6

4103241J-6/A

4103980D/A

28/05/2001

2.1.5Modification of a job.....................................31

2.1.6Creation of a job ..........................................32

2.1.7Counters ......................................................32

2.1.8Countdown counter ....................................... 33

2.2 Supervisor mode................................................ 34

2.2.1Length of flap moistening................................ 34

2.2.2Adjustment of the document alignment (feeders B

and C)......................................................... 35

2.3 Position of the address and adjustment of the folds..35

2.3.1Position of the address ................................... 35

2.3.2Adjustment of the folds ...................................35

2.4 Detection of double documents ............................36

2.4.1General remarks ........................................... 36

2.4.2Enabling and disabling the double document

detection......................................................36

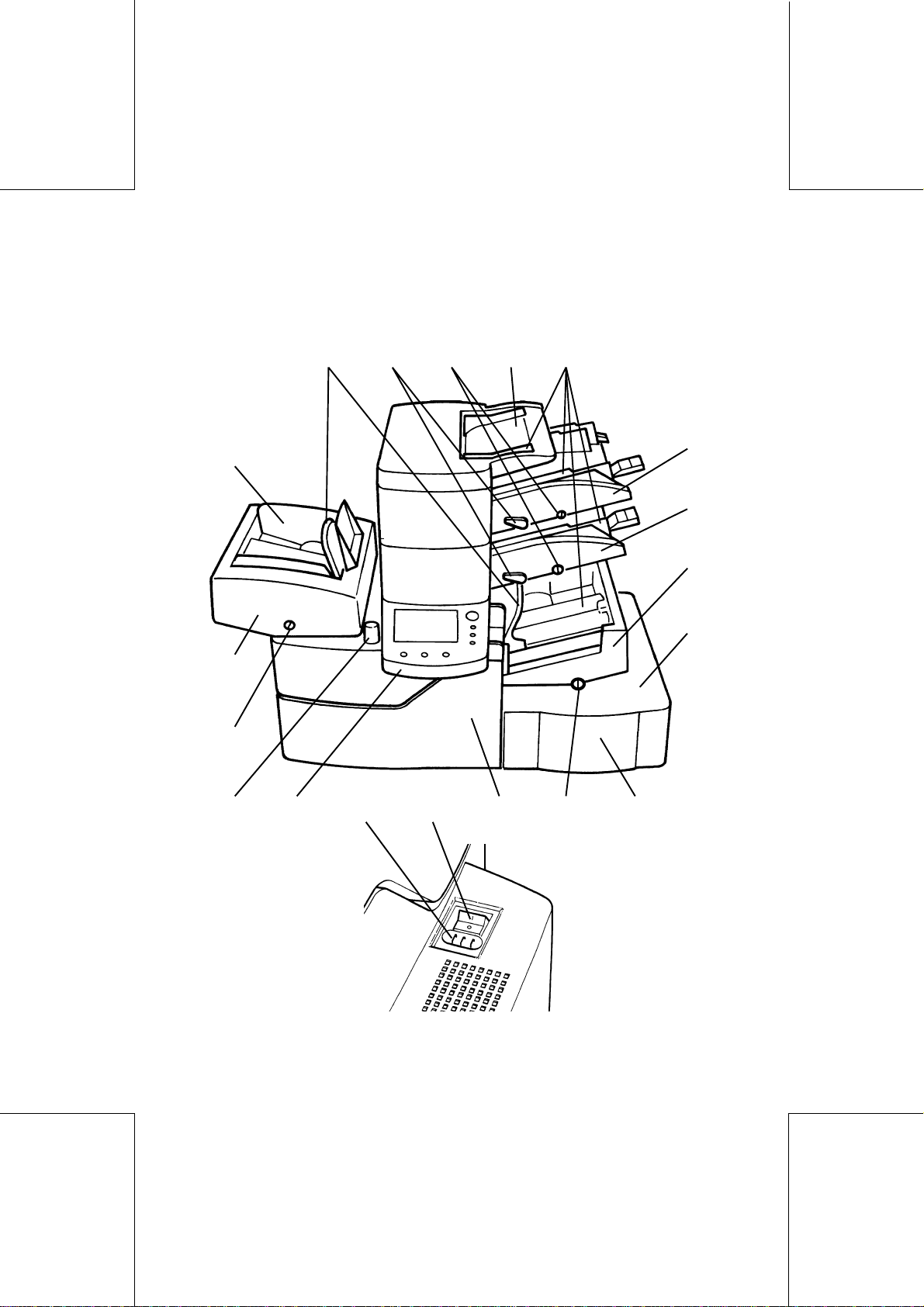

3. DOCUMENT FEEDING............................................37

3.1 Document feeding in the manual mode (feeder A)... 37

3.2 Document feeding in the automatic mode (feeders B

and C) .............................................................37

3.3 Envelope feeding (feeder E)................................. 39

3.4 Feeding of inserts and reply envelopes (feeder F).... 41

3.5 Feeding of inserts and reply envelopes (feeder D) ... 44

SECTION C: ASSISTANCE AND

RECOMMENDATIONS.......................... 49

1. TROUBLE SHOOTING ............................................51

2. JAM CLEARING..................................................... 59

2.1 Document Path ..................................................59

2.2 Envelope path ................................................... 61

2.3 Insert path......................................................... 63

2.4 Inserting area .................................................... 66