Neptune TRICON E Product manual

TRICON®/E/E2/E3 Transmitter

Installation and Maintenance Guide

TRICON®/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE ii

This manual is an unpublished work and contains the trade secrets and confidential information of

Neptune Technology Group Inc., which are not to be divulged to third parties and may not be reproduced

or transmitted in whole or part, in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of Neptune Technology Group Inc. All rights to designs or

inventions disclosed herein, including the right to manufacture, are reserved to Neptune Technology

Group Inc.

Neptune engages in ongoing research and development to improve and enhance its products. Therefore,

Neptune reserves the right to change product or system specifications without notice.

Trademarks Used in this Manual

Neptune, TRICON, and SmartTrol are registered trademarks of Neptune Technology Group Inc.

Other brands or product names are the trademarks or registered trademarks of their respective holders.

Neptune Technology Group Inc.

1600 Alabama Highway 229

Tallassee, AL 36078

USA

Tel: (800) 633-8754

Fax: (334) 283-7293

Neptune Technology Group (Canada) Ltd.

7275 West Credit Avenue

Mississauga, Ontario

L5N 5M9

Canada

Tel: (905) 858-4211

Fax: (905) 858-0428

Neptune Technology Group Inc.

Ejército Nacional No. 418

Piso 12, Desp. 1201-1202

Col. Chapultepec Morales

Delegación Miguel Hidalgo

11570 México, Distrito Federal

Tel: (525) 55203 5294 / (525) 55203 5708

Fax: (525) 55203 6503

TRICON/E/E2/E3 INSTALLATION AND MAINTENANCE GUIDE

Literature No. IM TRICON/E 07.14

©Copyright 2014, Neptune Technology Group Inc. All rights reserved.

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE iii

OVERVIEW

Transmitter Styles ............................................................................................................................... 1-1

Digital Pulse.............................................................................................................................. 1-1

Analog 4-20mA ......................................................................................................................... 1-1

Usage .................................................................................................................................................. 1-1

Contacting Customer Support............................................................................................................. 1-2

INSTALLING THE TRANSMITTER

Tools and Material .............................................................................................................................. 2-1

Preparation.......................................................................................................................................... 2-1

Inspection and Storage............................................................................................................. 2-1

Safety and Preliminary Checks ................................................................................................. 2-1

Installation .......................................................................................................................................... 2-2

Wiring the Transmitter.............................................................................................................. 2-2

Testing the Wires...................................................................................................................... 2-5

Final Assembly.......................................................................................................................... 2-5

Mounting the Transmitter......................................................................................................... 2-5

SPECIFICATIONS AND PERFORMANCE DATA

Environmental Conditions................................................................................................................... 3-1

Electrical Specifications (TRICON/E3 Models) ................................................................................... 3-1

Performance Data ............................................................................................................................... 3-3

MAINTENANCE

Troubleshooting................................................................................................................................... 4-1

1

2

3

4

CONTENTS

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE iv

TITLE PAGE

Elements of the Transmitter...............................................................................................................2-2

Inserting Multi-Conductor Cable........................................................................................................2-3

Creating a Hook in the Wire ..............................................................................................................2-3

Connecting the Conductors to the Terminal Screws ......................................................................... 2-3

TRICON/E/E2/E3 Wiring ....................................................................................................................2-4

Mounting the TRICON Transmitter .................................................................................................... 2-6

TITLE PAGE

TRICON/E/E2/E3 Wiring Codes .........................................................................................................2-4

Pulse Outputs (over 0-70°C operating temperature ) ........................................................................ 3-1

4-20mA Model (over 0-50°C operating temperature ) ......................................................................3-1

HF and UP/DN Models (over 0-70°C operating temperature )..........................................................3-2

All Models Absolute Limits................................................................................................................3-2

T-10 Disc Meters................................................................................................................................ 3-2

T-8 Disc Meters.................................................................................................................................. 3-3

Trident Turbine (TT) Meters................................................................................................................3-3

High Performance Turbine (HPT) Meters ........................................................................................... 3-3

TRU/FLO Compound Meters ..............................................................................................................3-4

4”, 6”, 8” and 10” HP PROTECTUS III Turbine Elements Performance Specifications......................3-4

FIGURE

2.1

2.2

2.3

2.4

2.5

2.6

TABLE

2.1

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

FIGURES AND TABLES

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 1-1

CHAPTER 1OVERVIEW

CHAPTER 1OVERVIEW

The TRICON®transmitter provides an electronic interface to Neptune water meters, enabling

customers to monitor their water usage and control various processes based on that usage. The

TRICON transmitter is available in two styles: Digital Pulse and Analog 4-20mA.

TRANSMITTER STYLES

Digital Pulse

The original Digital Pulse model is a 3-terminal transmitter which outputs electrical pulses at a rate

corresponding to the rate of flow through the meter. It requires 12-24VDC operating power and is

intended for use in applications requiring only a digital signal.

The TRICON/E2 and TRICON/E®3 Digital Pulse models are 5-terminal transmitters which have the same

features as the original Digital Pulse model plus two additional terminals (High Resolution Output and

Count Direction) for connection to a high-speed, bi-directional counter. It requires 12-24VDC operating

power, and is intended for use in applications requiring a high resolution digital signal.

Analog 4-20mA

The Analog 4-20mA model is a 5-terminal transmitter which has the same features as the original

Digital Pulse model, plus two additional terminals for a 4-20mA output that is proportional to the rate

of flow through the meter. It requires 24VDC operating power, and is intended for use in applications

requiring analog and/or digital signals.

USAGE

All models are designed to be mounted between the meter maincase and a totalizing register, and they

do not affect the normal operation of either the meter or the register. When used with a SmartTrol®

controller or other third-party instrumentation equipment, both models allow monitoring and/or

controlling complex metering systems. The Digital Pulse model TRICON/E transmitters are produced

in only two styles: Disc and Turbine, for use with ALL Neptune disc meters or ALL Neptune turbine

meters, respectively. The Analog 4-20mA model TRICON/E transmitters, however, are manufactured

specifically for the size and type of meter with which they are to be used. For this reason, special care

should be taken to ensure that you have the proper Analog 4-20mA model TRICON/E required for your

application. Contact Neptune for technical assistance, if necessary.

CONTACTING CUSTOMER SUPPORT

If you encounter any problems with the installation or operation of your TRICON, please call Neptune

Customer Support at (800) 647-4832.

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 2-1

CHAPTER 2INSTALLING THE TRANSMITTER

This chapter is designed to take you through the installation process for the TRICON transmitter.

TOOLS AND MATERIALS

The following equipment is required for the installation:

nmedium, flat-head screwdriver

nwire stripper

nhammer

nsmall (1⁄8”) diameter punch, or similar tool

nmulti-conductor, solid, #22 AWG, copper cable

nDow Corning®#4, or equivalent compound (optional)

PREPARATION

Be sure to review the following sections before beginning the installation.

Inspection and Storage

Remove the assembly parts from the parts bag and inspect them for any damage. The transmitter arrives

partially assembled, with the terminal cover and mounting ring being the only separate parts. Once the

inspection is complete, store the cartons in a clean, dry environment. The temperature should remain

between -40° and 185°F (-40° and 85°C).

Safety and Preliminary Checks

Always follow your local electrical and safety codes, and observe the following guidelines for running wire

between your TRICON/E transmitter and the receiving device.

nAvoid installing your TRICON/E instrumentation wiring near sources of electrical noise, such as:

ncontactors, motor starters, and relays

nradio transmitters and antennas

nhigh-voltage power wiring and transformers

nWhenever possible, separate your instrumentation wiring from other wiring by using a separate metal

conduit or metal wire tray.

nUse the minimum length of cable required for the installation and cut off any excess. Do not coil

excess wire.

CHAPTER 2INSTALLING THE TRANSMITTER

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 2-2

For longer runs (1,000’ maximum) use #22 AWG shielded twisted pair cable for signal connections, and tie the

shield to ground at the receiving device, not at the TRICON/E transmitter.

nWhen forced to cross other wiring, cross at right angles to minimize noise coupling between wiring.

nUse a dedicated power source, such as a separate circuit breaker or isolation transformer, for all

instrumentation equipment to reduce the effects of electrical noise from other equipment on the line.

nEnsure proper earth ground is available and installed in compliance with local electrical codes.

INSTALLATION

Wiring the Transmitter

Follow this procedure to wire the transmitter.

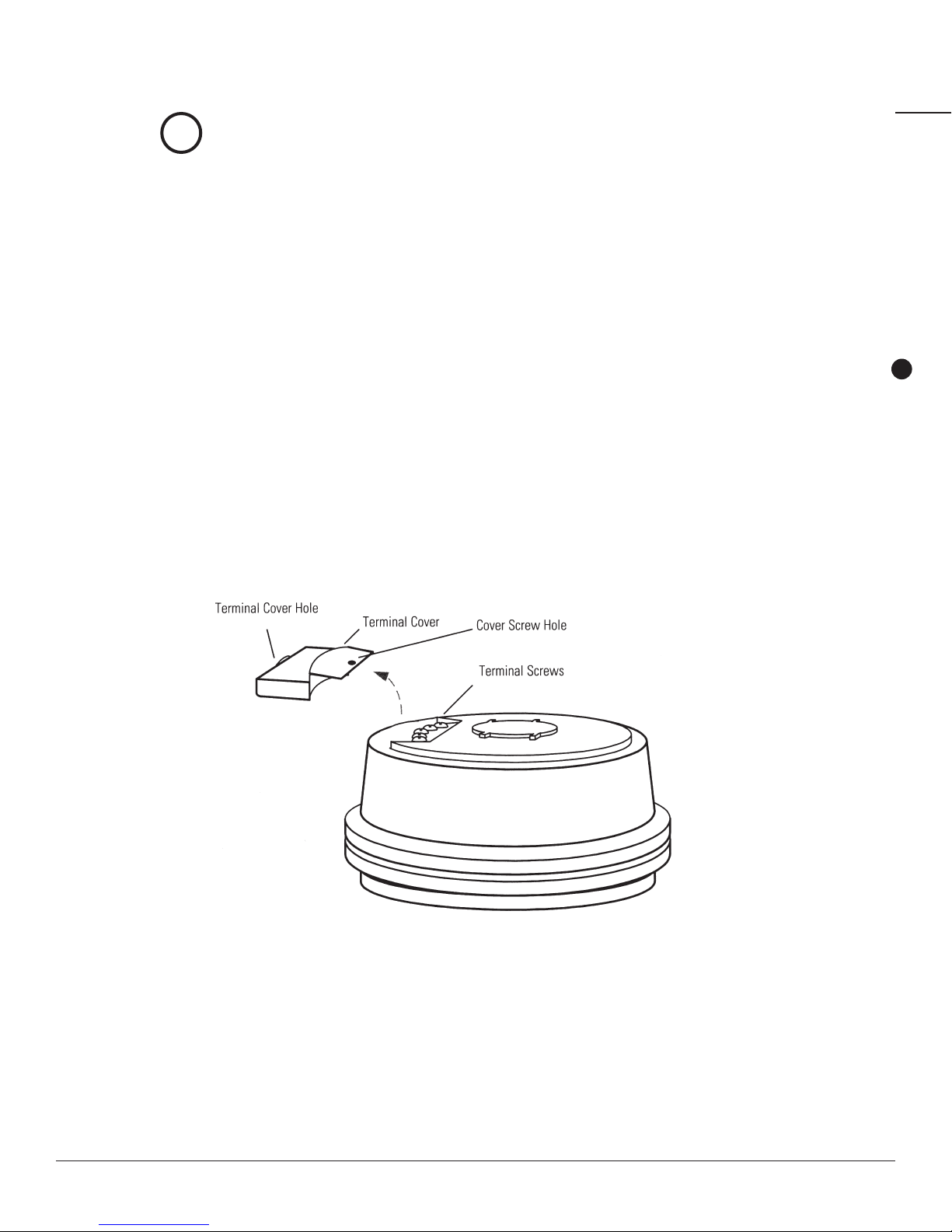

1Locate the terminal cover and remove the cover screw.

2Lift the terminal cover from the transmitter.

Refer to Figure 2.1.

3 Insert the end of the multi-conductor cable through the hole in the terminal cover

as shown in Figure 2.2.

Move the cover far enough down the cable to allow you to work with the end that

you just inserted.

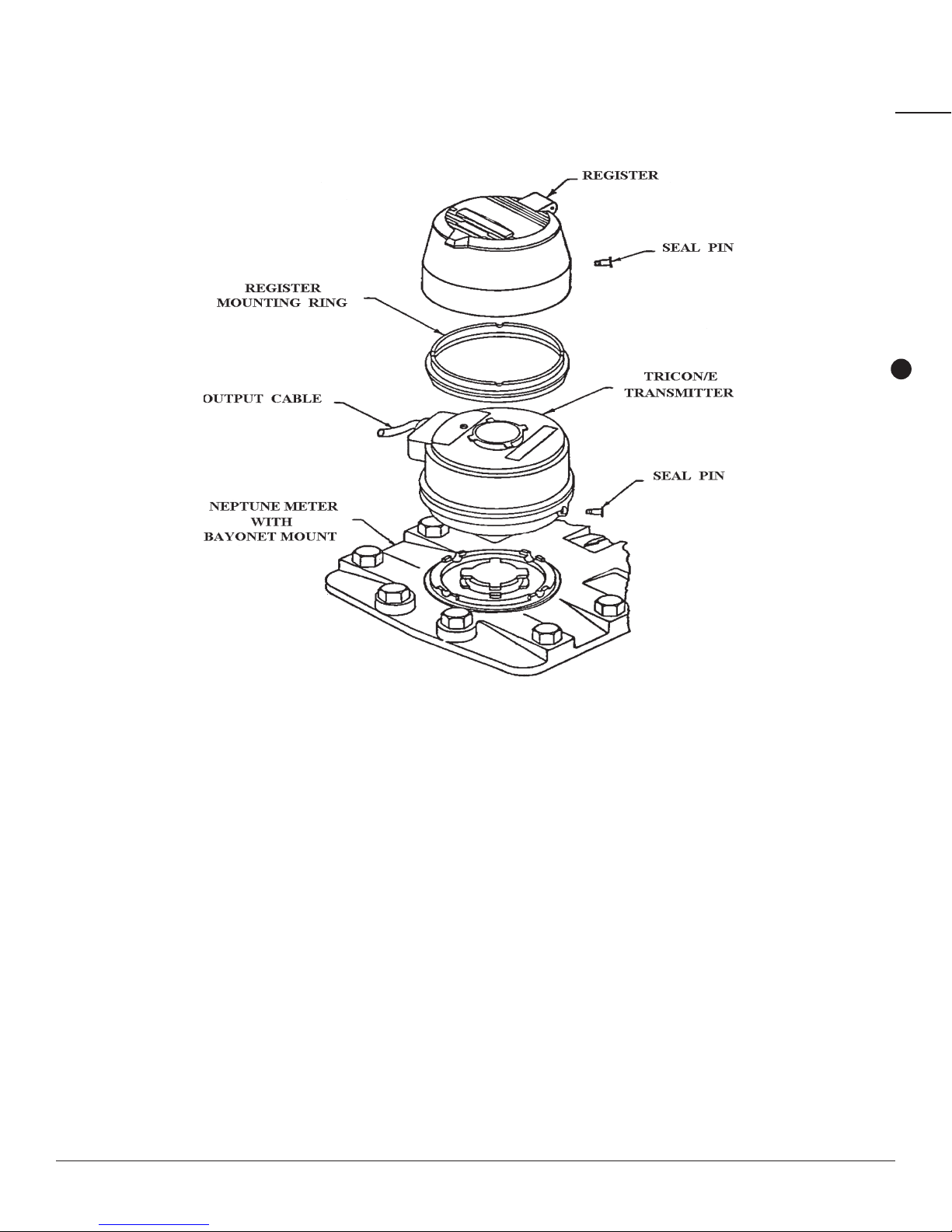

Figure 2.1 Elements of the Transmitter

i

CHAPTER 2INSTALLING THE TRANSMITTER

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 2-3

Figure 2.2 Inserting Multi-Conductor Cable

Figure 2.3 Creating a Hook in the Wire

Figure 2.4 Connecting the Conductors to the Terminal Screws

4Strip the outer covering of the cable back approximately 11⁄2” from the inserted end.

5Separate the individual conductors and strip the insulation back approximately 1⁄2” from the end

of each conductor.

6Using the rounded shaft of the screwdriver, form a hook in the end of each bare copper wire.

(See Figure 2.3.)

7Loosen the terminal screws, as shown in Figure 2.4.

8 Position the wire hook of each conductor under the proper terminal screw according to the

appropriate wiring diagram.

Refer to Figure 2.5 and Table 2.1 for the wiring diagram.

Figure 2.2 Inserting Multi-Conductor Cable

Figure 2.3 Creating a Hook in the Wire

Figure 2.4 Connecting the Conductors to the Terminal Screws

Figure 2.2 Inserting Multi-Conductor Cable

Figure 2.3 Creating a Hook in the Wire

Figure 2.4 Connecting the Conductors to the Terminal Screws

CHAPTER 2INSTALLING THE TRANSMITTER

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 2-4

Figure 2.5 TRICON/E/E2/E3 Wiring

1The (+) indicates conventional current exiting the TRICON.

2This connection is a contact closure to ground and requires DC power to be supplied through a pull-up

resistor. Typical pull-up resistor values are 2K per 5 volts of the DC voltage.

9Place each wire hook so that it runs in a clockwise direction around the screw terminal,

with no insulation under the screw head.

10 Use the tip of the screwdriver to close the hooks around the terminal screws and

tighten the screws until snug.

Take care not to overtighten the terminal screws when completing the wiring.

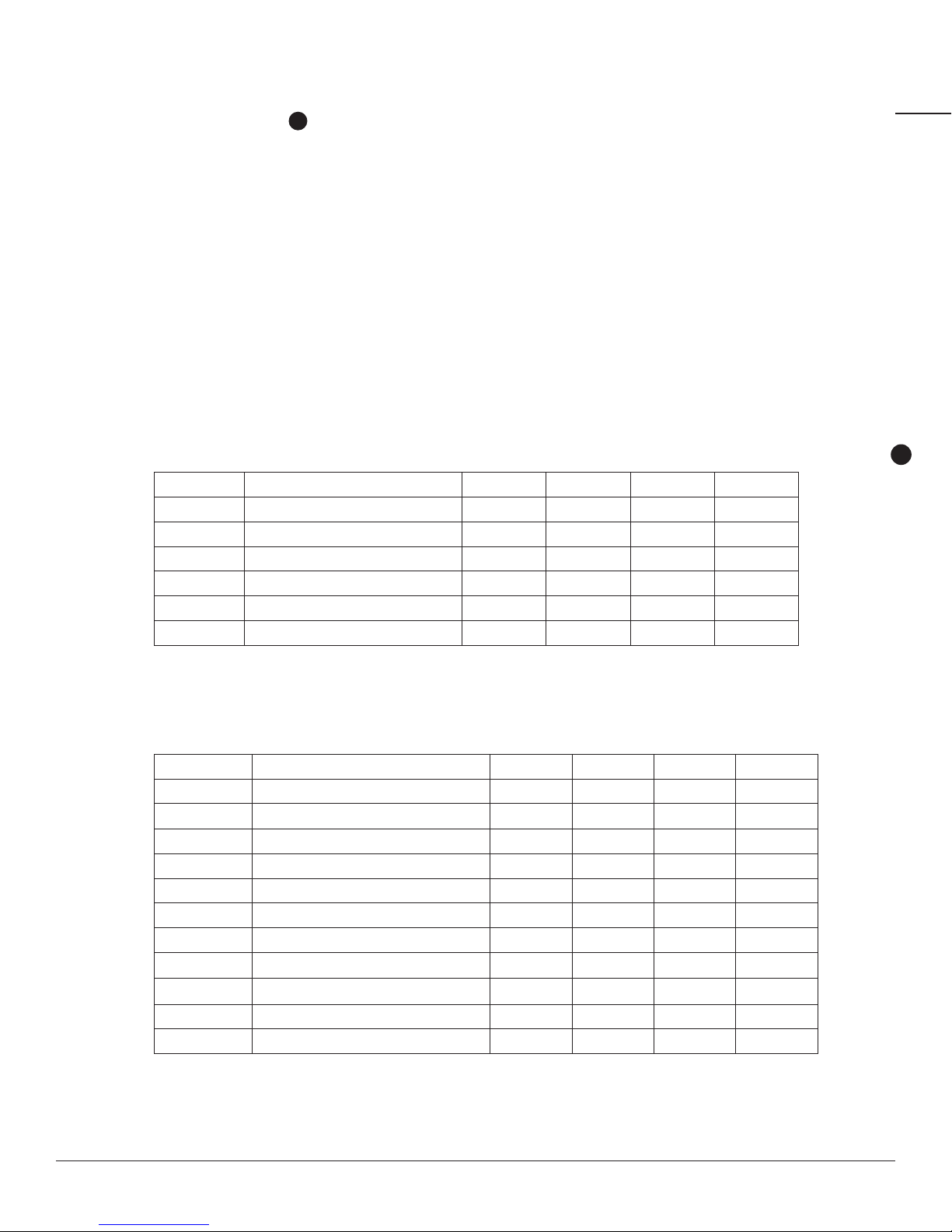

Table 2.1 TRICON E/E2/E3 Wiring Codes

PIN #

TRICON/E

DIGITAL PULSE

(PRIOR TO 1/96)

TRICON/E2 & E3

MODEL DIGITAL PULSE MODEL

(AFTER 1/96)

TRICON/E, E2

& TRICON/E3

4-20MA MODELS

1 No Connection High Resolution Output 4-20mA Source (+)1

2 No Connection Count Direction24-20mA Return (-)

3 12-24VDC Power In (+) 12-24VDC Power In 24VDC Power In (+)

4 Common Ground (- side) Common Ground (- side) Common Ground (- side)

5 Pulse Output Pulse Output Pulse Output

i

CHAPTER 2INSTALLING THE TRANSMITTER

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 2-5

Testing the Wires

After wiring the transmitter, double-check to ensure it is wired correctly. Apply power to the TRICON

transmitter and check the output signals as follows:

nAt No Flow – there should be no pulses out of the digital output terminal, and a 4mA direct current

should be present in the 4-20mA loop.

nAt 1/2 Flow – the pulse rate out of the digital output terminal should be 1⁄2the maximum pulse rate, and

a 12mA direct current should be present in the 4-20mA loop.

nAt Maximum Flow – the pulse rate out of the digital output terminal should be equal to the maximum

pulse rate, and a 20mA direct current should be present in the 4-20mA loop.

Final Assembly

Once testing is complete, the transmitter is ready for the final steps of the assembly process.

1Shut off all power to the TRICON.

2Place a generous amount of Dow Corning #4 on all exposed wire and terminals.

3Fill the inside of the terminal cover with the moisture compound.

4Slide the terminal cover in place over the terminal screws.

5Fasten the terminal cover with the cover screw and tighten until snug.

Take care not to overtighten the cover screw when securing the terminal cover.

6Snap the strain relief fitting over the cable and push it into place in the cable entry hole.

7Wipe away any excess compound.

Mounting the Transmitter

Once the transmitter has been assembled, it is ready to be mounted. If you are installing a TRICON

transmitter on a meter that does not already have a register mounted on it, skip to step 4. If the meter does

have a register mounted, begin at step 1.

1Position the small end of the punch on the center of the seal pin at the base of the register.

2Using the hammer, drive the punch through the center of the seal pin. The head of the pin

should shear off.

i

CHAPTER 2INSTALLING THE TRANSMITTER

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 2-6

3Twist the register approximately 1⁄4turn counter-clockwise and remove it from the meter.

4Position the TRICON transmitter on the meter and twist it clockwise until it locks into place.

5Place the register mounting ring on top of the TRICON transmitter with the four rounded

grooves facing upward.

6Align the notch in the base of the register mounting ring with the terminal cover of the TRICON

and snap the ring into place.

When properly oriented, the register mounting ring should sit flush on top of the

TRICON transmitter.

7Position the register on top of the TRICON transmitter and register mounting ring, and twist it

clockwise until it locks into place.

8Drive the new seal pins into the register base and TRICON base to secure the installation

and prevent tampering.

Figure 2.6 Mounting the TRICON Transmitter

Refer to Figure 2.6 for assistance with the following steps.

CHAPTER 2INSTALLING THE TRANSMITTER

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 3-1

CHAPTER 3SPECIFICATIONS AND PERFORMANCE DATA

CHAPTER 3SPECIFICATIONS AND PERFORMANCE DATA

This chapter will provide you with the electrical specifications and the performance data

for the models of the TRICON transmitter.

ENVIRONMENTAL CONDITIONS

Operating Temperature 32° to 158°F (0° to 70°C)

Storage Temperature -40° to 185°F (-40° to 85°C)

Operating Humidity 0 to 95% RH, non-condensing

ELECTRICAL SPECIFICATIONS (TRICON/E3 MODELS)

Table 3.1 Pulse Outputs (over 0-70°C operating temperature)

PARAMETER DESCRIPTION MINIMUM TYPICAL MAXIMUM UNITS

Vol Low Digital Pulse Output Voltage — 0.4 — V

Voh High Digital Pulse Output Voltage 8.5 Vdcin–1.0V 12 V

Iol Current @ Vol — -10 — mA

Ioh Current @ Voh — +10 — mA

trl-h1Output Rise Time — — 2 uS

tfh-l1Output Fall Time — — 2 uS

1Measured with Rl=2.4KΩand Cl=50pF.

Table 3.2 4-20mA Model (over 0-50°C operating temperature )

PARAMETER DESCRIPTION MINIMUM TYPICAL MAXIMUM UNITS

Vcc Power Supply Voltage 22.5 — 26.5 V

IS Power Supply Current 20 — 80 mA

RlLoop Resistance 0 — 600 Ω

Gain Scaling Accuracy — — 0.5 %FS

Zero Offset Accuracy — — 0.2 %FS

Vol Low Digital Pulse Output Voltage — 0.4 — V

Voh High Digital Pulse Output Voltage 8.5 — 12 V

Iol Current @ Vol — -10 — mA

Ioh Current @ Voh — 10 — mA

*trl-h1Output Rise Time — — 2 uS

*tfh-l Output Fall Time — — 2 uS

1Measured with Rl=2.4KΩand Cl=50pF

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 3-2

Table 3.3 HF and UP/DN Models (over 0-70°C operating temperature )

PARAMETER DESCRIPTION MINIMUM TYPICAL MAXIMUM UNITS

Vcc Power Supply Voltage 11.5 — 26.5 V

IS Power Supply Current 20 — 50 mA

Vol Low Digital Pulse Output Voltage 0 — — V

Voh High Digital Pulse Output Voltage — 24 26.5 V

Iol Current @ Vol -1.0 — — A

Ioh Current @ Voh — 0.04 +1.0 W/Voh A

trl-h1Output Rise Time — — 2 uS

tfh-l Output Fall Time — — 2 uS

1Measured with Rl=2.4KΩand Cl=50pF.

Table 3.4 All Models Absolute Limits1

PARAMETER DESCRIPTION MINIMUM MAXIMUM UNITS

T (op) Operating Temperature 0 85 °C

T (stg) Storage Temperature -40 85 °C

Vcc Power Supply Voltage -30 30 V

RlOutput Load (pulse output) 1200 — KΩ

Iout Output Current (pulse output) — 10 mA

1These limits cannot be exceeded without possible damage.

PERFORMANCE DATA

Table 3.5 T-10 Disc Meters

METER

SIZE (in)

MAXIMUM FLOW

RATE (gpm)

MAXIMUM

CONTINUOUS

FLOW RATE (gpm)

MINIMUM FLOW

RATE (gpm)

NUMBER OF

PULSES PER

GALLON1

PULSE OUTPUT

@ MAXIMUM

FLOW RATE (Hz)1

FLOW RANGE

OF 4-20MA

OUTPUT (gpm)

5⁄820 10 1⁄4578.10 192.70 0–20

3⁄430 15 1⁄2322.60 161.30 0–30

1 50 25 3⁄4150.80 125.67 0–50

11⁄2100 50 11⁄267.57 112.62 0–100

2 160 80 2 37.30 100.00 0–160

1For the High Resolution Output of TRICON/E2 transmitters, multiply these values by 36, and for the TRICON/E3, multiply by 40.

CHAPTER 3SPECIFICATIONS AND PERFORMANCE DATA

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 3-3

Table 3.6 T-8 Disc Meters

METER

SIZE (in)

MAXIMUM

FLOW RATE

(gpm)

MAXIMUM

CONTINUOUS

FLOW RATE (gpm)

MINIMUM FLOW

RATE (gpm)

NUMBER OF

PULSES PER

GALLON1

PULSE OUTPUT

@ MAXIMUM

FLOW RATE (Hz)1

FLOW RANGE

OF 4-20MA

OUTPUT (gpm)

5⁄820 10 1⁄4473.60 157.87 0–24.412

3⁄430 15 1⁄2329.14 164.57 0–29.40

1 50 25 3⁄4126.55 105.46 0–59.582

11⁄2100 50 11⁄247.86 79.77 0–141.182

2 160 80 2 25.60 68.27 0–234.372

1For the High Resolution Output of TRICON/E2 transmitters, multiply these values by 36, and for the TRICON/E3, multiply by 40.

2T-8 disc meters are no longer manufactured. Therefore, all TRICON/E transmitters manufactured for disc meters are the T-10 type. In most cases, the newer

T-10 meter chamber is smaller than its corresponding T-8 meter chamber, which results in the TRICON/E having a theoretical “Flow Rate at 20mA Output” that

is greater than the Maximum Flow Rate allowed for the meter. This means that the T-10 type TRICON/E running on a T-8 meter will never actually reach the 20mA

output level during normal operation. The calculated flow rate required to produce a 20mA output is provided as a reference for use in calibrating the 4-20mA

receiving instrument.

Table 3. 7 Trident®Turbine (TT) Meters

METER SIZE

(in)

MAXIMUM

CONTINUOUS

FLOW RATE (gpm)

MINIMUM

FLOW RATE

(gpm)

NUMBER OF

PULSES PER

GALLON1

PULSE OUTPUT

@ MAXIMUM

FLOW RATE (Hz)1

FLOW RANGE

OF 4-20MA

OUTPUT (gpm)

2 200 3 4.6080 15.36 0 – 200

3 450 5 2.8900 21.68 0 – 450

4 1,000 10 1.5900 26.50 0 – 1,000

6 2,000 20 0.4640 15.47 0 – 2,000

8 (through S/N 31918014) 3,500 35 0.2493 14.54 0 – 3,500

8 (from S/N 31918274) 3,500 35 0.2253 13.14 0 – 3,873

10 (through S/N 31919282) 5,500 50 0.1600 14.67 0 – 5,500

10 (from S/N 31919300) 5,500 50 0.1472 13.49 0 – 5,981

1For the High Resolution Output of the TRICON/E2 transmitters, multiply these values by 9and for the TRICON/E3, multiply these values by 10.

Table 3.8 High Performance Turbine (HPT) Meters

METER SIZE

(in)

MAXIMUM

CONTINUOUS

FLOW RATE (gpm)

MINIMUM

FLOW RATE (gpm)

NUMBER OF PULSES

PER GALLON1

PULSE OUTPUT @ MAXIMUM

FLOW RATE (Hz)1

FLOW RANGE OF

4-20MA

OUTPUT (gpm)

11⁄2160 4 6.09500 16.25 0 – 160

2 200 4 6.09500 20.32 0 – 200

3 450 5 11.20000 84.00 0 – 450

4 1,200 10 7.55600 151.10 0 – 1,200

6 2,500 20 0.72730 30.30 0 – 3,000

8 4,000 35 0.75560 50.37 0 – 4,000

10 6,500 50 0.75560 81.86 0 – 6,500

12 8,000 120 0.75560 100.75 0 – 8,000

16 13,500 200 0.07556 17.00 0 – 13,500

20 22,000 300 0.07556 27.71 0 – 22,000

1For the High Resolution Output of the TRICON/E2 transmitters, multiply these values by 9and for the TRICON/E3, multiply these values by 10.

CHAPTER 3SPECIFICATIONS AND PERFORMANCE DATA

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 3-4

Table 3.9 Compound Meters

Compound Meter1Size and Type Turbine Element Disc Element

3”TRU/FLO 3” TT 5⁄8” T-10

4”TRU/FLO 4” TT 3⁄4” T-10

6”TRU/FLO 6” TT 1” T-10

2” HP TRU/FLO 2” HPT 5⁄8” T-10

4” PROTECTUS III 4” TT 1” T-10

6” PROTECTUS III 6” TT 11⁄2” T-10

8” PROTECTUS III 8” TT 2” T-10

10” PROTECTUS III 10” TT 2” T-10

4” HP PROTECTUS III 21” T-10

6” HP PROTECTUS III 211⁄2” T-10

8” HP PROTECTUS III 22” T-10

10” HP PROTECTUS III 22” T-10

1For TRICON/E Performance Specifications of Compound Meters, refer to the specification information of each respective meter element.

2Refer to Table 3.10 for the performance specifications of the 4”, 6”, 8”, and 10” HP PROTECTUS III Turbine Elements.

Table 3.10 4”, 6”, 8”, and 10” HP PROTECTUS III Turbine Elements Performance Specifications2

METER SIZE

(in)

MAXIMUM CONTINUOUS

FLOW RATE (gpm)

NUMBER OF PULSES

PER GALLON1

PULSE OUTPUT

@ MAXIMUM FLOW RATE (Hz)1

FLOW RANGE OF 4-20MA

OUTPUT (gpm)

4 1,200 7.5560 151.2 0 – 1,200

6 2,500 0.7556 37.78 0 – 2,888

8 4,000 0.6095 40.63 0 – 4,959

10 6,500 0.5333 57.78 0 – 9,209

1For the High Resolution Output of the TRICON/E2 transmitters, multiply these values by 9and for the TRICON/E3, multiply these values by 10.

2Note: This table is based on mounting HPT TRICON/E3 on the same size HP PROTECTUS III Turbine Element.

CHAPTER 3SPECIFICATIONS AND PERFORMANCE DATA

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE 4-1

CHAPTER 4MAINTENANCE

CHAPTER 4MAINTENANCE

If you find that your TRICON system is not operating as expected when installed, use the following

guidelines to try to determine the source of the problem.

TROUBLESHOOTING

If the TRICON appears to be operating, but electronic flow indication does not agree with

mechanical register indication, try the following:

nVerify that the TRICON and register match the meter size and type.

If not, replace the TRICON and/or the register with the appropriate type to match the meter.

nVerify that the register turns smoothly when installed on the TRICON.

If not, replace the register or have it repaired to correct problems with excessive torque.

nVerify that the TRICON is wired and powered properly.

If not, correct the wiring/power problem.

nVerify compatibility and proper calibration of equipment to which the TRICON is connected.

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE I-1

Numerics

4-20mA.......................................1-1

model, selecting.....................1-1

operating power.....................1-1

operating temperature...........3-1

specifications .........................3-1

A

absolute limits

electrical specifications .........3-2

assembly

of transmitter .........................2-5

illustrated...........................2-3

C

codes

wiring .....................................2-4

compound meters.......................3-4

contacting

technical support ...................1-1

cover screw................................2-2

cover screw hole

illustrated...............................2-2

customer support .......................1-1

D

digital pulse................................1-1

operating power

E.........................................1-1

E2/E3 .................................1-1

styles

disc.....................................1-1

turbine................................1-1

E

E/E2/E3. See transmitter

electrical specifications .............3-1

4-20mA...................................3-1

absolute limits .......................3-2

HF models ..............................3-2

pulse outputs .........................3-1

UP/DN models .......................3-2

environmental conditions...........3-1

equipment ..................................2-1

H

HF models

operating temperature...........3-2

specifications .........................3-2

High Performance Turbine. See HPT meters

HPT meters

performance data...................3-3

humidity, operating ....................3-1

I

inspecting

transmitter .............................2-1

installation

equipment needed .................2-1

preliminary check...................2-1

safety .....................................2-1

wiring transmitter ..................2-2

M

maintenance...............................4-1

meters

compound...............................3-4

HPT.........................................3-3

Neptune .................................1-1

T-10 disc.................................3-2

T-8 disc...................................3-3

TT ...........................................3-3

models

4-20mA...................................1-1

digital pulse ...........................1-1

moisture compound....................2-5

mounting

transmitter .............................2-5

illustrated...........................2-6

N

Neptune meter...........................1-1

O

operating

conditions...............................3-1

humidity .................................3-1

temperature ...........................3-1

operating power

4-20mA...................................1-1

digital pulse

E2/E3..................................1-1

digital pulse

E.........................................1-1

operating temperature

4-20mA...................................3-1

HF models ..............................3-2

pulse outputs ........................ 3-1

UP/DN model .........................3-2

INDEX

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE I-2

P

performance

HPT meters.............................3-3

T-8 disc meters.......................3-3

TT meters ...............................3-3

performance data

T-10 disc meters.....................3-2

pre-installation...........................2-1

pulse outputs

operating temperature...........3-1

specifications .........................3-1

R

register mounting ring................2-5

illustrated...............................2-6

S

safety..........................................2-1

seal pin.......................................2-5

illustrated...............................2-6

shipment

inspecting...............................2-1

specifications

4-20mA...................................3-1

absolute limits .......................3-2

environmental ........................3-1

HF models ..............................3-2

pulse outputs .........................3-1

UP/ND models .......................3-2

storage

temperature ...........................2-1

storage, temperature .................3-1

storing

transmitter .............................2-1

strain relief fitting ......................2-5

T

T-10 disc meters

performance data...................3-2

T-8 disc meters

performance data...................3-3

temperature

operating ...............................3-1

storage ...................................3-1

terminal cover ...........................2-2

illustrated ..............................2-2

terminal cover hole ....................2-2

illustrated ..............................2-2

terminal screws .........................2-3

illustrated ..............................2-3

temperature

storage ..................................2-1

tools ...........................................2-1

transmitter

assembly ...................................2-5

illustrated ..............................2-6

elements, illustrated .................2-6

inspecting ..................................2-1

maintenance ..............................4-1

mounting ...................................2-5

illustrated ..............................2-6

storage ......................................2-1

storage temperature .................2-1

styles

4-20mA ..................................1-1

digital pulse ..........................1-1

testing wiring ............................2-5

troubleshooting .........................4-1

wiring ........................................2-2

wiring codes ..............................2-4

wiring diagram ..........................2-4

TRICON/E/E2/E3. See transmitter

Trident turbine. See TT meters

troubleshooting .........................4-1

TT Meters

performance data ..................3-3

Turbine style ..............................1-1

U

UP/DN models

operating temperature ..........3-1

specifications ........................3-2

W

wiring

codes .....................................2-4

diagram .................................2-4

testing ....................................2-5

transmitter ............................2-2

INDEX

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

NOTES

TRICON/E/E2/E3 TRANSMITTER INSTALLATION AND MAINTENANCE GUIDE I-3

Neptune Technology Group Inc.

1600 Alabama Highway 229

Tallassee, AL 36078

USA

Tel: (800) 633-8754

Fax: (334) 283-7293

Neptune Technology Group (Canada) Ltd.

7275 West Credit Avenue

Mississauga, Ontario

L5N 5M9

Canada

Tel: (905) 858-4211

Fax: (905) 858-0428

Neptune Technology Group Inc.

Ejército Nacional No. 418

Piso 12, Desp. 1201-1202

Col. Chapultepec Morales

Delegación Miguel Hidalgo

11570 México, Distrito Federal

Tel: (525) 55203 5294 / (525) 55203 5708

Fax: (525) 55203 6503

neptunetg.com

IM TRICON/E 07.14 © Copyright 2014, Neptune Technology Group Inc. Neptune is a registered trademark of Neptune Technology Group Inc.

Other manuals for TRICON E

2

This manual suits for next models

2

Table of contents

Other Neptune Transmitter manuals