6

QUICK START GUIDE

CB-1450 DATA BUOY PLATFORM

2091 Exchange Court

Fairborn, Ohio 45324

937-426-2703

www.NexSens.com

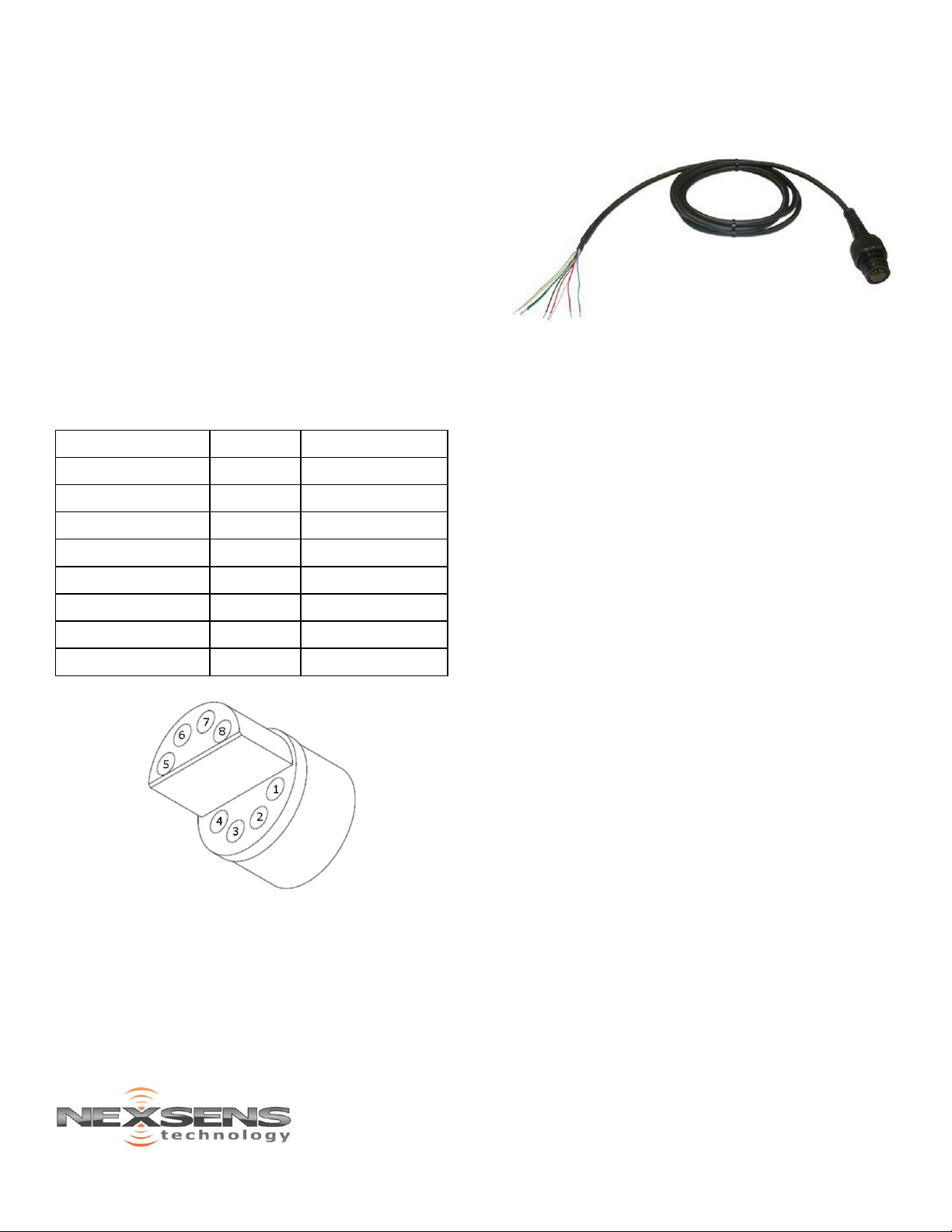

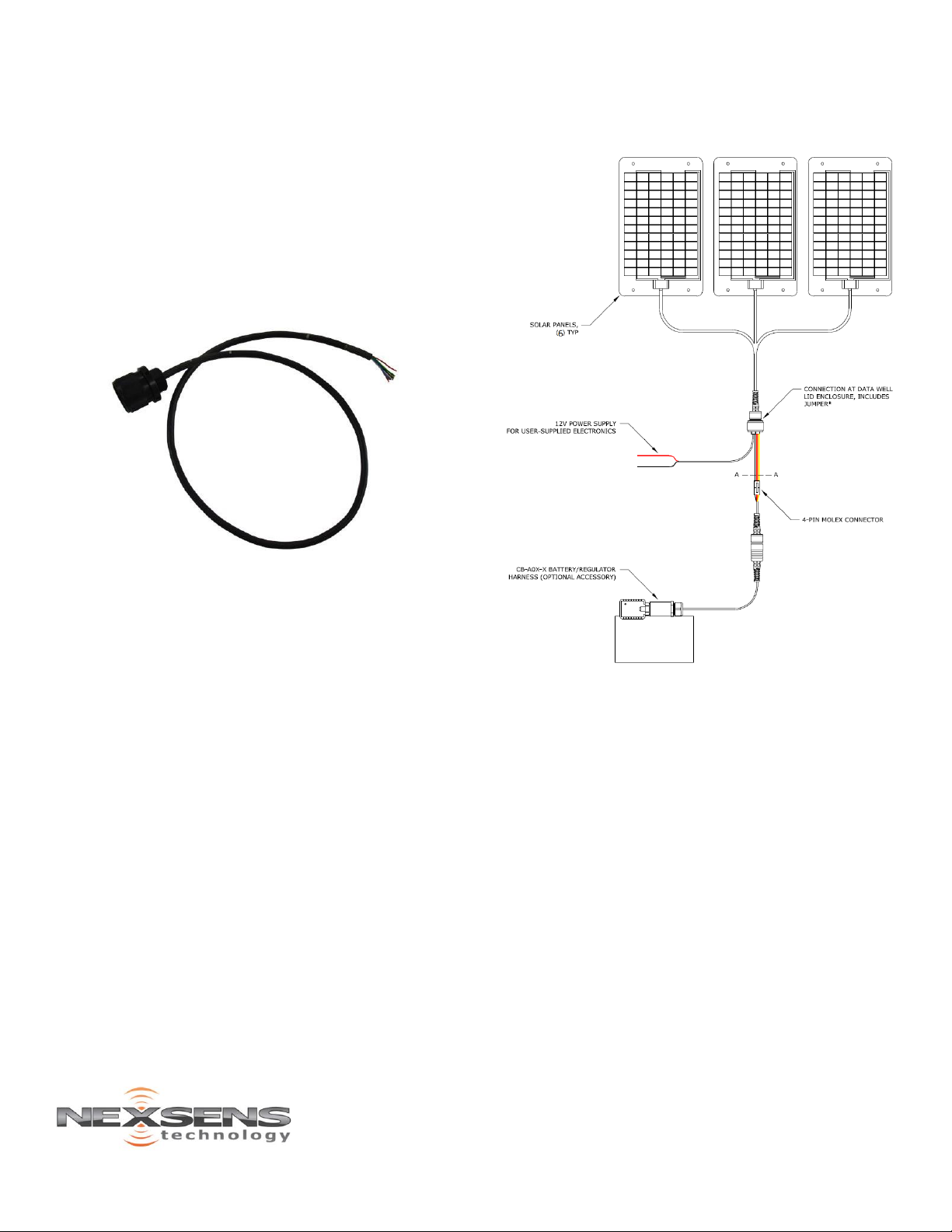

Table 2: Wiring for user-supplied battery/regulator

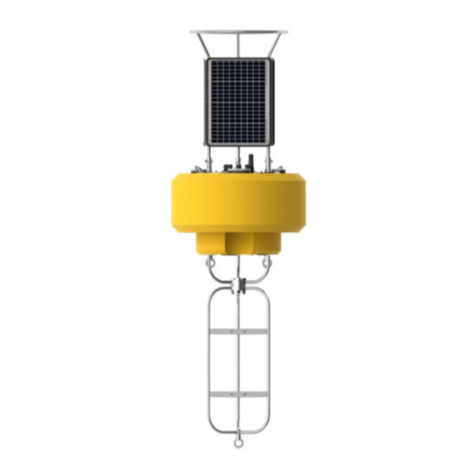

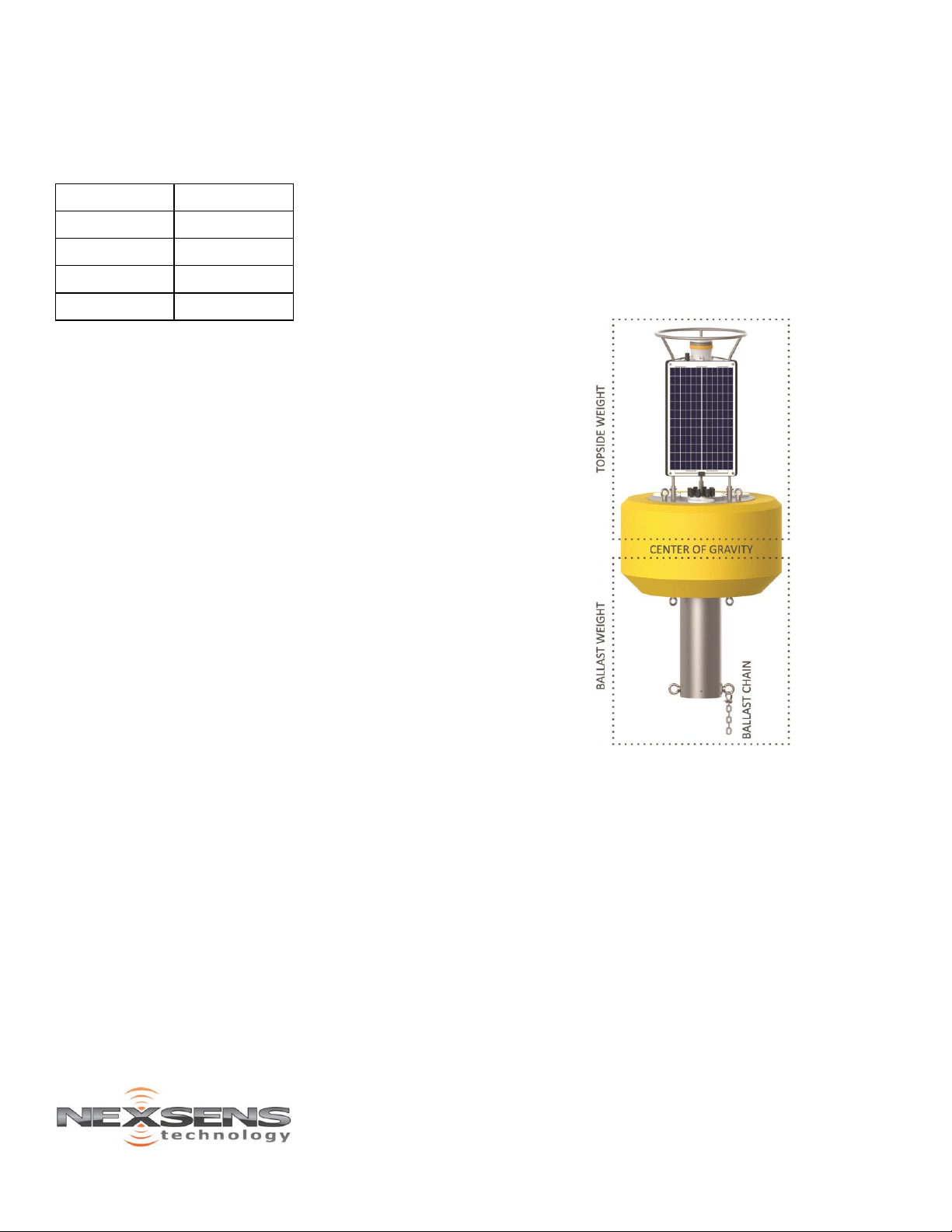

Ballast Weight and Stability

To prevent overturning of a CB-1450 buoy

system and to ensure that it is stable in the

water, sufficient ballast weight must be added.

The required amount is dependent on the wind

and wave conditions. The center of gravity of the

buoy is somewhere near the water surface

without instruments connected. Any weight

added above the water surface must be

appropriately counterbalanced by adding ballast

weight below the surface.

The larger the distance from the location of

added weight to the center of gravity, the greater

the effect on the stability of the buoy will be. For

example, if a weather sensor is mounted 36″

above the water surface, it will cause more

instability than if it were mounted 24″ above the

surface and, as a result, would require more

subsurface ballast weight to counterbalance the

buoy. Conversely, a ballast weight added further

below the surface will provide a greater

stabilizing effect than the same size weight

mounted closer to the surface.

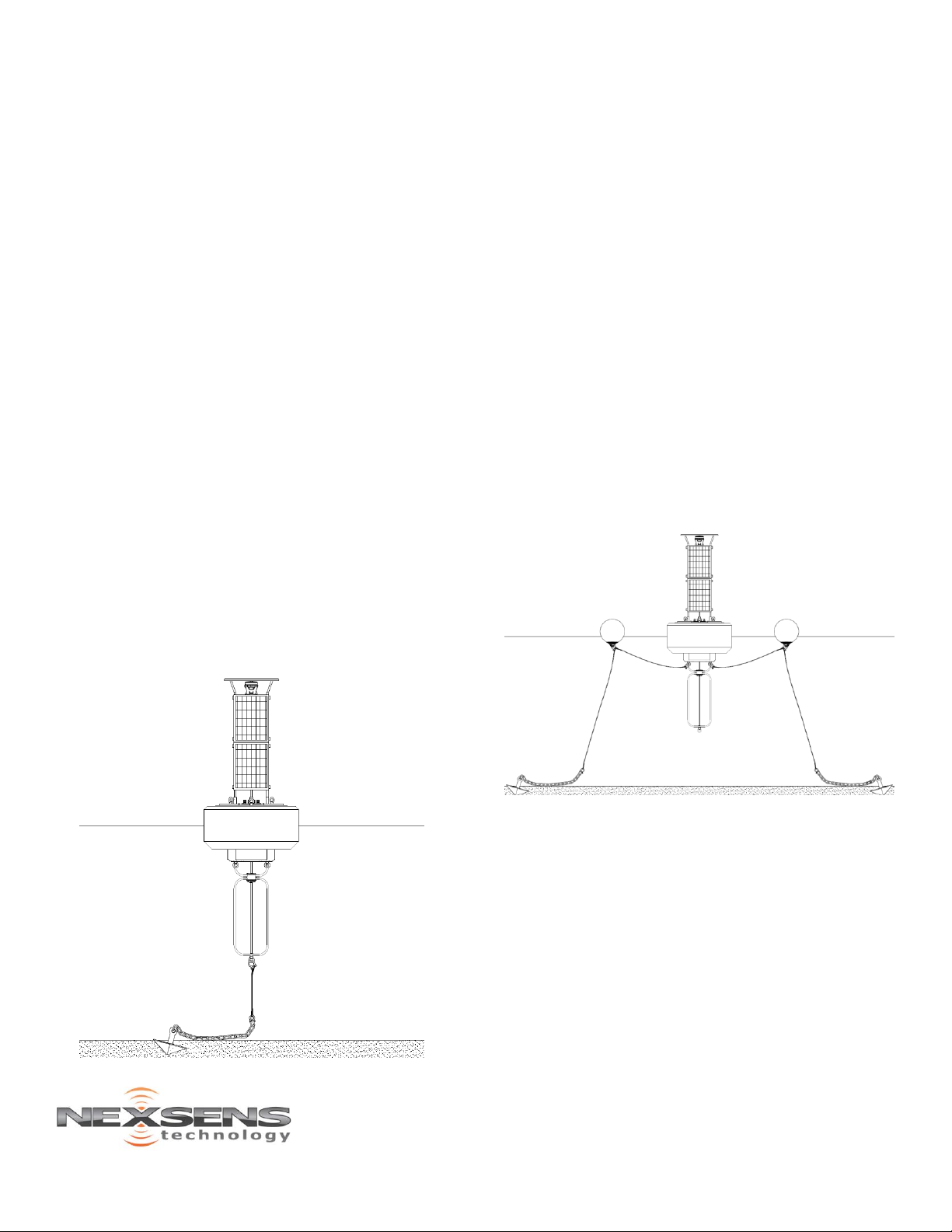

An instrument cage mounted to the buoy frame

helps to stabilize the buoy and provides a deeper

location for mounting additional weight. For

single-point mooring configurations, mooring

chain and lines connected to the bottom of the

cage may provide adequate ballast. For multi-

point configurations, the mooring hardware does

not contribute to the ballast weight.

Before deployment of a CB-1450 system, some

experimentation may be required to properly

balance the buoy. If needed, add ½” chain

(~2.3lb/ft) or other weight to the bottom of the

cage. Figure 13 shows an example of a buoy

system with a short section of chain added.

The buoy data well is not rated for submersion,

so proper ballast weight is critical to ensure that

the buoy does not overturn, including when the

buoy is subjected to additional loading (e.g. high

wind/waves, periodic snow/ice loads, etc.).

Figure 13: CB-1450 Data Buoy with Ballast Chain

Saltwater Deployment

Sacrificial zinc anodes should be used whenever a

buoy is deployed in a saltwater environment to

prevent corrosion. These zinc anodes must be

inspected and replaced as needed.