6V&12V Serials

09 10

Charge requirement

Charge requirement NoteCharge mode

More than two battery voltages in the battery

string are lower than 2.18V in oating operation Equalization charge

Equalization charge

Complement charge

Complement charge

Recommend charging if oat charge for

more than three months

Battery storage for more than 6 months

Before the battery is installed

and applied in the site.

After the battery discharged

Charge current:

Limited current I10~2.5I10

Charge voltage:

Limited voltage 2.35V/cell

Charge time:

24 hours

Note:

(1) When the depth of discharge is large (usually more than 5~10% C10), it is recommended to use the equalization voltage,

so that this charge mode is more adequate. When charges for 24 hours or the current drops below 0.005C10A, and the current

value is substantially constant for three consecutive hours, the charge is considered complete.

(2) The battery needs to be fully charged as soon as possible, the charge current can be increased appropriately, but it cannot

be higher than recommend value.

(3) If the battery is not recharged in time after discharge, or the power is off again during recharge, the insufcient-charged

batteries will be frequently discharge, thus the batteries will lose part of capacity in short period. And it may cause capacity

loss at initial stage and the batteries will be rejected if the situation is serious.

Battery recharge method

Step 1: Connect the batteries in series, and ensure that the bolts and screws are fastened.

Step 2: Connect the positive and negative poles of the battery to the positive and negative poles of the charging device.

Step 3: Turn on the charging power supply, set the charging current limit value and charging voltage value according to the

supplementary power requirements;

/<$+"%,4('"()';",(%$("(6$

.8"<%$+'18+$$D=>

| Parameter settings

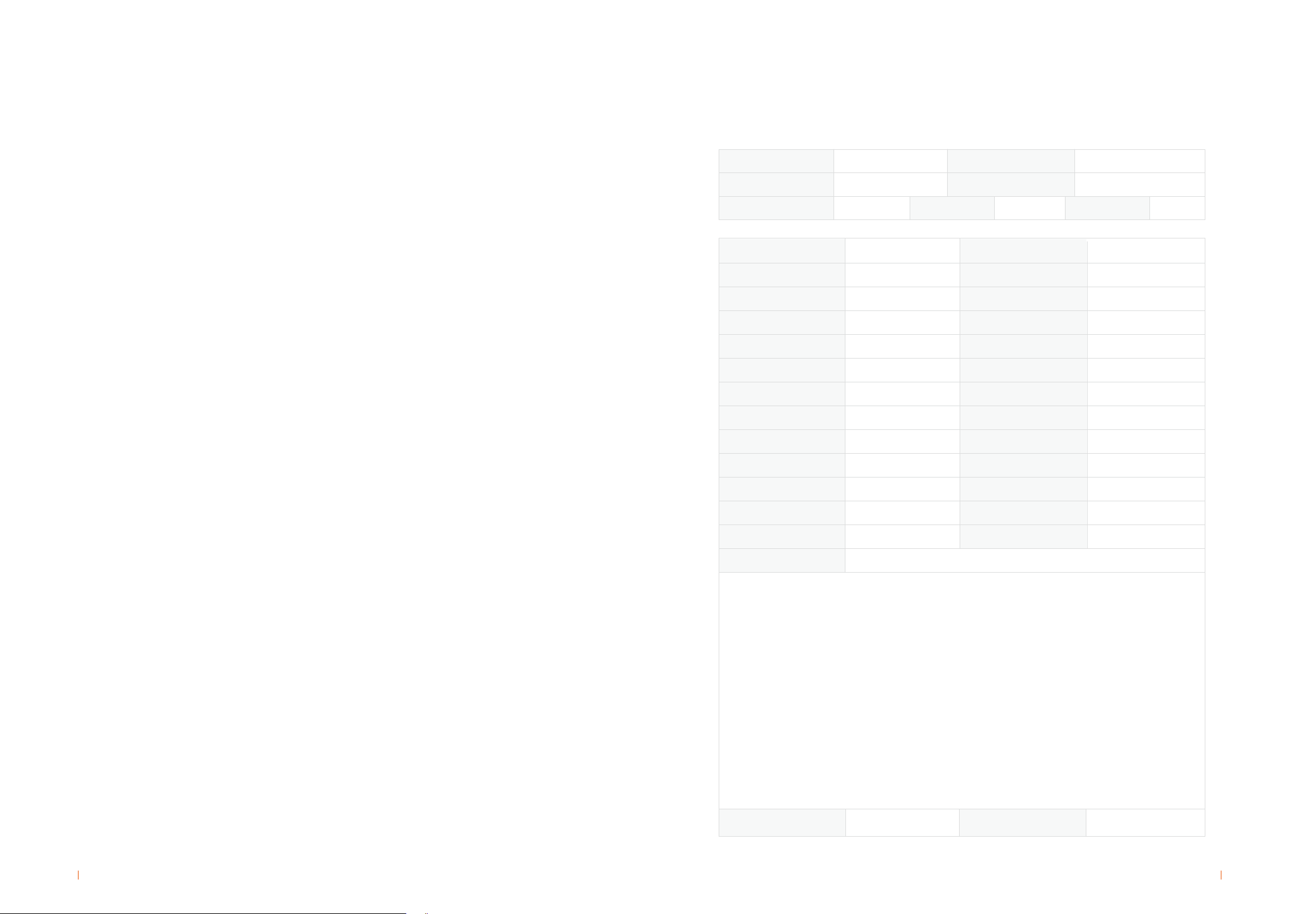

Table 3-1 Switching power supply parameter setup table (48V system, 25°C)

54.0

54.4

54.0

54.4

Parameter name Tough power supply

(Cyclic operation)

Normal power supply

(Floating operation)

<5

-5

<5

-5

56.4 56.4

Please refer to table 3-2

55.2

0.1C10

0.25C10

90

24

>50

49

57.6

46

-3

35

45

35

45

50

57.6

47

-3

55.2

0.2C10

0.25C10

30

24

>50

Acme, AcmeG, MP, MPG, GP, GPG,

12REXC, ICS, UDS, DT

HRL, HTB,HTB-F

Acme, AcmeG, MP, MPG, GP, GPG,

12REXC, ICS, UDS, DT

HRL, HTB,HTB-F

12REXC

Charging Current(A)

Limited Current For Charge (A)

Equalization Charge Cycle(day)

Equalization Charge Time(h)

LLVD (V)

BLVD (V)

BLVD Recover Voltage(V)

High Voltage Warning(V)

Low Voltage Warning(V)

Condition to Change Float Charge To

Equalization Charge(mA/Ah)

Acme, AcmeG, MP, MPG, GP, GPG,

ICS, UDS, DT, HRL, HTB,HTB-F

Condition To Change Equalization

Charge To Float Charge(mA/Ah)

Temperature Compensate Ratio With

Floating Voltage(mV/°C per cell)

Temperature Compensate Ratio With

Equalization Voltage(mV/°C per cell)

Floating Voltage(V)

Equalization Voltage(V)

High Temperature Warning(°C)