NF ZA57630 User manual

NF Corporation

IMPEDANCE ANALYZER

ZA57630

INSTRUCTION MANUAL

(BASICS)

IMPEDANCE ANALYZER

ZA57630

INSTRUCTION MANUAL

(BASICS)

DA00068820-003

Registered Trademarks

National Instruments, LabVIEW, and Measurement Studio are registered trademarks of National

Instruments Corporation in the United States.

WINDOWS® EMBEDDED 8.1 INDUSTRY PRO

Used with permission from Microsoft.

Other company names and product names used in this instruction manual may be trademarks or

registered trademarks of their respective companies.

Copyright

NI Measurement Studio

Copyright (C) 2019 National Instruments Corporation

All Rights Reserved.

i ZA57630

──── Preface ────

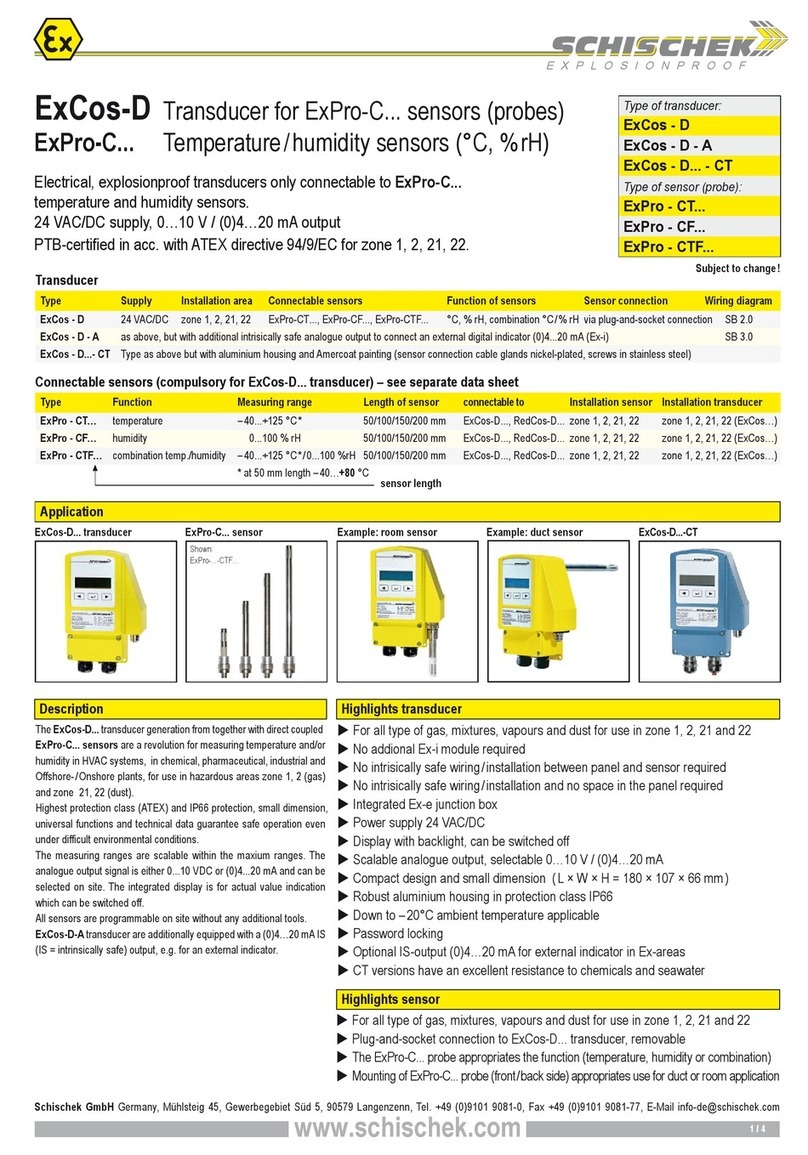

Thank you for purchasing the "ZA57630 IMPEDANCE ANALYZER".

For safe and correct use of this product, please read the "Safety Precautions" section that follows

before attempting to use this instrument.

■Marks and symbols

For safe operation by the user and to prevent damage to this instrument, please give attention to the

following marks and symbols that are used in this manual.

!

WARNING

This mark indicates information for preventing the possibility of death or serious

personal injury from electrical shock or other hazards or damage to this instrument

in the use or handling of this instrument.

!

CAUTION

This mark indicates information for preventing the possibility of injury to the user or

damage to this instrument and the use for handling of this instrument.

■The scope of this Manual

This manual describes the ZA57630 that conform to requirements of CE marking.

Products without CE marking affixed, may not meet directives for CE marking (EMC and others).

Please confirm the CE marking is affixed on the rear panel.

Preface

ii ZA57630

The manuals provided for the ZA57630 are listed below.

●Instruction manual (Basics)

This manual describes operation of the ZA57630 from this instrument’s control panel,

specifications, and other basic matters.

If you’re using this equipment for the first time, begin reading from Chapter 1.

●Instruction manual (Advanced)

This manual describes more advanced operation and maintenance.

●Instruction manual (Remote Control)

This manual describes remote control of the ZA57630

Basics

1. Introduction

This chapter provides a general description of this instrument, including its features,

applications, functions, and basic operating principles.

2. Preparation before use

This chapter describes important preparation that must be done before operating this

instrument.

3. Panel operations

This chapter explains the function, operating procedure, default values, and measurement

values for each part of the display screen. Read this chapter for a quick overall understanding

of the panel and its use.

4. Basic operation

This chapter explains the basic operating procedures of the ZA57630. Refer to this chapter as

you use this instrument.

5. Specifications

This chapter describes this instrument specifications (functions and performance).

Advanced

1. Advanced operation

This chapter explains a wider range of operations.

2. File formats

This chapter explains the various file formats for saving data in external storage devices

(USB memory device).

3. Troubleshooting

This chapter describes how to deal with error messages and cases in which you think this

instrument is malfunctioning.

4. Maintenance

This chapter explains maintenance, repacking, transportation, and performance testing

methods.

iii ZA57630

──── Safety Precautions ────

For safe use of this product, give full attention to the following warnings and cautions.

The NF Corporation shall not be held liable for damages that arise from failure to observe these warnings

and cautions.

This product is a Class I device (with protective conductor terminal) that conforms to the IEC insulation

standards.

Be sure to observe the instructions in the instruction manual.

This instruction manual contains information for the safe operation and use of this product.

Read the instructions and information before using the product.

All of the warning items contained in this instruction manual are intended to avoid risks that may lead

to serious accidents. Follow the warnings and instructions carefully.

Be certain that the product is properly grounded.

This product uses a line filter which may cause electric shock if the product is not grounded.

To prevent electrical shock accidents, connect the product to an earth ground so that ground resistance

is 100 Ωor less.

This product is automatically grounded by connecting a 3-pin power plug to a power outlet with a

protective ground contact.

Check the power supply voltage.

This instrument operates on the power source voltage described in "2.3 Grounding and Power

Connections".

Before plugging in the power cord, confirm that the outlet voltage conforms to the rated voltage of

this instrument.

If you think something is wrong, ...

If smoke or an unusual odor or sound comes from this instrument, immediately remove the power

cord from the socket and cease use of this instrument.

If any such abnormality occurs, take measures to prevent the use of this instrument until repairs have

been completed and promptly contact the NF Corporation or its authorized agent.

Do not use this product when gas is present.

Operating this instrument in the presence of flammable gases may cause an explosion.

Do not open the product case.

To prevent exposure to high voltages, never remove the cover of this instrument.

Only technicians certified by the NF Corporation are authorized to inspect or touch anything inside

the product case.

Safety Precautions

iv ZA57630

Do not modify this product.

Never modify this product in any way. Modification might create new risks. The NF Corporation may

refuse to service an instrument that has an unauthorized modification.

Do not expose this product to water.

Use of this product when it is wet may result in electrical shock or fire. If this instrument becomes wet,

immediately unplug the power cord and contact the NF Corporation or its authorized agent.

If lightning occurs nearby, turn off the power switch and unplug the power cord.

A lightning strike may cause electrical shock, fire, or instrument malfunction.

Safety-related symbols

The marks and codes defined below are used in this manual or on this instrument itself to indicate

safety information or instructions.

!

Instruction manual reference symbol

This notifies the user of a potential hazard and indicates that the user must

refer to the instruction manual.

Electric shock danger symbol

This symbol indicates a location that presents a risk of electric shock under

specific conditions.

Warning symbol

This contains information to avoid risks when handling the equipment that

could result in the death or serious injury of the operator.

Caution symbol

This contains information to avoid risks when handling the equipment that

could result in minor or moderate injury of the operator or damage to

property.

Other symbols

Indicates that the "ON" position of the power switch

Indicates the "OFF" position of the power switch

Indicates that the outer conductor of the connector is connected to this instrument

enclosure.

Indicates that the outer conductor of the connector is isolated from this instrument enclosure.

However, safe operation of this instrument requires that the potential difference from the

grounding potential is restricted to 42 Vpk or less.

This product is grounded when in use, so the electrical potential of this instrument enclosure is equal to

the ground potential.

!

CAUTION

!

WARNING

42Vpk

Safety Precautions

v ZA57630

Electromagnetic compatibility

This product is a CISPR 11 Group 1 Class A compliant instrument. It should not be used outside

industrial environments. Use of this product in ordinary office or residential areas may result in

electromagnetic interference with other devices.

Disposal of this product

To protect the environment, follow the guidelines described below for the disposal of this product.

a) This device is equipped with a lithium battery. Use the services of an industrial waste disposal

contractor to dispose of such batteries.

b) The LCD backlight module that is used in this product does not contain mercury.

c) Use the services of an industrial waste disposal contractor for disposal of the entire product.

vi ZA57630

Contents

Page

1. Introduction..............................................................................................................................1-1

1.1 Features...........................................................................................................................1-2

1.2 Applications......................................................................................................................1-3

1.3 Operating Principle...........................................................................................................1-4

2. Preparation before Use............................................................................................................2-1

2.1 Checking before Use........................................................................................................2-2

2.2 Assembly and Installation.................................................................................................2-4

2.3 Grounding and Power Supply Connection .....................................................................2-10

2.4 Simple Operation Check ................................................................................................2-12

2.5 Calibration......................................................................................................................2-13

3. Panel Operations.....................................................................................................................3-1

3.1 Functions and Operations of Panel Parts.........................................................................3-2

3.2 Input and Output Connectors ...........................................................................................3-8

3.3 Overview of the Operation Screens................................................................................3-19

3.4 Operation Tree ...............................................................................................................3-32

3.5 Setting Screen Reference ..............................................................................................3-42

3.6Initial Settings................................................................................................................3-111

4. Basic Operations.....................................................................................................................4-1

4.1 Display and Operation when Power Is Turned On............................................................4-2

4.2 Simple Operation for First Time Use ................................................................................4-5

4.3 Setting Measurement Signals.........................................................................................4-13

4.4 Measurement Controls...................................................................................................4-18

4.5 Setting Sweep Measurement .........................................................................................4-19

4.6 Setting Spot Measurement.............................................................................................4-25

5. Specifications...........................................................................................................................5-1

5.1 Measurement Modes........................................................................................................5-2

5.2 Measurement Value Display Ranges ...............................................................................5-3

5.3 Measurement Connectors (Measurement Mode IMPD−EXT)..........................................5-5

5.4 Measurement Connectors (Measurement Mode IMPD−3T).............................................5-8

5.5 Measurement Connectors (Measurement Mode IMPD−2T)........................................... 5-11

5.6 Measurement Connectors (Measurement Mode G−PH)................................................5-14

5.7 Measured Signal Control Section...................................................................................5-18

5.8 Measurement Accuracy..................................................................................................5-20

5.9 Measurement Processing Section..................................................................................5-31

5.10 Display Section............................................................................................................5-35

Contents

vii ZA57630

5.11 Memory .......................................................................................................................5-36

5.12 External Memory .........................................................................................................5-36

5.13 External Input/Output Function....................................................................................5-37

5.14 Miscellaneous Specifications.......................................................................................5-39

viii ZA57630

Figures and Tables

Page

Figure 1-1 Block Diagram .........................................................................................................1-4

Figure 2-1 Rack Mount Kit Assembly Drawing (JIS) .................................................................2-6

Figure 2-2 Rack Mount Kit Assembly Drawing (EIA).................................................................2-7

Figure 2-3 Rack Mount Dimensions (JIS) .................................................................................2-8

Figure 2-4 Rack Mount Dimensions (EIA).................................................................................2-9

Figure 3-1 Front Panel..............................................................................................................3-2

Figure 3-2 Rear Panel...............................................................................................................3-3

Figure 3-3 Functions of Measurement Connectors

(Measurement Modes IMPD−EXT and G−PH) ......................................................3-8

Figure 3-4 Functions of Measurement Connectors (Measurement Mode: IMPD−3T)...............3-9

Figure 3-5 Functions of Measurement Connectors (Measurement Mode: IMPD−2T).............3-10

Figure 3-6 Function of DC BIAS OUT Connector....................................................................3-11

Figure 3-7 Function of 10 MHz REF IN Connector..................................................................3-12

Figure 3-8 Function of 10 MHz REF OUT Connector..............................................................3-13

Figure 3-9 Handler Interface Connector Pin Assignment Diagram..........................................3-14

Figure 3-10 Equivalent Circuit of Handler Interface...................................................................3-17

Figure 3-11 AUX Connector Pin Assignment Diagram............................................................3-17

Figure 3-12 I/O Connector Equivalent Circuit ofAUX Connector............................................3-18

Figure 3-13 Screen Immediately after Startup.........................................................................3-19

Figure 3-14 Status Display Area..............................................................................................3-19

Figure 3-15 Measurement Condition Display Area..................................................................3-20

Figure 3-16 Basic Menu Operation Area.................................................................................3-21

Figure 3-17 Marker Display Area ............................................................................................3-21

Figure 3-18 Marker Operation Area ........................................................................................3-21

Figure 3-19 Menu Display Example........................................................................................3-23

Figure 3-20 Switching Menu (Top Menu) ................................................................................3-23

Figure 3-21 Menu Layer Operation.........................................................................................3-24

Figure 3-22 Function Keys......................................................................................................3-24

Figure 3-23 Numerical Settings (Immediate Settings).............................................................3-25

Figure 3-24 Numerical Settings...............................................................................................3-26

Figure 3-25 List Operations (Immediate Settings)...................................................................3-27

Figure 3-26 Palette Operations (Immediate Settings).............................................................3-27

Figure 3-27 Text Settings (Immediate Settings)......................................................................3-28

Figure 3-28 Switching Text Input Palette.................................................................................3-29

Figure 3-29 Execution Operations (Requiring Confirmation)...................................................3-30

Figures and Tables

ix ZA57630

Figure 3-30 Graph Display Styles ...........................................................................................3-30

Figure4-1Impedance Measurement ConnectionExample 1

(IMPD−EXT,MeasurementofHighVoltage).................................................................4-6

Figure 4-2 Impedance Measurement Connection Example 2

(IMPD−EXT, Measurement of DUT with Grounding)..............................................4-7

Figure 4-3 Impedance Measurement Connection Example 3

(IMPD−EXT, Measurement of High-Impedance DUT)............................................4-7

Figure 4-4 Impedance Measurement Connection Example 4 (IMPD−3T) ...................................4-9

Figure 4-5 How to Check Operation Using 100 Ω RESISTOR (IMPD−3T)................................4-10

Figure 4-6 Impedance Measurement Connection Example 5 (IMPD−2T) .................................4-11

Figure 4-7 Gain and Phase Measurement Connection Example...............................................4-12

Figure 5-1 External dimensions.................................................................................................5-40

Figures and Tables

x ZA57630

Table 2-1 Packing list...................................................................................................................2-2

Table 3-1 Handler Interface Signal Layout.................................................................................3-14

Table 3-2 Handler Interface Signal Functions............................................................................3-15

Table 3-3 AUX Connector Signal Layout ...................................................................................3-17

Table 3-4 Initial Settings (1/12)................................................................................................ 3-111

Table 4-1 Display Modes (Measurement Mode: IMPD−EXT / IMPD−3T / IMPD−2T) ................4-20

Table 4-2 Display Modes (Measurement Mode: G−PH) ............................................................4-21

Table 4-3 Graph Axis Parameters (Measurement Mode: IMPD−EXT / IMPD−3T / IMPD−2T)...4-21

Table 4-4 Graph Axis Parameters (Measurement Mode: G−PH)...............................................4-22

Table 4-5 Display Parameter Conversion Formulas

(Measurement Mode: IMPD−EXT / IMPD−3T / IMPD−2T)...................................4-23

Table 4-6 Display Parameter Conversion Formulas (Measurement Mode: G−PH)....................4-24

1-1 ZA57630

1. Introduction

1.1 Features..............................................................................1-2

1.2 Applications.........................................................................1-3

1.3 Operating Principle..............................................................1-4

1.3.1 Operating Principle ........................................................1-4

1.3.2 Measurement Modes.....................................................1-6

1.1 Features

1-2ZA57630

1.1 Features

The “ZA57630 IMPEDANCE ANALYZER”is an impedance analyzer with a maximum

frequency of 36 MHz, maximum signal amplitude of 3 Vrms, maximum DC bias of ±40 V, and

maximum sweep speed of 0.5 ms/point. It has a high basic accuracy of 0.08 % and is capable

of measuring impedance in a wide application range that extends to not only the

manufacturing and inspection lines of electronic components but also the research of

materials.

(1) Measurement frequency of 10 µHz to 36 MHz

This instrument can measure at a 10 µHz resolution in the entire range. It is also

capable of the detailed measurement of the impedance-frequency characteristics of a

device under test (DUT) with a sharp resonance.

(2) Maximum signal amplitude of 3 Vrms and maximum DC bias of ±40 V

The characteristics of a DUT can be measured in wide signal amplitude and bias voltage

ranges.

(3) High-speed measurement at 0.5 ms/point

Sweeping is possible at up to 0.5 ms/point (during frequency sweeping). This instrument

can thus contribute to the improvement of efficiency in research and development and

the shortening of tact time on manufacturing lines.

(4) Two types of measurement ports provided

This instrument is equipped with two types of measurement ports. There are the

three-port type (BNC connectors) that can be used with various test fixtures for

general-purpose LCR meters and the coaxial-port type (N connector) for performing

stable measurement at a high frequency. The port for measurement can be switched

depending on the application.

(5) Measurement signals can be amplified using a power amplifier

The impedance characteristics of a DUT can be measured using large signals by

amplifying the measurement signal output of this instrument using a power amplifier.

This enables impedance characteristics to be measured under conditions close to actual

usage conditions for piezoelectric actuators used at high power and inductors, capacitors,

and other components for power electronics.

(6) Resonant frequency tracking measurement

The resonance frequency fluctuations of piezoelectric vibrators and other devices can be

tracked automatically. Impedance measurement can also be performed while the DUT is

driven at the optimum frequency regardless of the variations in load and ambient

temperature.

1.2 Applications

1-3ZA57630

(7) Remote control

This instrument can be incorporated in manufacturing lines and measurement systems

because it is equipped with USB, GPIB, RS-232, LAN, and handler interfaces as

standard.

(8) Capable of measuring gain and phase characteristics

In addition to impedance characteristics, this instrument can measure the transfer

characteristics (gain and phase characteristics) of filters, amplifiers, etc.

1.2 Applications

● Inspection, sorting, and evaluation testing on the manufacturing lines of electronic

components such as inductors, capacitors, and sensors.

● Evaluation and research of magnetic materials and dielectrics.

● Evaluation of C-V characteristics of MEMS and semiconductor devices.

● Use in combination with a power amplifier for measurement of the impedance

characteristics of inductors and capacitors for power electronics, piezoelectric motors, and

piezoelectric vibrators.

● Measurement of the impedance characteristics of electrolytes, dielectric materials, and

solutions at micro voltage and current levels by using a high sensitivity voltage

preamplifier and current-voltage conversion amplifier.

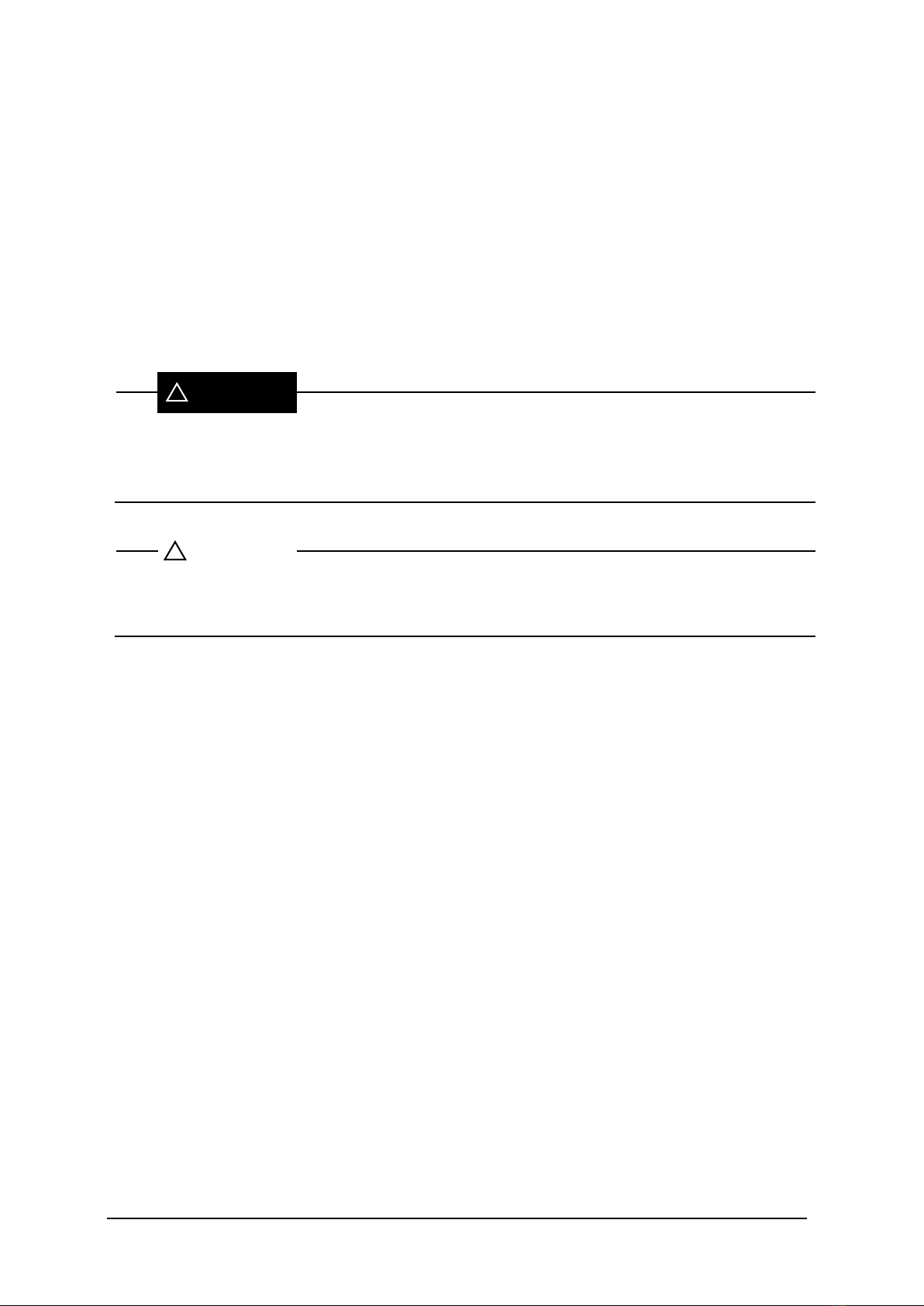

1.3 Operating Principle

1-4ZA57630

1.3 Operating Principle

1.3.1 Operating Principle

The ZA57630 applies a sine wave signal from an internal measurement signal source to the

device under test (DUT). It then detects current I flowing through the DUT and voltage V

applied to the DUT, performs discrete Fourier transform (DFT), and calculates impedance Z

(= V/I) of each analysis frequency component from the obtained Fourier coefficient obtained

through the DFT. Parameters such as inductance L, capacitance C, and resistance R are

calculated from the impedance (magnitude and phase angle).

Figure 1-1 Block Diagram

HCUR

OSC

HPOT

PORT1

LCUR

PORT2

~

o

+

POWER

SUPPLY

DC BIAS

OUT

DFT

OSC

CONTROL

~LINE

UI CPU

VGA

LCD

PANEL

REMOTE IF

USB−B

USB−A

GPIB

LAN

RS−232

10 MHz

REF IN

10 MHz

REF OUT

MEASUREMENT BLOCK

A/D

A/D

HANDLER

INTERFACE

AUX

LPOT

PORT3

1.3 Operating Principle

1-5ZA57630

The impedance and phase angle at the measurement frequency are obtained with one

measurement. Impedance frequency characteristics like a Bode diagram can be obtained by

measuring the gain and phase angle while sweeping the measurement signal source

oscillator (OSC) and measurement frequency. This instrument can measure the amplitude

dependence and DC bias dependence of each impedance since it can also sweep the AC signal

amplitude and DC bias in addition to the frequency.

a) MEASUREMENT BLOCK

The measurement block consists of a signal generation section to supply a signal for

measurement to the DUT, voltage detection section, current detection section, and DFT

section to calculate impedance.

The signal generation section has a setting resolution of 10 µHz for the range of 10 µHz to

36 MHz based on the direct digital frequency synthesizer technology.

The current of the LCUR connector is converted to a voltage and then A/D conversion and DFT

calculation are performed to calculate the current vector (magnitude and phase angle). The

voltage vector is also calculated by performing A/D conversion and DFT calculation for the

voltage applied to the DUT. The impedance (magnitude and phase angle) of the DUT is

calculated by dividing the voltage vector by the current vector and then various error

corrections are made and the result is transferred to the UI CPU section.

b) UI CPU CKT

This displays the measurement data obtained by the measurement block on the LCD in

various graph formats. It also outputs measurement commands to the measurement block in

accordance with the settings from the front panel or a remote interface. The USB-A

connector is located on the front panel and is used for connecting a USB memory device.

c) POWER SUPPLY CKT

This supplies various power required by the measurement bock in addition to power for

digital section control.

d) REMOTE IF CKT

This performs communication with an external controller, such as outputting various

settings and measurement data. It converts between the communication protocols of the

GPIB, USB, RS-232, and LAN general interfaces and the internal communication protocol of

UI CPU CKT. The USB-B connector is located on the rear panel and is used for connecting

with a PC to control this instrument.

1.3 Operating Principle

1-6ZA57630

1.3.2 Measurement Modes

This instrument has four measurement modes to use depending on the measurement purpose.

● Measurement mode IMPD−EXT

Impedance measurement mode

Current-voltage conversion needs to be performed externally.

DUT drive amplifier, probe, etc. can be used.

● Measurement mode IMPD−3T

Impedance measurement mode

Test fixture and test leads for LCR meters can be used.

● Measurement mode IMPD−2T

Impedance measurement mode

Stable measurement at high frequency is possible using an N

connector.

● Measurement mode G−PH

Gain-phase measurement mode

For measuring transfer characteristics of filters and amplifiers

The connector to use for measurement differs depending on the measurement mode setting.

・IMPD−EXT,IMPD−3T,G−PH :HCUR/OSC, HPOT/PORT1, LCUR/PORT2

・IMPD−2T :PORT3

○ Connection example for measurement mode IMPD−EXT

○ Connection example for measurement mode IMPD−3T

(Connection example for operation check)

PORT3

ZA57630

LCUR / PORT2

LPOT

HPOT / PORT1

HCUR / OSC

Test fixture

DUT

PORT3

ZA57630

LCUR / PORT2

LPOT

HPOT / PORT1

HCUR / OSC

Current probe

DUT

DUT drive amplifier

V

I

Voltage probe

PORT3

ZA57630

LCUR / PORT2

LPOT

HPOT / PORT1

HCUR / OSC

100 Ω RESISTOR

(accessory)

Table of contents

Other NF Measuring Instrument manuals