26850A003

9

bearings must be installed with .003 to .005 in preload;

the following procedure will provide an accurate adjust-

ment. Before starting, loosen the four cap screws on the

pinion shaft bearing cap.

A. Place about .045 shim on the right crankshaft

bearing cap, tighten the five cap screws.

B. Install the left cap without shims, secure with two

cap screws positioned exactly as shown in “Fig.13”.

Torque the two cap screws at 13 foot pounds, rotate

the crankshaft, retorque the cap screws. Do this

three times to properly seat the tapered roller

bearings.

C. Measure (adjacent to the cap screws) the shim gap

remaining between the bearing cap and the gear

case.

D. The required shim thickness for this cap is equal to

the average gap measurement plus .022”.

E. Insert correct shim thickness under left bearing cap

and tighten cap screws.

F. Install connecting links and caps; note the mark-

ings; torque cap screws to 40 ft. lb.

G. IMPORTANT - Check for adequate side clearance

of links on crankshaft. Some shims must be moved

from one end of the crankshaft to the other until

sideways movement of all links can be seen.

H. Check torque of cap screws on all bearing caps.

RECONDITIONED CRANKSHAFTS

When the crank throws are only slightly damaged, such

as small surface grooves cut part way around the

bearing surface, they can sometimes be reconditioned

for further use. This can be done by sandpapering and

polishing until all ridges are completely removed. The

final polishing operation should be with very fine emery

cloth. If the surface is badly damaged, the crankshaft

can often be salvaged by “metalizing” the crank throw

and then regrinding and polishing to the original diam-

eter of 3.1240-3.1245”.

SERVICING CONNECTING LINKS

The connecting rod link is furnished with replaceable

split sleeve bearing inserts at the crank throw. It is

never practical to attempt to refit connecting links to the

crankshaft bearings by filing or grinding the mating

faces of the link cap where it contacts the link. Always

be sure that the proper side of the link is placed upward

when attaching it to the crankshaft. The upper side

contains an oil hole at the crosshead end of the link.

This oil hole must be up to allow proper oil feeding to

the crosshead pin bushing. The wrist pin is press-fitted

into crosshead and slip-fitted through the bronze

bushing. Use arbor press instead of hammering the

wrist pin to force it in. Check to see if link is free to

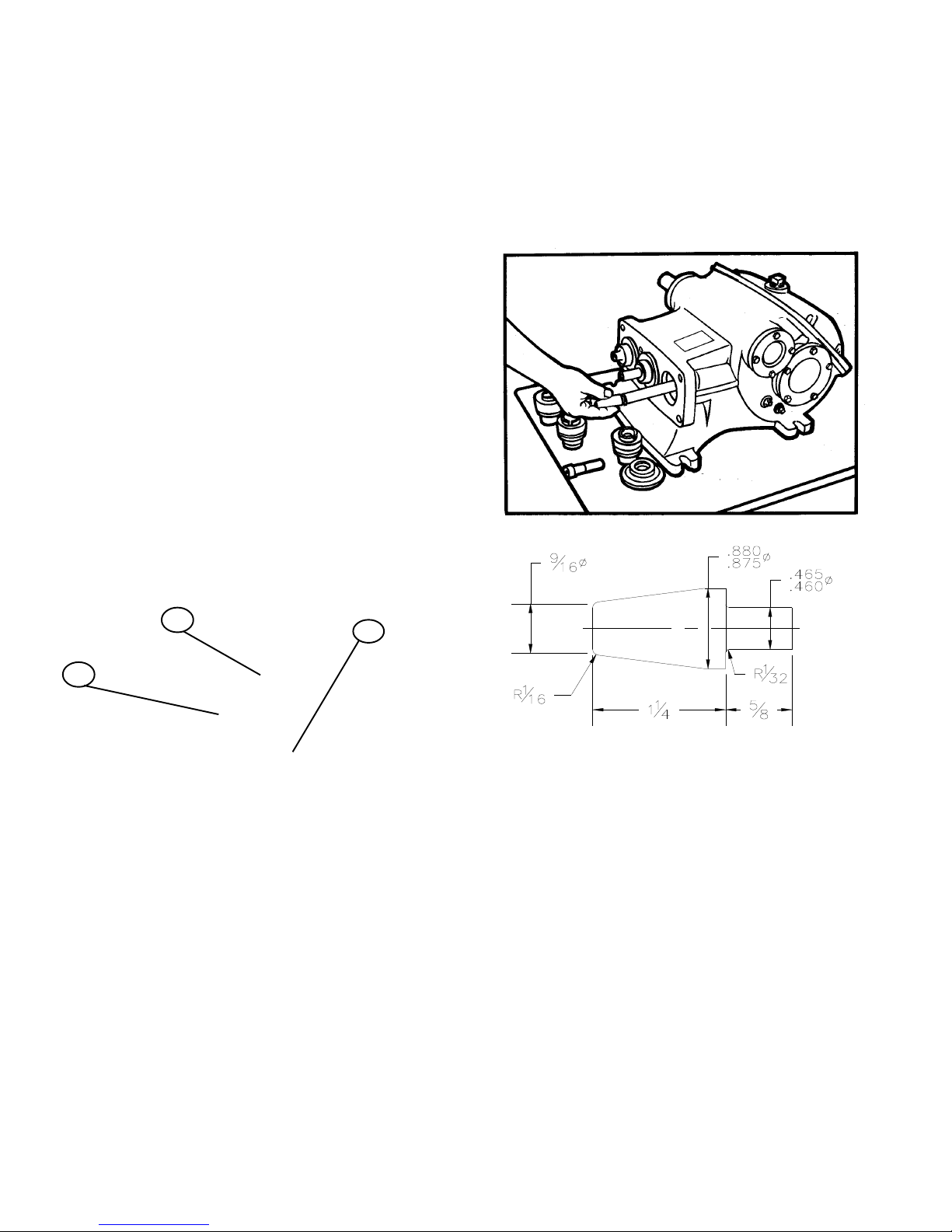

Fig. 14

rotate after the wrist pin is pressed in. Make sure that

either side of wrist pin does NOT protrude beyond the

crosshead.

The crosshead end of the connecting link is fitted with a

bronze bushing. When new replacement links are

obtained, these bushings are reamed to the proper size

for immediate installation. If the bushing only is

replaced, it may be necessary to ream the new bushing

to the proper inside diameter after it is pressed into the

link. When placing the bushing on the link be sure that

the oil holes in the bushing and link will be in line after

the bushing is pressed into position. Fig. 14 shows the

proper diameter to which the bushing must be reamed

for proper seating of the crosshead pin. Note that the

ream diameter must be parallel to the I.D. of the sleeve

bearings within 0.001” T.I.R.

CROSSHEAD AND PISTON RODS

Repair parts for the crosshead and piston rod are

supplied only as a complete unit. If either of these

parts becomes worn it is necessary to replace both the

crosshead and piston rod. Under normal conditions a

crosshead will not wear nor will the bore of the crank-

case wear to the extent that oversize crossheads will

be required. If extreme wear does occur, it will be due

to severe damage from the lack of oil or a fairly large

metal object scoring the crosshead bore. A clearance

of .002” to .004” is standard for the crosshead. The

parts can wear until considerably more clearance than

this exists before harmful operation will occur.

RECOMMENDED TORQUE (Foot-pounds)

FASTENER LOCATION

Link Bearing Caps 40

Crankshaft End Caps 20

Pinion Bearing End Caps 20

Cap Screw, 3/4

(Fluid End to Power End) 250

Cap Screw, 5/8

(Fluid End to Power End) 150

CALL 1-800-577-8111 FOR SALES AND SUPPORT