LCN Benchmark III 9130 User manual

Other LCN Door Opening System manuals

LCN

LCN 4040XP User manual

LCN

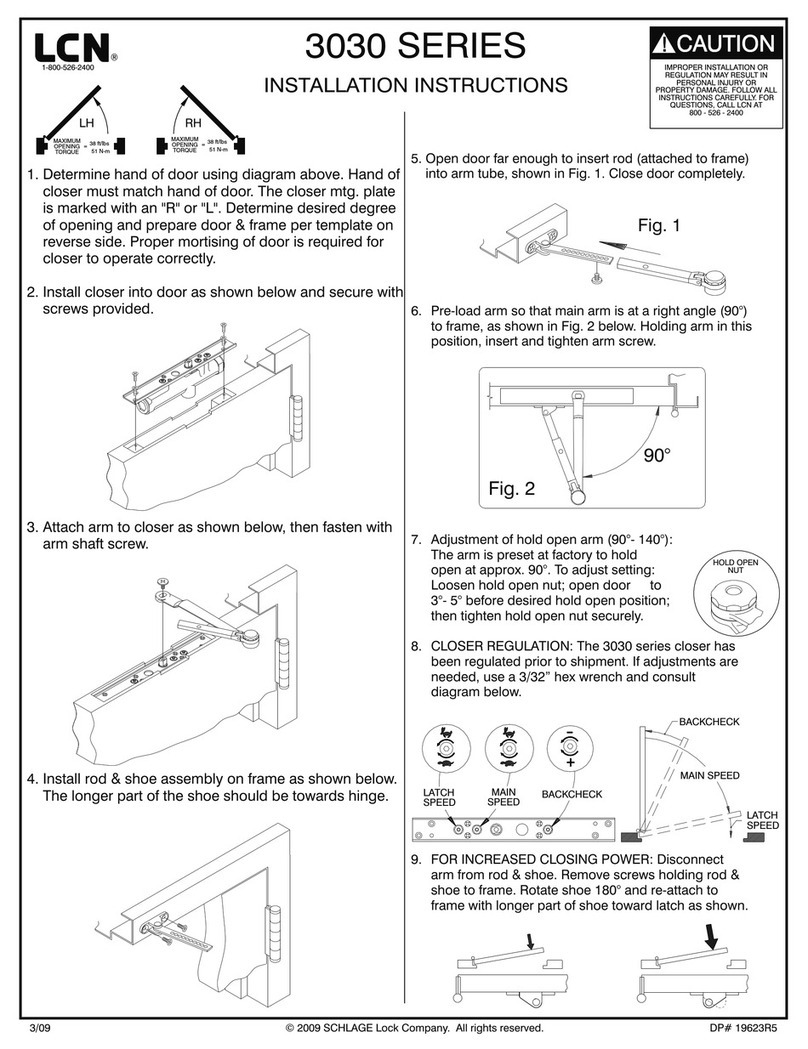

LCN 3030 Series User manual

LCN

LCN 4310ME Series User manual

LCN

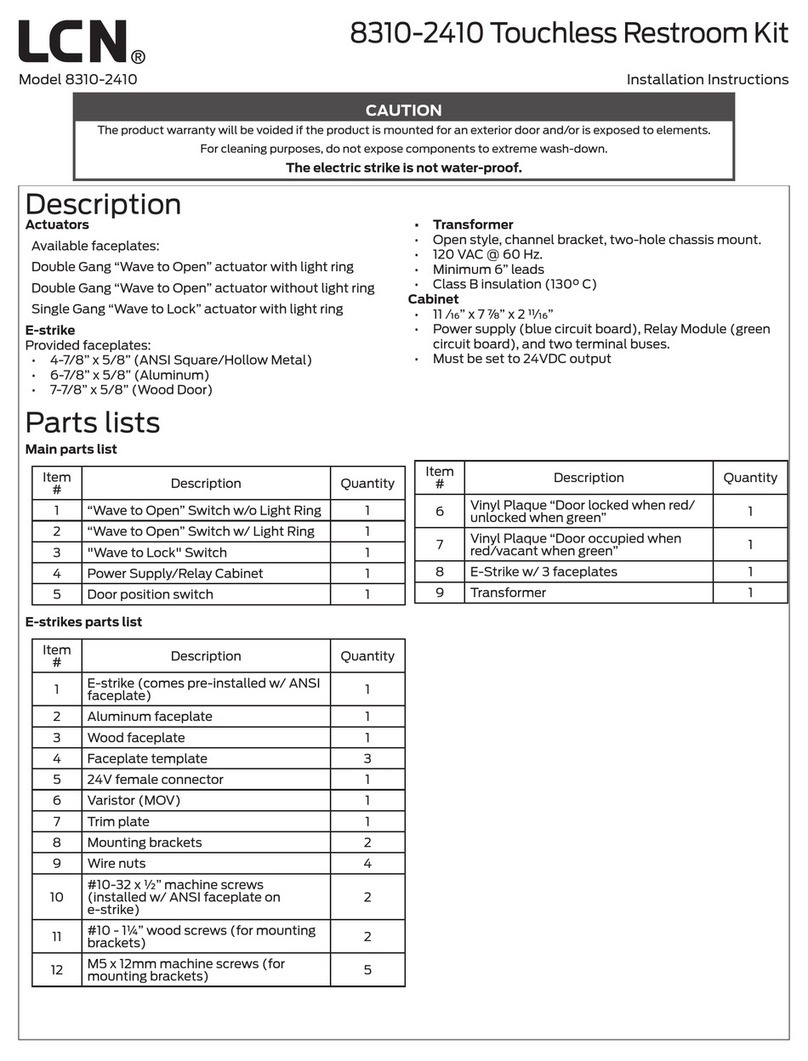

LCN 8310-2410 User manual

LCN

LCN 1261 CUSH User manual

LCN

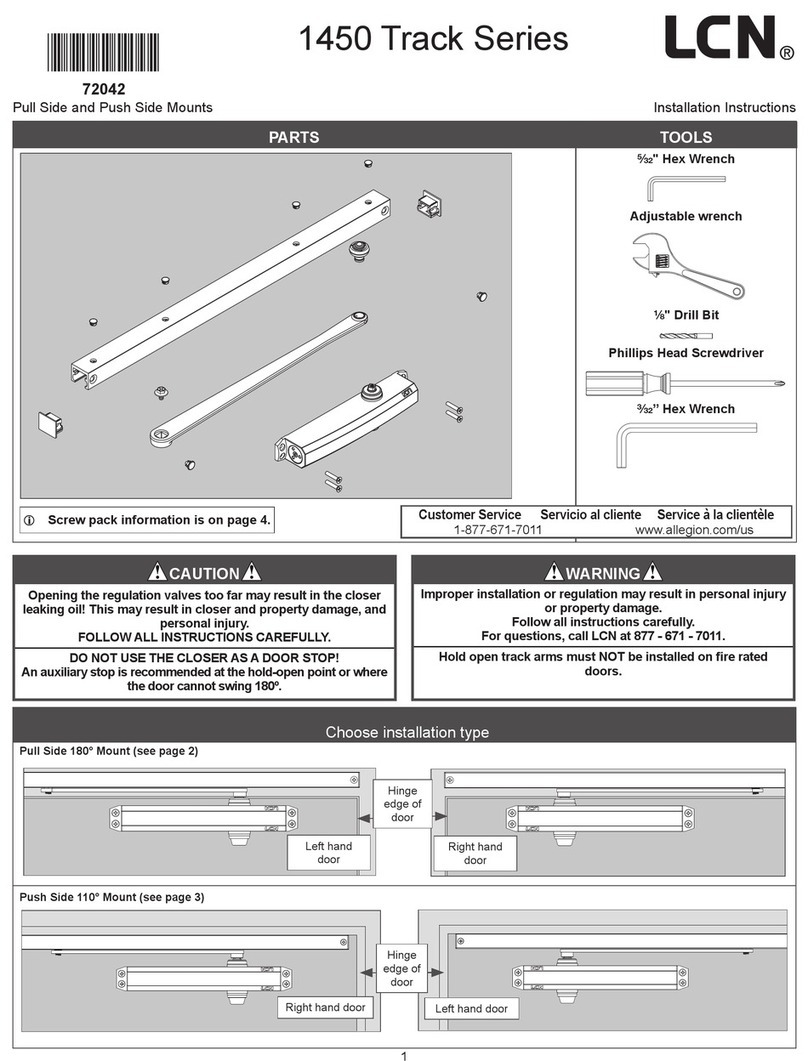

LCN 1450 Track Series User manual

LCN

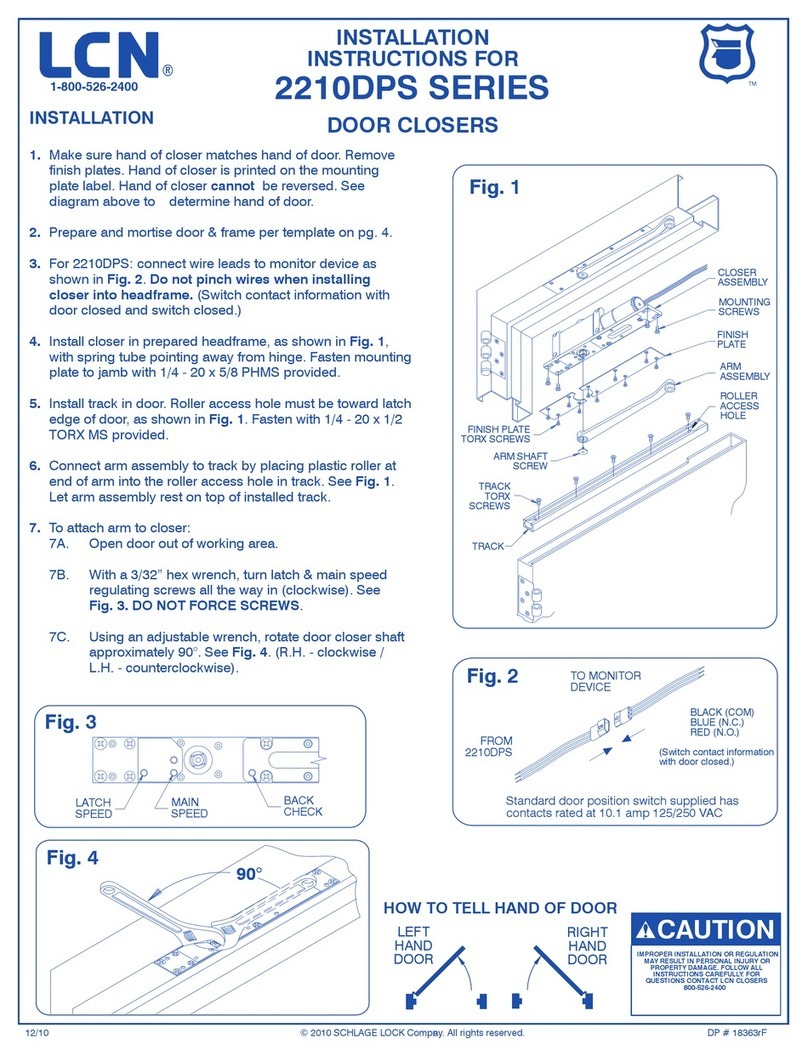

LCN 2210DPS Series User manual

LCN

LCN 4020 Series User manual

LCN

LCN 4050 Series User manual

LCN

LCN 4410ME Series User manual

LCN

LCN 4031 CUSH User manual

LCN

LCN 2010 SERIES User manual

LCN

LCN 8310-2420 User manual

LCN

LCN 4412 HSA Operation and maintenance manual

LCN

LCN 4630CS User manual

LCN

LCN 4040SE User manual

LCN

LCN 4020 Series User manual

LCN

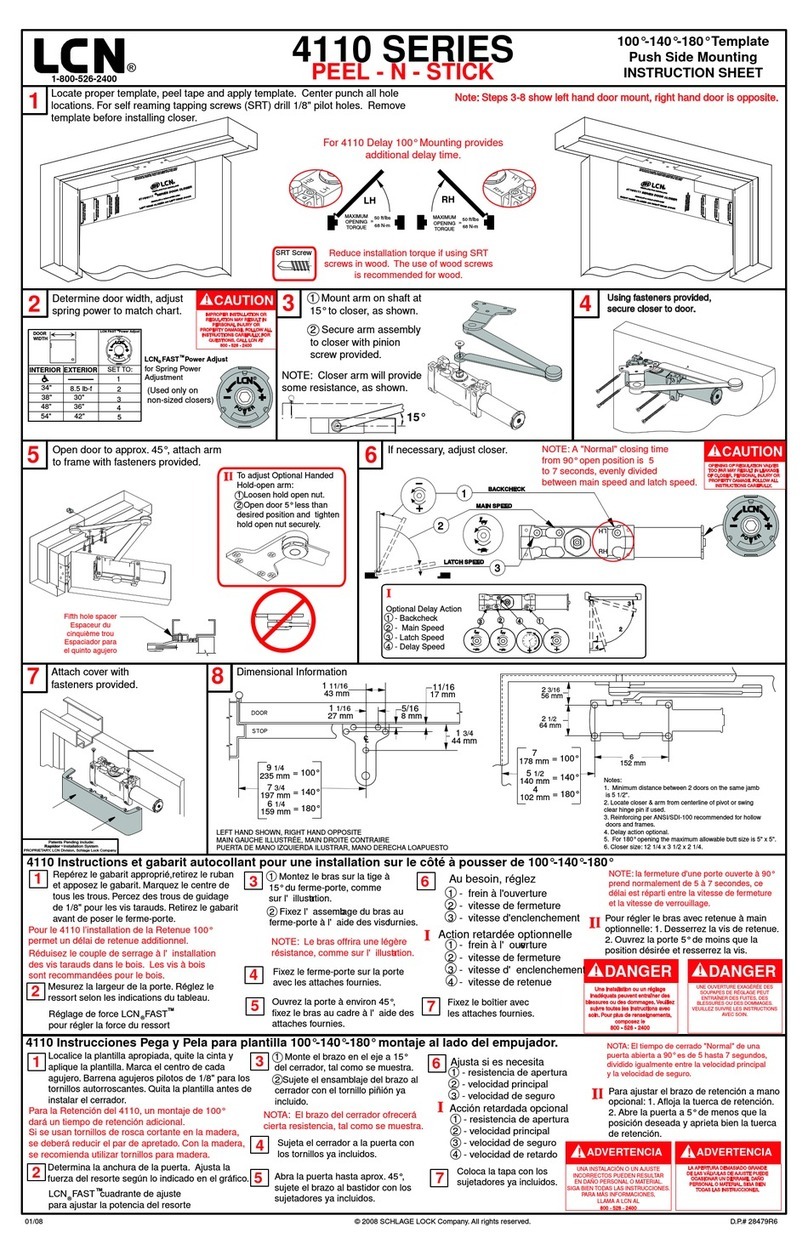

LCN 4110EDA User manual

LCN

LCN 4600 Series User manual

LCN

LCN COMPACT 6400 Series User manual

Popular Door Opening System manuals by other brands

AGS

AGS D-PL Instructions for fitting, operating and maintenance

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

GEZE

GEZE ECturn user manual