door opening .............................................................................................. 18

7.1.3. Owner liability.............................................................................................. 18

7.2. Preventive maintenance........................................................................................ 18

8. CE MARKING................................................................................................19

9. GENERAL ELECTRIC BLUEPRINT...................................................................20