-EA AN A INSTCTINS

-Never allow children to operate or play with door controls. eep the remote control where provided away from children.

-ersonnel should keep away from a door in motion and keep the moving door in sight until it is completely closed or

opened. N NE S CSS TE AT A MIN .

-Test the doors safety features at least once a month. After adusting the limit of travel, retest the door operators safety

features. ailure to adust the operator properly may cause severe inury or death.

-or products having a manual release, if possible, use the manual release only when the door is closed. se caution when

using this release when the door is open. eak or broken springs may cause the door to fall rapidly, causing severe inury

or death.

-EE S EY EATIN AN AANCE. See oor Manufacturers wners Manual. An improperly

operating or balanced door could cause severe inury or death. ave trained door systems technician make repairs to

cables, spring assemblies, and other hardware.

-ress the EN device or use emergency disconnect mechanism if a person is trapped under the door.

-SAE TESE INSTCTINS. The owner or users must understand the safety and operation of door system. Insure that

this installation manual be located close to the door system.

EA AN A INSTAATIN INSTCTINS

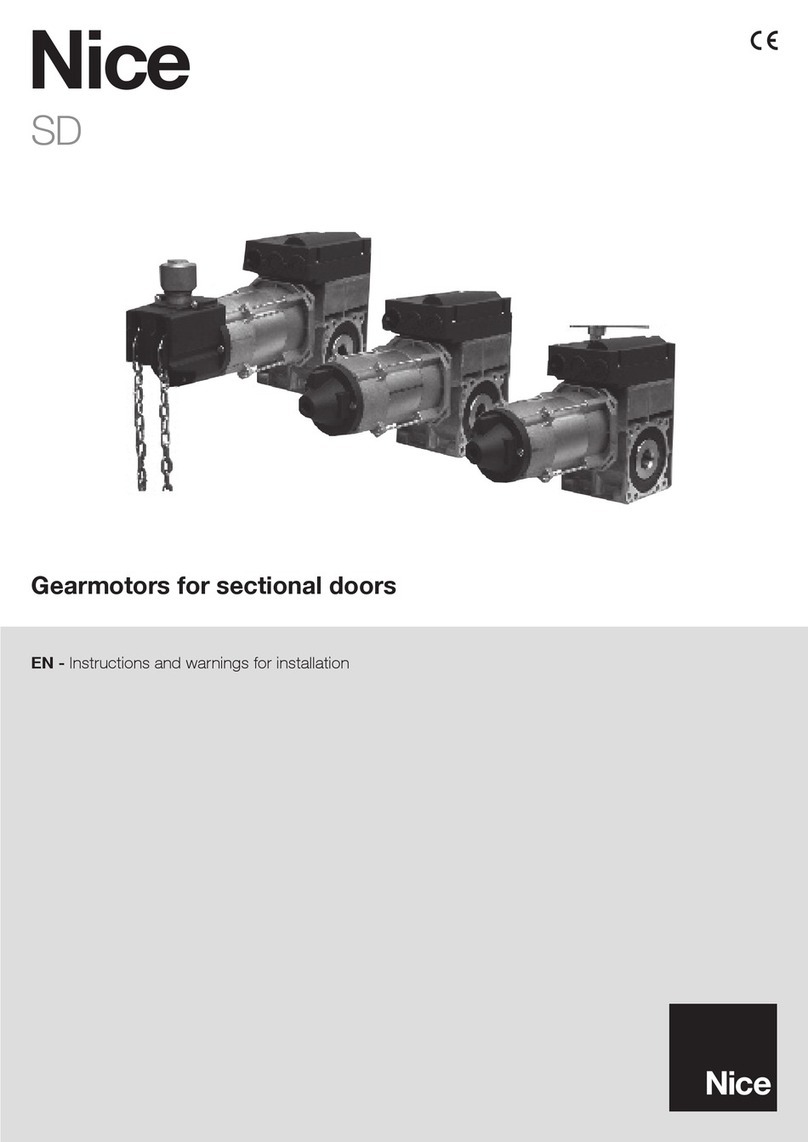

-Commercial door operators are never to be installed on a residential installation

-Install only on a properly operating and balanced door. A door that is operating improperly could cause severe inury. ave

ualified service personnel make repairs to cables, spring assemblies, and other hardware before installing the operator.

-emove all pull ropes and remove, or make inoperative, all locks unless mechanically andor electrically interlocked to the

power unit that are connected to the door before installing the operator.

-Install the door operator at least feet or more above the floor if the operator has exposed moving parts.

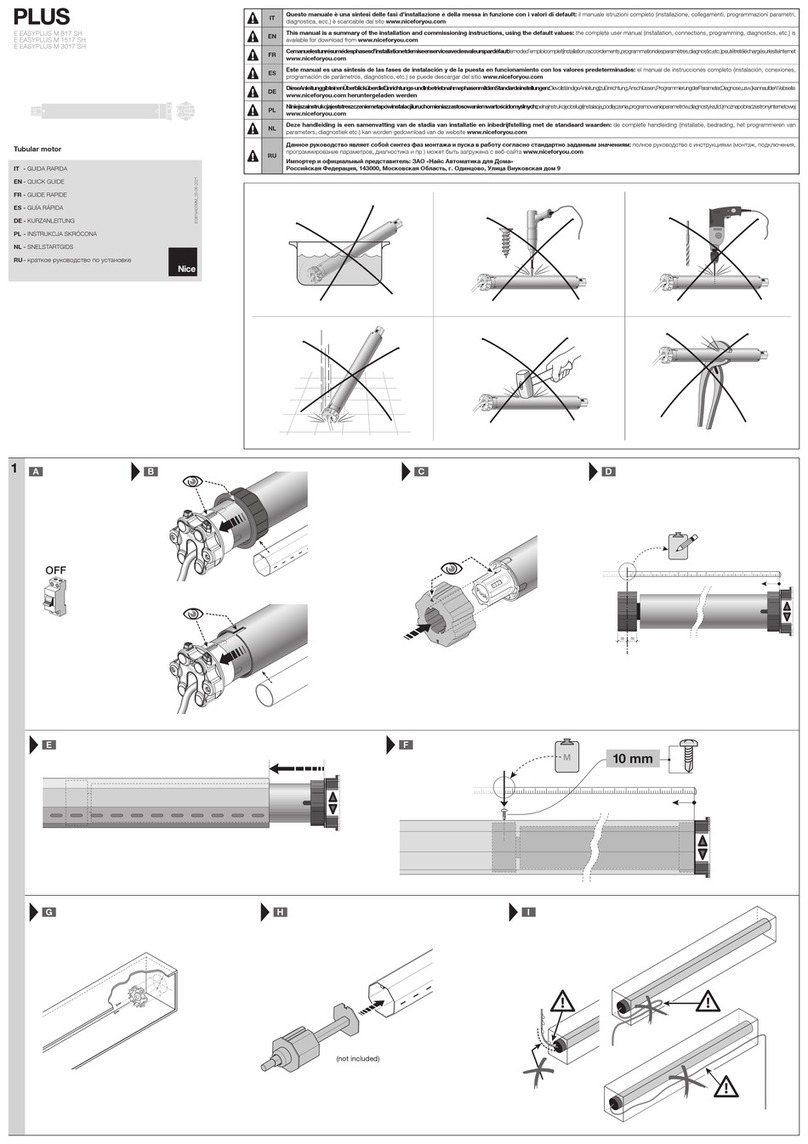

-o not connect the operator to the source of power until instructed to do so.

-ocate the control station a within sight of the door, b at a minimum height of feet so that small children cannot reach

it, and

c away from all moving parts of the door.

-Install the Entrapment arning lacard next to the control station in a prominent location.

-or products having a manual release, instruct the end user on the operation of the manual release.

-Install non-contact entrapment protection devices photocells andor contact entrapment protection devices

reversing edges. Note photocells should be installed at no more than from the floor. Edges should be installed

on the leading edge of the door.

IMTANT SAETY INSTCTINS

IMTANT INSTAATIN INSTCTINS

ANIN

T ECE TE IS INY EAT