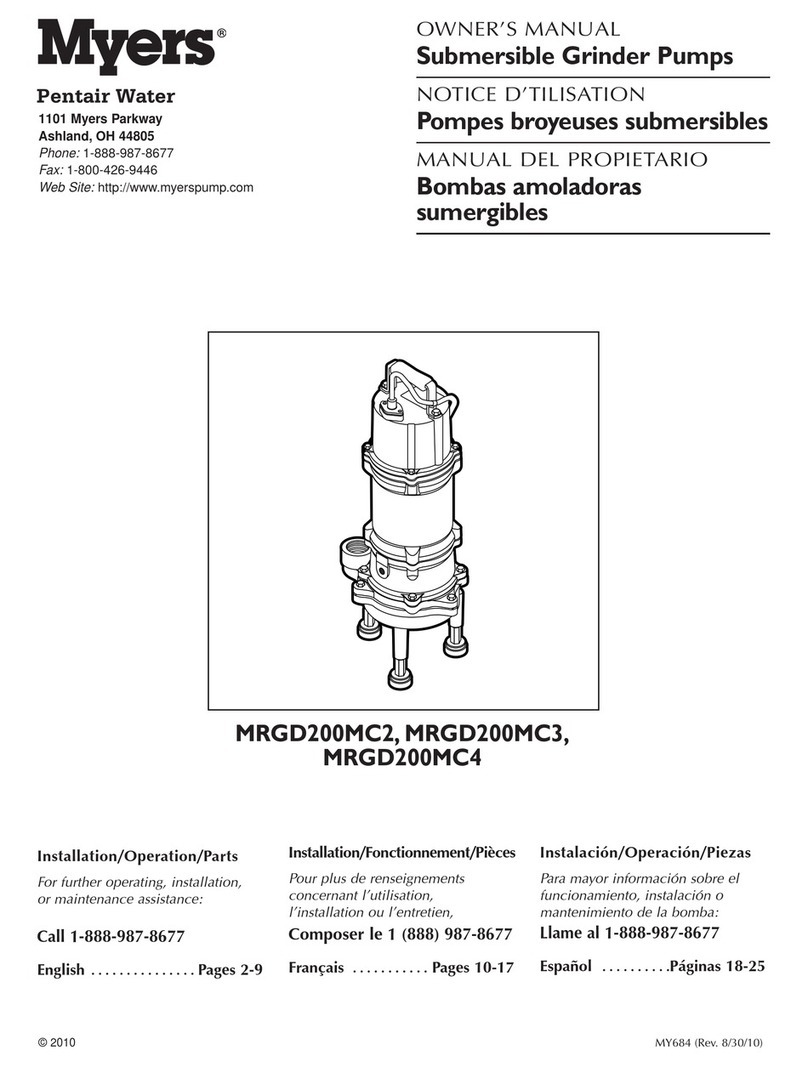

DESCRIPTION AND APPLICATION

S40HT series pumps are single seal units, available in

automatic and manual versions. These pumps are

designed for use in pumping high temperature liquids

that do not exceed 195°F (90°C). These pumps are

not designed for pumping potable water. These pumps

are not for use in swimming pools, decorative foun-

tains, or any installation where human contact with

pumped fluid is common or possible.

S40HT series pumps use a 4/10 HP shaded pole, 1550

RPM motor, and are available in 115 volt, single phase.

All pumps are supplied with a 20’ power cord. All

automatic pumps are supplied with a mechanical

(mercury-free) piggy-back float switch rated for high

temperature use. The S40HT series pumps are

designed to pass ¾” spherical solids. Pump impellers

are Class 20 cast iron vortex design. All pumps have

1½” NPT discharge.

AIR LOCKING

A pump is said to be air locked if water traps air in the

pump and it cannot get out, thus preventing the pump

from operating. S40HT series have 1/8” air vent hole in

the impeller chamber to let out trapped air. If this hole

becomes plugged, pump may air lock. As a secondary

precaution a 1/8” hole should be drilled in the discharge

pipe below the check valve. The check valve should be

12” to 18” above pump discharge. Do not put check

valve directly into pump discharge opening.

PACKAGING

Each pump is packaged separately in a carton marked

with a catalog number and Myers engineering number.

The pumps are carefully packaged to prevent damage

in shipping. However, occasionally damage may result

due to rough handling. Carefully go over pump and

check for damage that could cause pump to fail.

LEVEL CONTROLS

All S40HT-11P pumps are supplied with a 20 foot

mechanical (mercury-free), piggy-back float switch.

The piggy-back switch is tethered directly to pump.

The switch must float free from pump and basin wall.

Plug the switch cord plug into a properly grounded,

rated voltage receptacle. Plug the power cord into the

back of the switch cord and tape the cords to the

discharge pipe approximately every 12”. The power

receptacle must be located outside the wet sump or

basin due to the DANGER of current leakage.

MOTOR TYPE

The motors used in the S40HT series pumps are

pressed into the cast iron housings and surrounded by

dielectric oil for superior heat dissipation. All models

use a 4/10 HP shaded pole, 1550 RPM motor. All

models have Class F motor windings, are available in

115 volts with overload protection, and use a double

sleeve bearing design. These pumps have no starting

switches and do not require a control panel for

individual installations.

INSTALLATIONS

Basin or tanks must be vented in accordance with local

plumbing codes. These pumps are not designed for

and cannot be installed in locations classified as

hazardous in accordance with the National Electrical

Code ANSI/NFPA 70.

When installing S40HT series pumps in high tempera-

ture installations, ALL basins, tanks, piping, fittings,

additional floats and cables must have rating ex-

ceeding 195°F (90°C). Also pumps are not to be used

in environments where ambient temperatures exceed

195°F (90°C).

CAUTION: If pump is to be used for pumping sewage

effluent: never enter pump chamber after sewage or

effluent has been in basin. Sewage water can give off

methane, hydrogen sulfide and other gases which are

highly poisonous.

Myers recommends installing effluent pumps with a

quick removal systems. The quick removal system

may be a union or Cam-lok coupling if the pipe is within

reach from the surface, or a rail system type quick

disconnect on deeper installations.

The dosing tank or pumping chamber must be con-

structed of corrosion resistant materials and must be

capable of withstanding all anticipated internal and

external loads. It also must not allow infiltration or

exfiltration. The tank must have provisions for anti-

buoyancy. Access holes or covers must be adequate

size and be accessible from the surface to allow for

installation and maintenance of the system. Access

covers must be lockable or heavy enough to

prevent easy access by unauthorized personnel.

The pumping chamber holding capacity should be

selected to allow for emergency conditions.

The discharge pipe must be the same size as the

pump discharge, 1½” or larger. In order to insure

sufficient fluid velocity to prevent any residual solids

from collecting in the discharge pipe, it is recom-

mended that a minimum flow of 2’ per second be

maintained (12 GPM through 1½” pipe, 21 GPM

through 2” pipe and 46 GPM through 3” pipe). A full

flow (ball or gate) shut off valve must be installed to

prevent back flow of effluent if the pump must be

removed for service. A check valve must be installed

on pressure sewer systems to prevent backflow and to

reduce wear on the pump system.

A high water alarm must be installed on a separate

circuit from the pump circuit. The alarm should have

the ability to be tested for proper operation.

3