Nice Pro-LT Technical specifications

Other Nice Door Opening System manuals

Nice

Nice SPA2 Technical specifications

Nice

Nice AVIO600 Technical specifications

Nice

Nice STX KIT Technical specifications

Nice

Nice SD-70-20 3 400 Technical specifications

Nice

Nice F210S Product manual

Nice

Nice SWN Series Technical specifications

Nice

Nice Spider 6060 Installer manual

Nice

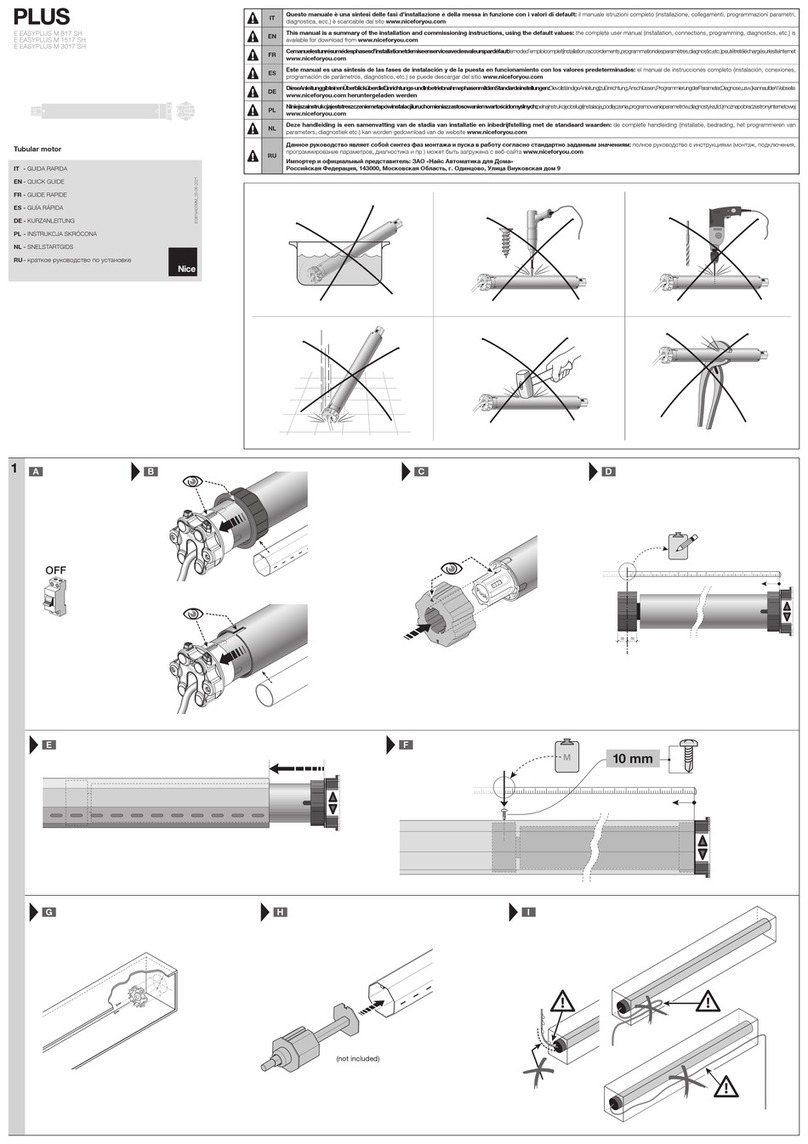

Nice PLUS Series User manual

Nice

Nice Pro-H Technical specifications

Nice

Nice SD Series Technical specifications

Popular Door Opening System manuals by other brands

AGS

AGS D-PL Instructions for fitting, operating and maintenance

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

GEZE

GEZE ECturn user manual