Table of Contents

Health, safety and environment ...................................................................11

Precautions and Safety Issues.........................................................................1

End of Life........................................................................................................2

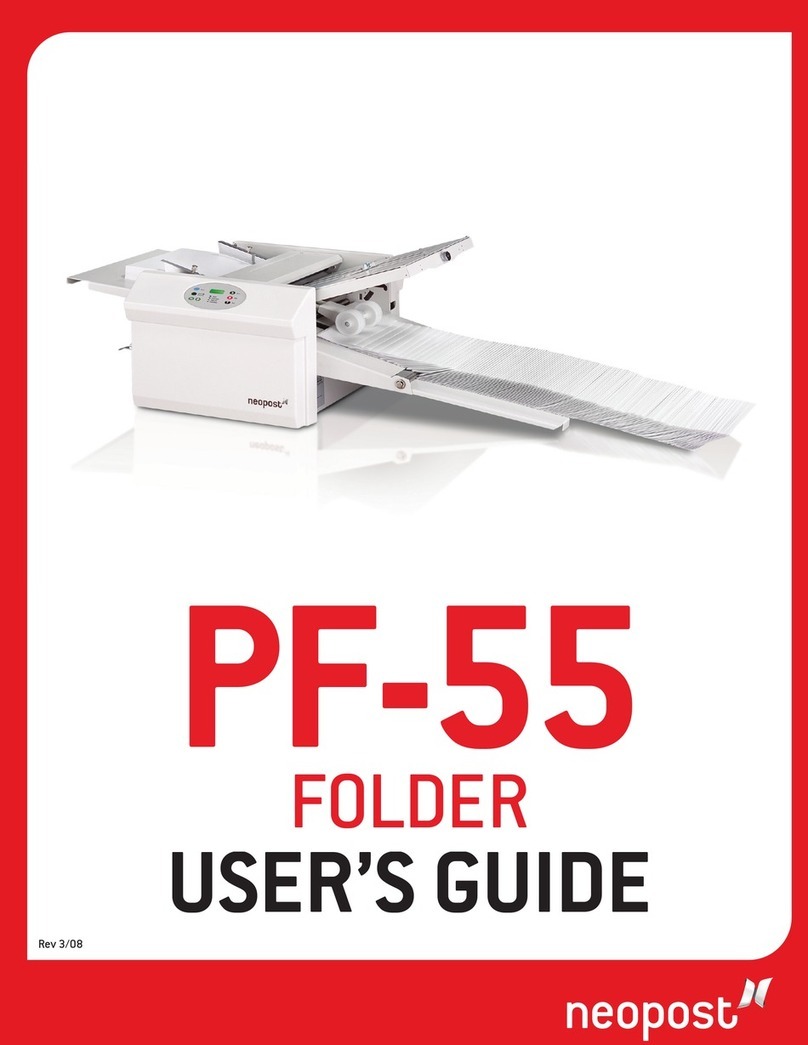

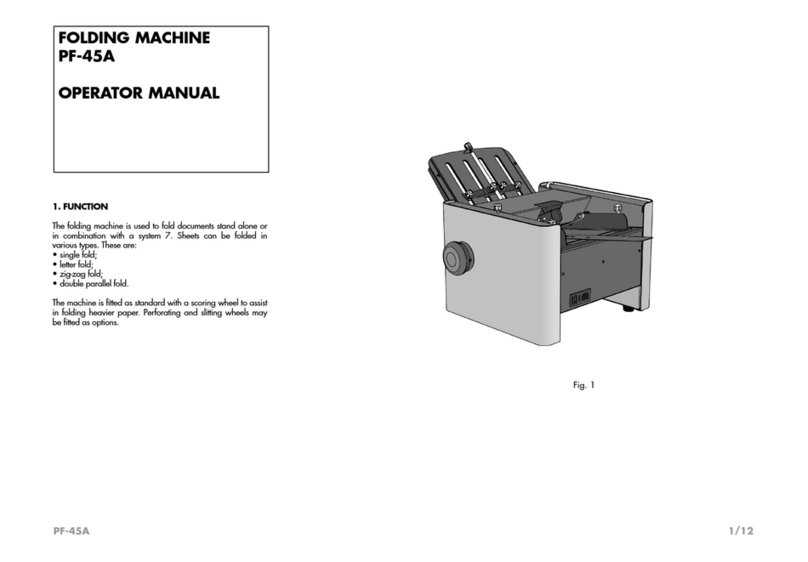

Functional description .................................................................................32

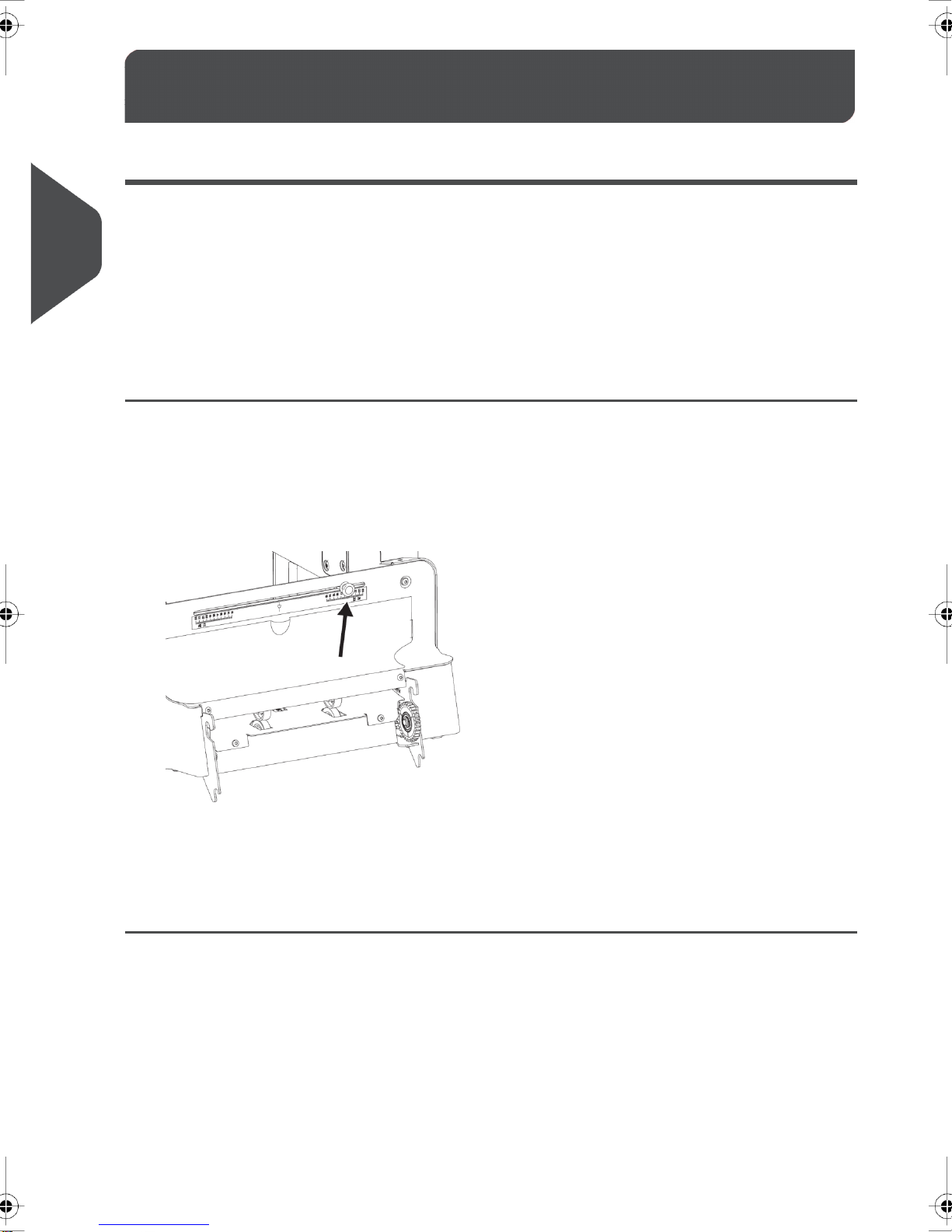

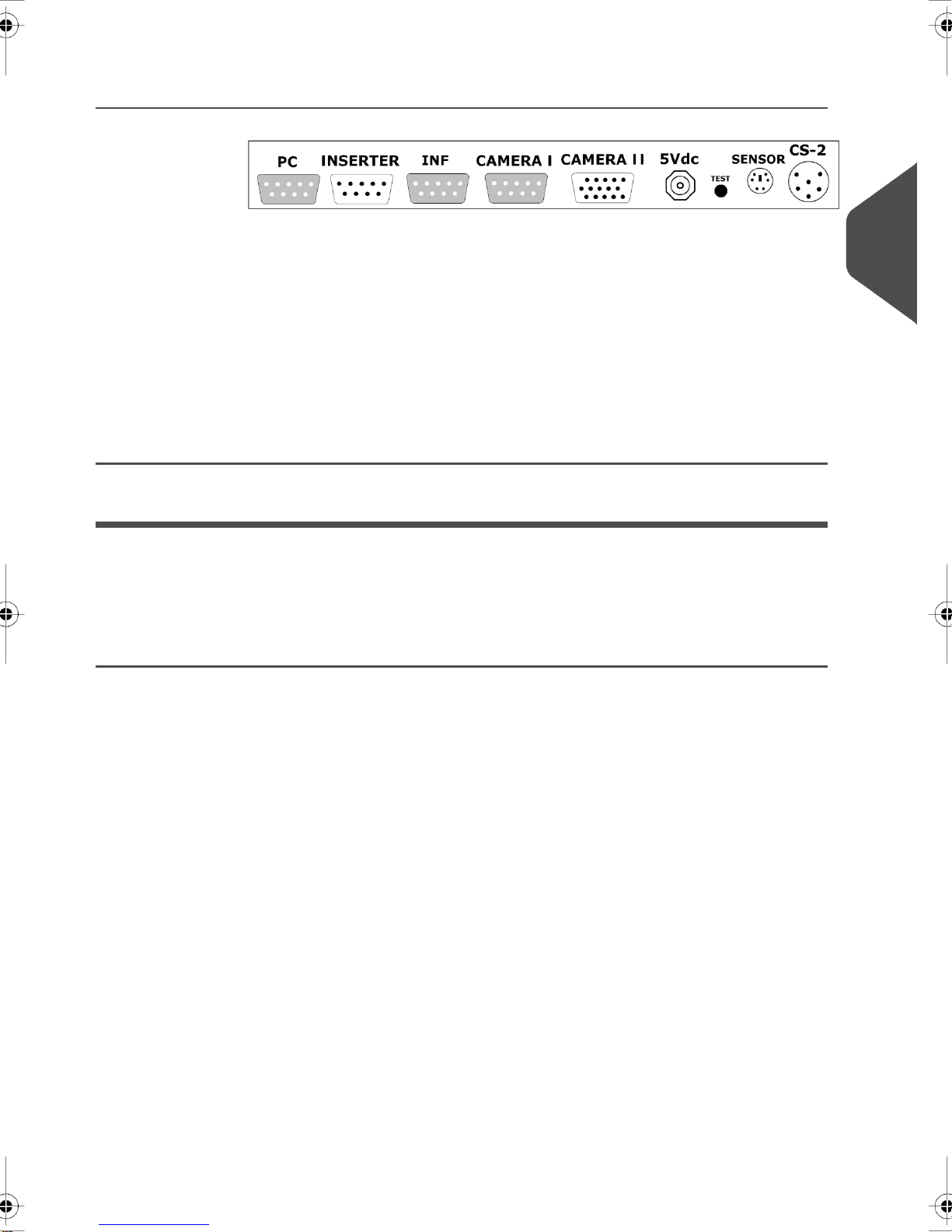

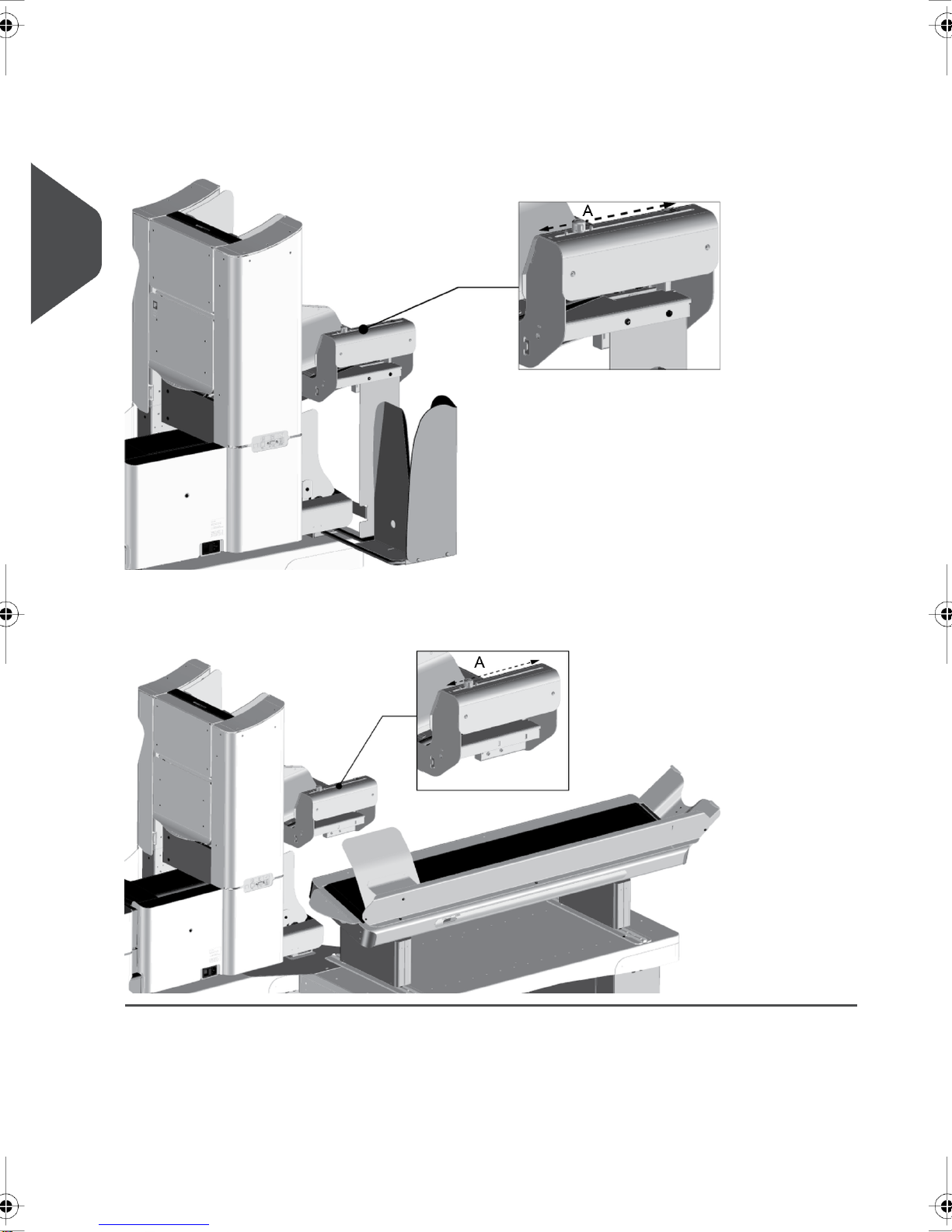

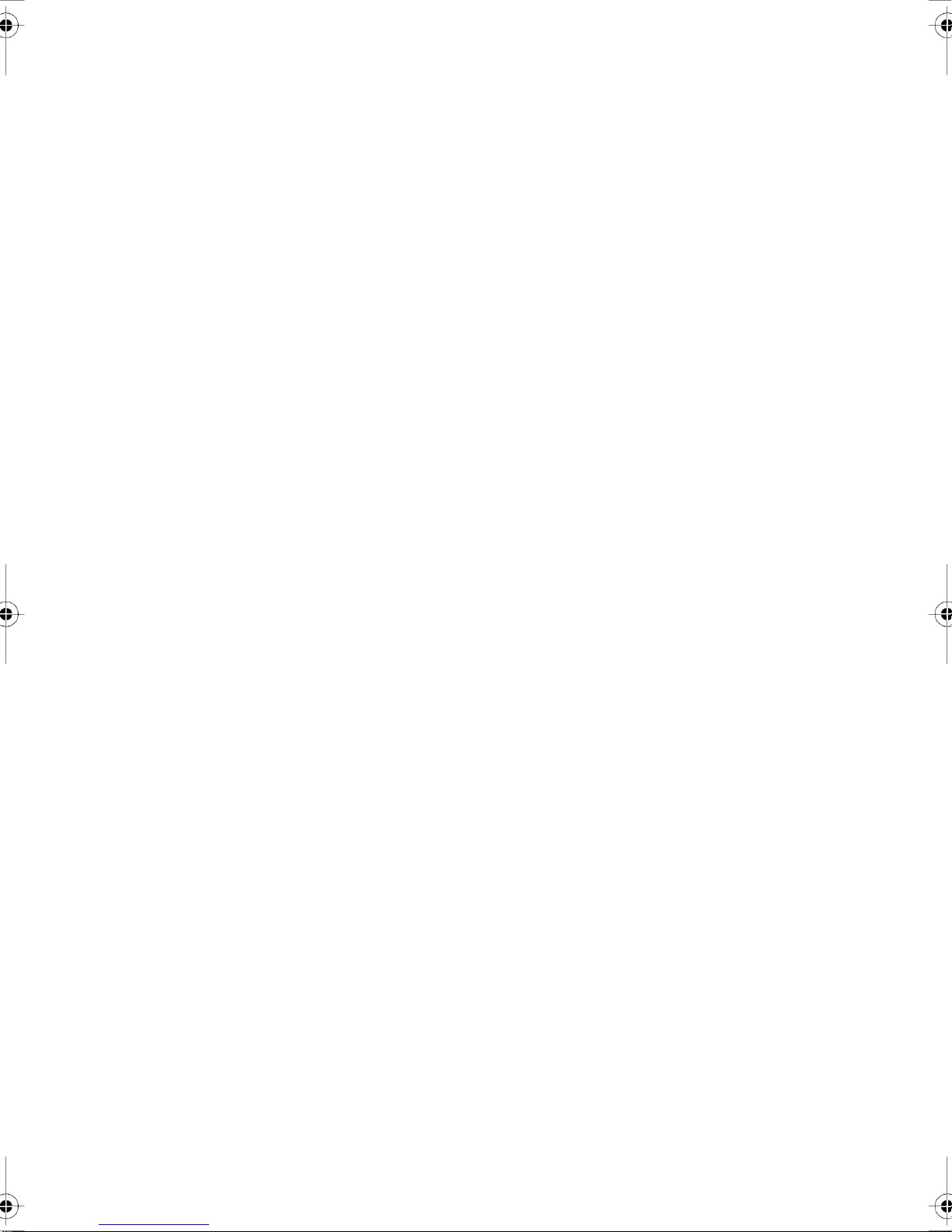

Installation .....................................................................................................43

Installation for the DS-75 and DS-85...............................................................4

Installation for the DS-90 and DS-90i...............................................................5

Installation for the Mailing (Franking) System..................................................7

Create Job ...................................................................................................104

Create Job on the DS-75...............................................................................10

Create Job on the DS-85...............................................................................12

Create Job on the DS-90...............................................................................14

Create Job on the DS-90i..............................................................................16

Create Job for the Mailing (Franking) System .........................................215

Create Job on the DS-75 for the Mailing (Franking) System..........................21

Create Job on the DS-85 for the Mailing (Franking) System..........................23

Create Job on the DS-90 for the Mailing (Franking) System..........................25

Create Job on the DS-90i for the Mailing (Franking) System.........................27

Fault finding ................................................................................................326

Fault finding....................................................................................................32

Specifications .............................................................................................337

Specifications.................................................................................................33

| Page 1 | TOC | Nov-25-2014 09:44 |