FORMNO.L-20301-A-0601

SINGLE AND DUSINGLE AND DU

SINGLE AND DUSINGLE AND DU

SINGLE AND DUAL RAL R

AL RAL R

AL ROO

OO

OTT

TT

TOROR

OROR

OR TENSION CONTRTENSION CONTR

TENSION CONTRTENSION CONTR

TENSION CONTROL BRAKESOL BRAKES

OL BRAKESOL BRAKES

OL BRAKES

MODELS: XTB-10, XTB-12, XTB-14, XTB-18, AND XTB-22MODELS: XTB-10, XTB-12, XTB-14, XTB-18, AND XTB-22

MODELS: XTB-10, XTB-12, XTB-14, XTB-18, AND XTB-22MODELS: XTB-10, XTB-12, XTB-14, XTB-18, AND XTB-22

MODELS: XTB-10, XTB-12, XTB-14, XTB-18, AND XTB-22

CALIPER INSTCALIPER INST

CALIPER INSTCALIPER INST

CALIPER INSTALLAALLA

ALLAALLA

ALLATION SUPPLEMENTTION SUPPLEMENT

TION SUPPLEMENTTION SUPPLEMENT

TION SUPPLEMENT

SERIAL No. 977256-977681SERIAL No. 977256-977681

SERIAL No. 977256-977681SERIAL No. 977256-977681

SERIAL No. 977256-977681

CALIPER INSTALLATION

NOTE

OnXTBCaliperBrakes,serialnumbers977256-977681havetwoadditionalWashers(NexenPartNo.100270)includedthat

mustbe used toallow for properspacing between theRotor and MountingRing. When installing theCaliper for XTBCaliper

Brakes, adhere to the following instructions. These instructions replace Page 3 of Literature No. L-20183.

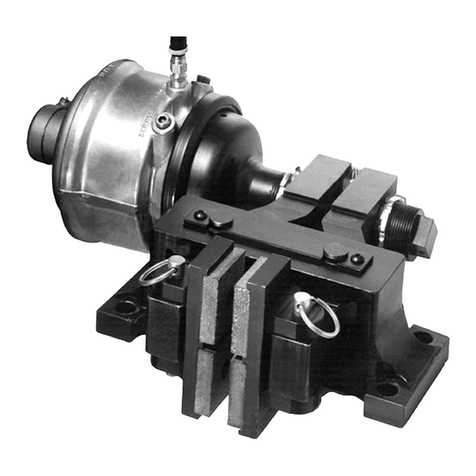

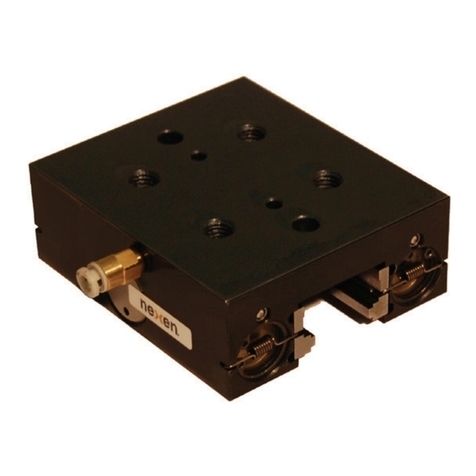

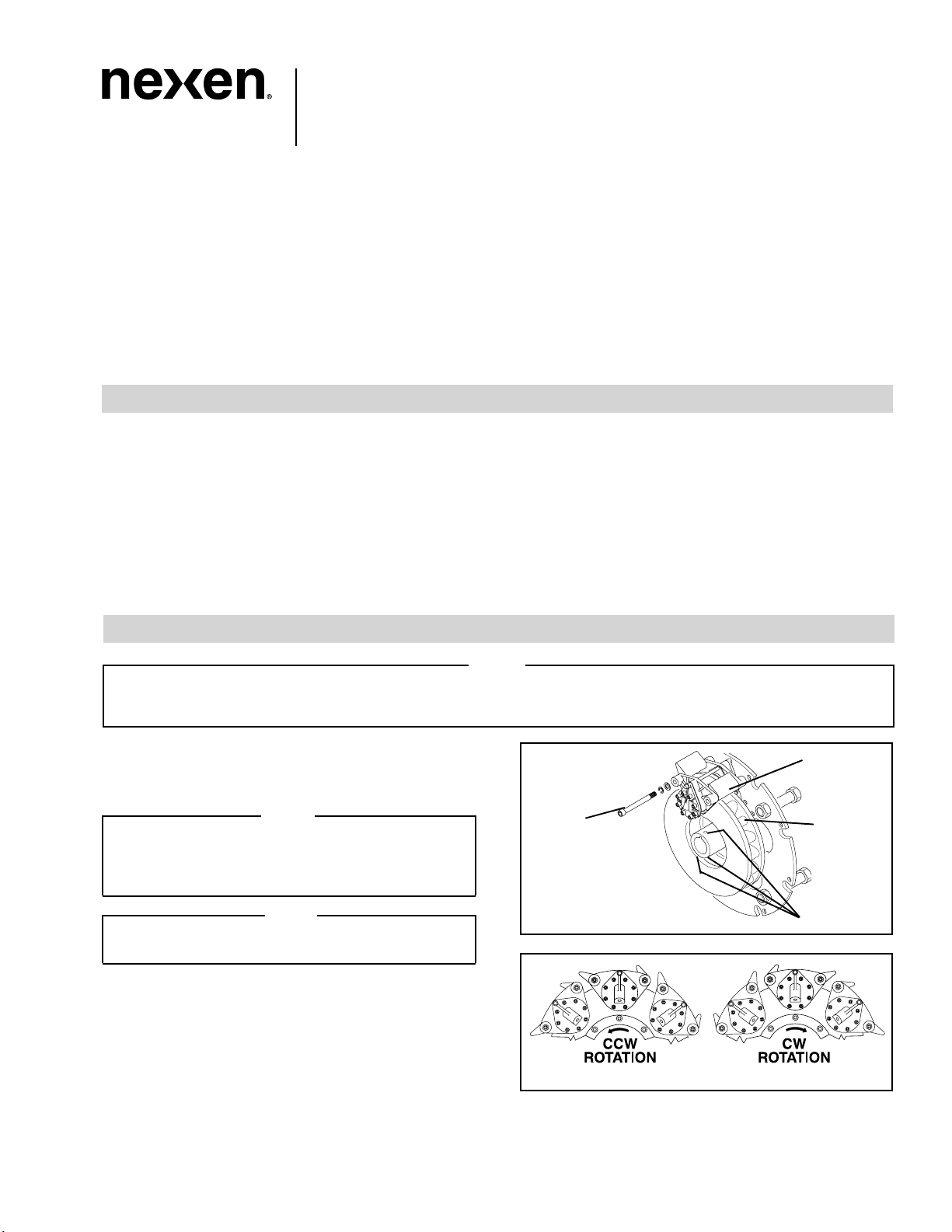

1. Slide one Caliper Assembly over the Rotor and Hub (See

Figure 1).

NOTE

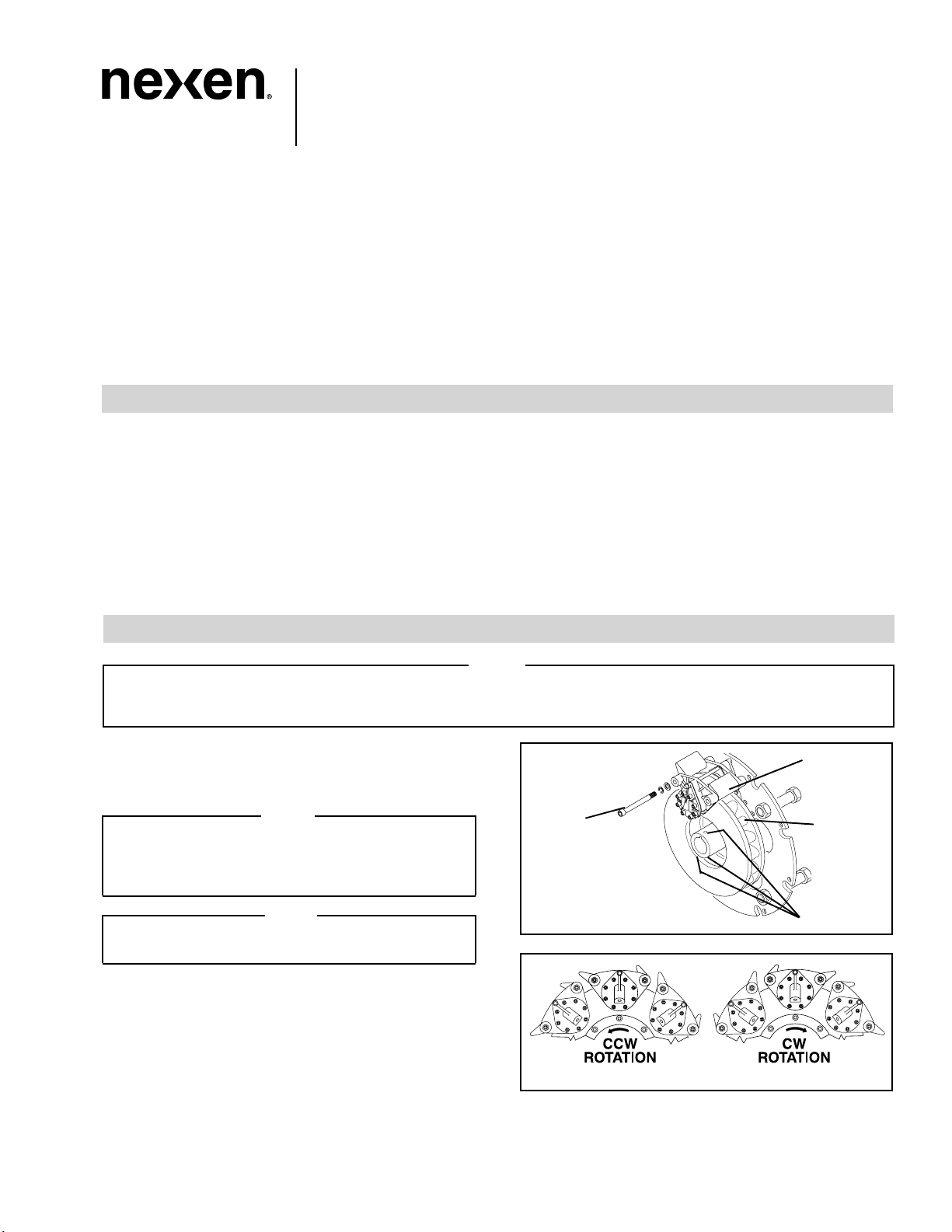

Forbestthermaldissipation,align theCaliperAssembly

as shown in relation to the direction of Rotor rotation.

Direction of Rotor rotation is stamped in the Rotor (See

Figure 2).

NOTE

Remove and discard the two Hex. Nuts used to hold the

Caliper Assembly together during shipping.

2. Install Washers between the Caliper Assembly and

Mounting Ring (See Figure 3).

3. Using Socket Head Cap Screws, Washers, and Lock

Washers, secure the Caliper Assembly to the Mounting

Ring (See Figure 1).

4. Tighten the Socket Head Cap Screws to 48 Ft. Lbs. [65.5

N•m] torque (See Figure 1).

Socket Head

Cap Screws,

Washers, and

Lock Washers

Caliper

Assembly

Rotor

and

Hub

Set Screws

FIGURE 1

FIGURE 2

WEB CONTROL PRODUCTS

User Manual

INTRODUCTION

Read this manual carefully, making full use of its explanations and instructions. The “Know How”of safe, continuous,

trouble-free operation depends on the degree of your understanding of the system and your willingness to keep all

components in proper operating condition. Pay particular attention to all NOTES, CAUTIONS, and WARNINGS to

avoid the risk of personal injury or property damage. It is important to understand that these NOTES, CAUTIONS, and

WARNINGS are not exhaustive. Nexen cannot possibly know or evaluate all conceivable methods in which service

may be performed, or the possible hazardous consequences of each method. Accordingly, anyone who uses a

procedure that is not recommended by Nexen must first satisfy themselves that neither their safety or the safety of the

product will be jeopardized by the service method selected.