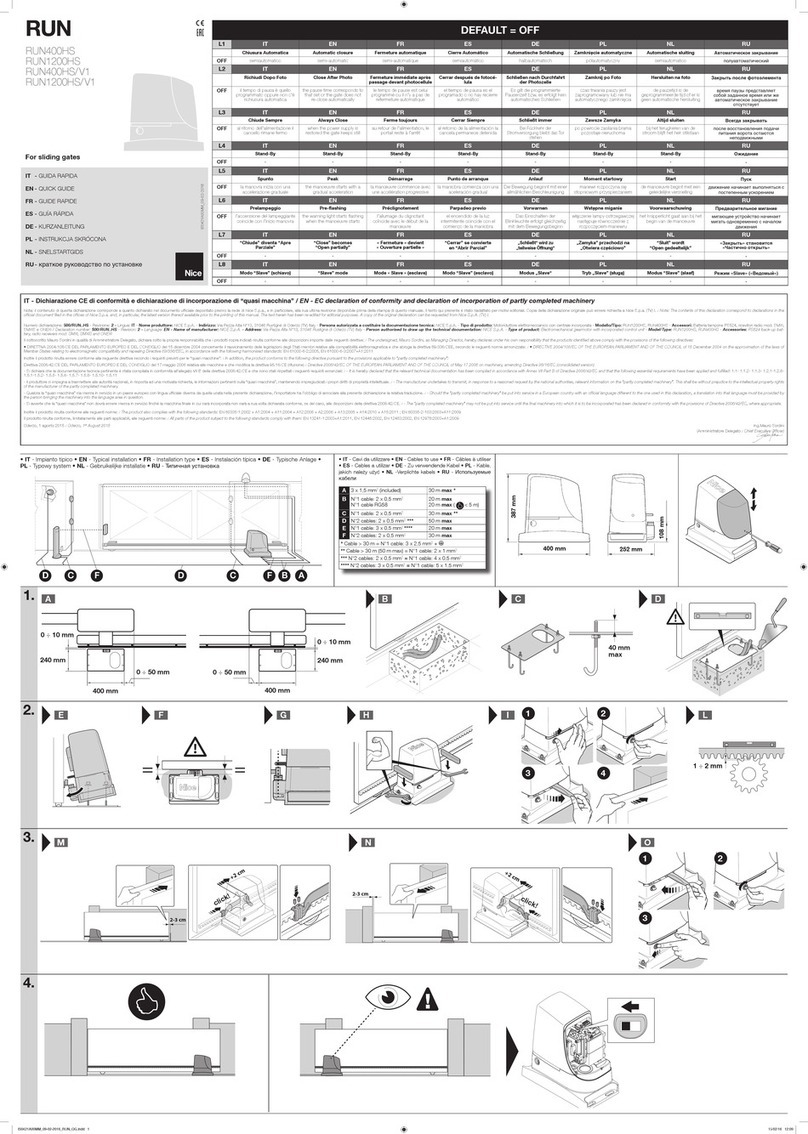

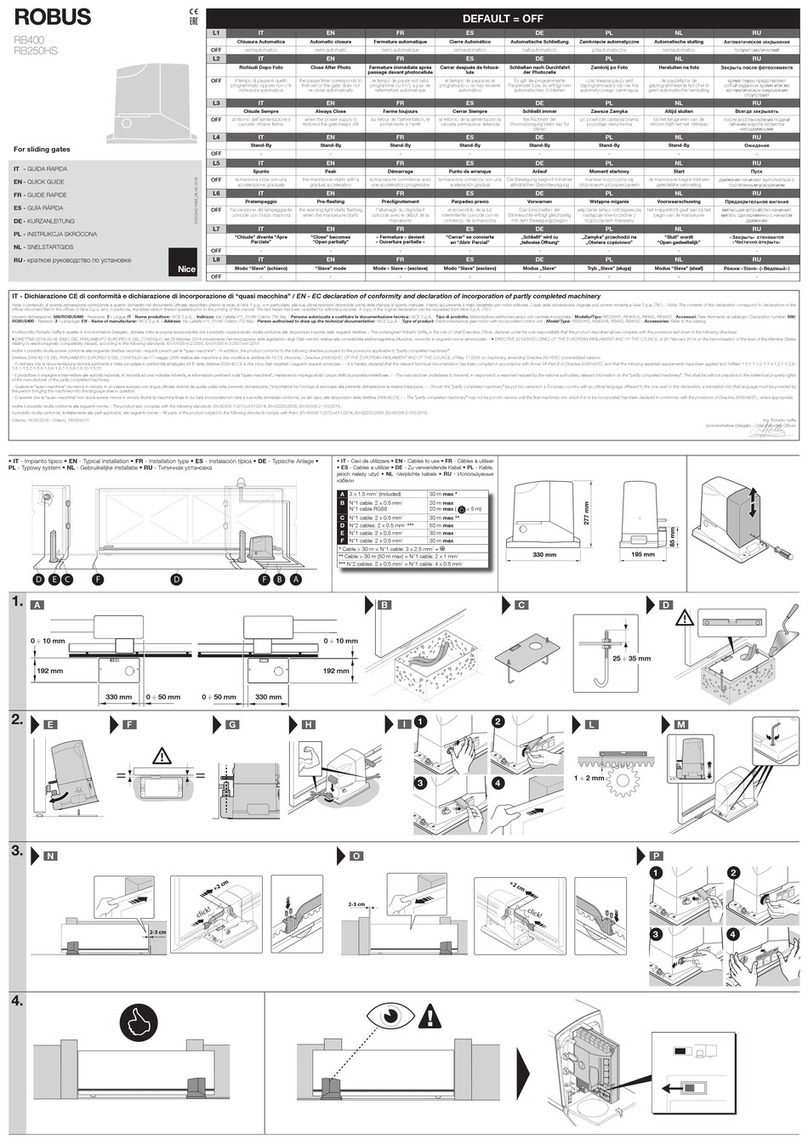

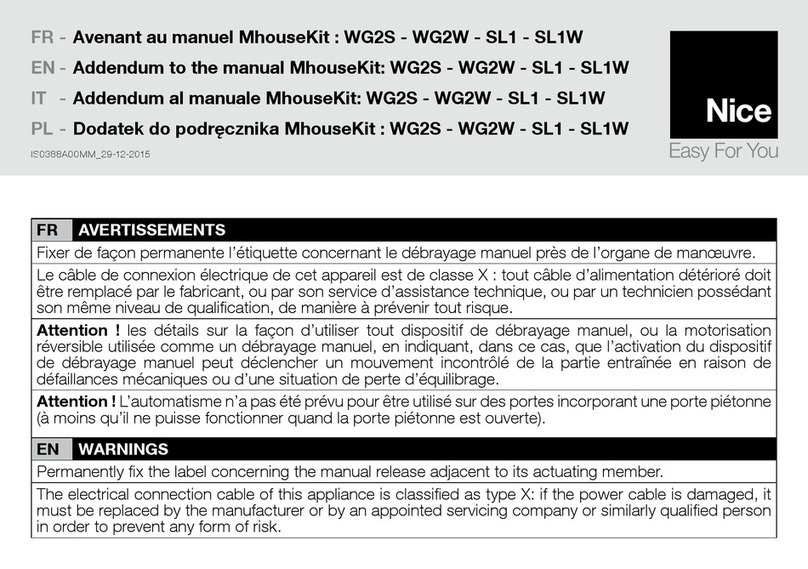

TABLE 1

Warnings

•The installation, testing and set-up of automation devices for doors and gates must

be performed by qualied and experienced personnel who must also determine the

type of tests required based on the risks involved, and ensure that laws, standards

and regulations in force are complied with.

•MHOUSE disclaims responsibility for any damage resulting from improper use of the prod-

uct; the only use authorized by the manufacturer is the one described in this manual.

•The packaging materials must be disposed of in compliance with the regulations

locally in force.

•The post-mounted photocells must not be immersed in water or any other liquid sub-

stances. If liquid substances should penetrate inside the device, disconnect the pow-

er supply immediately and call MHOUSE customer service; using the device under

these conditions could be hazardous.

•Do not place the photocells near heat sources or expose them to open ames; this

could damage the device and cause malfunctions, re hazards or other dangers.

Description and Intended Use

This set of PT50 and PT100 post-mounted photocells is a motion sensor for automatic

gates (D-type according to EN 12453 standard) designed to detect obstacles located on

the optical axis between the transmitter (TX) and the receiver (RX). PT50 is equipped with

a sensitive element located approximately 450 mm from the ground; PT100 is equipped

with 2 sensitive elements, the rst one at a height of approximately 455 mm and the sec-

ond at approximately 915 mm from the ground. PT50 and PT100 may only be used in

combination with MHOUSE control units featuring ECSBus-type connections.

Installation

Warning: disconnect the power supply to the system before performing any installa-

tion operations; if the system is equipped with a PR1 buer battery, the latter must be

disconnected.

1. Choose the position of the two elements that make up the photocell (TX post and RX

post); observe the following directions:

•Place the posts on both sides of the area to be protected and as ush with the gate

as possible.

•Make sure that the ground surface is suciently compact, enabling the posts to be

secured using the screws and anchors provided; if necessary, you can use other

suitable anchoring systems.

•A conduit for the wires must be provided at the intended installation point in the

ground.

•Point the TX transmitter at the RX receiver, with a maximum misalignment of 5°.

2. Remove the upper cap [A] by prising it out with a slotted tip screwdriver (Fig.1).

3. Remove the glass front [B] by pulling and sliding it upwards (Fig.2).

4. Place the base of the post at the point reached by the cable conduit. Mark the

drilling points and drill the holes using a hammer drill tted with an 8 mm bit. Finally,

secure the post using the 3 screws [C] shown in Fig.3 and the corresponding

anchors supplied.

5. Connect the electric cable to the appropriate terminals on the TX and RX units

(Fig.4). From an electrical viewpoint, all the TX and RX elements must be connected

to each other in parallel (Fig.5) and to the “ECSBus” terminal on the control board. It

is not necessary to observe any polarity. To facilitate the above operations you can

remove the terminals, make the connections and then reinsert the terminals.

6. After testing the operation of the device, insert the glass front by sliding it in from the

top, then insert the top cap and press it down hard.

Addressing

To ensure the correct recognition of the photocells by the control unit, the photocells

must be addressed by means of suitable jumpers. Addressing not only ensures their

correct recognition in the ECSBus, but also serves to assign the detection function.

The addressing operation must be performed on both TX and RX (the jumpers must be

positioned alike), making sure that there are no other pairs of photocells having the

same address.

•If the post-mounted photocell is used to replace a pre-existing one, the jumpers must

be set exactly as they were in the old post.

•Any unused jumpers must be stored in their designated compartment for future use

(Fig.6).

•Since every automation system has its own individual characteristics, the photocells

can be positioned at various points to perform dierent detection functions. Check

Fig.7, Fig.8 and Fig.9 to identify the appropriate locations, and position the jumpers

as illustrated in table 1:

SLIDING GATES: see g. 7

SWING GATES: see g. 8

GARAGE DOORS: see g. 9

Note: only photocell “A” can be used on automations with MhouseKit GD1 - GD1N .

Note regarding photocell “G”: there are normally no restrictions concerning the posi-

tion of the two elements that make up the photocell (TX-RX). However, when photocell G

is used in conjunction with photocell B the elements must be positioned as shown in

Fig.7.

Original instructions

Device recognition

If the post-mounted photocell is used to replace a pre-existing one, no recognition proce-

dure needs to be carried out. However, if you add or remove devices connected to the

ECS Bus, the recognition procedure has to be carried out. In this case proceed as follows:

1. On the control unit, press and hold down button P2 [A] shown in Fig.10 for at least

three seconds, then release the button.

2. Wait a few seconds until the control unit has completed the device recognition

process.

3. When the recognition procedure has been completed, the P2 LED [B] shown in

Fig.10 will go o. If the LED ashes it means that something is wrong.

Checking the operation of the device

After completing the recognition procedure, check whether the SAFE LED [A] Fig.11

on the photocell (both TX and RX) starts ashing. See table 2 to identify the status of

the photocell based on the type of ashing.

Testing

Warning: after adding or replacing any post-mounted photocells, you need to test the

entire automation system anew following the instructions found in the relevant installa-

tion manuals under the “Testing and set-up” chapter.

•To check the post-mounted photocells and make sure that there is no interference

with other devices, pass a 5 cm diameter, 30 cm long cylinder (Fig.12) on the optical

axis, rst near TX, then near RX and nally at the mid-point between them and make

sure that in all these cases the device is triggered, switching from the active to the

alarm status and vice-versa; nally, that it causes the intended action in the control

unit, for example, that it causes the reversal of the direction during the closing

manoeuvre.

Technical characteristics

PT50 and PT100 are produced by NICE S.p.a. (TV) I, MHOUSE S.r.l. is an aliate of the Nice S.p.a.

group.

Nice S.p.a., in order to improve its products, reserves the right to modify their technical characteris-

tics at any time without prior notice. In any case, the manufacturer guarantees their functionality and

tness for the intended purposes.

Note: all the technical characteristics refer to a temperature of 20°C.

Type: Post with motion detectors for automatic gate and door openers (type D

according to EN 12453) consisting of pairs of “TX” transmitters and “RX” receivers

Sensitive elements: PT50 : No.1, at approx. 450mm from the ground; PT100 : No.2,

the rst at 455mm and the second at 915mm from the ground Technology adopt-

ed: Optical, by means of direct TX-RX interpolation with a modulated infrared ray

Detection capacity: Opaque objects located on the optical axis between TX and RX,

whose dimensions exceed 50 mm and whose speed is less than 1.6m/s TX trans-

mission angle: Approx. 20° RX reception angle: Approx. 20° Useful range: Up

to 10m, with maximum TX-RX misalignment of ± 5° (the device can signal the presence

of obstacles even under very adverse weather conditions) Power supply/output:

The device may only be connected to “ECSBus” networks from which it is supplied

with power and sends the output signals. Absorbed power: PT50 : 1 ECSbus unit;

PT100 : 2 ECSbus units Maximum cable length: Up to 20 m (observe the warnings

in the control units regarding minimum gauge and type of cables) Addressing capa-

bility: Up to 7 detectors with protection function and 2 with opening control function.

The automatic synchronization prevents any interference between detectors. Ambi-

ent operating temperature: -20 ÷ 50°C Use in acid, saline or potentially explo-

sive at mosphere: No Mounting: On at ground surface Protection class: IP55

Dimensions / weight (TX and RX): PT50 : Ø 70, h 485 / 656g*; PT100 : Ø 70, h 945 /

1207g (* for details on the anchoring base see gure 3)

Declaration of Conformity

According to Directive 89/336/EEC

Number 160/PT50/GB

Date: 05/02/2003 Revision: 0

The undersigned Lauro Buoro declares that the following product:

Manufacturer’s name: NICE S.p.a.

Address: Via Pezza Alta 13, 31046 Z.I. Rustignè - ODERZO - ITALY

Model: PT50; PT100

Meets the essential requirements of Directive 89/ 336/EEC concerning electromagnetic compatibility.

)rotceridgniganaM(orouBoruaL3002-20-50,OZREDO

Photocell Jumper

A“Bottom” photocell trips

when gate is closing

B“Top” photocell trips when

gate is closing

C“Bottom” photocell trips

when gate is opening

and when it is closing

D“Top” photocell trips when

gate is opening

and when it is closing

Photocell Jumper

E“Right-hand” photocell

trips when gate is opening

F“Left-hand” photocell trips

when gate is opening

GFor “sliding” gates only

“Single” photocell covers

the entire automation

system, tripping when

gate is opening and when

it is closing

TABLE 2

LED SAFE

Spento

3 quick ashes and

1 second’s pause

Very slow ashes

Slow ashes

Quick ashes

Very quick ashes

Always on

Status

The photocell is either faulty

or not powered

Device not recognized by the

control unit

TX transmits regularly. RX re-

ceives a very good signal

RX receives a fairly good signal

RX receives a poor signal

RX receives a very poor signal

RX does not receive any si-

gnal

Action

Make sure that there is a voltage of

approximately 8-12 Vdc on the

photocell terminals; if the voltage is

correct, the photocell is probably

faulty

Repeat the recognition procedure.

Make sure that each pair of photo-

cells has a dierent address

Normal operation

Normal operation

Normal operation, but check the

TX-RX alignment and clean the

glass surfaces

The device is operating at maxi-

mum limit for normal operation,

check the TX-RX alignment and

clean the glass surfaces

Check whether the LED on the TX

is ashing very slowly. See if there

are any obstacles between TX and

RX; check the TX-RX alignment