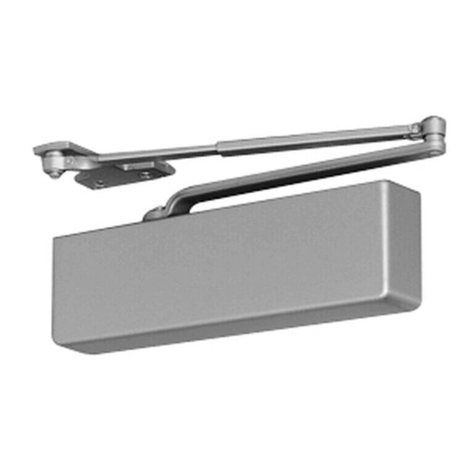

GENERAL DESCRIPTION

Each 8900 EMR series unit contains a door closer, hold

open electromagnet and smoke detector. The unit can be

used as a single installation or as a series of singles

powered from one or more power supplies. When a

series of 8900 EMR units are wired together in a run,

groups of up to 5 units may be interconnected.

Interconnection is accomplished through terminals #4

and #15 and results in all units alarming when any one

of them senses smoke. In turn, all associated hold

open electromagnets are de-energized. Within any run of

detectored units, it is permissible to form as many

interconnected groups as the total power supply

amperage will allow; but, again no more than 5 units

can be interconnected together.

Any detectored 8900 EMR series unit can be connected

to an auxiliary EMF non-detectored unit, or remote

detector, or both. It can be a single installation or part

of any of the multiple arrangements described above.

An auxiliary unit (double door applications) is a

companion to the main unit, and its electromagnet

de-energizes along with the main unit. A remote open

area detector sensing smoke alarms the 8900 EMR to

which it is connected and any other 8900 EMR to which

it is interconnected.

Single installations or groups of installations can be

connected to the alarm initiation circuit of a compatible

UL/ULC listed fire alarm control unit in 4-wire or 6-wire

configurations.

Additional functions are provided to separately power

the hold open electromagnets directly from the alarm

control panel as well as connections for a remote alarm

indicator lamp.

8900 EMR

(WITH DETECTOR)

INSPK NO. 08279530 Rev 08/13

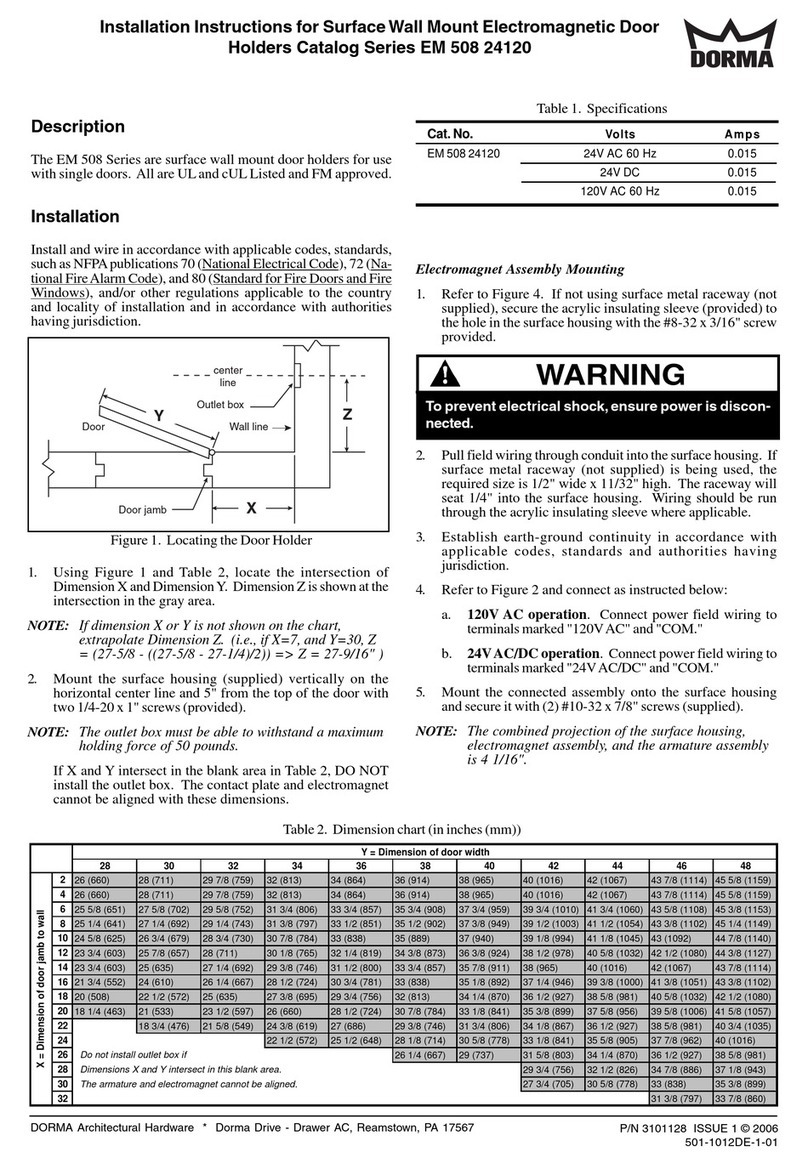

INSTALLATION

1. Read entire instruction sheet prior to installation

and refer to NFPA 72E. Standards may be obtained

from THE NATIONAL FIRE PROTECTION

ASSOCIATION, Batterymarch Park, Quincy,

MA 02269.

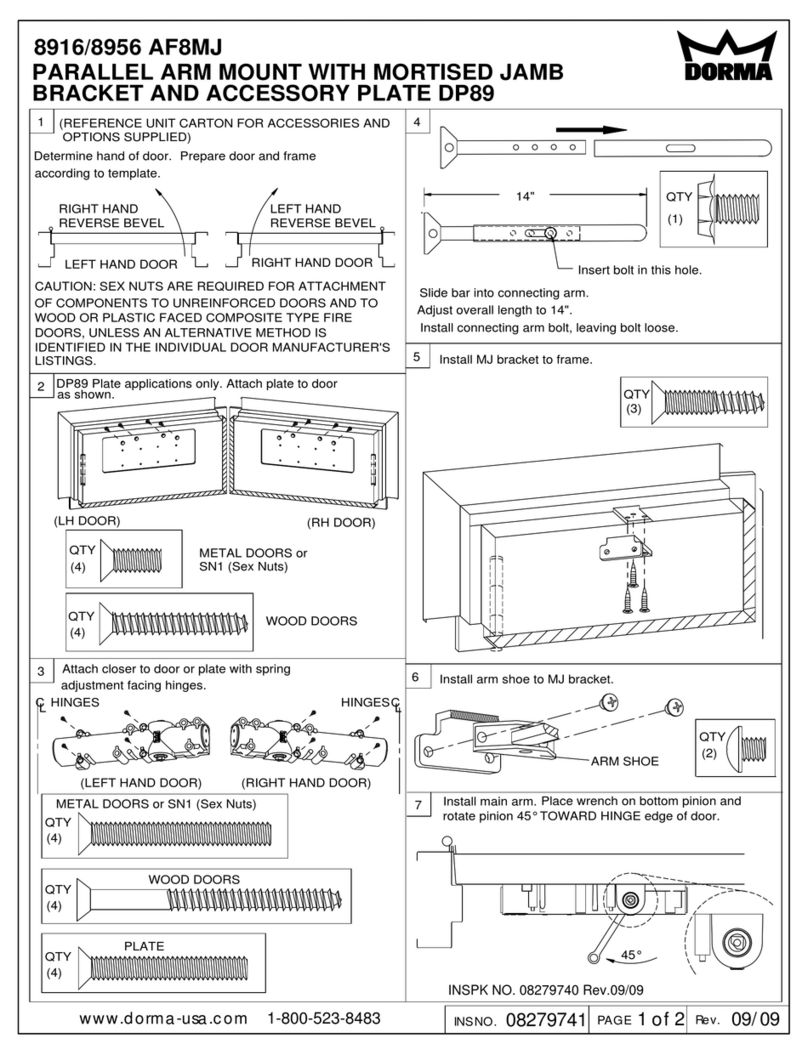

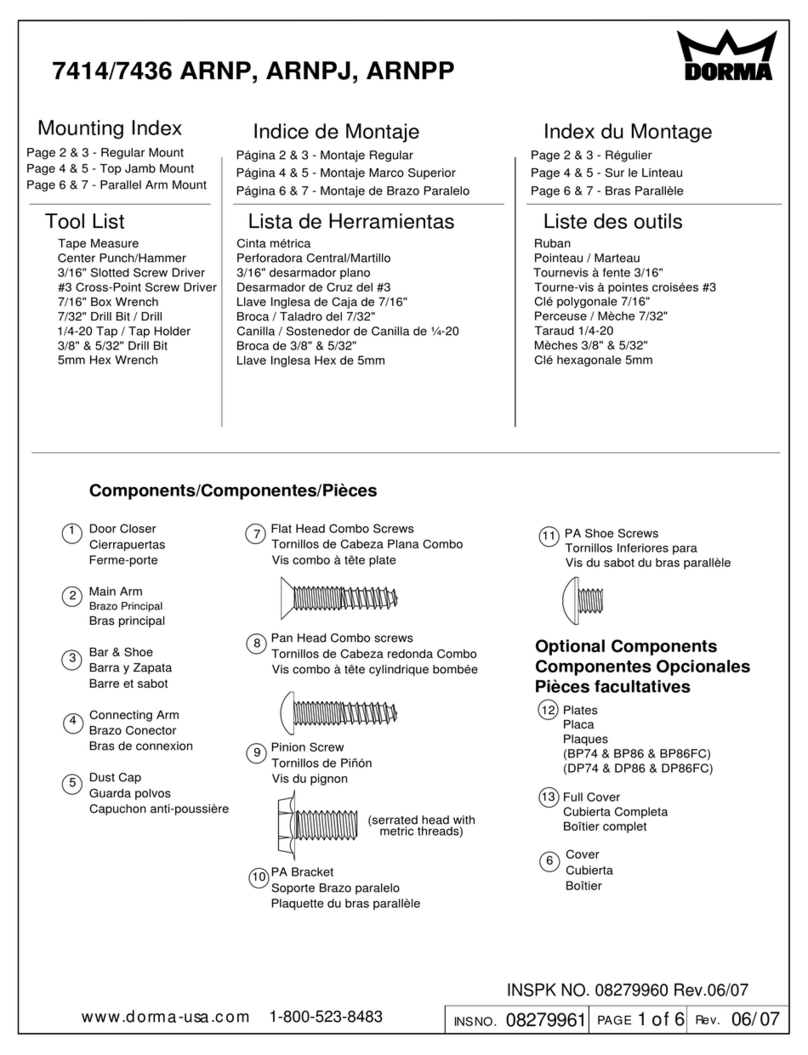

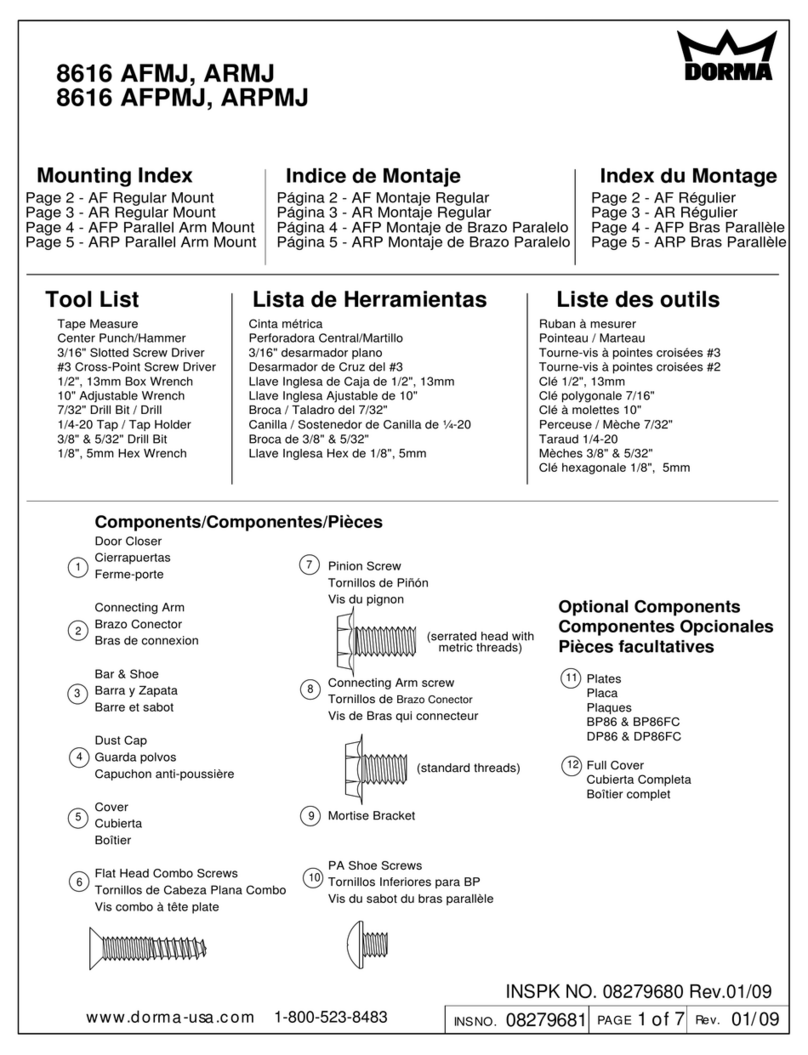

2. Reference unit carton for unit mounting type.

3. Prepare door and frame for fasteners using the

appropriate template. Mark, drill, and tap holes as

indicated. If surface wiring is used, omit 7/8" hole

for wire access.

NOTE:

If installing the optional bypass switch, install assembly

on the end of track as shown. Fasten track to door frame

with the screw provided (T mount uses a cylindrical spacer).

Fasten the end cap assembly with metal or wood screws

provided. Connect the switch with wire nuts and slide the

cover in place. For T mount, place end cap in extension

piece and fasten to frame with screw provided.

Optional Bypass Switch - PT Mount

Optional Track Bypass Switch - T Mount

www.dorma-usa.com 1-800-523-8483

INS NO.

Rev.

08280990

08/13

PAGE

1 of 14