NeoDen IN6 User manual

Hangzhou NeoDen Technology Co., Ltd

User Manual

Reflow Oven NeoDen IN6

-Full hot-air convection

-Built-in welding smoke filtering system

Content

1. Brief Introduction.................................................................................................................... 1

2. Specification............................................................................................................................ 1

3. Main Parts................................................................................................................................2

3.1 Reflow Oven Main Body.............................................................................................. 2

3.2 Operating Panel............................................................................................................. 2

3.3 Pedestal..........................................................................................................................2

4. Installation Instruction.............................................................................................................3

4.1 Power Supply Connection.............................................................................................3

4.2 Installation Attentions................................................................................................... 3

4.3 Status of Indicators........................................................................................................3

4.4 Operation instructions................................................................................................... 3

5. Temperature wave setting principle........................................................................................ 6

5.1 The reflow soldering theory and the temperature wave............................................... 6

5.2 The set of the temperature wave................................................................................... 6

6. Details about temperature area setting.................................................................................... 6

7. Temperature measurement method......................................................................................... 7

8. Both side soldering instruction................................................................................................7

9. Trouble shooting......................................................................................................................7

9.1 Soldering analysis..........................................................................................................7

9.2 Precautions.................................................................................................................... 8

9.3 Machine maintenance....................................................................................................8

1

Attention!Please read the user manual carefully before operating this machine.

1. Brief Introduction

IN6 is a newly designed, environmentally friendly reflow oven with stable performance. It can

achieve full hot-air convection, excellent soldering performance. It has 6 temperature zone, light

and compact. Intelligent temperature control with high sensitivity temperature sensor, temperature

can be stable within ±0.2°C. It adopts Japan NSK hot air motor bearing and Swiss imported heating

wire, which is durable and stable. CE approved, provide authoritative quality assurance.

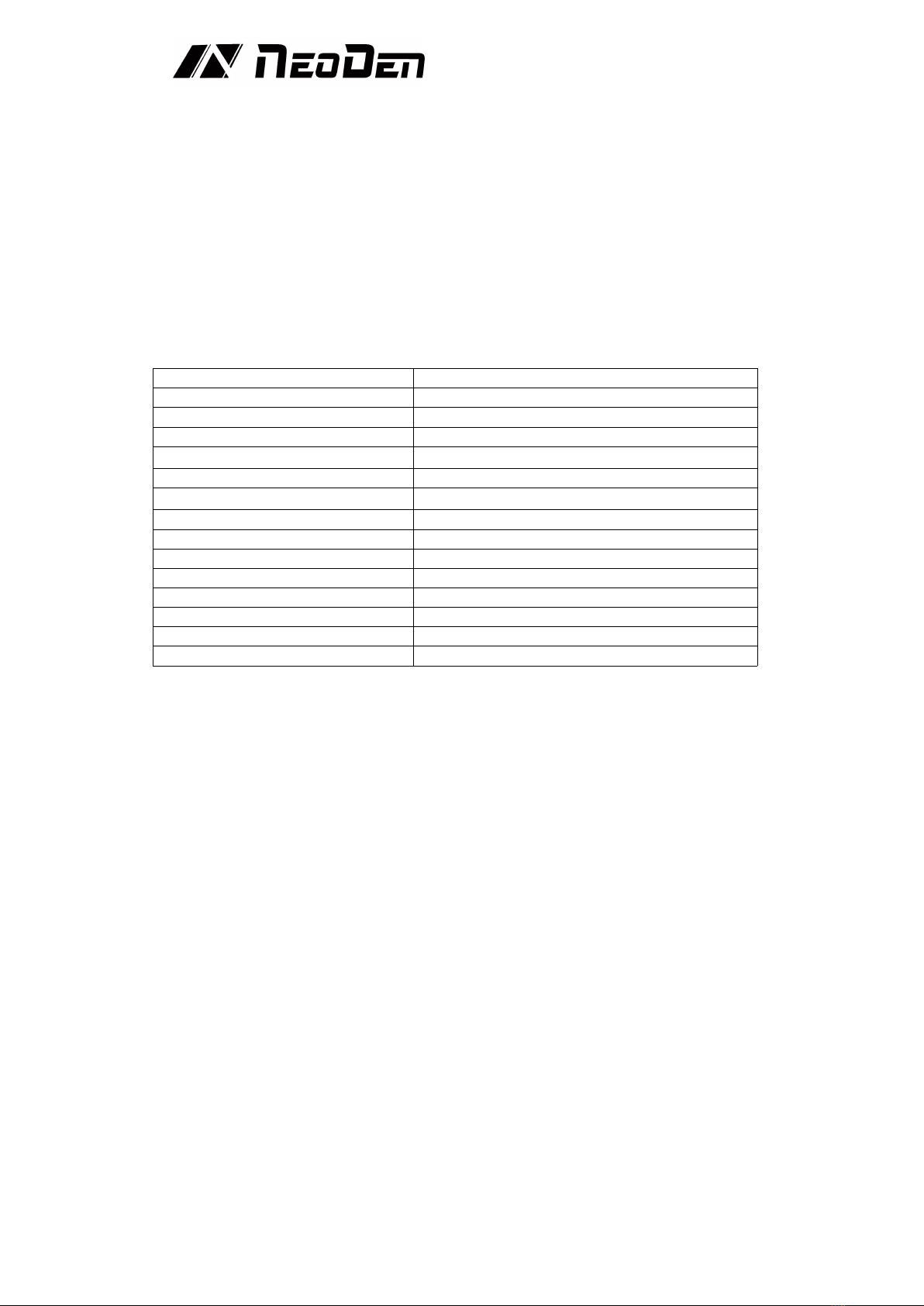

2. Specification

Model

IN6

Heating Zone Quantity

Upper 3/ Down 3

Heating Type

Nichrome wire and aluminum alloy heating

Cooling Zone Quantity

1

Conveyor Speed

5~30cm/min(2~12inch/min)

Standard Height Max(mm)

30mm

Temperature Range

Room temperature ~ 300℃

Heat-up Time

Approx. 20-30min

Soldering Width

260mm(26.8inch)

External Dimension

1020mm*507mm*350mm

Max Rated Power

~2000W

Working Power

~700W

Electricity Supply

110V/220V Single Phase

Operating Direction

Left → Right

Net Weight

49kg

2

3. Main Parts

3.1 Reflow Oven Main Body

3.2 Operating Panel

3.3 Pedestal

3

4. Installation Instruction

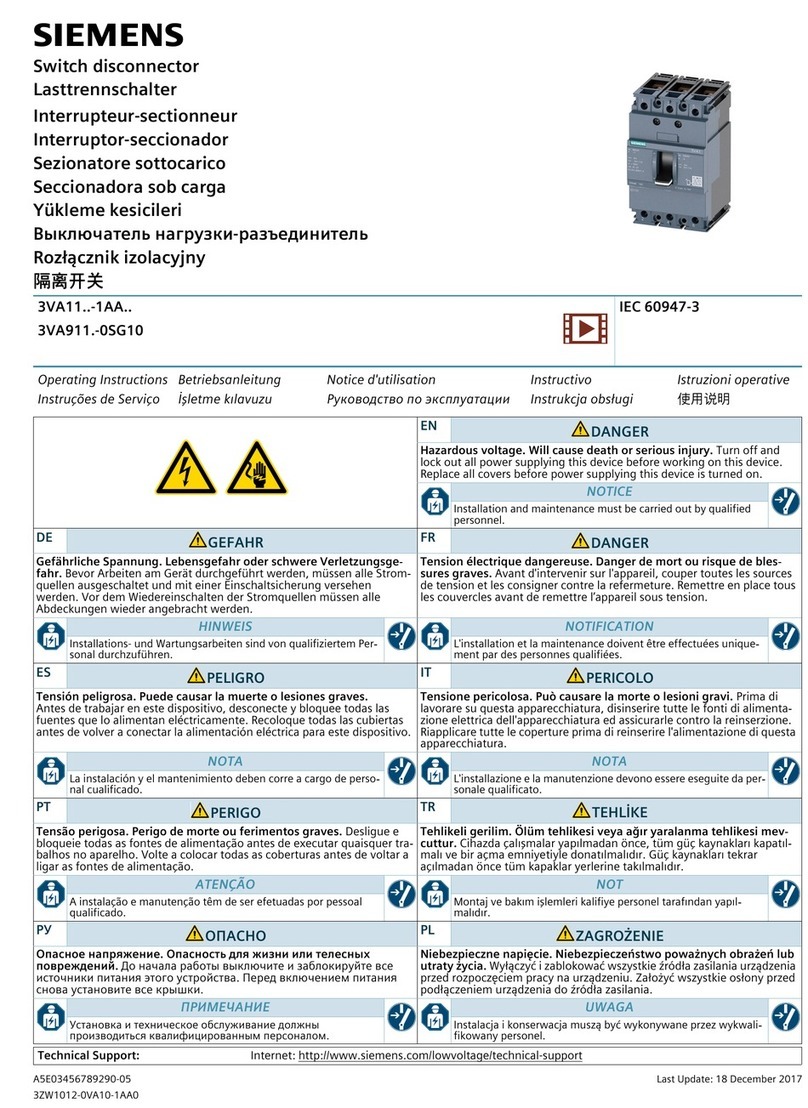

4.1 Power Supply Connection

IN6 is used in 110V/220V single-phase connection mode and is connected according to the user

environment. Wires connection method is shown as picture. L stands for the live wire, N stands for

the zero wire, and E stands for the ground wire, connect to the 220V (110V) power supply.

According to the wiring requirements, the L should be connected to one live wire, and the N should

be connected to one zero wire; the E should be connected to one ground wire properly

4.2 Installation Attentions

♦Power supply requirement:110V/220V

♦For desktop reflow oven, should be working on workbench, don’t suggest to use wooden material

♦The machine should be set in standard SMT workshop, stay away from flammable and explosive if

couldn’t meet previous requirements.

♦Exposed wire harness should be well protected, prohibit to expose at the passage or flue in case of

causing any accident.

4.3 Status of Indicators

There is a green bar indicator at the PCB entrance that indicates whether the temperature in all

zones has reached the set temperature. This indicator lights up when the actual temperature of all

zones reaches the set temperature.

4.4 Operation instructions

♦Power-on

L N E

4

Turn the red power switch to the ON position and the machine starts.

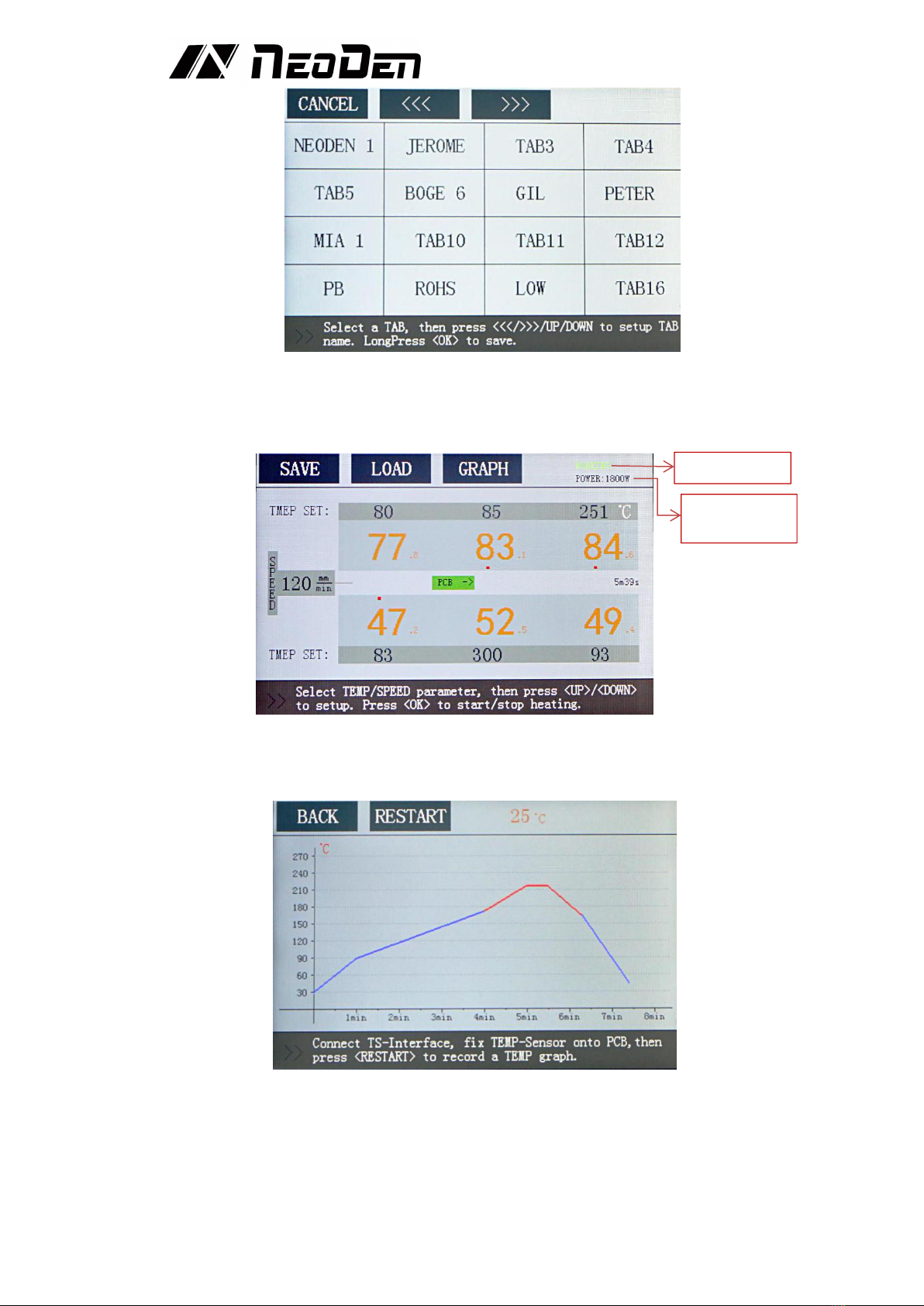

♦Transfer chain speed setting

Tap the speed parameter on the screen and press the Up/Down button to set the appropriate transfer

chain rotation speed. When the speed is set, the time required to transport a PCB at this setting

speed is displayed on the right side of the screen.

♦Temperature zone setting

Tap the temperature parameter on the screen and press the up/down buttons to set the temperature.

Black is “the set temperature”, and orange is “the real-time temperature”.

♦Save and Usage of speed and temperature settings

After setting the transfer chain speed and the temperature of each zone, you could press the SAVE

button to save the setting parameters of the transfer chain and the zone temperature. When the

SAVE button is pressed, it will enter the TAB interface. Click on a TAB, then you can use the

"<<<", ">>>" "Up" and "Down" buttons to change the TAB name, long press OK to save these

parameters to this TAB.

When you would like to call the previously saved speed and temperature of the transport chain,

click the LOAD button on the screen to enter the TAB interface, click the TAB name, and then click

the CONFIRM button to load the speed and temperature settings of the transport chain.

Speed setting

Time required

to transport a

PCB

Temperatur

e setting

Power switch

5

♦Start or stop heating

Press the OK button in the main interface, the machine will switch from STANDBY state to

WORKING state, and begin to warm up.

If you need to switch from WORKING state to STANDBY state, just press the OK button in

WORKING state.

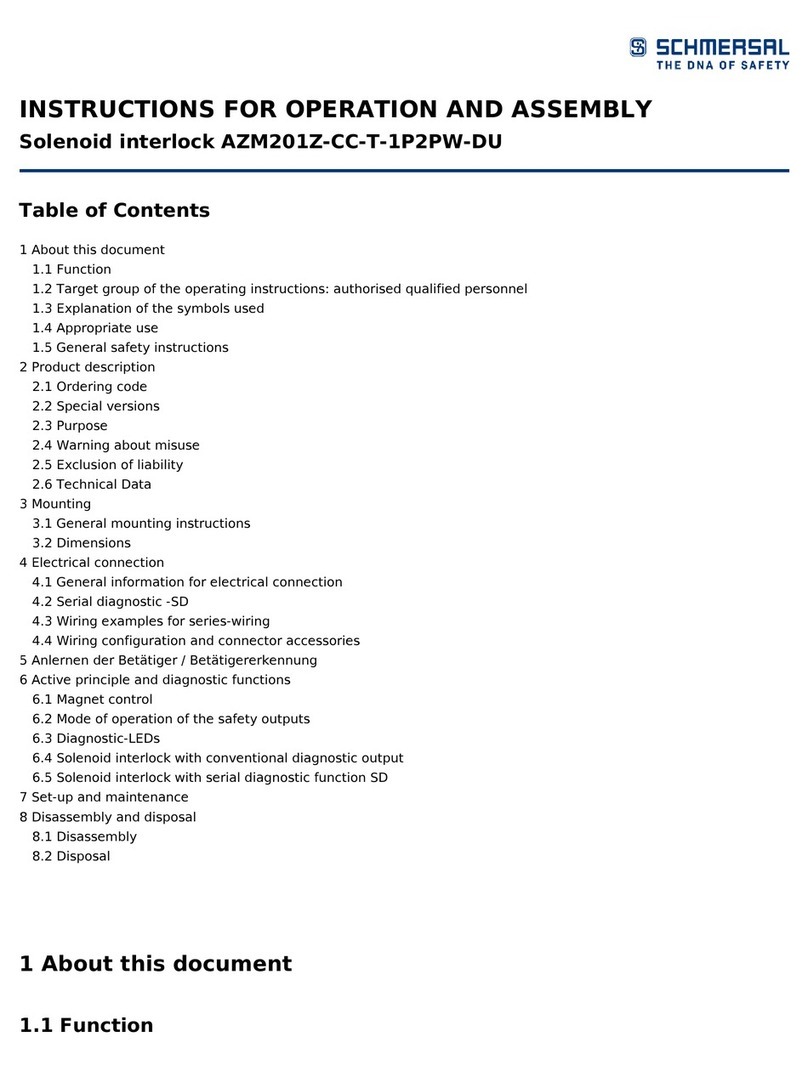

♦Temperature curve

Connect the temperature sensor to the TEMP SENSOR connector, attach the temperature sensor to

the PCB, and then click the “Restart”button on the Graph interface after PCB is put into the oven

to get the temperature curve.

♦Power-off

Turn the red power switch to the OFF position and turn off the machine.

♦Change language and the unit of temperature in machine

After the power switch is turned to ON, the NeoDen logo will be displayed on the screen. Long

press the OK button to enter the Debug mode interface. In this interface, you can change the

language and temperature unit of the machine.

Working State

Real-time

Power size

6

5. Temperature wave setting principle

5.1 The reflow soldering theory and the temperature wave

When the PCB goes into heat up area (dry area), the solvent and gas in the solder paste will

evaporate. At the same time, the flux can wet the pad and the component tip and foot. The solder

paste melts, caves in and covers the pad, leading to the pad and component pins insulate the oxygen.

PCB goes into heat preservation area. PCB and components get full preheating. In case of damaging

the PCB and components when it goes into the welding area and the temperature heats up quickly.

When PCB goes into the welding area, the temperature heats up and the solder paste melts. When

PCB goes into cooling area, the liquid solder paste the soldering points solidify. The reflow process

is finished.

The temperature is the key to welding quality. The actual and the setting temperature warming slope

and the peak temperature should be accordant. Before the temperature reaches 160℃, please control

the heat up speed in about 1℃/S. If heat up too quickly, the PCB and the components will be

damaged, and the PCB may be out of shape. On the other side, the flux volatilizes too fast. And it is

easy to make soldering tin ball. Set the peak temperature 20℃-40℃higher than the solder paste

melting point. Set the reflow time 10S-60S. If the peak temperature is low or the reflow time is

short, it will affect the welding quality, and serious is causing the solder paste does not melt. If the

peak temperature is high or the reflow time is long, the metal power will be oxidized and affect the

welding quality and serious is causing the component and PCB damaged.

5.2 The set of the temperature wave

Set the wave according to the solder paste and the above foundation. Different solder paste, choose

and set different waves. In addition, the temperature wave has related to the PCB, the density and

size of components. Generally lead-free welding temperature should be higher 40℃than melting

point.

6. Details about temperature area setting

♦Set the temperature and belt speed to initial value, to the cooling oven, should be preheated for 25

minutes.

♦When the temperature is stable, let PCB pass heat reflow system. If there is no reflow, can

properly reduce the transfer chain rotation speed. Another way is that, do not adjust the speed, and

increase the temperature properly. When adjust the temperature, notice that it cannot exceed the

PCB and component bearing capacity.

♦Let the PCB pass the reflow system in the new speed or new set temperature. If there is no reflow,

turn to redo the above step. Otherwise, need temperature fine-turning.

♦The heat temperature wave is adjustable according to the PCB. You can adjust the transfer chain

rotation speed to adjust the temperature. Reduce the transfer chain rotation speed can increase the

product heat temperature. On the contrary, you can reduce the product heat temperature.

Attention:

♦If the PCB has been placed components, the PCB pass the reflow and it reflow not very completely,

suggest you adjust then reflow again. Normally, it will not impact the PCB and components.

♦From low to high when set temperature. If the heat range is over the reflow temperature too high,

7

should increase the transfer chain rotation speed or reduce the set temperature.

♦Different PCBs boards have different heat transmission rate and heat absorption capacity, so it

requires the reflow oven offers different heated time and quantity of heating. To double-side PCB,

multi-board and other PCBs with many bonding pads, they have a higher temperature setting. To

one-side PCB, paper board and less bonding pads’ PCB, they have a lower temperature setting. And

it also be affected by quantity of PCB that you place. During actual work, reflow oven will adjust

itself automatically to some changes of PCB. If based on our suggested temperature, the machine

can work well, unless very big change of PCB’s absorption capacity, then it needs to adjust

properly.

7. Temperature measurement method

♦Attach the temperature thermocouple sensor to the PCB which is the same or similar size as the

working PCB in order to observe the reflow. Put the PCB on the transfer chain, then will get the

temperature profile, after that compare with the recommend temperature profile. If it is the same to

the standard profile or correspond with automodulation profile, then you can start to produce,

otherwise follow the temperature profile, the temperature controller with large temperature

difference is used to set the compensation temperature by 5 degrees, or the whole machine

integrated adjustment, in order to achieve the temperature profile can be produced

♦When starting to put PCB or abruptly change the number of PCB to be reflow oven, there is a

difference between the actual temperature and setting temperature, put the PCB with constant speed

for a period of time, the temperature difference will turn to normal temperature difference range.

8. Both side soldering instruction

♦Use hot air reflow soldering can finish double-side component soldering. Double-side soldering

design means components are in double-side of the PCB need to soldering. Double side soldering

includes double-side soldering tin and single-side soldering tin and another side drying glue, as for

single-side soldering tin and another side drying glue, it is easier. First, finish one side’s soldering

tin as the same as single-side, then finish another side tape glue drying in low temperature, finish

double-side SMT craft, after that carry on the next step plug-in or tin process on craft. Double-side

soldering is generally treated as below follows:

♦Start the reflow oven, set up the transfer chain speed controller, finish the A side components

reflow soldering with normal soldering craft.

♦Upend the PCB, repeat normal procedure to mount the component, adopt top heating strategy to let

the B side reflow soldering, but the upend A side has been reflow soldering, the compounds in thick

liquid volatilize, the melting point of tin is higher than the solder paste, which in order to keep the A

side components not fall out.

9. Trouble shooting

9.1 Soldering analysis

Problem

Possible causes

Solutions be available

Incomplete

reflow

Inadequate heating

lower the transfer chain speed

Shadows from components

a. Increase the transfer chain speed

b. Increase bottom heat

Due to the middle layer of copper foil

Decrease transfer chain speed and increase

temperature

Inadequate

moist

PCB, components without enough solder

paste

Pre-paste to components and PCB

No enough moist time

Increase the temperature of heating zone

PCB bend

Exceeding upper and lower temperature

difference limits

Reduce temperature difference between

preheating zone and bottom temperature zone

Increase transfer chain speed

PCB

discoloration

Exceeding tin temperature on the board,

exceeding temperature gradient or

heating speed

Increase transfer chain speed

Decrease the preset zone temperature

Decrease transfer speed and temperature

Excessive fines

Top layer temperature out of limit

Reduce top heat and increase bottom zone

temperature

Tin balls

Due to dry too fast

Decrease transfer chain speed and temperature

Solder pasting is unqualified or PCB re-

Use PCB after cleaning and drying

8

paste

Flux coking

Over heating

Add transfer chain speed, lower temperature

Components

wrong position

PNP wrongly, the tin on the solder pad is

irregular or asymmetrical, drying too fast

causes airflow to blow components

Check place position

Check the shape and thickness of tin

Lower transfer chain speed and temperature

Tin bridging

Misposition

Check position

Tin migration

Moist overtime

Increase the belt speed

Lower pre-setting temperature

Solder skips

The solder paste is not enough on pad,

the unevenness of the micro-component,

the PCB coplanarity problem

Thickened tin paste coating

Try to make the solder on the pad even

Check component pin stability

PCB over heat

Heating speed too fast

Decrease transfer chain speed and temperature

9.2 Precautions

If the PCB length is longer than the ESD tray, the ESD tray needs to be replaced by other suitable

carriers to place the soldered PCB.

9.3 Machine maintenance

♦Change the filter regularly

It is necessary to replace the filter regularly. The service life of filter is 8 months (depending on the

frequency of use). When it’s needed to replace the filter, you could find the welding smoke

automatic filter system in the figure below. Remove the 12 screws above and replace the filter.

♦Regularly add high temperature lubricating oil to transfer chain bearings.

Table of contents

Other NeoDen Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

schmersal

schmersal AZM201Z-CC-T-1P2PW-DU Instructions for operation

HYDROSCAND

HYDROSCAND AutoReel Dynamic user manual

Bender

Bender EDS44 L-CN Series quick start guide

ABB

ABB A265-L Operation manual

Bosch

Bosch rexroth ActiveShuttle System manual

Current Tools

Current Tools 281 Assembly, Operating, Safety and Parts Manual