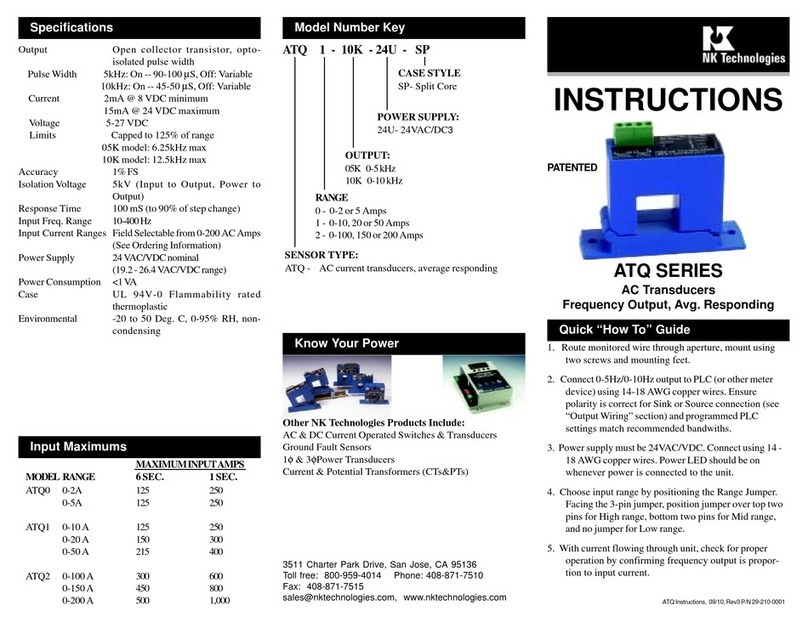

Place wire or bus bar to be monitored through the sensing

aperture.

AT and ATR Series transducers work in the same environ-

ment as motors, contactors, heaters, pull-boxes, and other

electrical enclosures. They can be mounted in any posi-

tion or hung directly on wires with a wire tie. Just leave at

least one inch distance between sensor and other magnetic

devices.

Description

Installation

Output Wiring

Model Range Select

AT and ATR Series transducers feature factory calibrated

ranges. This eliminates time consuming and inaccurate

field setting of zero or span.

1. Determine the normal operating amperage of your

monitored circuit using load specifications or a test

Trouble Shooting

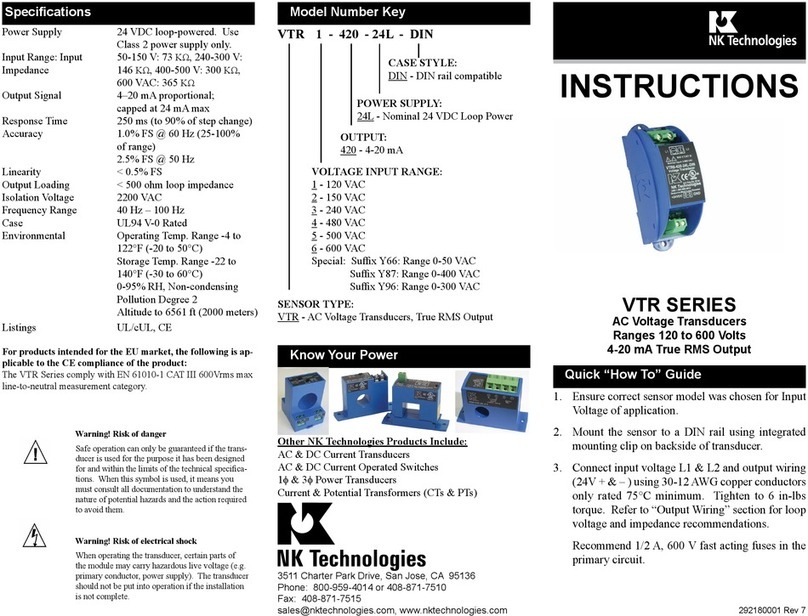

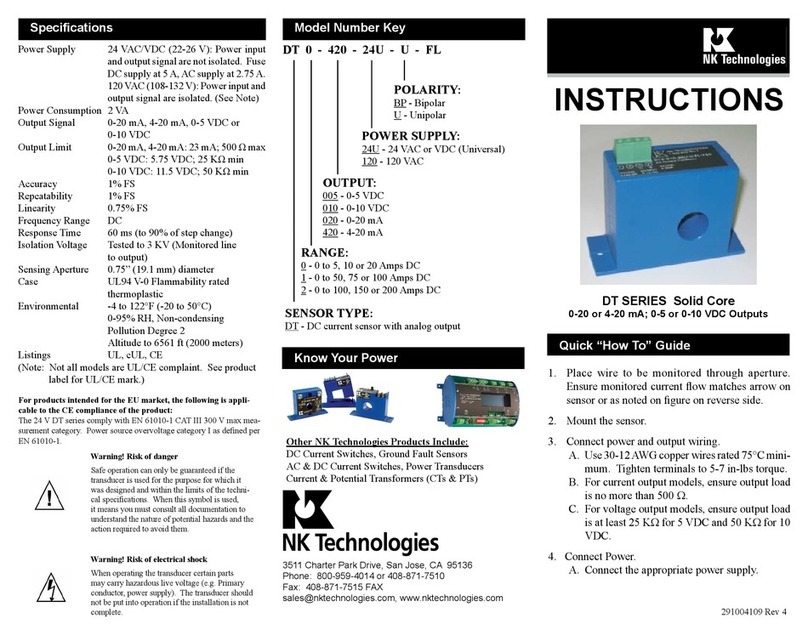

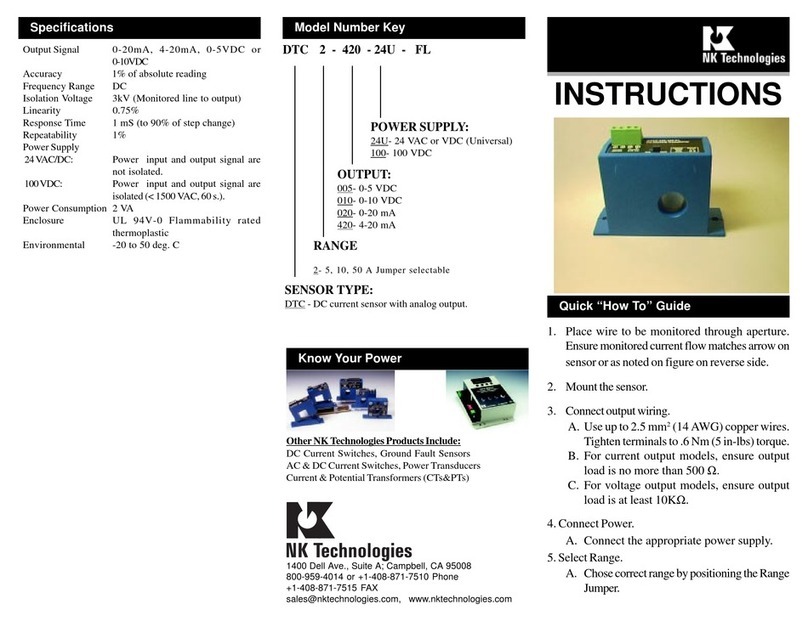

AT and ATR-LS Series transducers combine a current

transformer and a signal conditioner into a single pack-

age. This provides higher accuracy, lower wiring costs,

easier installation and save valuable panel space. Both

AT and ATR are available in a large split core housing

with 4-20mA output proportional to the primary AC cur-

rent. ATR Series feature a True RMS output. They are

designed for application on distorted current waveforms

such as VFD outputs.

ammeter.

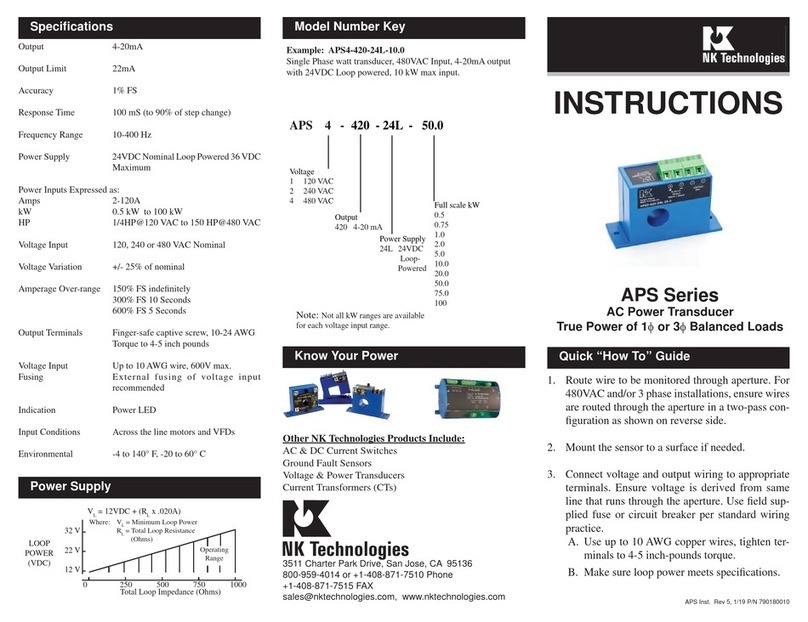

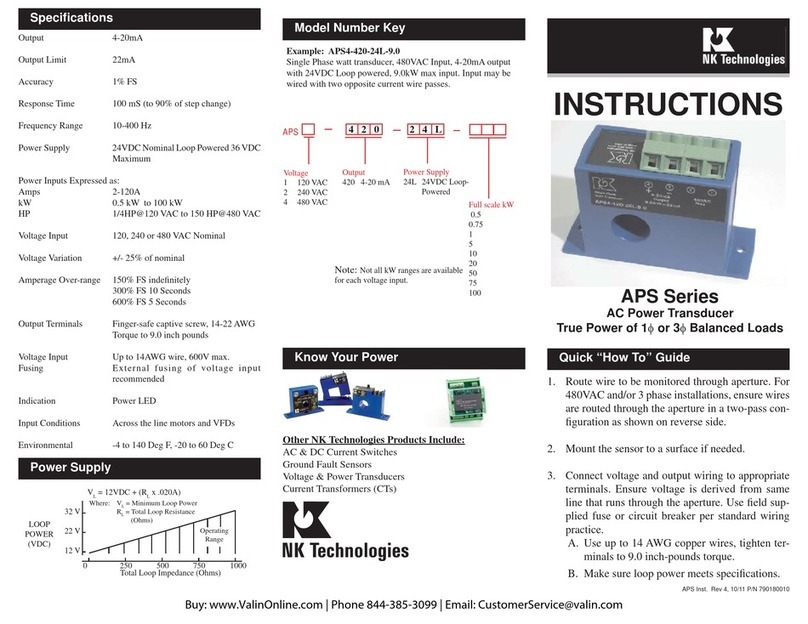

2. Select the model with a range that is equal to or

slightly higher than the normal operating amperage.

1. Sensor has no output

A. Power supply is not properly sized Check power

supply voltage and current rating.

B. Polarity is reversed. Check and correct output wiring

polarity.

2. Output Signal Too Low

A. The range may be too high for current being

monitored. Exercise care when selecting the model

range.

B. The load current is not sinusoidal. Select an ATR

transducer for use with distorted waveforms.

C. Monitored current is below minimum required. Loop

the monitored wire several times through the aperture

until the “sensed” current rises above minimum.

Sensed Amps = (Actual Amps) x (Number of Loops).

Count loops on the inside of the aperture.

3. Sensor is always at 4mA

A. Monitored load is not AC or is not on. Check that

the monitored load is AC and that it is actually on.

4. Output Signal is always at 20mA

A. The range is too low for current being monitored.

Select a model with a higher range.

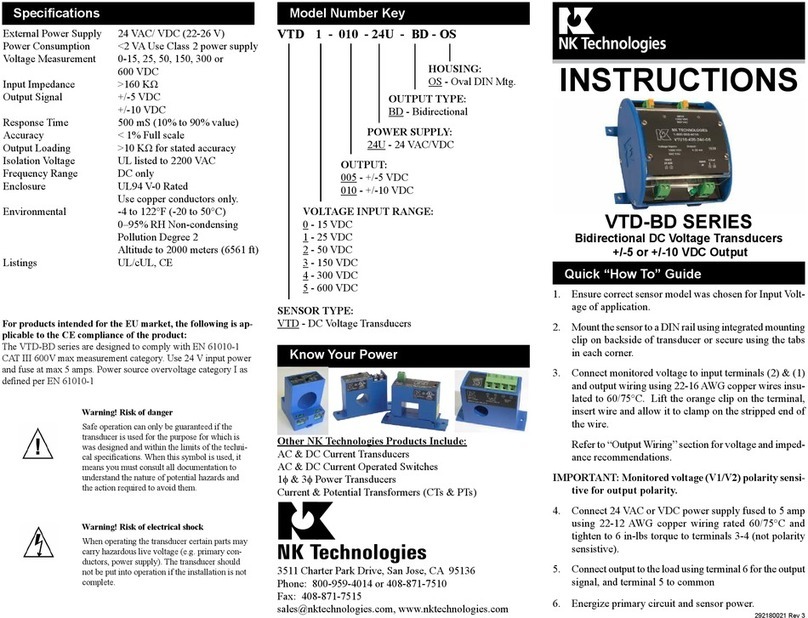

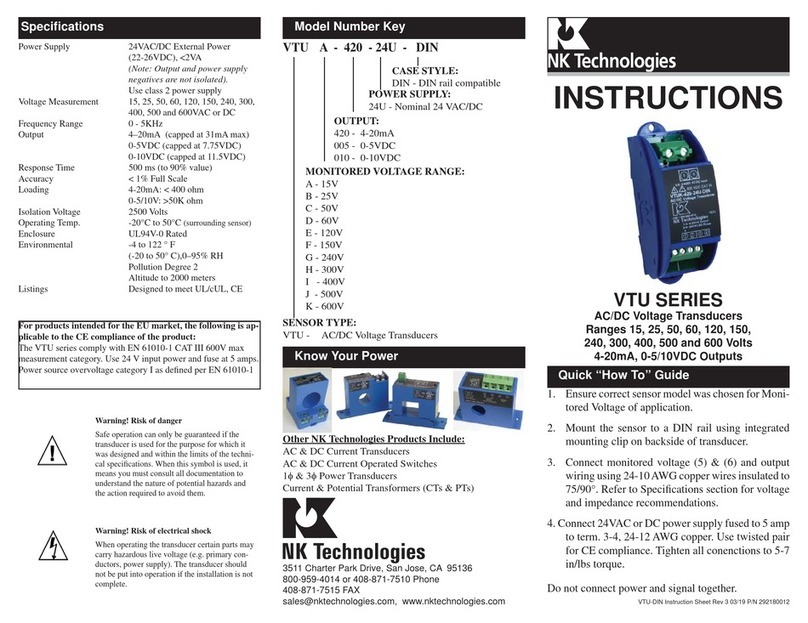

Connect control or monitoring wires to the sensor. Use

up to 14 AWG 75/90°C copper wire and tighten terminals

to 3.5 inch-pounds torque. Be sure the output load total

impedance does not exceed 800 ohms.

Connection Notes:

• Captive screw terminals.

•14-22 AWG solid or stranded.

•Observe Polarity

•See ordering information and label for monitored circuit

range

+

-

-

24VDC

Power

+-+

Load

(PLC, meter)

Power Supply

Minimum Power Supply = 12 VDC + Total Loop Voltage Drop

0 250 500 750 1000

32V

22V

12V

Operating

Range

Total Loop Impedance (Ohms)

LOOP

POWER

(VDC)

Use Class 2 power supply or fuse supply at 5 amps.