TM

NS-600

2

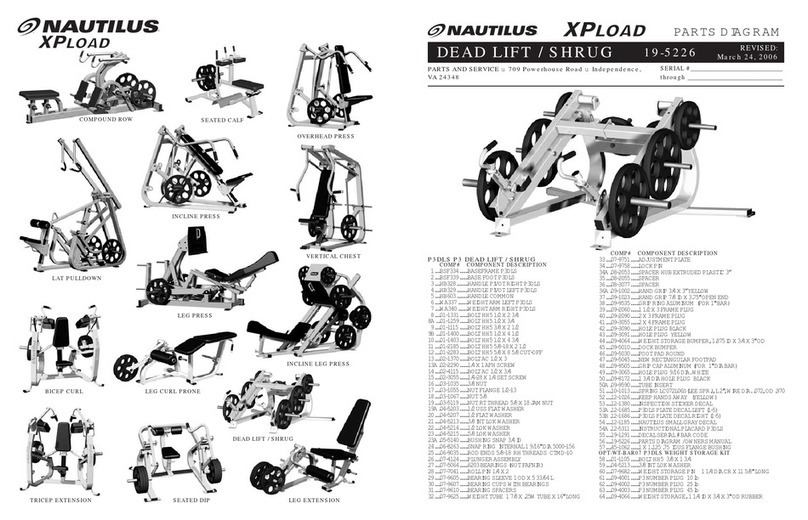

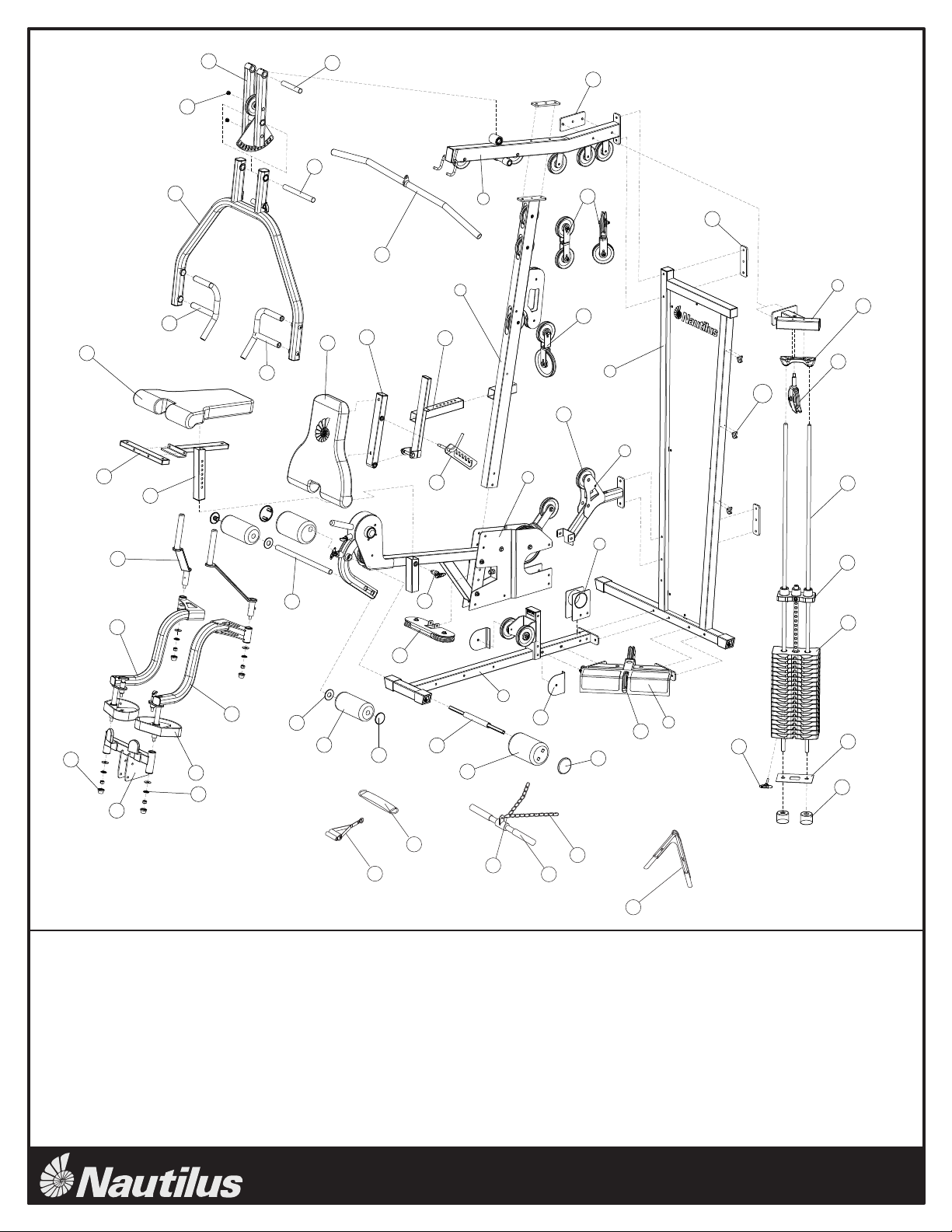

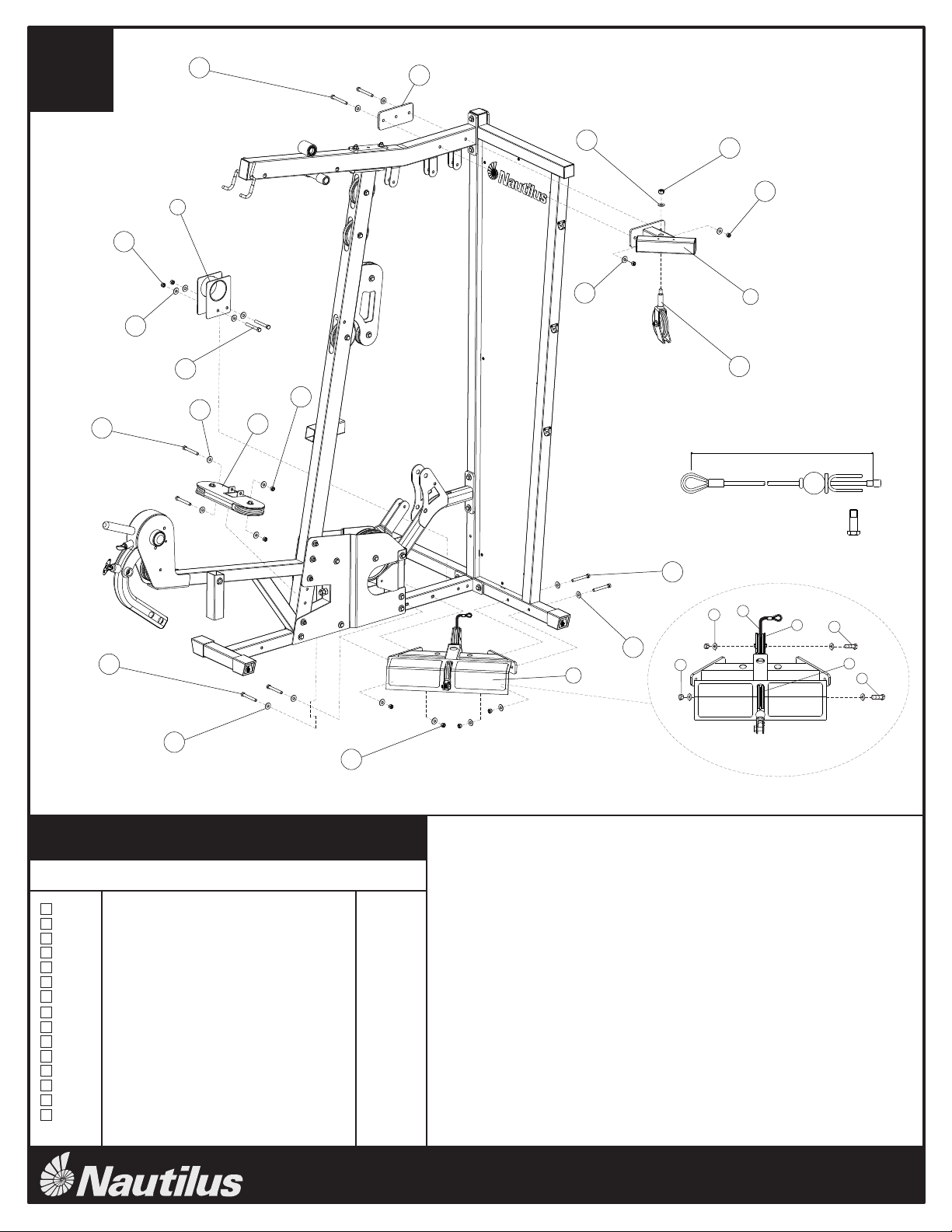

Gym Components Gym Components

Part # Part #

1 Main Base 1 14786

2 Rear Frame 1 14785

3 Top Frame 1 14124

4 Front Upright 1 14787

5 Leg Extension Frame 1 14434

6 Pulley Mount 1 14788

7 Calf Raise / Low Pulley Frame 1 14127

8 Top Stack Support Frame 1 14125

9 Cable Housing 1 14137

10 2 inch Backing Plate 3 14105

11 3 inch Backing Plate 1 14007

12 Press Arm Support Assembly 1 14132

13 Press Arm 1 14131

14 Right Press Arm Handle 1 14133

15 Left Press Arm Handle 1 14134

16 Pec Fly Mount 1 14135

17 Pec Fly Cam 2 14473

18 Right Pec Fly Arm 1 14148

19 Left Pec Fly Arm 1 14149

20 Pec Fly Handle 2 14151

21 Pec Fly Pulley Bracket 1 14438

22 Seat Adjuster 1 14128

23 Seat Cross Tube 1 14101

24 Back Pad Tube 1 14465

25 Back Pad Adjuster 1 14456

26 Back Pad Adjustment Plate 1 14469

27 Seat Pad 1 14190

28 Back Pad 1 14189

29 Pulley Bracket 1 14136

30 Pec Double Floating Pulley Bracket 1 14138

31 Double Floating Pulley Bracket 2 14138

32 Guide Rod Holder 1 14174

33 Low Pulley Cover 2 14437

34 T Handle Pop Pin 1 14211

35 Locking Roller Pad 2 14493

36 Foam Roller Pad 8"L 2 14270

37 Locking Roller End Cap 2 14486

38 Roller End Cap 2 14165

39 Plastic Washer 2 92058

40 Locking Roller Bar 1 14460

41 Roller Bar 1 14100

42 Plastic Cap 4 14158

43 3 1/2" Pulley 2 14173

44 4 1/2" Pulley 9 14537

45 Press Arm Support Shaft 1 14111

46 Press Arm Pivot Shaft 1 14110

47 Snap Cap Large 2 14182

48 Top Weight Assembly 1 14679

49 Weight Plate 19 14342

50 Weight Stack Bottom Plate 1 14106

51 Weight Stack Cushion 2 14176

52 Guide Rod 2 14102

CABLE

53 Cable #1 - Pulldown Cable (226") 1 14791

54 Cable #2 - Mid Pulley Cable (96.75") 1 14792

55 Cable #3 - Low Row Cable (137.75") 1 14793

56 Cable #4 - Pec Fly Cable (122.5") 1 14794

HARDWARE

57 Hex Bolt - 1/2" x 3 1/4"L 1 14243

58 Hex Bolt - 3/8" x 4 1/2"L 1 92170

59 Hex Bolt - 3/8" x 4 1/4"L 4 14246

60 Hex Bolt - 3/8" x 4"L 1 14247

61 Hex Bolt - 3/8" x 3 1/4"L 8 14267

62 Hex Bolt - 3/8" x 3"L 16 14245

63 Hex Bolt - 3/8" x 2 3/4"L 4 14241

64 Hex Bolt 3/8" x 2 1/4"L 3 14265

65 Hex Bolt 3/8" x 2"L 5 14242

66 Hex Bolt - 3/8" x 1 3/4"L 3 14239

67 Hex Bolt - 3/8" x 1 1/2"L Threadlock 2 14249

68 Cap Head Screw 1/4 x 1"L Threadlock 2 14258

69 Cap Head Screw 1/4" x 1/2"L Threadlock 2 14259

70 Button Head Screw 1 3/4"L 2 14256

71 Button Head Screw 1"L Threadlock 4 14251

72 1 3/8" x 1/2" Flat Washer 4 14272

73 1" x 1/2" Flat Washer 4 14273

74 3/8" Flat Washer 87 14233

75 Shim Washer 4 14274

76 1/2" Lock Nut 7 14232

77 3/8" Lock Nut 42 14234

78 Pulley Spacer 1"L 1 14196

79 Step Spacer 5/8"H 4 14195

80 Step Spacer 1"H 2 14795

81 Step Spacer 21/32"H 2 14796

82 Set Screw 5/16" x 1/4"L 6 14277

ACCESSORIES AND TOOLS

83 Rower Bar 1 14113

84 AB Strap 1 14215

85 Felt Back Ankle Strap 1 14217

86 Dual Ring Handle Strap 1 14384

87 Chain 1 92053

88 Lat Bar 1 14142

89 Cable Clip 4 92054

90 Weight Selector Pin 1 14210

91 M4 Allen Wrench 1 14680

92 M5 Allen Wrench 1 14532

93 M6 Allen Wrench 1 14533

94 M8 Allen Wrench 1 14534

95 Touch Up Paint White 1 14536

96 Touch Up Paint Gray 1 14535

97 NS 600 Documentation 1 14797

98 Decal Kit 1 14789