Nitroset NTS8X Use and care manual

NTS8X Tool Operation

& Safety Manual

VER 18.8

US Patent: US8397969B2

Additional Patents Pending

Table of Contents

Warnings and Safety Precautions

Basic Instructions

Required Safety & Protective Equipment

Misuse of the Tool

General Safety Precautions

Spall Guard Usage Instructions

Worksite Preparation

Acceptable Base Materials

Inappropriate Base Materials

Check Before Fastening

NTS8X Universal Nosepiece

Adapter Usage Table

Operating Instructions

Loading and Actuating Instructions

Using NITROSET® Tool with a NITROSET® Pole

DOs and DON’Ts

DOs

DO NOTs

Troubleshooting Guide

Changing the Firing Pin

Tool Disassembly

Tool Assembly

Cleaning Procedure

NITROSET® Tool Full Cleaning Procedure

Interim Cleaning Procedure

Parts List & Diagram

Parts List

Parts Diagram

3

3

3

4

4

5

5

5

6

7, 8

8

9

10

11, 12

13

14

15

16

16

17

18

DO NOT OPERATE THE NITROSET TOOL

UNLESS YOU HAVE COMPLETELY READ

AND UNDERSTOOD THE OPERATION

AND SAFETY MANUAL

WARNING

Training is required for use of this tool.*

*Please contact your local distributor or visit www.nitroset.com for more information.

You are required to understand and follow all safety instructions for proper and

safe use of NITROSET® tools. If you require any assistance, please contact your

jobsite safety foreman or call Nitroset, LLC. at 1.800.524.4649.

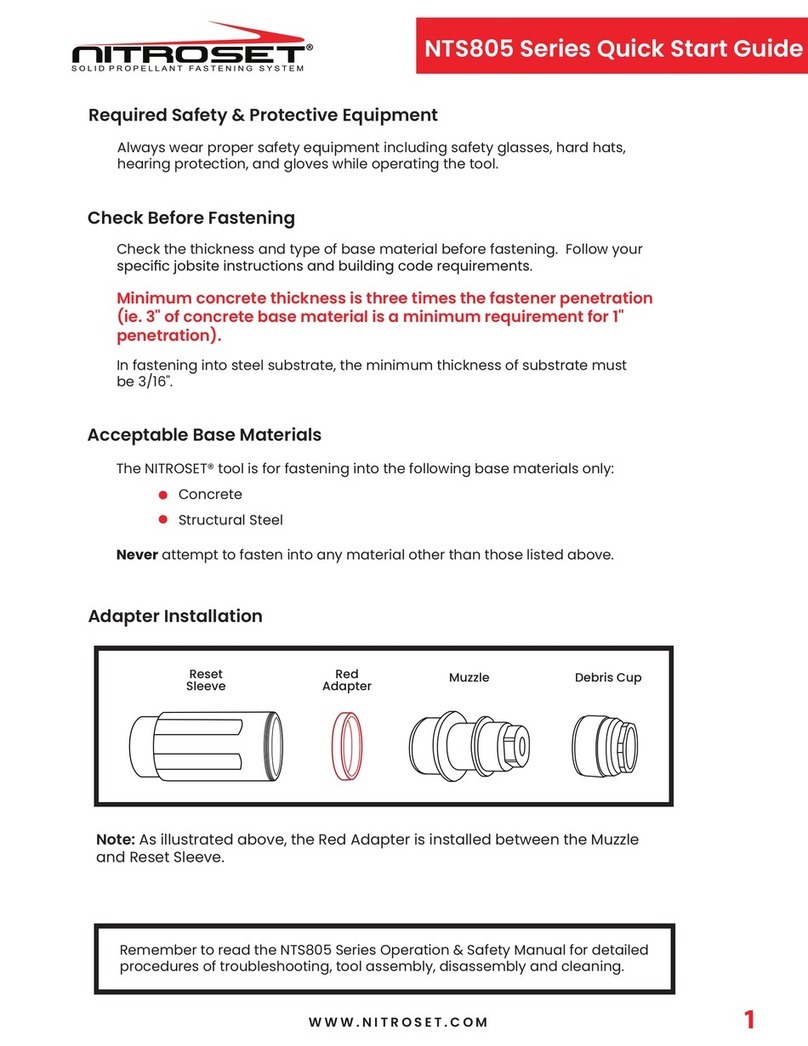

Always wear proper safety equipment including safety glasses, hard hats,

hearing protection, and gloves while operating the tool.

Manipulation or modification of the tool is not permitted. Any alteration of the

tool or use of non-genuine NITROSET® parts might impair function or cause

damage to the tool. Use of non-genuine parts will void any warranties.

Do not operate in an explosive or inflammable environment.

Never put your hand over the nosepiece of the tool.

Never point the tool at yourself or any bystanders.

Never press the nosepiece against any part of your body or anyone else’s body.

Only fasten into appropriate substrates. Use of inappropriate substrates may

cause injuries.

Never attempt to disassemble, modify or alter the fastener assemblies. Use only

the required length and type of pin (with correct adapter) for the application

(Refer to the Adapter Usage Table on Page 6).

Use only genuine NITROSET® Fasteners with the NITROSET® system. Use of

incorrect fasteners might lead to injury or damage to the tool.

Required Safety & Protective Equipment

Basic Instructions*

Safety Precautions

WWW.NITROSET.COM

Misuse of the Tool

*According to ANSI A10.3 and DOT (ref: EX2009040168) NITROSET® tools are not classified as a powder

actuated tool, thus no licensing is required.

3

CAUTION

Face shield

(recommended)

CAUTION

Wear hard

hats

CAUTION

Wear hearing

protection

CAUTION

Wear safety

gloves

CAUTION

Wear safety

glasses

WWW.NITROSET.COM

Safety Precautions

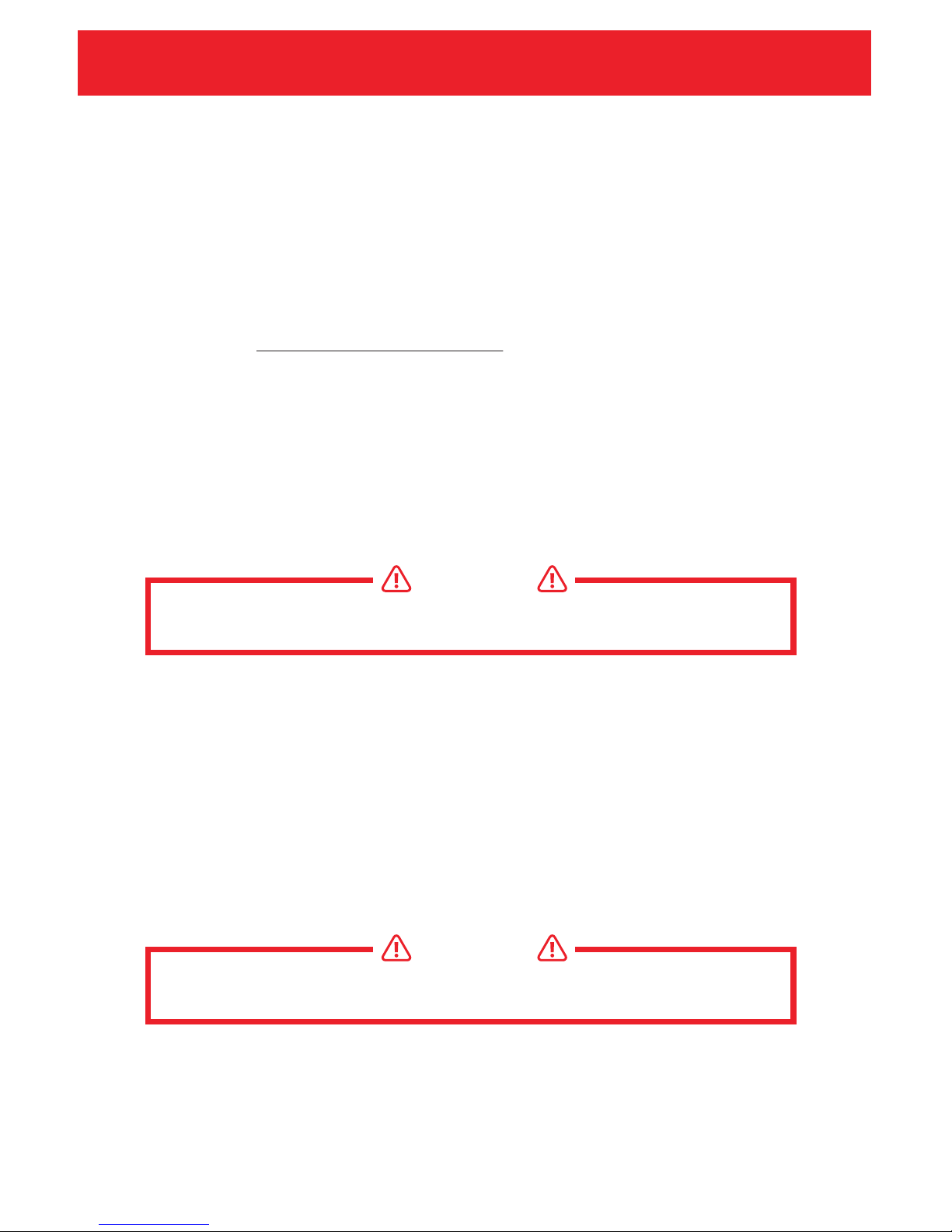

Install appropriate spall guard to nosepiece.

Ensure spall guard is installed flush.

Install the spall guard clip to the nosepiece to hold spall guard in place.

Round Spall Guard - Use with Pins & Pins with Washers

Spall Guard with Cut - Use with Fastener Assemblies with Clips

General Safety Precautions

Round Spall Guard Spall Guard with Cut

For Pins & Pins with Washers

Spall Guard Usage Instructions

For Clip Assemblies

SPALL

GUARD

CLIP

ROUND SPALL GUARD

SPALL

GUARD

CLIP

SPALL GUARD WITH

CUT

DEBRIS

CUP

MUZZLE

DEBRIS

CUP

MUZZLE

b

a

4

Inspect the tool to ensure that the tool is complete, undamaged, and all parts

are secure prior to use. Damaged parts should be replaced using genuine

NITROSET® parts.

Insert the fastener assembly completely into the muzzle to ensure the

correct function of the tool. Fasteners that do not completely insert into the

muzzle should not be used and should be disposed of appropriately.

Never leave a loaded tool unattended. Only load the tool prior to fastening.

The NITROSET® tool should be reset after every actuation to clear any debris

from the nosepiece (muzzle+debris cup) of the tool.

The trigger body and reset sleeve should be held in place when loading a fastener.

Always remove fasteners and any debris from the muzzle prior to cleaning,

servicing, maintenance, or storage of the tool.

Always hold the tool securely and perpendicular to the working surface when

making a fastening.

Use the NITROSET® round or cut spall guard with clip to prevent concrete spall.

The NITROSET® tool is NOT for fastening into the following base materials:

Wood

Drywall

Glass

Tile

Rock

These materials may shatter causing the fastener or base substrate to

fly free and might cause serious injury to the operator or bystanders.

WWW.NITROSET.COM

Worksite Preparation

The NITROSET® tool is for fastening into the following base materials only:

Concrete

Structural Steel

Check the thickness and type of base material before fastening, following

your specific jobsite instructions and building code requirements.

In fastening into steel substrate, the minimum thickness of substrate must

be 3/16".

Minimum concrete thickness is three times the fastener penetration

(ie. 3" of concrete base material is a minimum for a 1" penetration).

Never attempt to fasten into any other materials other than those listed above.

Acceptable Base Materials

Inappropriate Base Materials

Check Before Fastening

5

WWW.NITROSET.COM

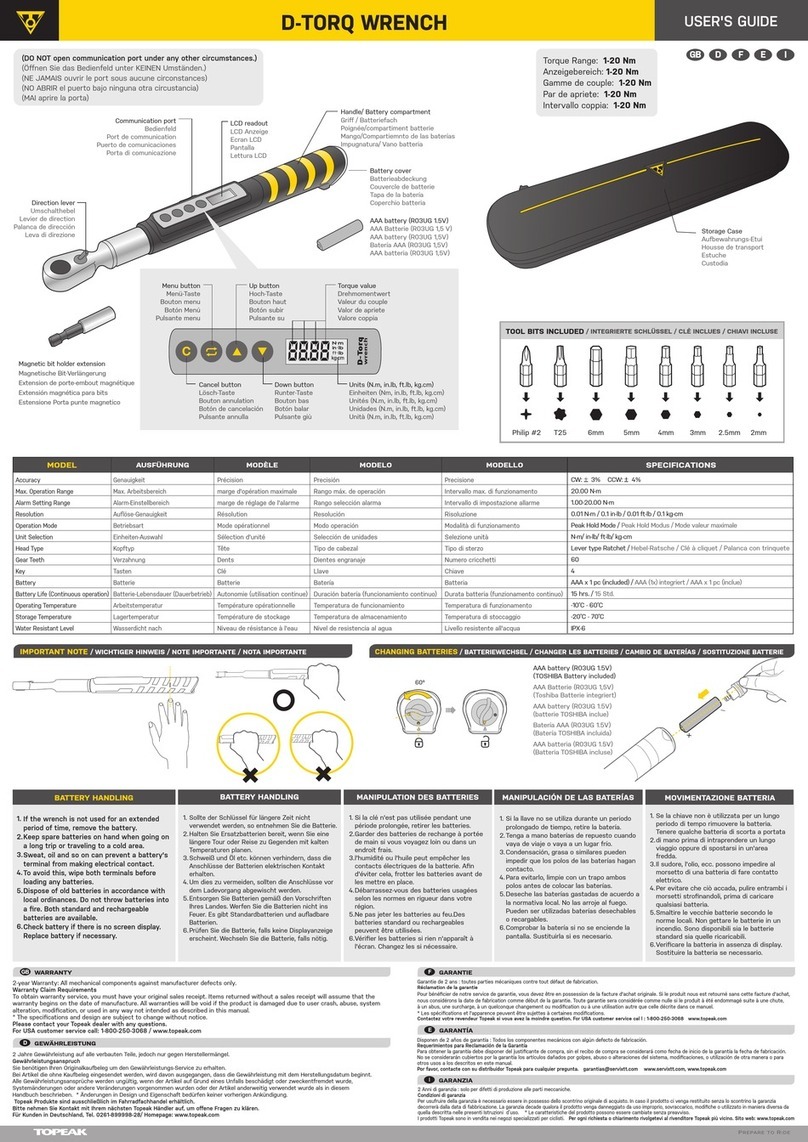

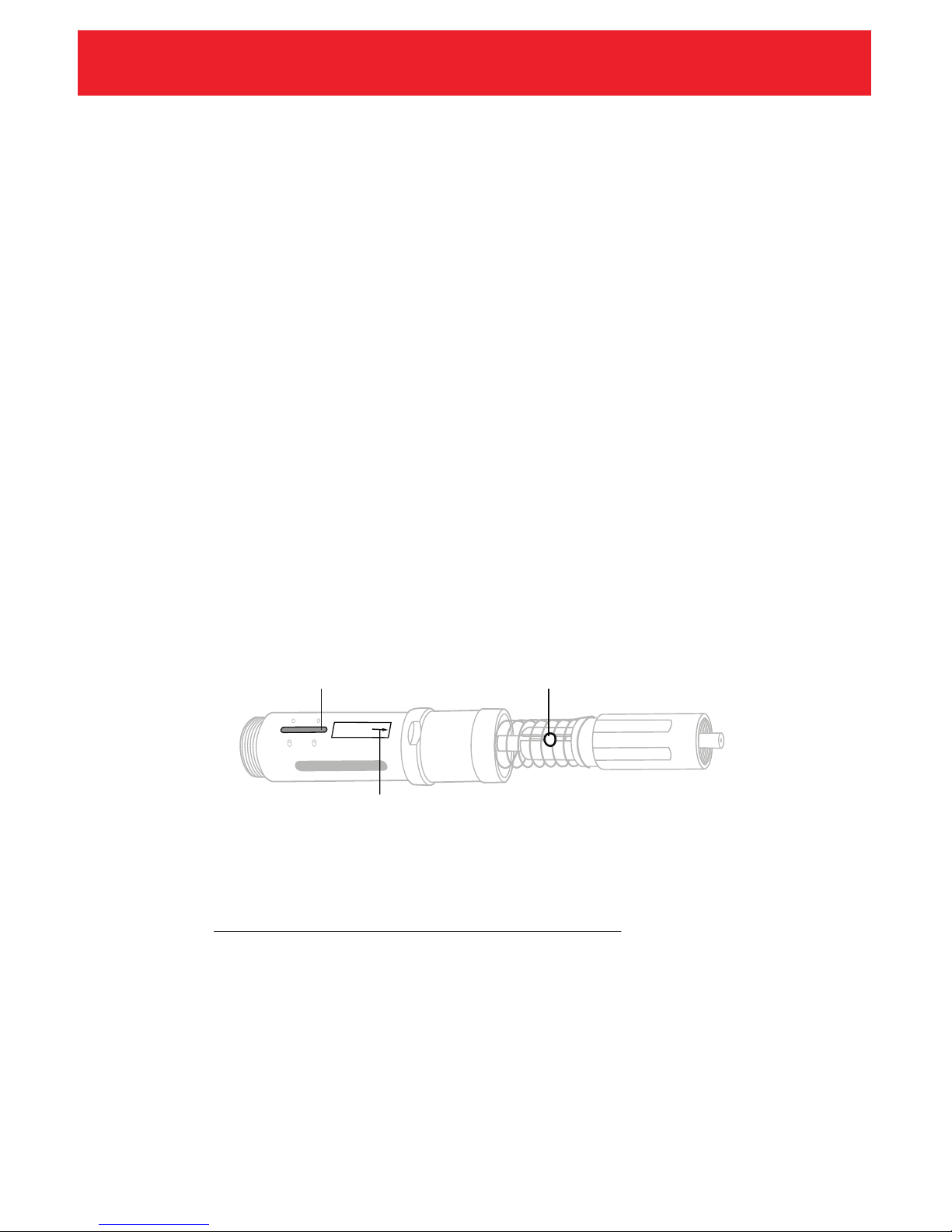

NTS8X Universal Nosepiece

The universal nosepiece with two different adapters (NTS101-1S-C3-C) will be used

for different length pin or clip assemblies.

Note: Adapter is placed between the muzzle and the reset sleeve.

Adapter Usage Table

6

Adapter

Requirement

No Adapter

Needed

With A-Adapter

(Red)

With B-Adapter

(Blue)

Types of Pin and Pin/Clip Assembly

CLAS532, CLSUPL532, PIN532NW, STT14*

CLAS525, CLSUPL525, CLRHD14-525, PIN222, PIS525W

*Use NTS101-1-ST Nosepiece with A-Adapter (Red) for STT14.

A-Adapter B-Adapter Muzzle Debris Cup

NTS101-1S-C3-C

CLU222,

CLS222S,

CLR14-222,

CLR38-222,

CLT219,

CLC38-222,

CLC12-222,

CLC34-222,

CLC1E-222,

CLR14222-BRT114

PIN219,

PIN219T,

PIN222W,

PIN222SW,

PIN319,

PIK313,

PIK316,

PIS222W

REMEMBER

Always use correct adapter for different types of pin and pin/clip assembly.

Please refer to Adapter Usage Table below.

WWW.NITROSET.COM

Operating Instructions

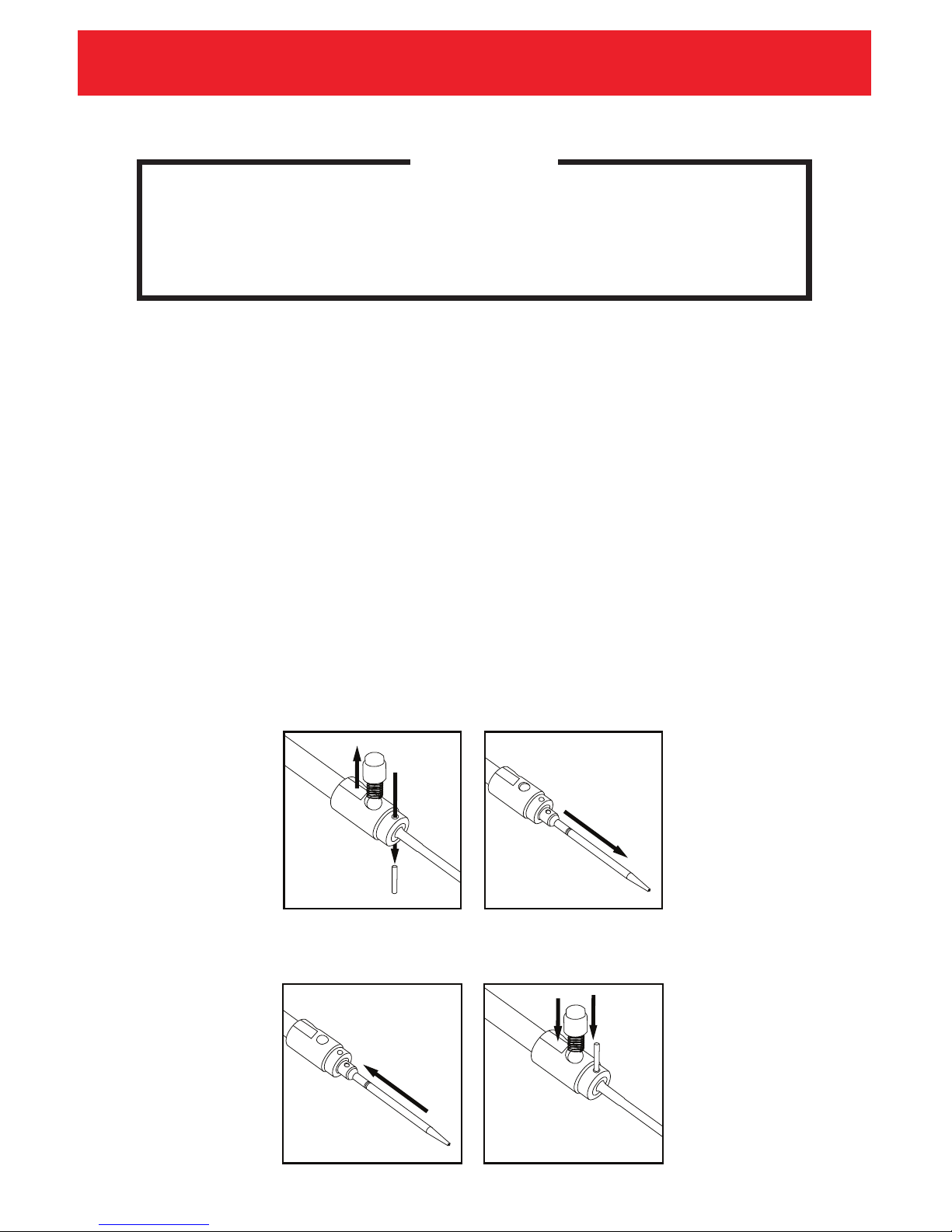

1. Reset the tool before each fastening to ensure the muzzle barrel is clear

of any debris.

2. Insert the fastener fully into the muzzle of the tool. Fasteners must be fully

seated in muzzle to ensure proper actuation.

(Hold reset sleeve before inserting fasteners)

3. Place the NITROSET® tool perpendicular against the fastening surface.

A) Pull back on front of muzzle until reset spring fully collapses.

B) Ensure firing pin guide clears all debris from muzzle chamber

prior to inserting new fastener assembly.

In case of jammed fasteners – Refer to the Troubleshooting Guide (Page 11) for

proper removal of all jammed fasteners.

Loading and Actuating Instructions

7

If the fastener assembly cannot be inserted into the muzzle, do not force the

fastener into the muzzle. This can jam the fastener in the tool and damage

the fastener. Fasteners that cannot be inserted should be removed and

discarded appropriately.

WARNING

Fasteners should not be driven close to the edge of the base

substrate.

Always maintain a distance of at least 3" from the concrete

edge or 1" from the steel edge.

Too close to edge

WARNING

Cracked concrete may cause loud noise when using the tool.

WWW.NITROSET.COM

Operating Instructions

4. Position the tool and push directly to feel the engagement of the firing

spring. Follow with a smooth and forceful motion to compress the firing

spring to trigger the firing mechanism. This is the correct fastening

procedure to minimize spalling and noise.

5. Reset the tool to ensure the muzzle barrel is clear of debris and repeat

from Step 1 to 4.

If the tool fails to fasten, remove the spent fastener assembly while pointing

the tool away from yourself and any bystanders.

The use of NITROSET® pole is recommended for maximum eciency on ceiling

fastening applications. The end of the wire assembly should be placed inside the

pole for better control. Actuate by following the actuating instructions as detailed.

Using NITROSET® Tool with a NITROSET® Pole

8

When using an electrically conductive or metallic pole, be sure to maintain a

minimum 10 ft clearance from all electrical lines to avoid electrical hazard.

WARNING

After the tool has been in use, the muzzle and other parts may be hot.

Always wear gloves to handle these areas.

WARNING

IMPORTANT: DO NOT BOUNCE FIRE THE TOOL!

WWW.NITROSET.COM

DOs and DON’Ts

DO read and understand the correct and safe usage instructions for the

NITROSET® Fastening System.

DO recognize that operator and bystander safety is the most important factor

when considering a NITROSET® tool application.

DO wear safety goggles and other suitable personal protective items while

using NITROSET® tool.

DO ensure all individuals working in the same area as those using the

NITROSET® system also are wearing proper safety equipment.

DO make sure when fastening into concrete, the base material thickness is at

least 3 times the shank penetration.

DO make sure when fastening into steel substrate, the minimum thickness of

the substrate must be 3/16".

DO use correct adapter for different types of pin and pin/clip assembly.

DO make sure that the tool is firmly flat to the surface before fastening.

DO reset the tool pointed away from yourself and any bystanders and eject any

debris from muzzle piece before inserting the fastener into the barrel.

DO remove defective tools, parts and/or accessories from service immediately.

DO only use the correct tools to disassemble the NITROSET® Tool. Use of pipe

wrenches or vise grips can damage the tool.

DO only use genuine NITROSET® repair parts. Any parts from dierent

manufacturers might impair function or cause damage to the tool and lead to

injury.

DO clean the tool daily and empty the debris cup every 500 fastenings or as

needed.

DOs

9

WWW.NITROSET.COM

DOs and DON’Ts

DO NOT use NITROSET® tools to fasten into brittle materials such as brick, tile,

rock or glazed material.

DO NOT attempt to drive fasteners into soft materials such as wood or drywall

or light gauge metal.

DO NOT attempt to drive fasteners into hardened steel, cast iron, or natural rock

such as marble.

DO NOT drive fasteners into base steel thinner than the shank diameter of the

fastener.

DO NOT fasten into cracked or spalled areas of concrete.

DO NOT drive fasteners closer than 3" to the edge of the concrete materials and

1" to the edge of steel base materials.

DO NOT use NITROSET® tools in a hazardous environment.

DO NOT use the tool prior to ensuring that all parts are in good working order

and securely attached to the tool. All parts should be fully threaded and hand

tight.

DO NOT place hand over the muzzle end to reset the tool.

DO NOTs

10

WWW.NITROSET.COM

Troubleshooting Guide

A) If cycling the tool does not clear the jammed fastener, remove the

nosepiece completely. The jammed fastener can then be removed

from the other end.

B) DO NOT strike the tool against the substrate to dislodge the fastener.

C) If the fastener remains permanently jammed, please contact the

appropriate support personnel.

A) Check if you are fastening to the appropriate substrate material.

B) Check the nosepiece is free of debris and reset the tool.

C) Check if the correct adapter is being used (Refer to Adapter Usage

Table on Page 6).

D) Ensure the tool is assembled properly according to the manual and

instructions.

E) Before firing, make sure the nosepiece is perpendicular (right angle) to

the material surface. The tool is not designed to fasten at other angles.

F) Check if the firing pin is piercing the NITROSET pill. If it's piercing the

pill and not firing, then check for damage to the firing pin. Replace

firing pin if damaged.

G) If the tool still does not actuate after checking all the above, follow the

instructions (Page 14) and disassemble to check for broken parts.

11

I. The fastener is jammed inside the nosepiece.

II. The tool does not fire.

Lorem Lorem ipsum dolor sit

amet, consectetuer adipiscing

elit, sed diam nonummy nibh

Make sure the trigger key is in line with the trigger ball release

The guiding arrow may wear out, use the trigger key

as a guide in such occurrence

WWW.NITROSET.COM

Troubleshooting Guide

A) Check if you are fastening to the appropriate substrate material.

B) Check if the correct adapter is being used.

C) Before firing, make sure the nosepiece is perpendicular to the material

surface. The tool is not designed to fasten at other angles.

D) Check and clean the debris cup. Ensure the vents in the debris cup are

clear of debris.

E) Ensure the debris cup and muzzle are securely fastened to the tool.

A) Ensure the tool is assembled properly according to the manual and

instructions.

B) Clean and lubricate according to the operator's manual.

C) Check that the springs are clean and straight.

A) Disassemble the tool and check to see if the buer is in place. This part

acts as a shock absorber. Damage to the tool is possible if used without

the buer properly inserted.

B) Clean to the tool to ensure no debris has gotten into the main body of

the tool.

If all of the above fails, please contact your local supplier's technical support

personnel to address the issues or visit our website at:

12

III. The tool fires loudly.

IV. The tool is dicult to depress and fire.

V. Firing Pin Holder and Guide are damaged.

REMEMBER

WWW.NITROSET.COM

WWW.NITROSET.COM

Changing the Firing Pin

1. Use the provided roll pin punch to knock out the 1/8" roll pin.

2. Remove the worn firing pin from the firing pin holder

3. Seat a new 1/8" roll pin into the holder. Do not insert the roll pin completely.

4. Insert a new firing pin into the slot in the firing pin holder. Ensure that the

holes on the back of the firing pin line with the holes in front of the holder.

5. Using a hammer, fully insert the 1/8" roll pin.

6. Reinstall the trigger spring and trigger ball release into the appropriate slot

on the firing pin holder.

7. While depressing the trigger ball spring, insert the firing assembly into the

firing pin guide.

When removing the firing pin, depress the trigger ball release, and guide the

pin out.

Keep the trigger ball release depressed until the pin exits the guide, otherwise

the spring will propel the trigger ball away.

13

REMEMBER

Assembly

Disassembly

WWW.NITROSET.COM

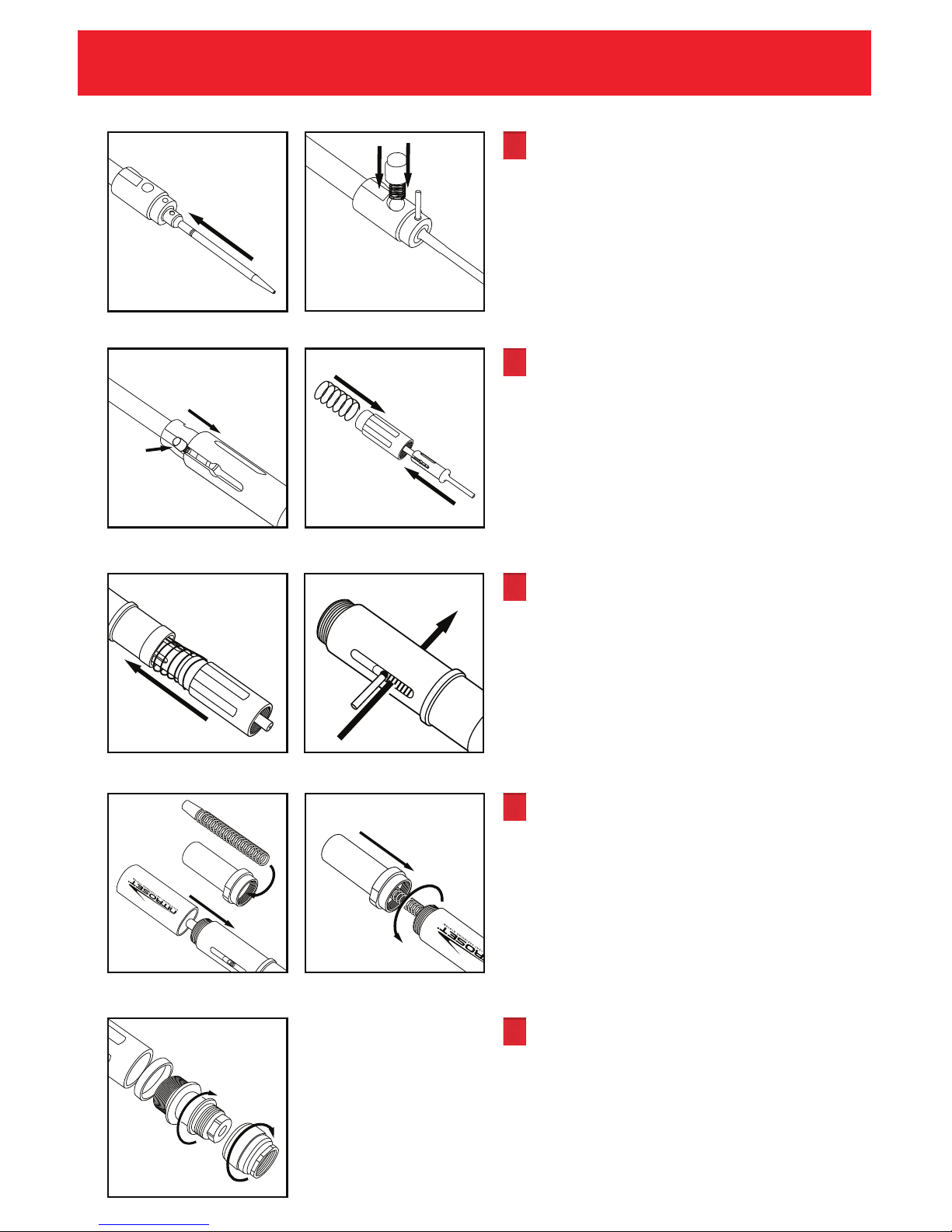

Tool Disassembly

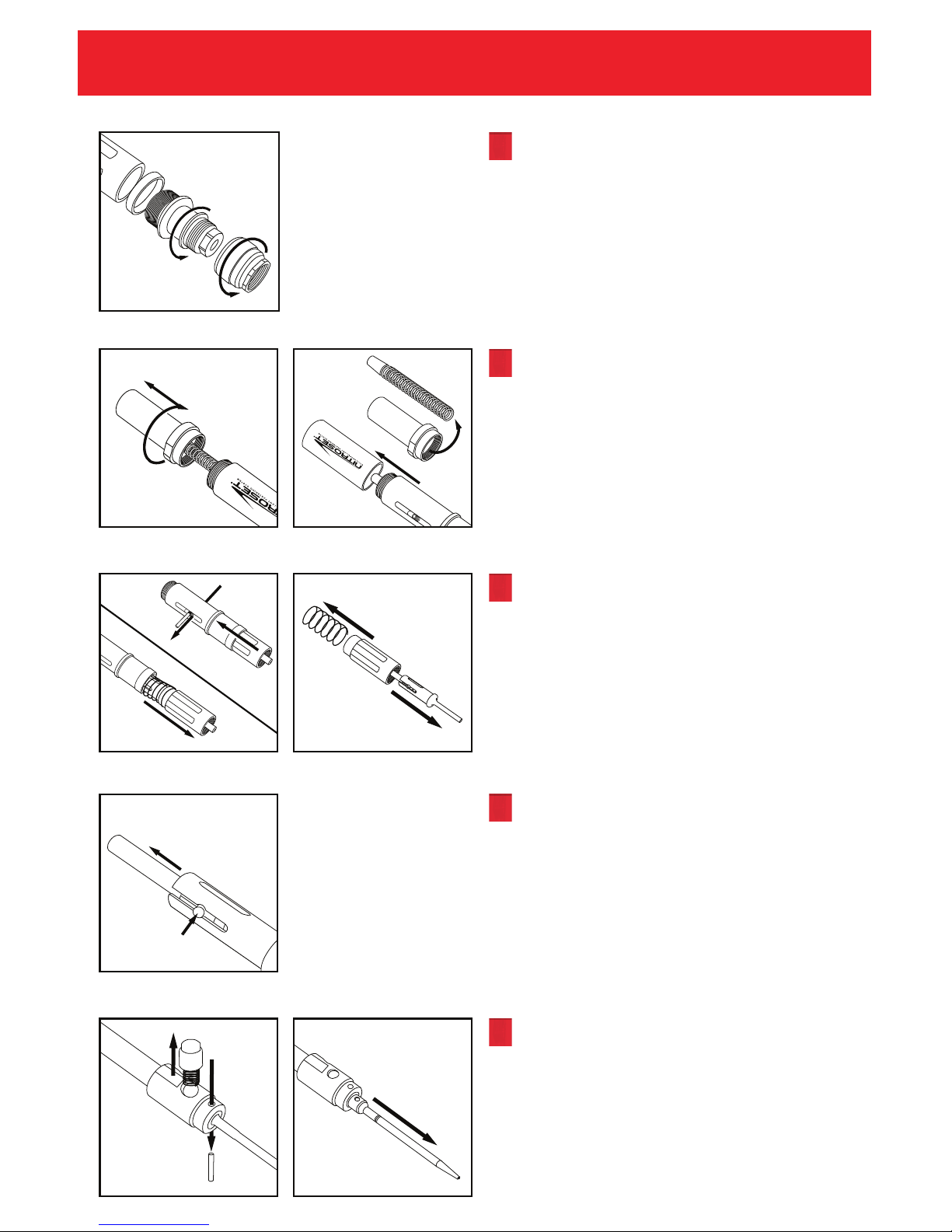

2

2

1

1

1

2

Remove Debris Cup from the Muzzle.

Remove Muzzle from the Reset Sleeve.

Use the included wrenches for

assistance as necessary.

Slide the Adapter off the threads of the

Muzzle as necessary.

Remove the End Cap from the tool.

Slide the Firing Spring off the tool. Note

the Buffer is attached to the end of the

Firing Spring. Check condition of Firing

Spring and Buffer.

Slide off the Outer Cover Sleeve.

Depress the Reset Spring to collapse

the Reset Sleeve. This will loosen the

Main Assembly Pin and allow it to be

removed from the tool.

Slide the Main Firing Assembly from

the main body of the tool.

Depress the Trigger Ball Release to

compress the Trigger Ball Spring and

slide the Firing Pin Assembly from the

Firing Pin Guide.

Keep pressure over the Trigger Ball to

hold it in place while removing the

assembly. Releasing the Trigger Ball

may cause it to spring up.

Once the Firing Pin Assembly has been

removed from the Guide, slowly

release the Trigger Ball and remove it

from the Firing Pin Holder.

To remove the Firing Pin, use the

provided firing pin punch and knock

out the 1/8" Roll Pin.

14

WWW.NITROSET.COM

Assemble Firing Pin into Firing Pin

Holder using the 1/8" Roll Pin.

Insert Trigger Ball Spring into Trigger

Ball Release and place into the Firing

Pin Holder.

Slide complete Firing Assembly into

the Guide while depressing the

Trigger Ball Release until it clicks into

the Guide.

Insert Guide and Holder through the

Reset Sleeve. Attach Reset Spring to

Reset Sleeve.

Insert Reset Sleeve into the Trigger

Body. Make sure the trigger key on

the body aligns properly with the

Trigger Ball Release.

Insert Main Assembly Pin. Ensure

coils of the Reset Sleeve are all above

the pin.

Slide Outer Cover Sleeve over the

Trigger Body.

Insert the Firing Spring with the Buffer

attached over the Holder.

Attach the End Cap of the tool.

Secure the Debris Cup to the Muzzle.

Slide appropriate Adapter onto the

Nosepiece.

Secure the complete Nosepiece

Assembly onto the Reset Sleeve.

Tool Assembly 15

2

1

WWW.NITROSET.COM

Cleaning Procedure 16

1. It is recommended that the NITROSET® tool be cleaned every day after use.

Proper maintenance and cleaning of the tool enables the tool to operate at

peak performance.

2. First, be sure all fastener assemblies and debris are ejected from the tool by

resetting it pointed away from yourself or any bystanders.

3. Remove the muzzle by unscrewing it from the tool shank. Then, remove the

end cap and disassemble the entire tool following the tool disassembly

instructions (Page 14).

4. Empty the debris cup.

5. To clean, you should use diluted industrial cleaner and degreaser similar to

Strike-Hold or other similar non-oil base degreaser to spray or wipe the tool

surface. Allow contact time of 3 to 5 minutes before scrubbing. Rinse with

water and wipe it dry with towel or paper.

6. Re-assemble the tool (Page 15).

NITROSET® Tool Full Cleaning Procedure

1. Empty the debris cup after every 500 fastenings, or as needed to optimize

performance.

2. A liquid shot of degreaser lubricant at approximately every 500 to 1000

fastenings is recommended to maintain a smooth operation.

3. This will help tool performance and actuating consistency, making your

end-of-day cleaning easier.

Interim Cleaning Procedure

WWW.NITROSET.COM

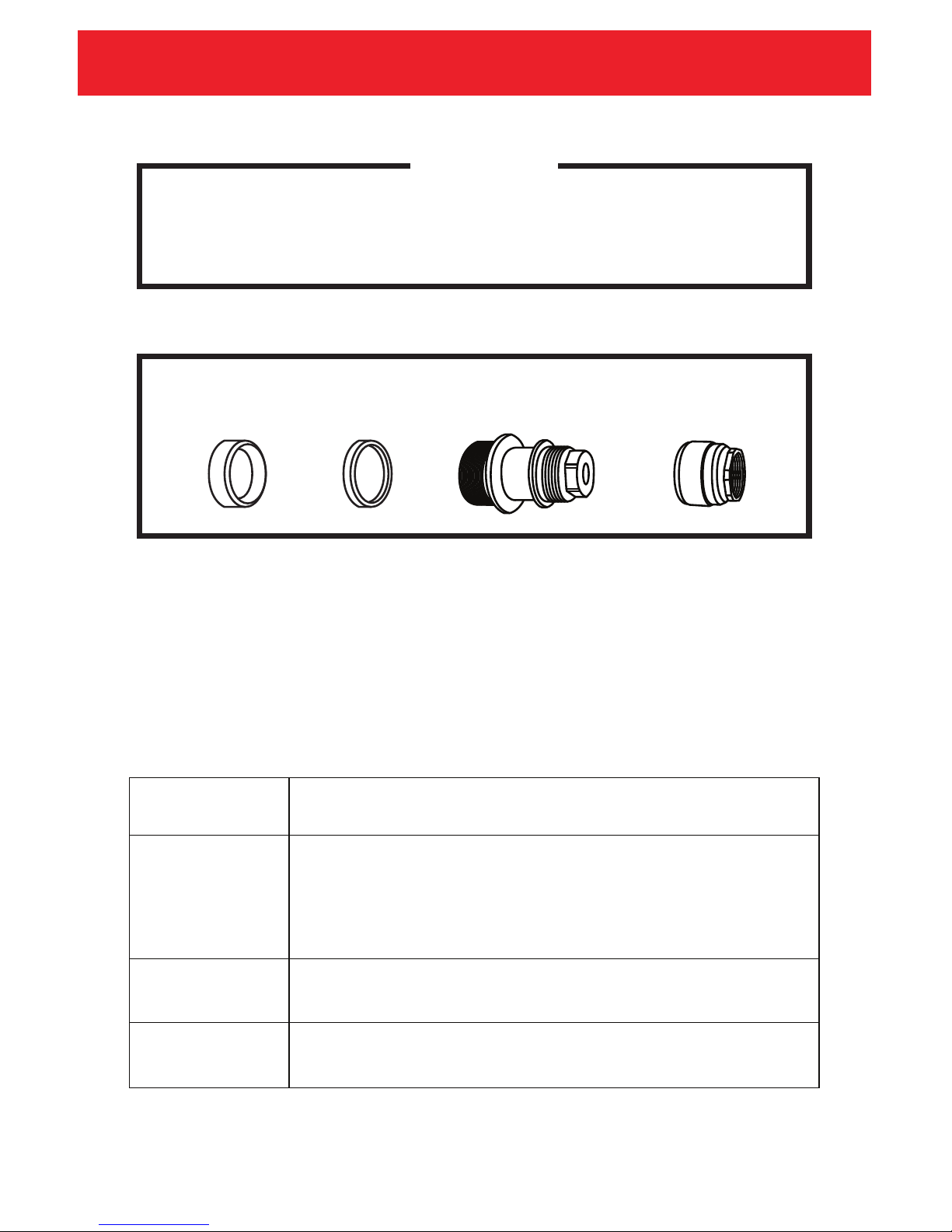

Parts List 17

1/8" Roll Pin

NTS1018

Trigger Ball Release

NTS1017

Nosepiece Rubber Gasket

NTS10129

Spall Guard*

NTS1010C

Firing Pin

NTS1014

Firing Pin Holder

NTS1016

Trigger Ball Spring

NTS1015

Firing Pin Guide

NTS5X3

Firing Spring

NTS1019SOTCS

Spall Guard Clip*

NTS1010U

Debris Cup

NTS1012C

Muzzle

NTS101C3

Debris Cup Rubber Gasket

NTS10130

Outer Cover Sleeve

NTS5X14

End Cap

NTS5X15

Buffer

NTS10116

Triple Play Extension*

NTS10118

Reset Spring

NTS5X11

Reset Sleeve

NTS8X10

1/4" Main Assembly Pin

NTS5X12

Trigger Body

NTS5X13

Hand Grip*

NTS10119

* These parts are included in the tool kit.

Blue/Red Adapter*

NTS10117

WWW.NITROSET.COM

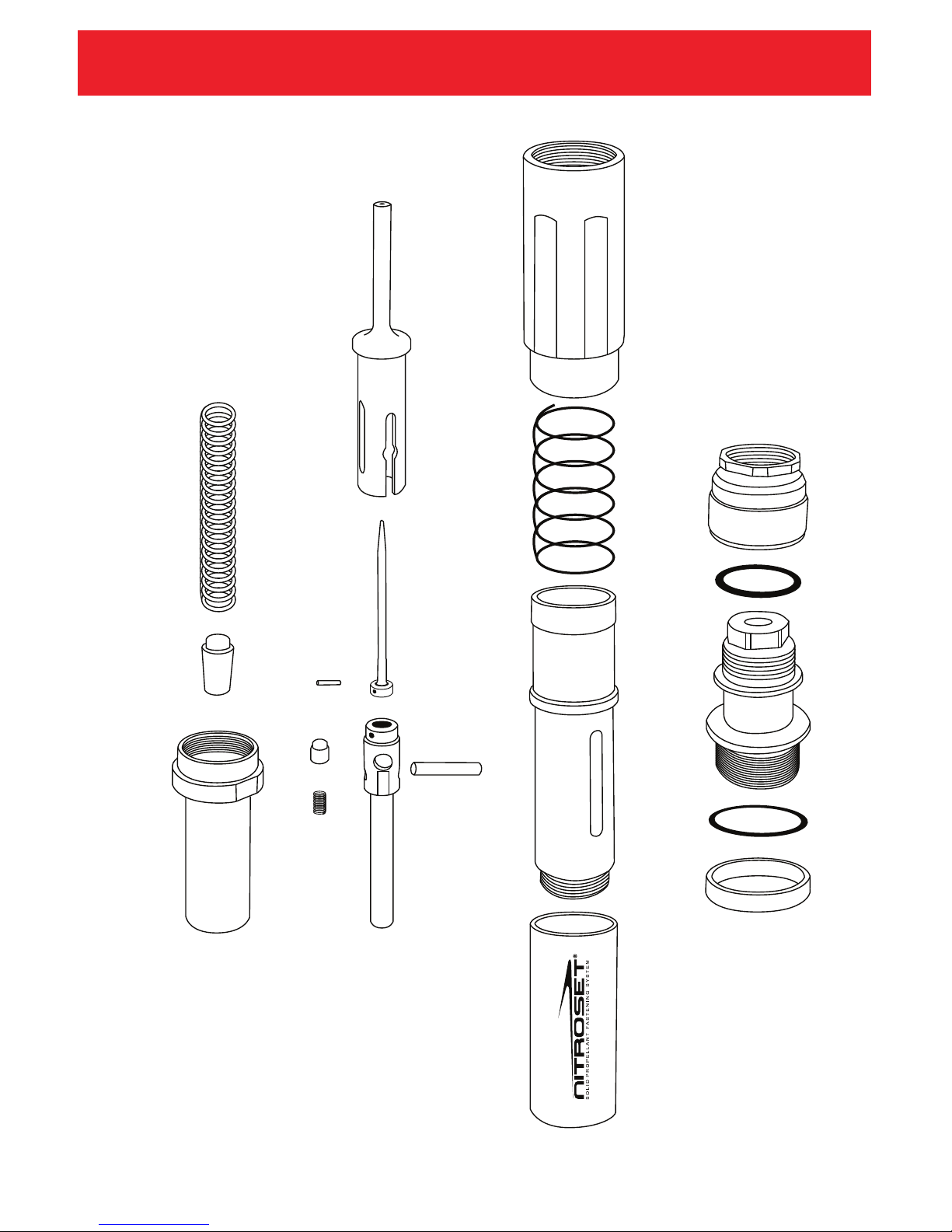

Parts Diagram 18

NTS5X3

NTS1017

NTS1015 NTS5X12

NTS1018

NTS1014

NTS1016

NTS10116

NTS1019SOTCS

NTS5X15

NTS5X10

NTS5X11

NTS5X13

NTS5X14

NTS1012C

NTS101C3

NTS10130

NTS10129

NTS10117

* Parts in this diagram are to scale.

5600 Bonhomme Rd., Ste. D

Houston, TX 77036

Tel: 1.800.524.4649 Fax: 713.781.5677

www.nitroset.com

Nitroset One-Year Limited Warranty

• Nitroset, LLC. offers a one-year limited warranty on the Nitroset

Fastening Tools against manufacturing defect from the date

of purchase.

• The manufacturing defect warranty covers performance

issues of the covered parts.

• Excluded are normal wear and tear parts, improper

maintenance, improperly handling, alteration, abuse, neglect,

accident, vandalism, theft, fire, water, or damage because of

other peril or natural disaster.

• The determination if the tool is covered by defect warranty is

at the sole discretion of Nitroset, LLC. We reserve the right to

repair or replace the item with like and kind products.

• The product owner is responsible for inbound shipping costs.

Excluded from all warranties are inbound freight and postage

or freight losses.

• Damage resulting from the installation or use of any part,

accessory, or attachment not approved by Nitroset, LLC for

use with the products(s) will void the warranty as to any

resulting damage.

• The warranty is non-transferable and limited exclusively to the

original purchaser.

All warranty returns for repair must include a Return Merchandise Authorization (RMA) number

obtained from a Nitroset representative. The claim product must be sent at customer’s

expense to Nitroset, LLC. for evaluation. Unauthorized returns without RMA will not be accepted.

Table of contents

Other Nitroset Tools manuals