NeuraLabel 550e User manual

Page 2

www.neuralabel.com

Table of Contents

•Unpacking

•Part Identification & Required Equipment

•Step 1: Select your work area

•Step 2: Printer Placement

•Step 3: Tower Placement

•Step 4: Unwinder Sensor Setup

•Step 5: Rewinder Sensor Setup

•Step 6: Feeder Setup

•Step 7: Power Up the System

•Step 8: Media Setup

•Step 9: Load Media

•Step 10: Printing and Winding

•Printing Tips & Troubleshooting

•Firmware and Contact Information

Page 5

www.neuralabel.com

Part Identification & Required Equipment

In the Box

•Tower with spindles

•Two piece Printer Base Plate

•Unwinder Sensing Pad attached to base plate

•Rewinder Sensing Pad

•Flanges –2 permanent rear and 2 removable

•Power cord

•4 screws

Equipment Required

C

Knobs

Spindles B

•Phillips head screwdriver

•Rolled media

•3 inch core

Outer Flanges

Power Cord

Rewinder Sensor

Unwinder Sensor

Attached to Baseplate

Rear Flanges

Baseplate

Tower

Screws

Tower

Page 6

www.neuralabel.com

Step 1: Select your work area

Place the baseplate on the table, but do not connect the 2 pieces. The side with

the larger printer outline with the 2 datum slots goes to the right. The side with

the smaller tower outline with 4 screw posts goes to the left.

Before you begin: Find a flat sturdy workspace with access to power and network.

Printer Guides

Baseplate Dimensions: 41” x 20.5”

Recommended Minimum Table Size: 60” x 30”

Tower Guides

Printer Slots

Tower Posts

Page 7

www.neuralabel.com

Step 2: Printer Setup

Place the printer on the right side baseplate and align to pattern. The printer will slide into the slots

on the baseplate when properly placed.

After the printer is positioned, attach left side baseplate to right side baseplate.

Moving the printer requires two people.

Power Port at

Back of Printer

Bottom

Hole

Plug the printer’s power cord into the printer port (bottom right side of back of printer) and wall outlet, but

keep the printer turned OFF. Plug in the network cable into the printer port (middle left side of back of

printer) and wall outlet. (USB is also supported.)

Always plug laser printers directly into a wall power outlet.

Page 9

www.neuralabel.com

Step 3: Tower Placement

Place the Tower onto the left side baseplate to align to pattern and posts.

Use provided screws and hex spacers with Phillips head screwdriver to screw the Tower

to the baseplate. Screw down snugly and verify there is no “wobble.”

Plug the Tower’s power cord into the Tower port (bottom left side of Tower) and wall outlet, but

keep the Tower turned OFF.

Tower Power

Port

4 Screws and hex spacers

attach tower to baseplate

Page 11

www.neuralabel.com Page 11

Attach the rewinder sensor onto the center of the printer’s media output lip by sliding it onto the attach

clip. Use your index finger and thumb to grasp the base of the sensor and attach clip; slide it on the

attach clip by pressing together. Be sure not to grasp the movable spring-loaded trigger.

Step 5: Rewinder Sensor Setup

Tower must be powered OFF during this step.

Plug the rewinder sensor into the port on the bottom right side of the Tower.

Rewinder Attach Clip

on printer

Rewinder Sensor Port Rewinder Sensor slides

onto Attach Clip

Page 12

www.neuralabel.com

Step 6: Feeder Setup

Place the Continuous Feeder Attachment onto the front of the printer. It slides on to the

mounting bar on the printer tray. Make sure it attaches squarely to the printer.

Attach the feeder round “barrel” connector to the round connector at the back of the

printer just above the printer’s power port.

Continuous Feeder Attachment

Printer power must be OFF when attaching or removing continuous feeder attachment.

Feeder Barrel Connector

NOTE: The Feeder is powered by the printer.

Page 13

www.neuralabel.com Page 13

Turn on the printer and feeder

Press the power button near the printer operator panel. The printer and the attached

feeder will boot up. This will take about one minute.

•The printer operator panel displays the NeuraLabel logo and then the home screen.

•The feeder executes a boot up diagnostic sequence which exercises all the motors.

•The feeder LED turns white if configured for marks or green if configured for gaps.

The printer is powered OFF by pressing the power button for at least 5 seconds.

Keep the printer ON for the next steps.

Make sure both tower and printer power cords are connected and test the system.

Step 7: Power up the System

Turn on the roll system

Turn on the power switch just above the tower’s power port.

•The tower LED flashes the version number.

•The upper spindle may spin for a few seconds (depends on firmware version).

•The lower spindle turns for about 6 seconds (when no media loaded).

•The LED turns green when the system is fully booted.

•Test the unwinder sensor by waving your hand over it. The unwinder and rewinder should turn.

•Test the rewinder sensor by closing and opening the clamp. The rewinder should turn.

The tower is powered OFF using the power switch.

Turn the tower OFF for the next steps.

Page 14

www.neuralabel.com Page 14

Place media roll on lower spindle,

media face down.

Step 8: Media Setup

Tower must be powered OFF during this step.

Loosen winding spindles by

turning nobs counterclockwise.

unlocked

locked

Media face down

•Flat side of flange should always face media.

•Media must be loaded with printable side facing down.

Slide unlocked flange onto lower

spindle, flat side facing the media.

Lock the flange. Tighten the

spindle by turning nob clockwise.

Repeat these steps to place a

core on the upper spindle.

Page 15

www.neuralabel.com Page 15

Step 9: Load Media

Printer must be powered ON during this step. Media roll is on the unwinder spindle.

The Tower may be ON or OFF.

Load the leading edge of media into the feeder. Push media in until the feeder automatically

loads it.

If the Tower is OFF make sure there is significant slack in the media.

If the Tower is ON the media will unwind slightly and the rewinder will spin for a few seconds.

unlocked

locked

Rewinding Options for Start of Print

Tower OFF: (Easier) Keep the tower OFF until you

begin printing AND you are able to tape the media

edge on the rewinder core. Then turn the Tower ON.

Tower ON: The tower will begin spinning when the

printer starts. Wait until it stops and tape the media

edge on the rewinder core. Squeeze the rewinder

trigger to start rewinding.

Check to make sure the media is loaded in straight and flat.

Page 16

www.neuralabel.com

Step 10: Printing and Winding

Send a sample print job.

•Printed form matches your media size.

•Initial Job is 15-20 labels for auto-calibration and to practice media webbing.

As media exits the printer, tape the leading edge onto the rewinder core.

Turn on Tower to begin winding. (Alternatively leave tower ON and squeeze the

rewinder trigger to start the rewinder turning.)

Printer is ON; Tower is OFF

Media is loaded correctly on the unwinder and into the feeder with lots of slack

Rewinder core is ready to receive the media

Tape is available to attach media to the rewinder core

The rewinder is always manually started.

Watch as the unwinder and rewinder elegantly control media rolls.

If you have trouble:

The NeuraLabel 550e printer has a slow start feature. You must add Leading Blank

Space to the print job and select Leading Blank Space Slowdown. Use this feature until

you are ready to web up the media at the normal print speed.

Page 17

www.neuralabel.com

NeuraLabel 550e NoTouch Tips and Checklist

•Make sure the media and flanges are aligned and the flanges have been latched.

•Make sure the chucks are tightened so the media cores do not slip.

•Make sure the receiving core is not too small and the receiving flanges are not too

tight for the media width.

•Media width must be 8.5”.

•Maximum supported media roll Diameter is 8 inches.

•Always make sure the NoTouch is turned OFF when loading and unloading media.

Page 18

www.neuralabel.com

Contact Information

•www.neuralabel.com

•support@neuralabel.com

•orders@neuralabel.com

NeuraLabel 550e Engine and Feeder Firmware

Engine and Feeder Version is accessible via the printer operator panel or web server.

Settings->Reports->Device->Device Information

Engine and Feeder are updated through the printer’s web server

Settings->Device->Update Firmware

NeuraLabel 550e NoTouch Firmware

NoTouch Firmware Version is accessible by watching the LED on Power ON.

Two sets of flashes that indicate version number.

For example 1 flash, pause, 2 flashes, indicates version 1.2.

Update the NoTouch Firmware with a USB cable connected from the NoTouch firmware port to

your PC. Run the provided update program.

All available Firmware Updates are found at NeuraLabel.com/setup/550e

Updating Your Devices

Other manuals for 550e

2

Table of contents

Other NeuraLabel Label Maker manuals

NeuraLabel

NeuraLabel 600e Configuration guide

NeuraLabel

NeuraLabel 600e User manual

NeuraLabel

NeuraLabel Sprint User manual

NeuraLabel

NeuraLabel 300x NoTouch User manual

NeuraLabel

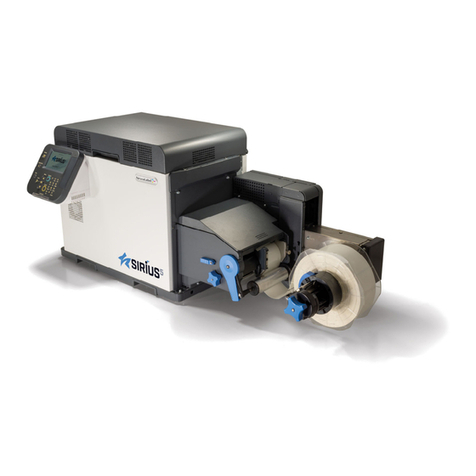

NeuraLabel Sirius 4 User manual

NeuraLabel

NeuraLabel 550e User manual

NeuraLabel

NeuraLabel 550e Operator's manual

NeuraLabel

NeuraLabel Sirius User manual

NeuraLabel

NeuraLabel Sprint User manual

NeuraLabel

NeuraLabel 500e User manual