NF ZM2376 User manual

NF Corporation

LCR METER

ZM2376

Instruction Manual (Basics)

LCR METER

ZM2376

Instruction Manual (Basics)

DA00042208-005

Registered Trademarks

National Instruments and LabVIEW are registered trademarks of National Instruments

Corporation in the United States.

Other company names and product names used in this Instruction Manual may be trademarks or

registered trademarks of respective companies.

f

iZM2376

Preface

Thank you very much for purchasing our “ZM2376 LCR METER”.

Please read, first of all, "Safety Precautions" on the follawing pages, to use the instrument in the

correct and safe manner.

Caution Symbols Used in This Manual

The following caution symbols are used in this manual. Be sure to observe these caution symbols and

their contents to ensure the safety of the user and avoid damage to the equipment.

!

WARNING

Equipment handling could result in death or serious injury. This symbol contains

information to avoid such risk.

!

CAUTION

Equipment handling could result in minor or moderate injury or property damage. This

symbol contains information to avoid such risk.

The scope of this Manual

This manual describes the ZM2376 with the firmware version 1.00 or more and CE Marking.

Please make sure the CE marking on the rear panel.

Please watch the version that appears at the power-on.

Preface

ii ZM2376

The following instruction manuals are provided for ZM2376.

ZM2376 Instruction Manual (Basics)

This manual describes basic items such as how to operate ZM2376 from the panel,

specifications, and maintenance.

ZM2376 Instruction Manual (Remote Control)

This manual describes how to remote control ZM2376.

It includes the description of standard commands (ZM2376 primary commands).

ZM2376 Instruction Manual (Alternative Commands)

This manual describes the alternative commands of ZM2376.

If you find the alternative commands easier to use than the standard commands, you can use

them. However, the alternative command provides limited functions.

This manual (Basics) has the following chapters.

If using this equipment for the first time, start from Chapter 1.

1. OUTLINE

This chapter describes the overview, specificities, applications, functions and simple principle of

operations of this product.

2. PREPARATIONS BEFORE USE

This chapter describes important preparation before installation and operation.

3. PANEL FEATURES AND BASIC OPERATIONS

This chapter describes the functions and basic operations available for each panel screen part.

Read while operation the instrument.

4. ADVANCED OPERATIONS

This chapter describes even further the instrument operation.

5. TROUBLESHOOTING

This chapter describes how to deal with error messages and troubles.

6. MAINTENANCE

This chapter describes storage, repacking transportation as well as performance testing.

7. SPECIFICATION

This chapter describes the product’s specifications (functions and performance).

Safety Precautions

iii ZM2376

———— Safety Precautions ————

To ensure safe use, be sure to observe the following warnings and cautions.

NF Corporation shall not be held liable for damages that arise from a failure to observe these warnings

and cautions.

This product is a Class I product (with protective conductor terminal) that conforms to the IEC insulation

standards.

Be sure to observe the contents of instruction manual.

This instruction manual contains information for the safe operation and use of this product.

Be sure to read this information first before using this product.

All the warning items contained in this instruction manual are intended for preventing risks

that may lead to serious accidents. Ensure to obey them.

Be sure to ground the product.

This product uses a line filter, which may cause electric shock if the product is not

grounded.

To prevent electric shock accidents, connect it to an earth ground so that ground resistance

is 100Ω or less.

Check the power supply voltage.

This product operates on the power supply voltage indicated in “Grounding and Power

Supply Connection”in this instruction manual.

Prior to connecting the power supply, check that the voltage of the power outlet matches

the rated power supply of the product.

In case of suspected anomaly

If this product emits smoke, an abnormal smell, or abnormal noise, immediately power it

off and stop using it.

If such an abnormal occurs, prevent anyone from using this product until it has been

repaired, and immediately report the problem to NF Corporation or one of our

representatives.

Do not use this product when gas is present.

An explosion or other such hazard may result.

Do not remove the cover.

This product contains high-voltage parts. Absolutely never remove its cover.

Even when the inside of this product needs to be inspected, do not touch the inside. All

such inspections are to be performed by service technicians designated by NF Corporation.

Safety Precautions

iv ZM2376

Do not modify this product.

Never modify or try to modify the instrument. Your modification of the instrument could

cause unexpected accidents or failures. NF Corporation has the right to refuse providing

services for any instruments modified by unauthorized persons.

Do not expose this product to water.

When this product is used in wet condition, it may cause an electric shock and a fire. If

this product is exposed to water, unplug the power cord immediately, and contact NF

Corporation or one of our representatives.

If lightning occurs, power off this product and unplug the power cord.

A lightning may cause an electric shock, a fire and a failure.

Safety-related symbols

The general definitions of the safety-related symbols used on this product and in the

instruction manual are provided below.

!

Instruction Manual Reference Symbol

This symbol is displayed to alert the user to potential danger and refer him/her

to the instruction manual.

Warning Symbol

This symbol indicates information for the avoidance of a hazard such as electric

shock that may endanger human life or cause injury during handling of the

equipment.

Caution Symbol

This symbol indicates information for the avoidance of damage to the

equipment during handling.

Other Symbols

This symbol indicates the “on”position of the power switch.

This symbol indicates the “off”position of the power switch.

Shows when connected to the housing.

———— Electromagnetic Compatibility ————

This product may cause interference if used in residential areas. Such use must be avoided unless the

user takes special measures to reduce electromagnetic emissions to prevent interference to the reception

of radio and television broadcasts.

———— Request about disposal ————

To protect the environment, ensure that this device is disposed of by an appropriate industrial waste

processor. This product does not use batteries or a backlight that contains mercury.

!

CAUTION

!

WARNING

vZM2376

Table of Contents

Page

1.OUTLINE··························································································1-1

1.1 Features···································································································1-2

1.2 Applications·······························································································1-3

1.3 List of Functions·························································································1-4

1.4 Principle of Operation··················································································1-5

2.PREPARATIONS BEFORE USE···························································2-1

2.1 Checking Before Use ··················································································2-2

2.2 Installation·································································································2-6

2.2.1 General Precautions for Installation····························································· 2-6

2.2.2 Installation Conditions ·············································································· 2-6

2.2.3 Rack Mounting························································································ 2-7

2.3 Grounding and Power Supply Connection ·····················································2-12

2.4 Simplified Operation Check ········································································2-13

2.5 Calibration·······························································································2-14

3.PANEL FEATURES AND BASIC OPERATIONS·······································3-1

3.1 Panel Component Names and Functions·························································3-2

3.2 Display at Power “ON”and Initial Settings ·······················································3-4

3.2.1 Check before Power “ON”········································································· 3-4

3.2.2 Displays and Indications at Power “ON”························································ 3-5

3.2.3 Initialization···························································································· 3-6

3.3 Operation Tree·························································································3-13

3.4 Connection of DUT ···················································································3-17

3.4.1 Measurement Terminals ········································································· 3-17

3.4.2 Connection to DUT················································································ 3-18

3.4.3 Precautions on Connection······································································ 3-19

3.5 Basic Operations······················································································3-21

3.5.1 Outline of Measurement Screen ······························································· 3-21

3.5.2 Basic Key Operations············································································· 3-22

3.5.3 Simplified Operating Method When You Use Instrument for the First Time········· 3-25

3.5.4 Initialization·························································································· 3-29

3.5.5 Setting of Measurement Parameters·························································· 3-30

3.5.5.1 Selection of Primary Parameters ································································ 3-30

3.5.5.2 Setting of Equivalent Circuit······································································· 3-32

3.5.5.3 Setting of Secondary Parameters ······························································· 3-33

3.5.6 Setting of Basic Measurement Conditions··················································· 3-35

3.5.6.1 Measurement Frequency·········································································· 3-35

3.5.6.2 Measurement Signal Level········································································ 3-36

3.5.6.3 Measurement range················································································· 3-37

3.5.6.4 Trigger·································································································· 3-43

3.5.6.5 Measurement speed················································································ 3-48

3.5.6.6 Correction of Measurement Error································································ 3-51

3.5.6.7 OPEN Correction ···················································································· 3-53

3.5.6.8 SHORT Correction ·················································································· 3-59

3.5.6.9 LOAD Correction····················································································· 3-63

Table of Contents

vi ZM2376

3.5.6.10 Cable Length Correction··········································································· 3-73

4.ADVANCED OPERATIONS··································································4-1

4.1 Measuring with Specific Voltage or Current (ALC)·············································4-2

4.2 Restricting the Variation of Measured Value (Averaging) ····································4-6

4.3 Displaying the Deviation from the Reference Value ···········································4-7

4.4 Sorting the Part (Comparator) ·····································································4-10

4.5 Connecting to the Part handler (Handler Interface)··········································4-20

4.6 Measuring with More Than One Condition (Multi-measurement) ························4-30

4.7 Changing the Contents Displayed on the Second Line of Measurement Screen

(Auxiliary Display)·····················································································4-37

4.8 Saving/Recalling the Setting and Correction Value into the Memory····················4-39

4.9 Setting the Contact Check··········································································4-41

4.10 Applying the DC Bias Voltage ·····································································4-44

4.11 Applying the DC Bias Current······································································4-51

4.12 Disabling the Key-Operation of Panel ···························································4-54

4.13 Changing the Settling Wait Time During Automatic Adjustment··························4-55

4.14 Initializing of All Settings ············································································4-56

4.15 Self-Diagnosis ·························································································4-59

4.16 Checking the Version ················································································4-60

4.17 Remote Control························································································4-61

4.18 Switching the Operation Mode (alternative command)······································4-62

5.TROUBLESHOOTING ········································································5-1

5.1 Error Message ···························································································5-2

5.1.1 Errors at Power ON·················································································· 5-3

5.1.2 Errors at Panel Operation·········································································· 5-4

5.1.3 Errors During Measurement······································································· 5-5

5.1.4 Measured Value Display in Case of Error······················································ 5-6

5.2 When the Device Appears to be a Problem······················································5-8

6.MAINTENANCE·················································································6-1

6.1 Preface·····································································································6-2

6.2 Daily Maintenance······················································································6-3

6.3 Storage, Repacking, and Transportation ·························································6-3

6.4 Checking Version Number············································································6-3

6.5 Checking Isolation ······················································································6-4

6.6 Performance Testing···················································································6-4

6.6.1 Measurement Frequency Accuracy ·····························································6-5

6.6.2 Measurement Signal Level Accuracy ··························································· 6-5

6.6.3 Voltage Monitor Accuracy·········································································· 6-6

6.6.4 DC Bias Voltage Accuracy········································································· 6-7

6.6.5 AC Impedance Measurement Accuracy························································6-8

6.6.6 DC Resistance Measurement Accuracy······················································ 6-13

6.7 Calibration·······························································································6-15

Table of Contents

vii ZM2376

7.SPECIFICATION················································································7-1

7.1 Specification······························································································7-2

7.2 External Dimensions ·················································································7-17

Table of Contents

viii ZM2376

Attached figures and tables

Page

Figure 1-1 Block Diagram······················································································· 1-5

Figure 2-1 Rack-mount assembly (mm-rack)······························································ 2-8

Figure 2-2 Rack-mount assembly (inch-rack) ····························································· 2-9

Figure 2-3 Size and dimensions of the rack-mount (mm-rack) ······································2-10

Figure 2-4 Size and dimensions of the rack-mount (inch-rack)······································2-11

Figure 3-1 Front panel··························································································· 3-2

Figure 3-2 Rear panel ··························································································· 3-3

Figure 3-3 Functions of measurement terminals ························································3-17

Figure 3-4 Connection to DUT················································································3-18

Figure 3-5 Capacitance to measurement signal level characteristics······························3-39

Figure 3-6 Measurement sequence·········································································3-43

Figure 3-7 Signal acquisition time ···········································································3-49

Figure 3-8 Terminal processing at OPEN correction ···················································3-54

Figure 3-9 Terminal processing at SHORT correction ·················································3-60

Figure 3-10 Connection circuit network for LOAD correction ··········································3-63

Figure 3-11 Measurement of LOAD standard value······················································3-70

Figure 3-12 Measurement of LOAD correction value ····················································3-71

Figure 4-1 Maximum capacitance measurable at constant voltage (typical value)·············· 4-5

Figure 4-2 Inductance range measurable at constant voltage (typical value)····················· 4-5

Figure 4–3 Output of comparator result ····································································4-11

Figure 4–4 Range setting and comparison when sorting into bins ··································4-16

Figure 4–5 Equivalent circuit of handler interface························································4-23

Figure 4–6 Handler interface operation timing····························································4-24

Figure 4–7 Dummy output timing·············································································4-29

Figure 4-8 Handler interface operation timing in the multi-measurement·························4-35

Figure 4-9 Example of external voltage bias circuit·····················································4-49

Figure 4-10 Example of external current bias circuit ·····················································4-51

Figure 7-1 Range of error······················································································7-11

Figure 7-2 LC - Z conversion graph·········································································7-12

Figure 7-3 ZM2376 external dimensions ··································································7-17

Table of Contents

ix ZM2376

Table 2-1 Package contents ·················································································· 2-2

Table 3-1 Setting items and initial values·································································· 3-7

Table 3-2 Measurement range list··········································································3-37

Table 3-3 Max. current, max. voltage, and output impedance

in each measurement range····································································3-39

Table 3-4 Example of measurement time (typical value)·············································3-48

Table 4-1 Display format of measured value and interpretation of setting value

(example of L)······················································································4-14

Table 4–2 Initialization contents of comparator··························································4-14

Table 4–3 Handler interface signal layout·································································4-20

Table 4–4 Functions of handler interface signal·························································4-21

Table 4-5 Handler interface output in the multi-measurement······································4-34

Table 5-1 When the device appears to be a problem ·················································5-11

1-1 ZM2376

1.OUTLINE

1.OUTLINE .........................................................................1-1

1.1 Features...........................................................................1-2

1.2 Applications......................................................................1-4

1.3 List of Functions...............................................................1-5

1.4 Principle of Operation.......................................................1-6

1.1 Features

1-2 ZM2376

1.1 Features

The “ZM2376 LCR Meter” is a high speed LCR meter with the maximum frequency 5.5MHz and

maximum signal level 5V. It has high basic accuracy of 0.08% and is capable of measuring the impedance

in a wide application range from manufacturing and inspection lines of electronic parts up to the research

of materials.

Measurement frequency 1mHz to 5.5MHz

The instrument has the maximum 6-digit resolution and thus it is capable of measuring the detailed

frequency characteristics of the DUT (Device Under Test).

Signal level 10mV to 5V / Maximum current 200mA

It is capable of measuring the characteristics of DUT in a wide signal level range.

Constant voltage / Constant current drive

It can make evaluation on stable signal level even for the DUT of which characteristics vary with

the signal level.

High speed measurement

It provides high speed measurement at the fastest 2ms (1kHz - 1MHz) or 10ms (120Hz).

Cable length 0m / 1m / 2m / 4m

Allowable length of connection cable to the DUT is maximum 4m. However, it is limited by the

frequency.

Triggered drive

A signal is output after the instrument contacted the DUT, thus reducing the contact damage when

high capacitance capacitor is measured. Also, this feature reduces measurement dispersion of the

DUT having hysteresis characteristics.

Contact check

A contact failure to DUT can be detected based on an abnormally low capacitance or abnormal

voltage/current signal, with little additional time required.

Handler interface

The bin sorting results of maximum 14 categories can be output to the part handler.

Remote control

The instrument is equipped with the USB, RS-232 (230.4kbps max), and GPIB interfaces as

standard, which is useful for installing it in production lines or measurement systems. A LAN

interface is also available optionally.

1.1 Features

1-3 ZM2376

DC (Direct-current) resistance measurement

Direct-current resistance such as a winding resistance of inductor or transformer can be measured.

Setting/correction value memory

32 sets of settings and correction values can be stored in nonvolatile memory, and they can be used

selectively.

1.2 Applications

1-4 ZM2376

1.2 Applications

Inspection, sorting, and evaluation test in production lines of electronic parts

such as inductors, capacitors, and sensors.

Evaluation and research of magnetic materials and dielectrics.

Impedance measurement of batteries.

1.3 List of Functions

1-5 ZM2376

1.3 List of Functions

The following shows the functional tree of ZM2376.

1.4 Principle of Operation

1-6 ZM2376

1.4 Principle of Operation

The ZM2376 gives sine wave signal from an internal oscillator to the DUT (Device Under Test). The

impedance bridge detects the current I flowing in DUT and the voltage V applied to DUT, and then the

main processor obtains the impedance Z (= V / I). The parameters such as inductance L, capacitance C,

resistance R, etc. are calculated from the impedance (magnitude, phase angle).

Figure 1-1 Block Diagram

Main Processor

According to the user’s operation, the main processor controls the oscillator and impedance bridge to

calculate the vector ratio from the voltage signal and current signal obtained from the DUT. Then, the

main processor makes necessary correction, and finally converts the data into the required parameter

to be displayed or output.

Main Processor

Panel

LCD Character Display,

Key & Lamp

GPIB

RS-232

Isolator

A/D

V

signal

Handler

Interface

DUT

I

signal

HCUR

HPOT

LPOT

LCUR

USB

Oscillator

Power

Amp

Frequency

Synthesizer

Amplitude

Control

DC Bias

Impedance

Bridge

R_range

diff-AMP

diff-AMP

DC canceller

LAN

(Option)

1.4 Principle of Operation

1-7 ZM2376

Oscillator

The oscillator generates sine wave signals having exact frequencies by means of a direct digital

frequency synthetic method based on the reference clock of crystal oscillator.

When the Automatic Level Control (ALC) function is effective, the main processor adjusts

automatically the signal level so that the voltage and current monitored values become the specified

values.

Impedance Bridge

The current flowing in the DUT is converted into the voltage by the range resistance and differential

amplifier. At this time, the potential of LCUR between LPOT terminals is maintained to almost zero by

automatic balancing motion of the bridge. Accordingly, the current that runs away to the ground

through capacitance to earth and insulation resistance and is not detected can be reduced.

The voltage applied to the DUT is detected by the differential amplifier.

After that, the voltage signal and current signal are converted into digital values by the A/D converter,

and sent to the main processor.

Other manuals for ZM2376

1

Table of contents

Other NF Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Sper scientific

Sper scientific 850015 instruction manual

horiba

horiba LAQUA WQ-310 instruction manual

Tektronix

Tektronix 1720 instruction manual

Endress+Hauser

Endress+Hauser airtrol CPC 200 operating instructions

Agilent Technologies

Agilent Technologies 86142B user guide

GT LASERS

GT LASERS CYL-2000/S user manual

M-system

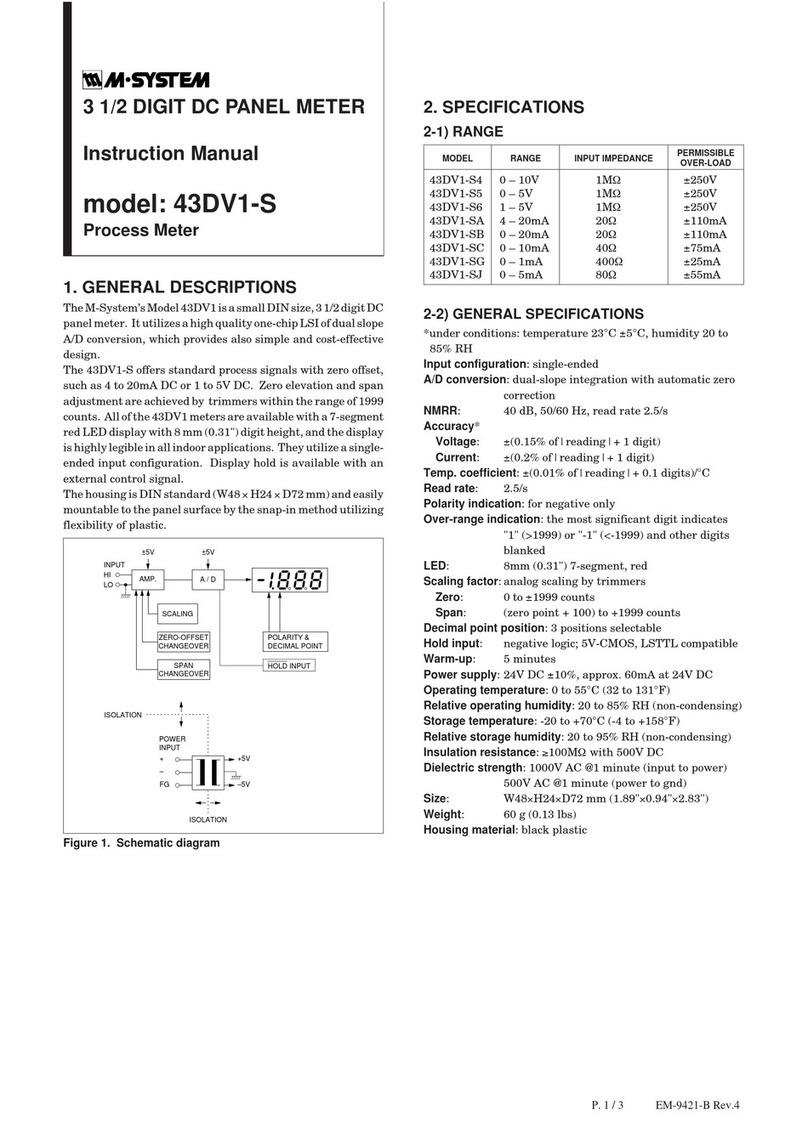

M-system 43DV1-S instruction manual

Berger & Schroter

Berger & Schroter LW800 PRO operating instructions

Pixsys

Pixsys 2000.35.021 user manual

Amprobe

Amprobe AT-2005-A quick guide

Milwaukee

Milwaukee MC510 user manual

PCB Piezotronics

PCB Piezotronics Imi Sensors ICP 602D02 Installation and operating manual