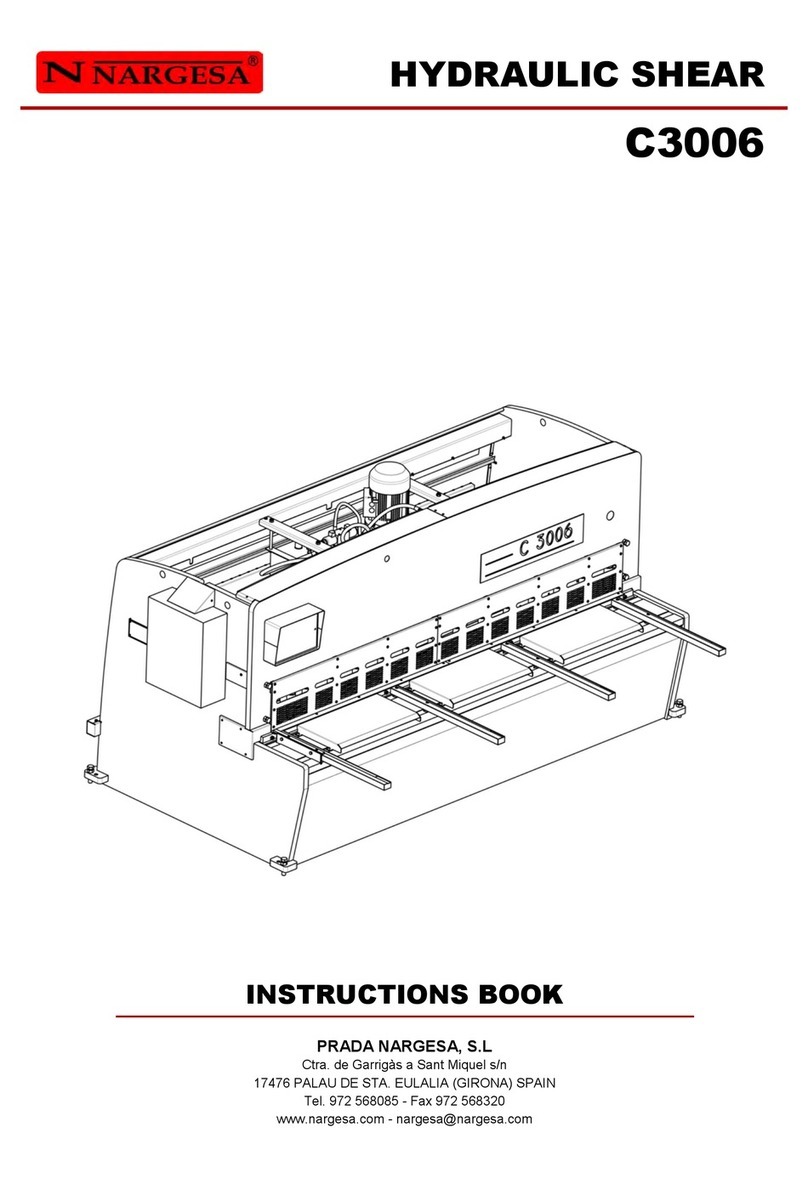

C3006 HYDRAULIC SHEAR INSTRUCTIONS BOOK 2

INDEX

1. CHARACTERISTICS OF THE MACHINE .................................................................................. 4

1.1. Identification of the machine ......................................................................................... 4

1.2. General dimensions ....................................................................................................... 4

1.3. Description of the machine ........................................................................................... 4

1.4. Identification of the machine ........................................................................................ 5

1.5. General features ............................................................................................................ 6

1.6. Description of safety devices .......................................................................................... 7

2. TRANSPORTATION AND STORAGE .................................................................................. 8

2.1. Transportation ................................................................................................................ 8

2.2. Storage conditions ........................................................................................................ 8

3. MANINTENANCE ................................................................................................................... 9

3.1. General Maintenance ..................................................................................................... 9

3.1.1. Oil change …………………………………………………………………………… 9

3.1.2. Lubrication of bolts ………………………………………………………………. 10

3.1.3. Lubrication of the guides ………………………………………………………… 10

3.1.4. Lubrication of the gauge spindles ……………………………………………….. 11

4. INSTALACINSTALLMENT AND START UP .......................................................................... 12

4.1. Location of the machine .............................................................................................. 12

4.2. Dimensions and working site ................................................................................... 12

4.3. Admissible outer conditions ……............................................................................... 13

4.4. Connection to power supply ………………………......................................................... 13

5. HANDLING BOOK ................................................................................................................. 14

5.1. Introduction ................................................................................................................. 14

5.2. Control panel …............................................................................................................. 14

5.3. Feeding of the guillotine ........................................................................................... 15

5.4. Activation of the machine ............................................................................................. 15

5.5. Gauge retraction …….................................................................................................... 18

5.6. Light .............................................................................................................................. 19

5.7. Laser ........................................................................................................................... 19

5.8. Calculator .................................................................................................................... 20

5.9. Automatic mode ........................................................................................................... 20

5.10. Program management ................................................................................................ 22

5.11. Gauge adjustment ...................................................................................................... 24

5.12. Blade adjustment ..................................................................................................... 26

5.13. Lateral length of the cut ............................................................................................. 27

5.14. General emergency .................................................................................................... 27

5.15. Photocell interruption …………................................................................................... 29

5.16. Pump thermal protection ............................................................................................ 29