V8200A,C,H,M AND VR8200A,C,H,M CONTINUOUS PILOT COMBINATION GAS CONTROLS

69-0422—05 6

Perform Gas Leak Test

Fire or Explosion Hazard can cause property

damage, severe injury or death.

Check for gas leak with soap and water solution

any time work is done on a gas module.

Gas Leak Test

1. Paint pipe connections upstream of gas

control with rich soap and water solution.

Bubbles indicate gas leak.

2. If leak is detected, tighten pipe connections.

3. Stand clear of main burner while lighting to

prevent injury caused from hidden leaks which

could cause flashback in the appliance

vestibule. Light main burner.

4. With main burner in operation, paint pipe joints

(including adapters) and control inlet and

outlet with rich soap and water solution.

5. If another leak is detected, tighten adapter

screws, joints, and pipe connections.

6. Replace part if leak can't be stopped.

Light Pilot

1. Rotate the gas control knob clockwise to OFF.

Wait five minutes to allow any unburned gas to

dissipate. Sniff around the appliance near the floor.

Don't relight if you smell gas.

2. Rotate the gas control knob counterclockwise

to PILOT. Push down and hold the red reset

button while you light pilot burner according to

appliance manufacturer's instructions.

3. After about one minute, release reset button. Pilot

should remain lit. If it goes out, turn gas control

knob clockwise to OFF. To relight, repeat

steps 1-3.

4. After pilot remains lit when red reset button is

released, turn gas control knob counterclockwise

to ON.

Turn On Main Burner

Follow instructions provided by appliance manufacturer

or turn thermostat up to call for heat.

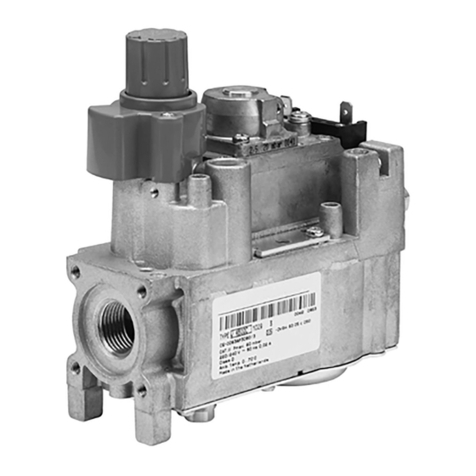

Adjust Pilot Flame

The pilot flame should envelop 3/8 to 1/2 in.

(10 to 13 mm) of the tip of the thermocouple. Refer to

Fig. 9.

1. Remove pilot adjustment cover screw.

Refer to Fig. 4.

2. Turn inner adjustment screw clockwise to

decrease or counterclockwise to increase

pilot flame.

3. Always replace cover screw after adjustment.

Tighten firmly to prevent gas leakage.

Fig. 9. Proper Flame Adjustment.

Check and Adjust Gas Input to Main Burner

1. Do not exceed input rating stamped on

appliance nameplate, or manufacturer's

recommended burner orifice pressure for size

orifice(s) used. Make certain primary air supply

to main burner is properly adjusted for

complete combustion. Follow appliance

manufacturer's instructions.

2. IF CHECKING GAS INPUT BY CLOCKING GAS

METER: Make certain there is no gas flow

through the meter other than to the appliance

being checked. Other appliances must remain

off with their pilots extinguished (or their

consumption must be deducted from the meter

reading). Convert flow rate to Btuh as

described in form 70-2602, Gas Controls

Handbook, and compare to the Btuh input

rating on appliance nameplate.

3. IF CHECKING GAS INPUT WITH MANOMETER:

Make certain gas control is in PILOT position

before removing outlet pressure tap plug to

connect manometer (pressure gauge). Also

turn gas control knob back to PILOT when

removing gauge and replacing plug. Before

removing inlet pressure tap plug, shut off gas

supply at the manual valve in the gas piping to

the appliance or, for LP, at the tank. Also shut

off gas supply before disconnecting

manometer and replacing plug. Repeat Gas

Leak Test at plug with main burner operating.

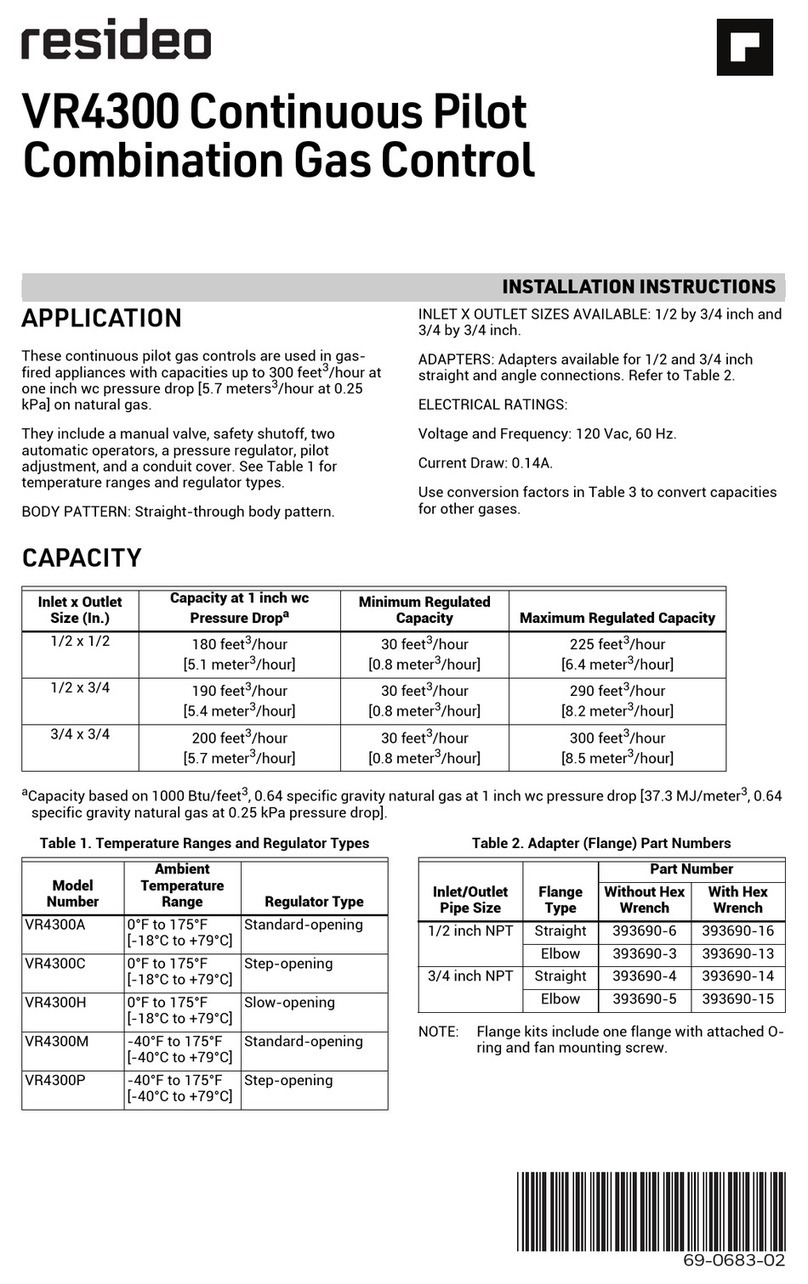

Standard Pressure Regulator

1. Check the manifold pressure listed on the appli-

ance nameplate. Gas control outlet pressure

should match the nameplate.

2. With main burner operating, check gas control flow

rate using the meter clocking method or pressure

using a manometer connected to the outlet

pressure tap on the gas control. Refer to Fig. 4.

3. If necessary, adjust pressure regulator to match

appliance rating. Refer to Table 7 for factory set

nominal outlet pressure and adjustment range.

a. Remove pressure regulator adjustment cap and

screw.

b. Using screwdriver, turn inner adjustment screw

clockwise to increase or

counterclockwise to decrease gas

pressure to burner.

c. Always replace cap screw and tighten firmly to

ensure proper operation.

4. If desired outlet pressure or flow rate cannot be

achieved by adjusting the control, check the

control inlet pressure using a manometer at the

inlet pressure tap. If inlet pressure is in normal

range (refer to Table 7), replace the control.

Otherwise, take the necessary steps to provide

proper gas pressure on the control.

Step-Opening and Slow Opening Pressure

Regulator

1. Check the full rate manifold pressure listed on the

appliance nameplate. Gas control full rate outlet

pressure should match this rating.

2. With main burner operating, check the control flow

rate using the meter clocking method or pressure

using a manometer connected to outlet pressure

tap on the control. Refer to Fig. 4.

M3086B

PROPER FLAME

ADJUSTMENT

3/8 TO 1/2 IN.

(10 TO 13 MM)

THERMOCOUPLE