Nixie UNIVERSAL TUBE CLOCK KIT Installation instructions

UNIVERSAL NIXIE TUBE CLOCK KIT

Assembly instruction and user manual

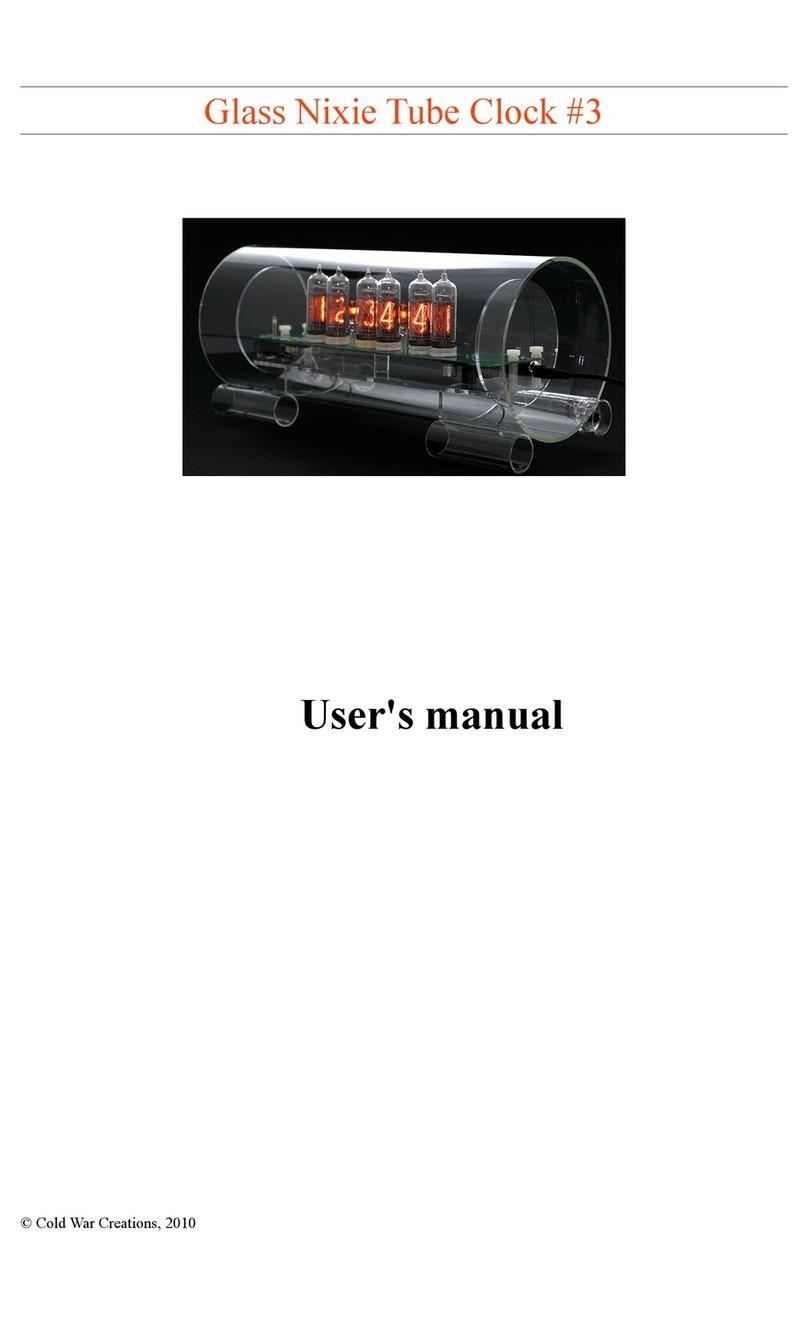

Bring to your home a piece of history with The Vintage Nixie Clock and its Cold War era

components. The clock will give a cosiness and a uniqueness for your house.

2

Introduction

This parts kit intended for an electronics hobbyists that want to make a Nixie clock and do not want

go deep to complicated clock control electronics and software. This instruction step-by-step assists

you to assemble the clock.

The kit consists all necessary electronics parts (excluding Nixie tubes and power adapter) and a

microcontroller with pre-programmed an application software.

The main features of the clock

Hours, Minutes and Seconds display

12 or 24 hour operation modes

Time accuracy is provided by built-in RTC (Real Time Clock) based on extremely precise

DS3231 module with temperature compensation and backup with CR2032 battery

Programmable leading zero blanking

Date display in either DD/MM/YY or MM/DD/YY format

Alarm

Simple time setting using three buttons

Standard, crossfade and scrollback display modes

“Slot Machine” Cathode poisoning prevention routine

Programmable Blue LED tube lighting

Not AC frequency dependent –works in all countries

Auto increase of adjusting value for quick time setting

Neon colon indicators blinking at 1 Hz

Tubes are driven in high frequency dynamical indication and provide service for many years

3

Safety precautions

The clock printed circuit board (PCB) includes a High Voltage source that powers the Nixie tubes. It

output voltage can reach 180 Volts DC. The voltage generated by this source can give a potentially

LETHAL ELECTRIC SHOCK. When PCB is powered its contacts shall be not touched by hands or non-

isolated tools (non-isolated tweezers for example).

Required experience

This product is supplied as a kit of parts, intended only for suitably qualified electronic hobbyists, who

are suitably qualified and experienced in electronics assembly and electronics components proper

soldering, and are familiar with safe procedures for working with high voltage and its potentially

danger.

Assembly and testing of the clock from this kit should be attempted by competent persons only, or

under supervision of someone fully experienced in this field.

Correct component placement is critical. A few minutes spent checking placement and orientation

prior to soldering will save hours of mistakes search and rework later.

REMEMBER: A properly placed components and carefully soldered PC board will perform well for

years, a hastily assembled board will cause ongoing clock problems and failures.

The most important skill for our kit assembly is an electronic components soldering. If you have not

an experience enough, next site with Basic Soldering Guide will be useful for you:

https://learn.sparkfun.com/tutorials/how-to-solder-through-hole-soldering

Tools and materials required for assembly

Screwdriver

Angled tweezers with thin noses

Long nose pliers for tube leads bonding

Side cutting pliers to trim the excess component leads after soldering

Electronics grade solder 0.5-1mm thickness that contains cores of "flux" which helps the

molten solder to flow more easily over the joint

De-soldering wick or pump may be useful if you accidentally create solder bridges between

adjacent solder joints or improper solder any component

Soldering iron with small a “tinned” tip

Multi-meter for voltage measurements and for identifying the resistors

Magnifying glass.

4

The clock kit does not include next components

A power adapter. Output voltage 12V DC, output current ~1A. Output end plug –5.5 x 2.1mm,

centre positive. It is cheaper to buy such power adapter in your local electronics shop because

it will be equipped by necessary grid plug. You may have similar power adapter in your house

also because such type power adapters are popular and widely use.

The KIT consists electronics components necessary for a clock assembly only. Nixie tubes need

to purchase separately. This KIT can work with many nixie tube models. Tested with In-8, In-8-

2, In-18, In-12, In-14, In-16, In-1, z573m. Controller does not support biquinary type nixie

tubes.

The KIT does not consist the case of the clock also.

Wires and nixie tubes sockets are not included.

5

Parts list

Component designation

Component description

RESISTORS

R1

1kΩ, 0.25W

R2

470kΩ, 0.25W

R3

3.3kΩ, 0.25W

R4

0.5Ω, 0.5W

R5, R6, R7, R8, R9, R10, R11, R14, R17, R18

R19, R20

10kΩ, 0.25W

R12

330Ω, 0.25W

R15, R16

270kΩ, 0.25W

R21

1K, 0.1W (Potentiometer)

CAPACITORS

C5

2.2uF, 250V, Electrolytic

C2, C4, C6, C7

0.1uF, Ceramic

C3

2.2nF, Ceramic

C1

220uF, 25V, Electrolytic

TRANSISTORS

6

Q1

BC557

Q2

IRF840, MOSFET

Q3, Q4, Q5, Q7

BC547

Q6

MPSA42

OK1-OK6

EL817, Optocoupler

DIODES

D1

1N4004

D2

1N914

D3

UF4004

LED1-LED6

LED, 3mm

INTEGRATED CIRCUITS

U1

LM7805

U2

MC34063

U3

K155ID1

U4

ATMEGA328P-PU

U5

DS3231

MISCELLANEOUS

PCB

Nixie Clock PCB

BAT_1

CR2032 Battery socket

Battery

3V CR2032

DB1, DB2

Neon bulb

FUSE

0.5A

L1

330uH, 1A Inductor

S1 - S3

Buttons

U3 Socket

16pin socket

U4 Socket

28pin socket

Power socket (JP1)

5.5mm x 2.1mm

Speaker (SP1)

Active alarm buzzer

PCB Spacers

4 PCB spacers

Screws

4 Screws 3mm

J2, J3, J4, J5, DB1, DB2

Pin strips

7

Components review

Resistors

1kΩ (R1)

10kΩ (R5, R6, R7, R8, R9,

R10, R11, R14, R17, R18, R19, R20)

470kΩ (R2)

0.5Ω (R4)

3.3kΩ (R3)

330Ω (R12)

270kΩ (R16, R17)

1k (R21)

NOTES:

Components actual view can differ due to different manufacturers.

If an inscription or color bar coding of the component is small, it is necessary to use the

magnifying glass.

8

The resistors used in the kit are marked with four coloured bands to identify the value. Bands 1 and 2

identify the first two digits, band 3 is the Multiplier and band 4 is the tolerance.

The first, second and third coloured bands on the resistors indicate the resistance using a colour code.

This table indicates how to convert each colour to its numerical equivalent. Gold band means 5%

tolerance.

To read a resistor code, first locate the gold band and read the colours in order from the other end.

(All resistors in this kit have a gold band indicating 5% tolerance.) The first two bands indicate digits in

the resistance; the third band (called the multiplier) indicates the number of zeroes to be added to

the digits to obtain the resistance. However, it is sometimes unclear in which direction the bands

should be read. Therefore, we recommend that the resistors will be identified with a multimeter.

Use the resistor code to identify and sort all of the resistors. One good way to keep them sorted is to

tape one end to a piece of paper and write the resistance and component number (R1, R2, etc.). Once

you have identified and sorted all of the resistors, you are ready to solder them to the PCB. To

prepare a resistor for insertion into the board, bend the two leads so that they form a right angle to

the resistor body.

Capacitors

0.1uF (Code 104), (C2, C4, C6, C7)

2.2nF (Code 222), (C3)

220uF 25V, (C1)

Band colour

Numerical

equivalent

Band colour

Numerical

equivalent

black

0

green

5

brown

1

blue

6

red

2

violet

7

orange

3

grey

8

yellow

4

white

9

10

IRF840, MOSFET, (Q2)

EL817, (OK1-OK6)

Diodes

1N4004 (D1)

UF4004 (D3)

1N914 (D2)

LED, 3mm

11

Integrated Circuits

LM7805 (U1)

MC34063 (U2)

K155ИД1 (U3)

ATMEGA328P-PU (U4)

DS3231 (U5)

12

Miscellaneous

CR2032 Battery socket (BAT_1)

Battery

Neon bulb (DB1, DB2)

Fuse

330uH, 1A Inductor (L1)

13

Button (S1-S3)

16 pin socket

28 pin socket

Power socket (5.5mm x 2.1mm)

Speaker

PCB Spacers

3mm screw

14

Packing Sheet

Component description

Quantity, pcs

RESISTORS

1kΩ, 0.25W

1

470kΩ, 0.25W

1

3.3kΩ, 0.25W

1

0.5Ω, 0.5W

1

10kΩ, 0.25W

12

330Ω, 0.25W

1

270kΩ, 0.25W

2

1k (Potentiometer)

1

CAPACITORS

2.2uF, 250V, Electrolytic

1

220uF, 25V, Electrolytic

1

0.1uF, Ceramic

4

2.2nF, Ceramic

1

TRANSISTORS

BC557

1

IRF840, MOSFET

1

BC547

4

MPSA42

1

EL817, Optocoupler

6

DIODES

1N4004

1

1N914

1

UF4004

1

LED 3mm

6

INTEGRATED CIRCUITS

LM7805

1

MC34063

1

K155ID1

1

ATMEGA328P-PU

1

DS3231

1

MISCELLANEOUS

Nixie Clock PCB

1

CR2032 Battery socket

1

CR2032 Battery

1

Neon bulb

2

330uH, 1A Inductor

1

Buttons

3

16 pin socket

1

28 pin socket

1

Power socket (5.5mm x 2.1mm)

1

Speaker

1

PCB spacers

4

Screws

4

Fuse

1

Pin Strips (Male)

30

Pin Strips (Female)

30

15

PCB assembly sequence

1. Screwing PCB spacers to PCB by screws

Spacers lift the PCB over table surface. It will be more convenient to install and to solder components

to the PCB. These spacers can use for fixing an assembled clock in applicable casing also.

NOTES:

This instruction contents high definition pictures. If anywhere is uncertainty, PCB view

can magnify and an interested component may to view in details.

The side of the board that has printed component marking is the “component side”. This

means that components must mount by inserting them down from the printed side.

Make sure that the components mount on the proper side of the PCB!

Prior to beginning an assembly, make sure to have a well-lighted, well-ventilated

workplace. Make sure that all of the electronic assembly tools are available.

16

2. Low Voltage Power source components preparation for insertion into the board

and soldering order

U1

LM7805

C1

220uF, 25V, Electrolytic

C7

0.1uF, Ceramic

D1

1N4004

FUSE

FUSE 0.5A

Power socket

5.5mm x 2.1mm PCB DC Jack

2.1. Bend U1 integrated circuit leads.

2.2. Bend the two leads of the fuse and diode D1 so that they form a right angle to the component

body.

2.3. To install, place the leads of the component through the appropriate holes and press the

component down against the component side of the PCB.

2.3.1. The small-value ceramic capacitor (C7) may be installed in either orientation, but the larger-

value cylindrical capacitor (C1) must be installed with the proper polarity. The polarity is indicated on

the PCB by a “+” sign near one end of the capacitor location. The polarity is indicated on the body of

the capacitor with a stripe with a minus (-) sign located on the negative side of the capacitor. In

addition, the shorter lead is the negative lead.

17

2.3.2. Either lead of the fuse may be inserted in either hole its location.

2.3.3. Turn the board over while holding the relevant component in position and bend the leads

slightly outward to hold the component in place. Solder the leads to the contact and trim the excess

lead wire above the solder joint.

NOTES:

To make sure that capacitor C1 and diode D1 polarity is not mistaken.

To make sure that integrated circuit U1 (LM7805) is not mistaken with transistor Q2

(IRF840) and diode D1 (1N4004) is not mistaken with diode D3 (UF4004) because they look

like similar.

18

3. High voltage generator components preparation for insertion into the board and

soldering order

U2

MC34063

Q1

BC557

Q2

IRF840

D3

UF4004

D2

1N914

L1

Inductor 330uH

C5

2.2uF, 250V

C2, C4

0.1uF

C3

2.2nF

R4

0.5Ω 0.5W

R1

1k

R3

3.3k

R2

470k

R21

1k (Potentiometer)

3.1. All resistors (except R4) leads bend in accordance with this picture

that each resistor place on board surface will be minimal.

3.2. Repeat actions pointed in items 2.3, 2.3.1 and 2.3.3 for proper components insertion into the PCB

and soldering.

19

4. Low and High Voltage sources operability test

After Low and High Voltage sources components assembly it is necessary to check relevant source

proper operability.

4.1. Select multi-meter DC 200 V measuring range.

4.2. Identify the test ground (GND), 5V and HV test points as shown below.

4.3. Plug in the power supply, and then test HV source operability using a multi-meter in DC voltmeter

mode. Touch the black probe on the GND test point and the red probe on the HV test point. The

voltage should measure between 140 and 180 Volts. When PCB is powered its HV source contacts

shall be not touched by hands or non-isolated tools (non-isolated tweezers for example). If not,

disconnect power and remember that the HV source output could still hold charge at 165-175 V.

Check all relevant joints quality and polarity.

Do not continue with the next test until the error in HV source exists.

NOTES:

Turn the potentiometer to adjust the voltage to approximately 165V. A potentiometer is

needed to change the brightness of the nixie tube.

20

4.4. Test low voltage (LV) source operability. Touch the black probe on the GND test point and the red

probe on the 5V test point. The voltage should measure between 4.8 and 5.2 Volts. If not, disconnect

power and check all relevant joints quality and polarity.

Do not continue with the assembly until the error will be corrected.

4.5. Once the last test of LV source is completed, disconnect the power.

5. Microcontroller circuit components assembly

U4

Atmega328P-PU

R11

10kΩ

U4 Socket

28 pin socket

5.1. Take the resistor R11 and bend it, like pointed in item 3.1. Insert resistor into the board holes

marked as R11 and solder it leads.

5.2. Insert U4 socket and solder it leads.

This manual suits for next models

1

Table of contents

Other Nixie Clock manuals

Popular Clock manuals by other brands

La Crosse Technology

La Crosse Technology 404-1210S instruction manual

Oregon Scientific

Oregon Scientific BAR623PA user manual

La Crosse Technology

La Crosse Technology 513-1417H-AL Faqs

American Time

American Time PGE441RFE-W Quick start installation guide

LA CROSSE CLOCK

LA CROSSE CLOCK BBB85456 instruction manual

Bogen

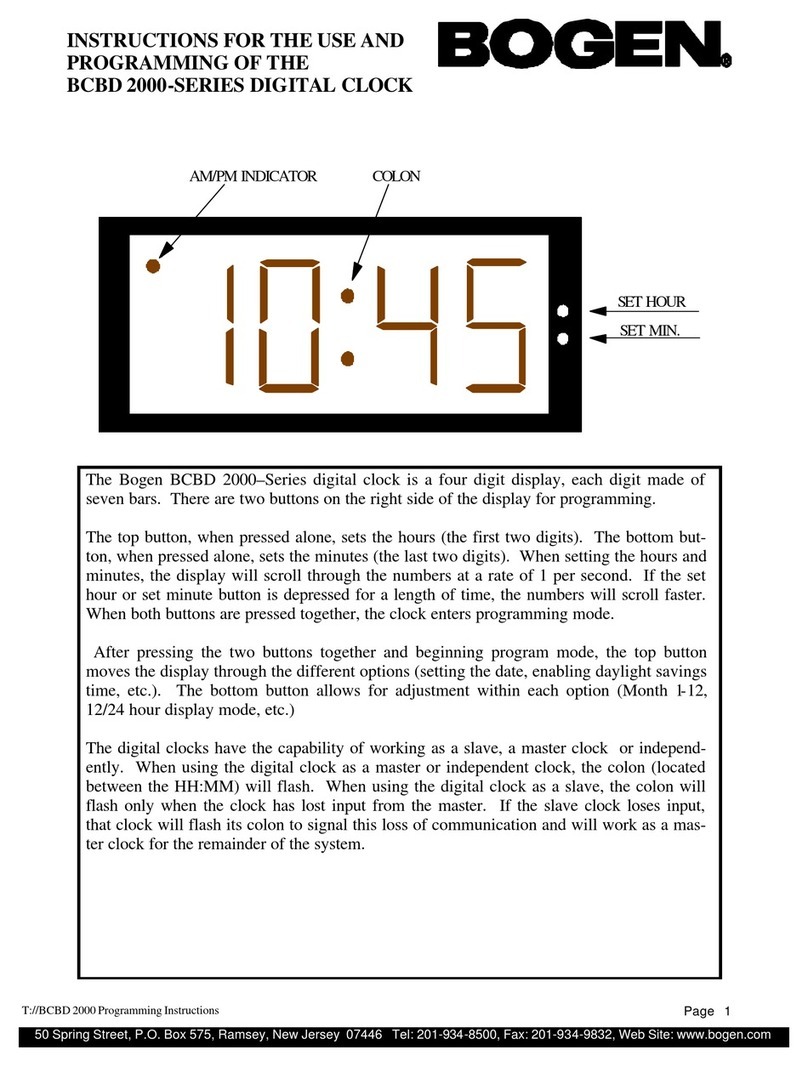

Bogen BCBD 2000-SERIES instructions

Valentin Elektronik

Valentin Elektronik C 210 Series installation instructions

ABB

ABB twa-1 user manual

La Crosse Technology

La Crosse Technology BBB84022 instruction manual

Clas Ohlson

Clas Ohlson IP22B manual

SG Electronics

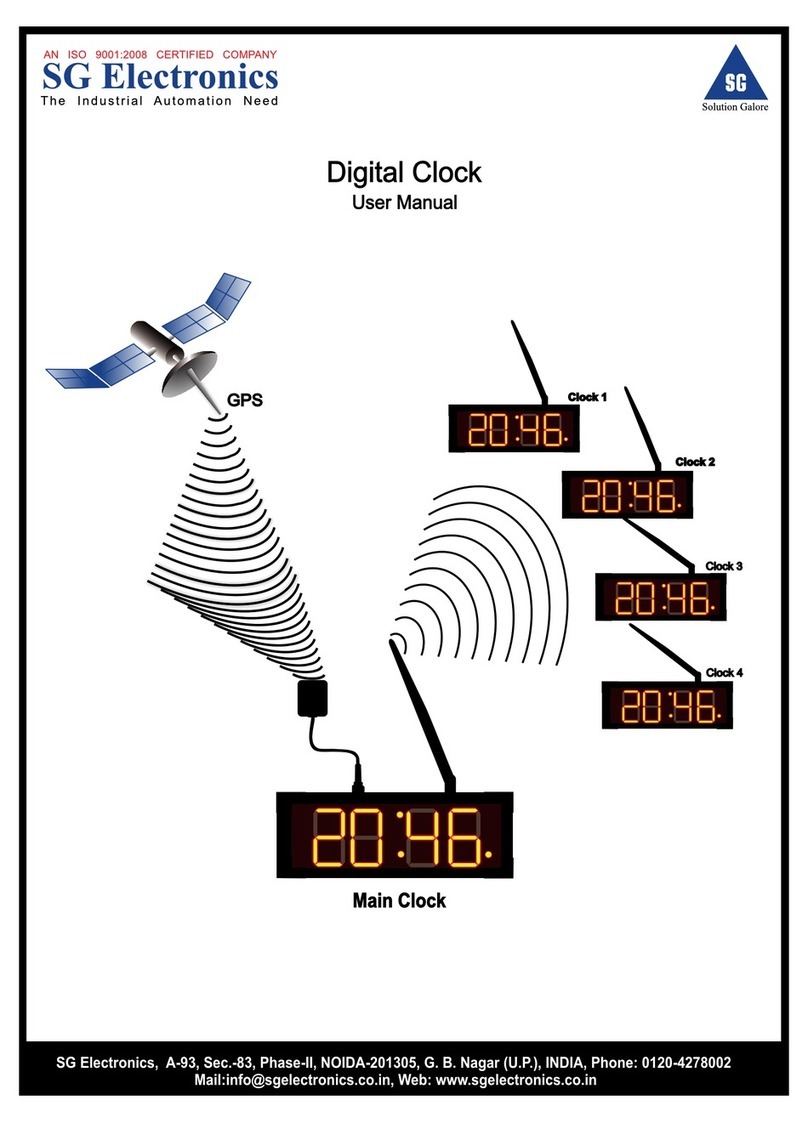

SG Electronics SGCLK046 user manual

Infineon

Infineon TRAVEO T2G family CYT4D Series manual