Newport Oriel MS260i Series User manual

Family of Brands –ILX Lightwave® • New Focus™ • Ophir® • Corion • Richardson Gratings™ • Spectra-Physics®

M74050, Rev B

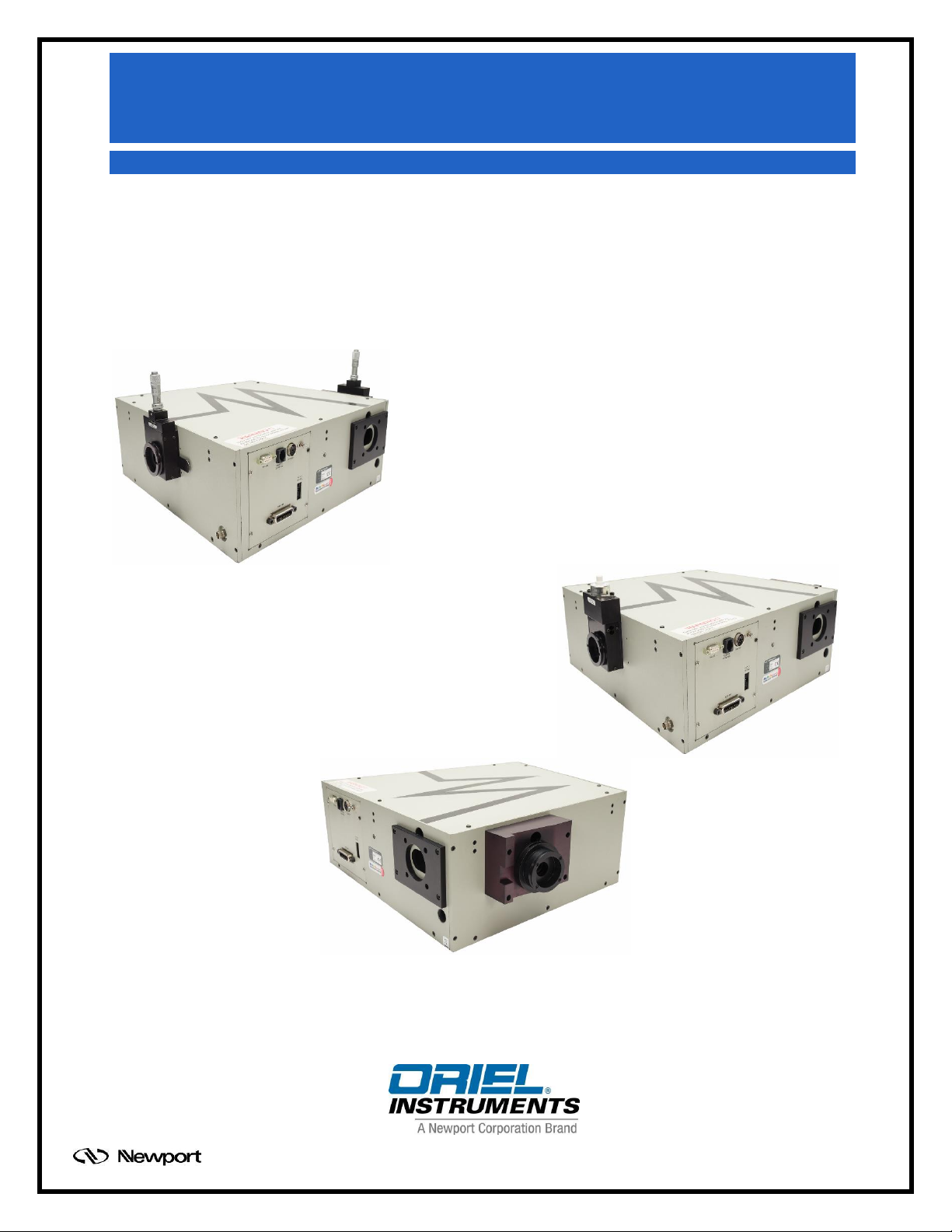

Oriel®1/4m Imaging

Spectrograph Family

User's Manual

MS260i™

M74050

1/4M IMAGING SPECTROGRAPHS

2

TABLE OF CONTENTS

1GENERAL INFORMATION..................................................................................................................5

1.1 SYMBOLS AND DEFINITIONS .............................................................................................6

1.2 GENERAL WARNINGS .........................................................................................................7

1.3 ELECTRICAL HAZARDS.......................................................................................................7

1.4 MECHANICAL HANDLING....................................................................................................8

1.5 OPTICS CARE AND HANDLING...........................................................................................8

2INTRODUCTION..................................................................................................................................9

2.1 OPTICAL CONFIGURATION.................................................................................................9

2.2 STRAY LIGHT REJECTION ................................................................................................10

2.3 AVAILABLE MODELS..........................................................................................................10

3INITIAL SETUP ..................................................................................................................................11

3.1 WHAT’S INCLUDED ............................................................................................................11

3.2 UNPACKING........................................................................................................................11

3.3 CHOOSING A LOCATION...................................................................................................11

3.4 MOUNTING OPTIONS.........................................................................................................12

3.5 ELECTRICAL AND COMPUTER CONNECTIONS.............................................................13

4SHUTTER...........................................................................................................................................15

4.1 REMOTE OPERATION........................................................................................................15

5SLITS AND ARRAY DETECTOR ADAPTER ....................................................................................16

5.1 FIXED SLIT HOLDER AND FIXED SLITS...........................................................................16

5.2 MICROMETER ADJUSTABLE SLIT....................................................................................17

5.3 MOTORIZED SLIT ...............................................................................................................19

6DIFFRACTION GRATINGS ...............................................................................................................20

6.1 GRATING TYPES................................................................................................................21

6.2 GRATING EFFICIENCY AND BLAZING .............................................................................22

6.3 POLARIZATION EFFECTS..................................................................................................25

7SPECTROGRAPH RESOLUTION AND BANDPASS .......................................................................26

7.1 DETERMINING RESOLUTION............................................................................................27

8GETTING LIGHT INTO A MONOCHROMATOR...............................................................................29

8.1 ACCEPTANCE PYRAMID ...................................................................................................29

8.2 F NUMBER MATCHING ......................................................................................................30

9BLOCKING HIGHER ORDER RADIATION.......................................................................................31

9.1 ORDER SORTING FILTERS...............................................................................................31

10 COMMUNICATION METHODS .........................................................................................................32

10.1 UTILITY SOFTWARE...........................................................................................................34

10.2 HAND CONTROLLER..........................................................................................................35

10.3 TRACQ BASIC SOFTWARE ...............................................................................................36

10.4 LOW-LEVEL COMMANDS ..................................................................................................37

10.5 MONO TERM SOFTWARE AND LABVIEW EXAMPLES...................................................37

11 GRATING INSTALLATION AND CALIBRATION...............................................................................38

11.1 RECALIBRATION SERVICES.............................................................................................38

11.2 SETTING THE WAVELENGTH OFFSET............................................................................38

11.3 DETERMINING THE GRATING CALIBRATION FACTOR .................................................39

11.4 GRATING INSTALLATION ..................................................................................................40

12 TROUBLESHOOTING .......................................................................................................................42

12.1 CORRUPTED MEMORY .....................................................................................................42

12.2 GRATING TURRET POSITION ERROR.............................................................................43

13 SPECIFICATIONS..............................................................................................................................44

14 DIMENSIONS.....................................................................................................................................46

16 APPENDIX I: LOW LEVEL COMMANDS AND QUERIES ................................................................49

16.1 OPENING LOW LEVEL COMMUNICATION INTERFACE .................................................49

M74050

1/4M IMAGING SPECTROGRAPHS

3

16.2 COMMAND AND QUERY SYNTAX ....................................................................................49

16.3 STANDARD MODE..............................................................................................................50

16.4 HANDSHAKE MODE...........................................................................................................51

16.5 COMMAND REFERENCE SUMMARY................................................................................52

16.6 DETAILED COMMAND REFERENCE ................................................................................53

16.7 ERROR CODES FOR LOW LEVEL COMMANDS..............................................................58

17 APPENDIX II: HAND CONTROLLER COMMANDS.........................................................................59

17.1 ACTIVATING THE HAND CONTROLLER...........................................................................59

17.2 USING THE KEYPAD ..........................................................................................................59

17.3 KEY REFERENCE...............................................................................................................60

18 APPENDIX III: USB DLL ...................................................................................................................62

18.1 GENERAL CONSIDERATIONS...........................................................................................62

18.2 LABVIEW USERS................................................................................................................62

18.3 C# USERS ...........................................................................................................................63

18.4 C++ USERS .........................................................................................................................66

19 APPENDIX IV: GRATING PHYSICS TUTORIAL..............................................................................67

19.1 THE GRATING EQUATION.................................................................................................67

19.2 THE GRATING EQUATION IN PRACTICE.........................................................................68

19.3 GRATING ORDER...............................................................................................................69

19.4 GRATING DISPERSION......................................................................................................70

19.5 GRATING ILLUMINATION AND RESOLUTION..................................................................70

20 WARRANTY AND SERVICE .............................................................................................................71

20.1 CONTACTING NEWPORT CORPORATION......................................................................71

20.2 REQUEST FOR ASSISTANCE / SERVICE.........................................................................72

20.3 REPAIR SERVICE ...............................................................................................................72

20.4 NON-WARRANTY REPAIR.................................................................................................72

20.5 WARRANTY REPAIR ..........................................................................................................73

20.6 LOANER / DEMO MATERIAL..............................................................................................74

M74050

1/4M IMAGING SPECTROGRAPHS

4

LIST OF FIGURES

Figure 1: Optical Configuration of the MS260i.............................................................................................9

Figure 2: Model Number Codes.................................................................................................................10

Figure 3: Model 74104 Mounting Kit..........................................................................................................12

Figure 4: Spectrograph Connections .........................................................................................................14

Figure 5: Remote Shutter Control BNC Connector....................................................................................15

Figure 6: A Fixed Slit Installed into the Holder...........................................................................................16

Figure 7: Available Fixed Slits....................................................................................................................16

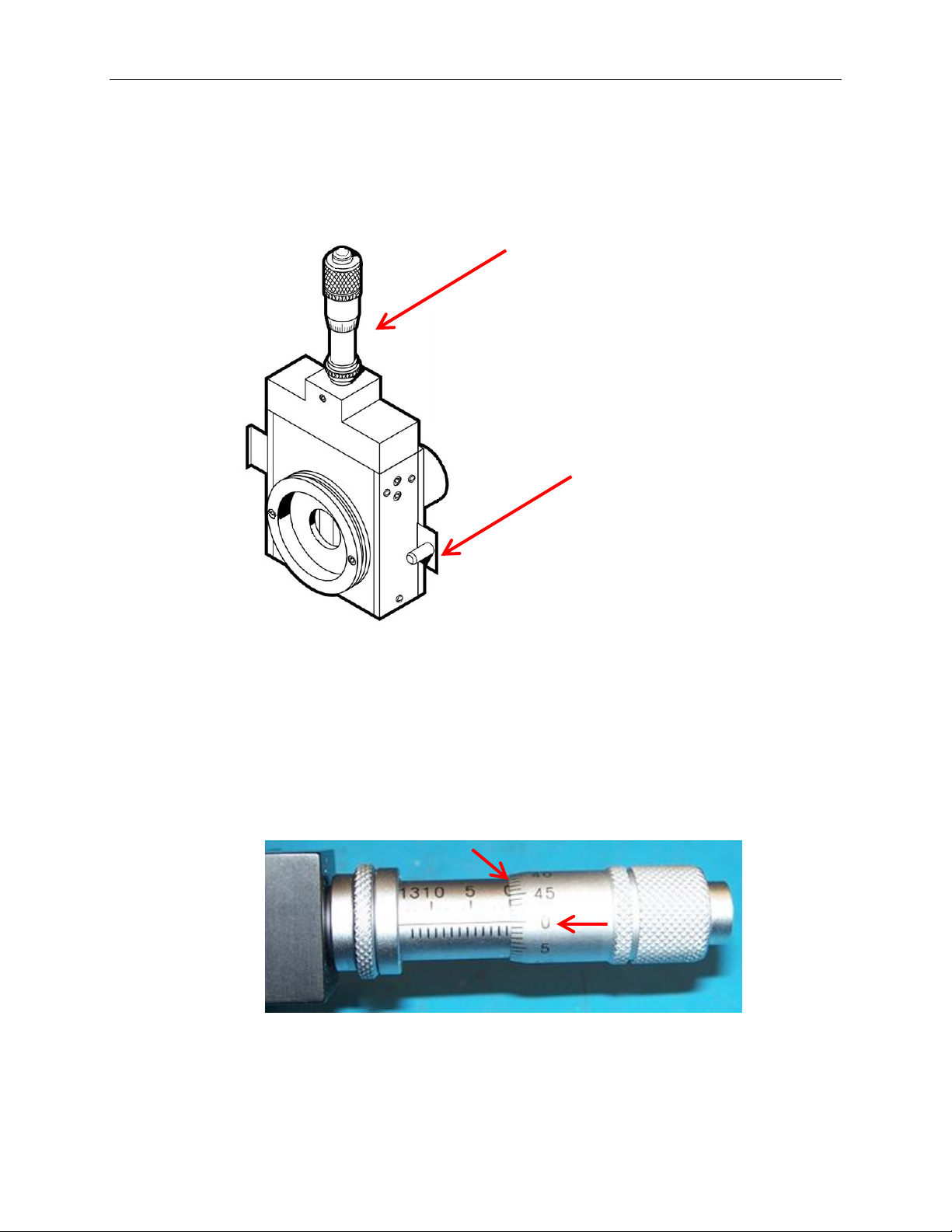

Figure 8: A Micrometer Adjustable Slit.......................................................................................................17

Figure 9: A Fully Closed Micrometer Adjustable Slit..................................................................................17

Figure 10: Shortest Micrometer Adjustable Slit Height..............................................................................18

Figure 11: Tallest Micrometer Adjustable Slit Height.................................................................................18

Figure 12: A Motorized Slit.........................................................................................................................19

Figure 13: Mono Utility Software Slit Control.............................................................................................19

Figure 14: Gratings Installed onto Mounts.................................................................................................20

Figure 15: Grating Properties Table...........................................................................................................21

Figure 16: Grating Efficiency Curves, High Resolution and Holographic Models......................................23

Figure 17: Grating Efficiency Curves, Extended Range and Wide Bandpass Models..............................24

Figure 18: Resolution vs. Throughput........................................................................................................26

Figure 19: Acceptance Pyramid of Spectrograph......................................................................................29

Figure 20: Grating Correctly “Filled” with Light ..........................................................................................29

Figure 21: Mismatched F Numbers Resulting in Stray Light .....................................................................30

Figure 22: F Number Matcher Used with Fiber Optic Cable......................................................................30

Figure 23: Model 74010 Filter Wheel.........................................................................................................32

Figure 24: Model USFW-100 Filter Wheel

………………………………………………………………………34

Figure 25: Mono Utility Software Screens..................................................................................................34

Figure 26: 74009 Hand Controller..............................................................................................................35

Figure 27: TracQ Basic Screens................................................................................................................36

Figure 28: Query Using MonoTerm Software............................................................................................37

Figure 29: Grating Platform Without Gratings............................................................................................41

Figure 30: Grating Platform With Three Gratings Installed........................................................................41

Figure 31: Entering Calibration Values in Utility Software .........................................................................42

Figure 32: Grating Turret Position Sensor Pin Range ...............................................................................43

Figure 33: MS260i Dimensions..................................................................................................................46

Figure 34: Micrometer Adjustable Slit Dimensions....................................................................................47

Figure 35: Model 74104 Mounting Kit........................................................................................................47

Figure 36: 74009 Hand Controller Keypad ................................................................................................59

Figure 37: MonoTerm LabVIEW Source Code..........................................................................................62

Figure 38: The Sawtooth Pattern of a Grating Section..............................................................................67

Figure 39: The Grating Equation Satisfied for a Parallel Beam of Monochromatic Light ..........................68

Figure 40: Polychromatic Light Diffracted From a Grating.........................................................................68

Figure 41: Sign Convention for the Angle of Incidence, Angle of Diffraction and Grating Angle...............69

M74050

1/4M IMAGING SPECTROGRAPHS

5

1 GENERAL INFORMATION

Thank you for your purchase of this MS260i™Imaging Spectrograph from Oriel Instruments®.

Please carefully read the following important safety precautions prior to unpacking and operating this

equipment. In addition, please refer to the complete User’s Manual and all other documentation provided

for additional important notes and cautionary statements regarding the use and operation of the system.

Do not attempt to operate any system without reading all the information provided with each of the

components.

Please read all instructions that were provided prior to operation of the system. If

there are any questions, please contact Newport Corp. or the representative

through whom the system was purchased.

M74050

1/4M IMAGING SPECTROGRAPHS

6

1.1 SYMBOLS AND DEFINITIONS

WARNING

Situation has the potential to cause bodily harm or death.

CAUTION

Situation has the potential to cause damage to property or equipment.

ELECTRICAL SHOCK

Hazard arising from dangerous voltage. Any mishandling could result

in irreparable damage to the equipment, and personal injury or death.

EUROPEAN UNION CE MARK

The presence of the CE Mark on Newport Corporation equipment

means that it has been designed, tested and certified as complying with

all applicable European Union (CE) regulations and recommendations.

WEEE

This symbol on the product or on its packaging indicates that this

product must not be disposed of with regular waste. Instead, it is the

user’s responsibility to dispose of waste equipment according to the

local laws. The separate collection and recycling of the waste

equipment at the time of disposal will help to conserve natural resources

and ensure that the materials are recycled in a manner that protects

human health and the environment.

ON

The ON symbol in the above figure indicates the ON position of the

power switch.

OFF

The OFF symbol in the above figure indicates the OFF position of the

power switch.

M74050

1/4M IMAGING SPECTROGRAPHS

7

1.2 GENERAL WARNINGS

•Read all warnings and operating instructions for this system prior to setup and use.

•Do not use this equipment in or near water.

•To prevent damage to the equipment, read the instructions in the equipment manual for proper

input voltage and check the requirement on the power supply.

•This equipment is grounded through the grounding conductor of the power cord.

•Route power cords and other cables so they are not likely to be damaged.

•Disconnect power before cleaning the equipment

•Do not use liquid or aerosol cleaners; use only a damp lint-free cloth.

•Lock out all electrical power sources before servicing the equipment.

•To avoid explosion, do not operate this equipment in an explosive atmosphere.

•Qualified service personnel should perform safety checks after any service.

•If this equipment is used in a manner not specified in this manual, the protection provided by this

equipment may be impaired.

•Do not position this product in such a manner that would make it difficult to disconnect the power

cords.

•Use only the specified replacement parts.

•Follow precautions for static sensitive devices when handling this equipment.

•This product should only be powered as described in the manual.

•Do not remove the cover for normal usage.

1.3 ELECTRICAL HAZARDS

Make all connections to or from the instrument with the power off.

This instrument requires DC voltage for operation, which is provided by an external power supply.

This power supply has no user serviceable parts. Do not attempt to open the external power supply.

Do not attempt to work in the instrument compartment without first disconnecting the power cord,

since electrical hazards are present inside the compartment even with the power switch in the “off”

position.

The MS260i contains a microprocessor and should be installed with appropriate surge/EMI/RFI

protection on the power line. A dedicated power line or line isolation may be required for some

extremely noisy sites. The electronic circuits within the spectrograph are extremely sensitive to static

electricity and radiated electromagnetic fields. Operation of this instrument close to intense pulsed

sources (lasers, xenon strobes, arc lamps, etc.) may compromise performance if shielding is

inadequate, and may cause permanent damage to the microprocessor.

Note: This instrument conforms to CE standards for both safety and EMC. During normal use, this

equipment will not pose any electrical hazards to the user. Read all warnings before installing or

operating this system. If there are any questions or concerns, contact Oriel Instruments or the

regional sales representative for Newport.

M74050

1/4M IMAGING SPECTROGRAPHS

8

1.4 MECHANICAL HANDLING

Avoid dropping, sudden shocks, or rough handling of the spectrograph since this may cause the

system to lose its calibration and may destroy the high precision drive components or optics.

1.5 OPTICS CARE AND HANDLING

Do not touch any optical surfaces since this is likely to cause irreparable damage. Always wear

powder-free gloves that cover the entire hand, not finger cots. Never touch the surface of a diffraction

grating, even when wearing gloves.

Dust or debris on the grating surface may negatively impact performance, so it should be prevented

from entering the instrument by keeping the protective grating covers in place when it is not in use.

If the gratings do require cleaning, do not attempt to clean any optical surface except by blowing off

dust or lint particles with a stream of dry clean air or nitrogen. Wiping the grating surface will cause

permanent damage.

Avoid getting any moisture or condensation onto the grating. Do not breathe on or talk directly in

front of a grating, as the moisture from one’s breath should never be allowed to condense on the

grating surface.

This instrument comes with gratings pre-installed, aligned and the calibration parameters set. An

experienced user may choose to install a different grating in the field, although it is strongly

encouraged to send the instrument back to the factory instead.

If a grating is installed in the field, the grating cover must never touch the grating’s front surface.

The specially designed grating cover contacts only the edges of the grating. When removing this

cover, a grating can be scratched easily, so use extreme caution when handling.

Hand tighten the grating mount screws. Do not use tools, since this may cause damage to the drive

assembly. Never touch the surface of the grating, even while wearing gloves. Handle the grating

assembly only by its mount.

M74050

1/4M IMAGING SPECTROGRAPHS

9

2 INTRODUCTION

The Oriel MS260i is a high performance, economical, and user-friendly imaging spectrograph –an ideal

instrument for research and OEM applications.

Each of these instruments includes up to three diffraction gratings, filter wheel control circuitry, and an

integrated electronic shutter. Communication may be established using USB, RS232, GPIB (IEEE-488) or

an optional hand controller designed specifically for use with the MS260i family of spectrographs.

The MS260i includes a utility program designed to run on a computer using the Microsoft Windows

operating system. The simple, intuitive interface means that users can get up and running within minutes

of opening the box. Instrument control examples using National Instruments LabVIEW are provided, along

with a command set and API for those wishing to develop their own programs. An optional hand controller

may be used for quick access to all common commands and queries, without requiring a computer. This

is especially beneficial in universities and secure facilities. Please note that the utility software controls only

the spectrograph and does not acquire data from the camera connected to the instrument’s output port.

A wide selection of preconfigured grating selections are available for the MS260i, as well as special order

options. Throughput and resolution can be adjusted by selecting the appropriate slit size. Fixed slits are

available for high accuracy and repeatability, and micrometer adjustable slits may be used for maximum

flexibility. Automatic bandpass control is available with the use of motorized slits.

2.1 OPTICAL CONFIGURATION

The optical design of the MS260i is based upon an asymmetrical in-plane version of a Czerny-

Turner spectrograph. The optical configuration is designed to ensure high resolution and maximum

throughput. This F/3.9 spectrograph is optimized to provide excellent stray light rejection while

minimizing aberrations. A high precision motor is used to select the desired wavelength and switch

between diffraction gratings quickly, without sacrificing performance.

Figure 1: Optical Configuration of the MS260i

M74050

1/4M IMAGING SPECTROGRAPHS

10

2.2 STRAY LIGHT REJECTION

Stray light may have a variety of origins. Its presence may be caused by a wide variety of design

and manufacturing factors. The level of stray light due to the dispersed radiation inside the

spectrograph is affected by the design of the instrument, its baffles and interior finish. The MS260i

incorporates a sophisticated design, proven materials, and a quality manufacturing system to ensure

high stray light rejection.

The amount of stray light measured on top of true signal will depend on many experimental factors

as well as the performance of the instrument. When comparing stray light specifications, it is

important to compare values that were measured under identical circumstances. The spectral

distribution of the source and the response of the detection system are often the dominant factors

when determining a stray light value.

2.3 AVAILABLE MODELS

The model number of each spectrograph reflects its features. Refer to the part number code to

determine the features present in the instrument. If the model number differs from the code, it is a

Special Order configuration. In that case, refer to the Sales Order of the instrument for more

information. Available standard configurations are listed on Newport.com. Please note that not all

configurations may be available.

MS260i- _ _ _ - _ - _ _ - _

COMPUTER INTERFACE

RG = RS232 and GPIB (IEEE-488)

USB = USB 2.0

GRATING CONFIGURATION

1 = High Resolution

2 = Holographic

3 = Extended Range

4 = Wide Bandwidth

SLIT(S)

FH = Fixed Slit Holder

MC = Micrometer Adjustable Slit

MT = Motorized Slit

OUTPUT PORT

A = Axial Output Port

D = Dual Output Ports (Axial and Lateral)

Figure 2: Model Number Codes

M74050

1/4M IMAGING SPECTROGRAPHS

11

3 INITIAL SETUP

3.1 WHAT’S INCLUDED

•Preselected diffraction gratings, installed and aligned

•Electronic shutter at input port

•A choice of single or dual output ports

•A choice of micrometer adjustable slits, motorized or fixed slit holders at the input port and

optional output port(s)

•Oriel LineSpec™ CCD detector adapter flange at axial output port

•A choice of electronics interface for GPIB/RS232 or USB communication

•LabVIEW™ based utility software

•Application Programming Interface (API) for LabVIEW with examples

•MonoTerm low-level command software

•Certificate of Calibration

•Spectrograph Power Supply

•Line cords (U.S. and European)

•User’s manual

3.2 UNPACKING

Remove all items from the shipping containers and verify each item is accounted for. The instrument

is carefully packaged to minimize the possibility of damage during shipment. Inspect the shipping

box for external signs of damage or mishandling. Inspect the contents for damage.

If any item is missing or damaged, immediately contact Oriel Instruments or the Newport

representative from whom the system was purchased.

It is suggested to save the packaging material and shipping container, in case the equipment needs

to be relocated at a future date.

WARNING

Do not attempt to operate this equipment if there is evidence of shipping

damage or there is suspicion that the equipment will not operate

correctly. Damaged equipment may present hazards.

3.3 CHOOSING A LOCATION

Choose an installation location where the power requirements can be met for the spectrograph, as

well as the rest of the optical system. Be sure power is not applied to the system until the setup has

been completed and all electrical connections made.

Ensure that there is easy access to the spectrograph’s power switch and the electrical outlet.

M74050

1/4M IMAGING SPECTROGRAPHS

12

3.4 MOUNTING OPTIONS

The ability to mount the spectrograph simplifies setup and alignment of the optical system. The

mounting plate or kits also helps ensure consistent results over time, as the spectrograph cannot be

accidentally moved out of position. The following options are available for securing the MS260i:

•Mounting plate

•Mounting kit to couple with Oriel’s Research Lamp Housings

•Optical rods

The 74105 Mounting Plate is used to secure a MS260i Spectrograph to an inch or metric optical

table. The plate adds 0.25 inch [6.35 mm] to the optical height. If the MS260i will be used with Oriel’s

research lamp housing, consider using the 74104 mounting kit.

The 74104 Mounting Kit connects the MS260i spectrograph to an arc lamp or quartz tungsten

halogen light source. This kit is compatible with Oriel's Research Lamp Housings that hold 50 to 250

watt lamps. It includes a base plate, a flexible light shield, a 1.5-inch diameter focusing lens and lens

holder. All the hardware required to mount the lamp housing and spectrograph to the base plate is

provided. The mounting kit's base plate uses four adjustable leveling feet. The feet may be removed

to secure the base plate to an inch or metric optical table.

The most economical option is to use optical rods and rod holders to mount the MS260i to an optical

table or breadboard. On the spectrograph’s mounting surface, four #1/4-20 threaded holes may be

used to install standard optical rods. Care should be taken to ensure the instrument is level and

secured well enough that its location remains consistent over time, even if the instrument is bumped

or components coupled to the ports.

Figure 3: Model 74104 Mounting Kit

M74050

1/4M IMAGING SPECTROGRAPHS

13

3.5 ELECTRICAL AND COMPUTER CONNECTIONS

Before powering up the system for the first time, it is suggested to have a qualified electrician verify

the wall socket to be used with the instrument meets the requirements for operation as noted.

Before making any electrical connections, verify the front panel power switch is in the off position for

the spectrograph.

WARNING

To avoid electric shock, connect the instrument to properly earth-

grounded, 3-prong receptacles only. Failure to observe this precaution

can result in severe injury or death.

The line voltage requirement is as follows:

Spectrograph Power Adapter 100 to 240 VAC, 47-63 Hz

The spectrograph conforms to CE standards for both safety and EMC. During normal use, this

equipment will not pose any electrical hazards to the user. Read all warnings before installing or

operating this system. If there are any questions or concerns, contact Oriel Instruments or the

regional sales representative for Newport.

ELECTRICAL SHOCK

Never attempt to open the lamp power supply or spectrograph power

adapter. These items do not contain any user serviceable parts. Failure

to follow this warning can result in severe injury or death.

The spectrograph’s power adapter connects to an AC wall socket and supplies DC voltage to the

instrument. Do not open the spectrograph cover and attempt to work inside without first turning the

instrument off and disconnecting the power cord from the AC mains.

The spectrograph provides power to the filter wheel and allows the user to select which filter is

placed in the optical path.

Ensure the spectrograph power switch is in the off position (marked as O). Then connect the power

adapter to the spectrograph, as shown. Insert the power cord provided into the power adapter and

connect to the AC mains.

Connect the USB, RS232 or GPIB cable to the spectrograph. If using the computer’s USB port,

plug the other end of the USB cable into the computer only after the TracQ Basic software is

installed.

M74050

1/4M IMAGING SPECTROGRAPHS

14

Figure 4: Spectrograph Connections

The USB models of the MS260i each include a USB 2.0 cable. A GPIB cable (model 70038) and

RS232 cable (model 70040) are available from Oriel, ordered separately.

If using a commercially available USB/GPIB or USB/RS232 converter cable, the driver for the cable

must be installed before communication to the spectrograph can be established. This driver is

available from the manufacturer of the cable.

Follow the instructions provided in the Quick Start Guide to install the utility software onto a computer.

The software is named MonoTerm. The utilty software instructions apply to the MS260i, as well as

the Cornerstone 130 and Cornerstone 260 monochromator families.

M74050

1/4M IMAGING SPECTROGRAPHS

15

4 SHUTTER

An electronic shutter is integrated into spectrograph’s design. It is mounted inside the housing at the input

port. This shutter is normally closed.

The shutter is used to close the light path when light is not required. This allows the light source to remain

on, and therefore remain warmed up, so that it continues to provide stable performance. Additionally,

restarting a lamp results in wear of the filament (with quartz tungsten halogen lamps) or wear of the

anode/cathode (with arc lamps). Therefore, when the light is not needed during short periods, closing the

shutter is suggested.

Diffraction gratings are mounted on a rotating turret inside the spectrograph. When the spectrograph

switches between diffraction gratings, the changing angle of the grating causes light to be diffracted at

various wavelengths. This includes white light, which is output at a higher power than other individual

wavelengths. In order to prevent saturation of a detection system, it is suggested to close the shutter

temporarily while changing gratings. It is especially important to prevent saturation and possible damage

when using a photomultiplier tube.

A scan may be completed while the shutter is closed to perform background subtraction calculations on

subsequent scans completed while the shutter is open.

Please note that the shutter is not designed to block high power direct light. When using a 450W or greater

light source, heat mitigation strategies should be employed. For example, Oriel offers liquid filters to protect

the shutter, filters and other items to prevent potential heat damage.

4.1 REMOTE OPERATION

The BNC female connector located on the outside of the spectrograph allows the shutter to be

controlled remotely, if desired. A TTL low condition will open the shutter. The shutter may also be

opened by completing a connection between the BNC conductor and shield (i.e. shorting out the

connector). Control can be overridden by the shutter commands issued from a computer or the

optional hand controller.

Figure 5: Remote Shutter Control BNC Connector

M74050

1/4M IMAGING SPECTROGRAPHS

16

5 SLITS AND ARRAY DETECTOR ADAPTER

To operate any spectrograph, a slits are required at the input port. All types of slits offered with the MS260i

all have 1.5-inch male flanges, allowing them to be easily connected to the wide variety of Oriel accessories

and instruments. The detector is mounted at the axial output port, where an adapter is installed to mount

the Oriel LineSpec detector at the optical plane. The LineSpec detector may be ordered separately, or the

adapter port removed by the end user for installation of a custom adapter.

Note: If it is desired to use this instrument as both a monochromator and spectrograph, dual output port

instrments are available where the lateral output port features a slit identical to the one located at the input

port. The slits should be the same width and height at the input and output ports. A wider input slit when

compared to the output slit results in more stray light inside the instrument. A wider output slit with respect

to the input slit will not increase throughput.

5.1 FIXED SLIT HOLDER AND FIXED SLITS

The fixed slits slide into the holders at the input and optional lateral output port. The width and height

cannot be adjusted, but may be individually replaced with other slit sizes. Fixed slits are a low cost

alternative to micrometer adjustable or motorized slits, and provide excellent repeatability. They are

a good choice when only a few slit sizes are required.

Fixed slits are sold separately to allow customized choices based on the needs of the application.

When ordering an instrument with a fixed slit holder, be sure to purchase one fixed slit for single

output port instruments. When ordering a dual output port instrument, be sure to purchase two fixed

slits of the same model –one for the input port, and the other for the output port. Insert the slit as

shown, with the label facing outward. Be sure that it is fully inserted into the holder’s slot to ensure

the best performance and repeatability.

Figure 6: A Fixed Slit Installed into the Holder

Fixed Slit Model

Width

Height

77222

10 µm

2 mm

77220

25 µm

3 mm

77725

25 µm

3 mm

77221

50 µm

6 mm

77219

50 µm

3 mm

77728

100 µm

6 mm

77729

100 µm

3 mm

77730

200 µm

10 mm

77731

200 µm

3 mm

77732

500 µm

10 mm

Figure 7: Available Fixed Slits

M74050

1/4M IMAGING SPECTROGRAPHS

17

5.2 MICROMETER ADJUSTABLE SLIT

A micrometer adjustable slit assembly is continuously variable from fully closed to 3 mm width. A

height adjustment slide allows variation in the height from 2 to 12 mm. Benefits of the micrometer

adjustable slit are flexibility and high throughput. This type of slit is designed primarily for versatility

and convenience in changing resolution and throughput, which are related to the slit width.

Figure 8: A Micrometer Adjustable Slit

The slit width setting is read on the micrometer. A set of numbers go around the turning dial. Another

set of numbers are located on the shaft. When the zeroes in both these locations line up, the slit is

fully closed. Turning the dial clockwise advances the dial position further down on the shaft, closer

to the body of the micrometer. This opens the slit.

Use a 10x multiplier to convert the micrometer reading to the actual slit opening size. For example,

turning the dial one full revolution starting from the fully closed position will give a reading of 50 on

the micrometer. Using the multiplier, this indicates the micrometer width is set to 500 um. If unsure

of the reading, begin at the fully closed position and add up each full revolution made.

Figure 9: A Fully Closed Micrometer Adjustable Slit

The slit height is continuously adjustable. Pull the lever out for the shortest height. Push the slide

in for the tallest height setting.

The micrometer is used to make the slit

narrow or wide

The slide is used to

change the slit height

M74050

1/4M IMAGING SPECTROGRAPHS

18

Use a 10x multiplier to convert the micrometer reading to the actual slit opening size. For example,

turning the dial one full revolution starting from the fully closed position will give a reading of 50 on

the micrometer. Using the multiplier, this indicates the micrometer width is set to 500 um. If unsure

of the reading, begin at the fully closed position and add up each full revolution made.

Figure 10: Shortest Micrometer Adjustable Slit Height

Figure 11: Tallest Micrometer Adjustable Slit Height

M74050

1/4M IMAGING SPECTROGRAPHS

19

5.3 MOTORIZED SLIT

A motorized slit assembly may be adjusted from 6 µm to 2 mm width in 6 µm steps. The slit width is

controlled through the utility software, optional hand controller, optional TracQ Basic software or by

using low level commands.

An advantage of using the motorized slit is that in addition to setting a specific slit width, the software

may be configured to an automatic bandpass setting. The software then adjusts the slit width to

maintain the chosen bandpass as scans are performed using multiple gratings. The mathematics

involved in determining the slit width takes into account the input and output focal lengths of the

instrument’s design, as well as the angle of the grating at the specified wavelength.

Please note that a motorized slit is not available for use at the lateral output port of the MS260i.

Figure 12: A Motorized Slit

Figure 13: Mono Utility Software Slit Control

M74050

1/4M IMAGING SPECTROGRAPHS

20

6 DIFFRACTION GRATINGS

Diffraction gratings are used to disperse light, i.e. to spatially separate light of different wavelengths. They

have replaced prisms in most fields of spectral analysis. Two or three gratings are installed into the MS260i

spectrograph, depending upon the configuration selected. In general, the grating with the highest efficiency

is chosen at a particular wavelength. The optional Oriel TracQ™Basic Data Acquisition and Radiometery

Software allows users to set up a specific grating switchover wavelength, so the most appropriate grating

will automatically be chosen while performing a scan over a range of wavelengths.

The MS260i spectrographs feature diffraction gratings produced by Richardson Gratings. Both Oriel

Instruments and Richardson Gratings are part of the Newport family of brands, and have a long history of

working together to design spectrographs that are appropriate for a wide variety of applications.

A tutorial on grating physics may be found in the Appendix of this user’s manual.

The photo below illustrates diffraction gratings mounted into holders for installation into the MS260i

spectrograph. The grating is precisely positioned on the mount using a fixture, and then the grating angle

is aligned by Oriel, with the screws locked into place using the red adhesive. An unmounted grating cannot

be installed by the user in the field; gratings must be installed onto the appropriate mount for the MS260i

spectrograph and aligned at the factory. The mount differs, depending on whether it is a dual-grating or

triple-grating instrument configuration.

Figure 14: Gratings Installed onto Mounts

Other manuals for Oriel MS260i Series

1

This manual suits for next models

4

Table of contents

Other Newport Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Renfert

Renfert lay:art Mixing palette crystal instruction manual

Modena

Modena Purificare Series User manual book

Endress+Hauser

Endress+Hauser CPY7B operating instructions

Nippon Genetics

Nippon Genetics FASTGENE ELECTRONIC PIPETTE-200 manual

Biohit

Biohit eLine instruction manual

Thermo Scientific

Thermo Scientific Dionex UltiMate 3000 Series operating instructions