NK TECHNOLOGIES DTC 2-420-24U-FL User manual

Other NK TECHNOLOGIES Transducer manuals

NK TECHNOLOGIES

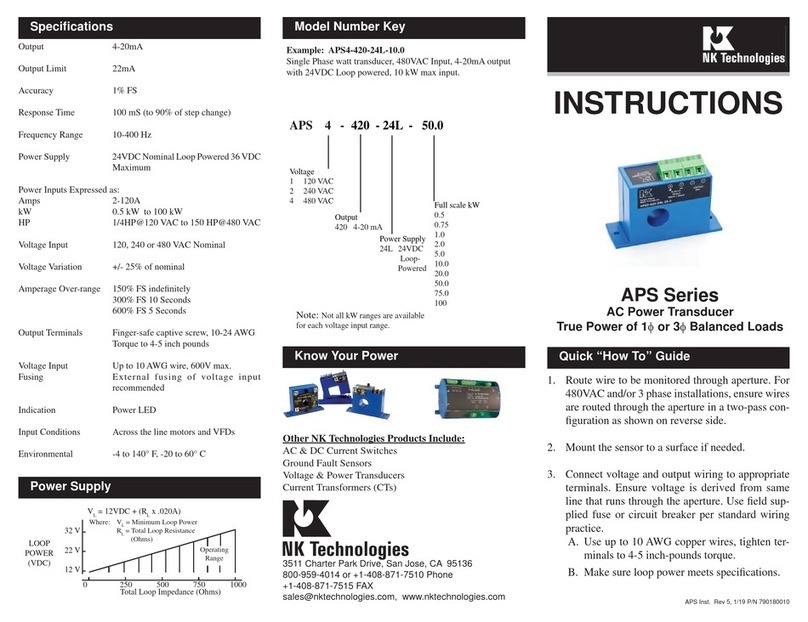

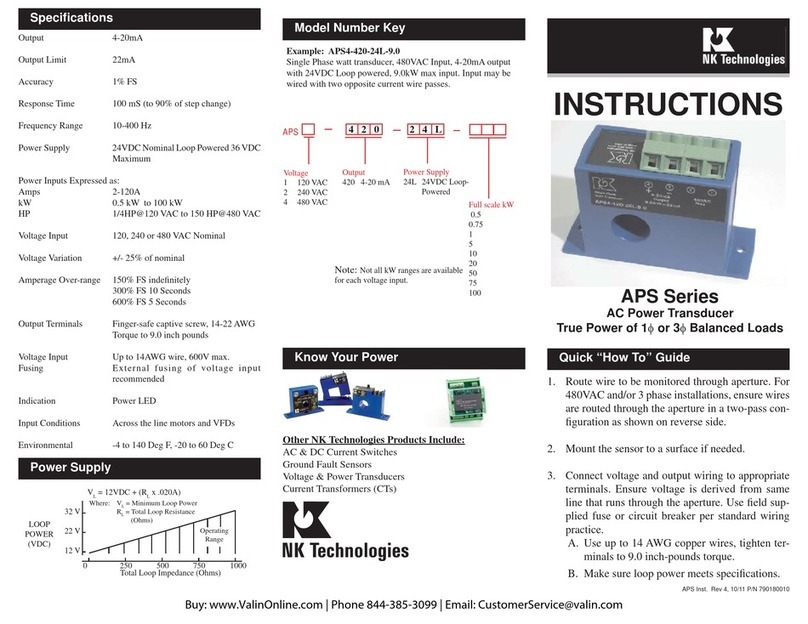

NK TECHNOLOGIES APS Series User manual

NK TECHNOLOGIES

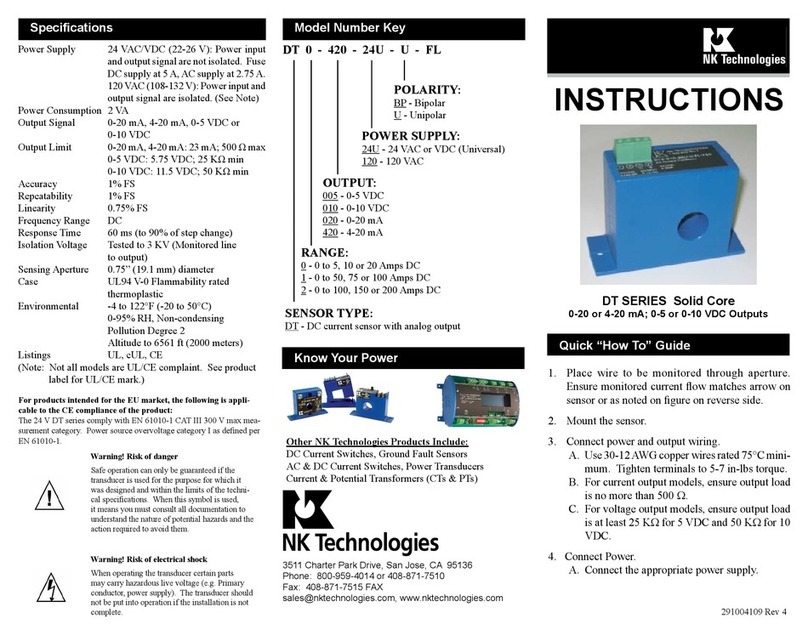

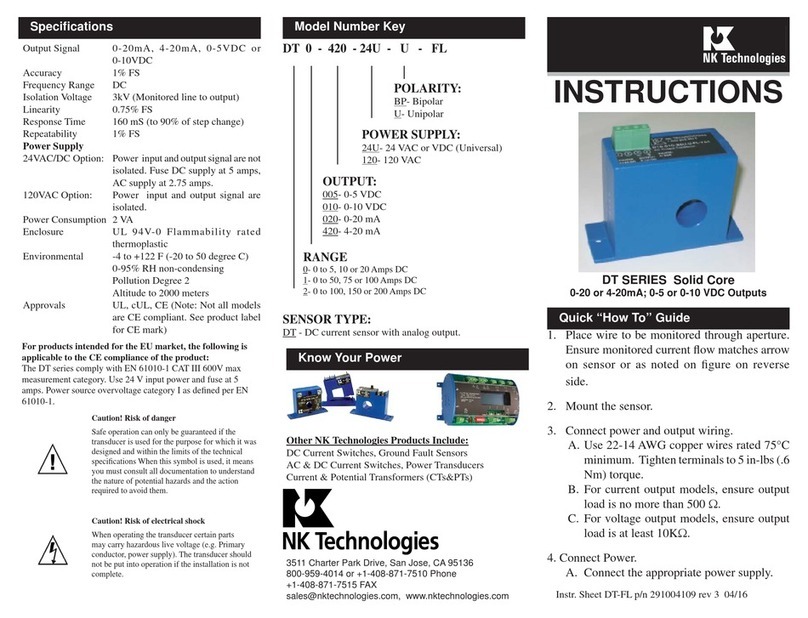

NK TECHNOLOGIES DT Series User manual

NK TECHNOLOGIES

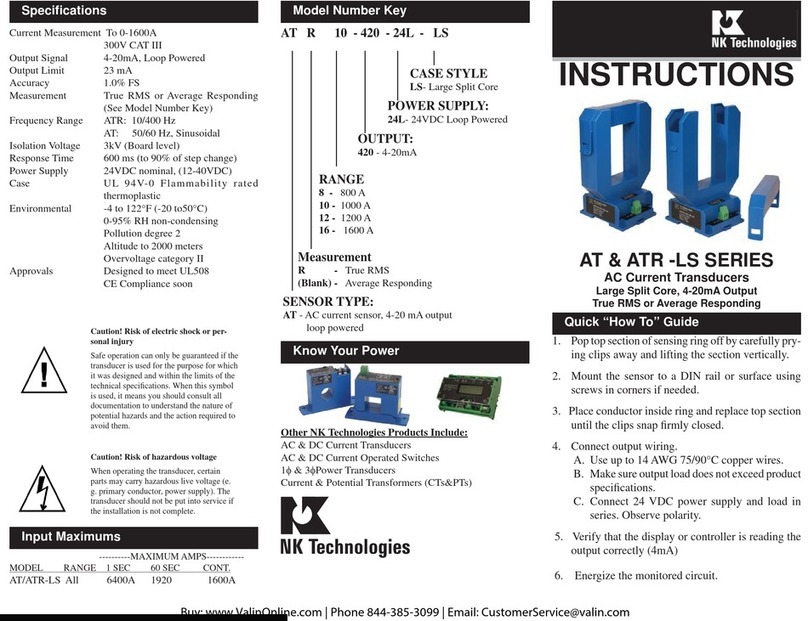

NK TECHNOLOGIES AT SERIES User manual

NK TECHNOLOGIES

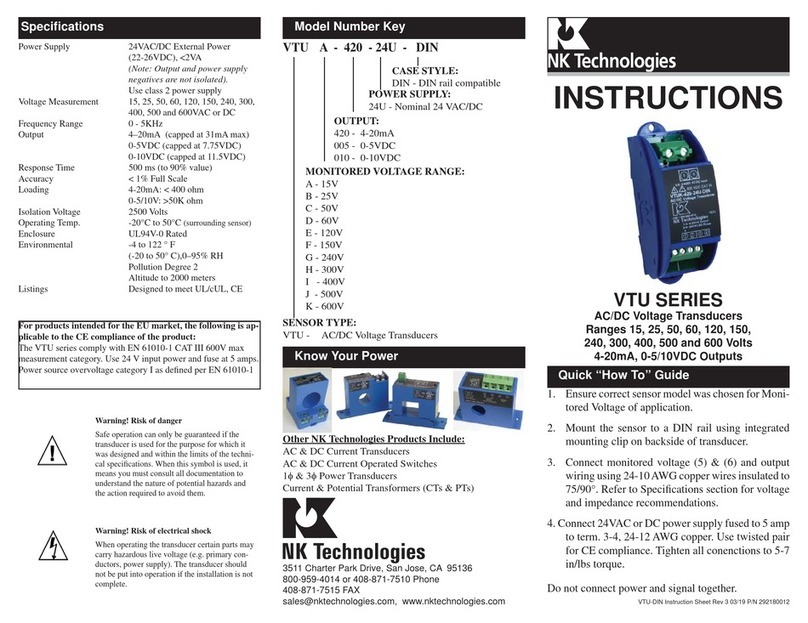

NK TECHNOLOGIES VTU Series User manual

NK TECHNOLOGIES

NK TECHNOLOGIES AT 2 Series User manual

NK TECHNOLOGIES

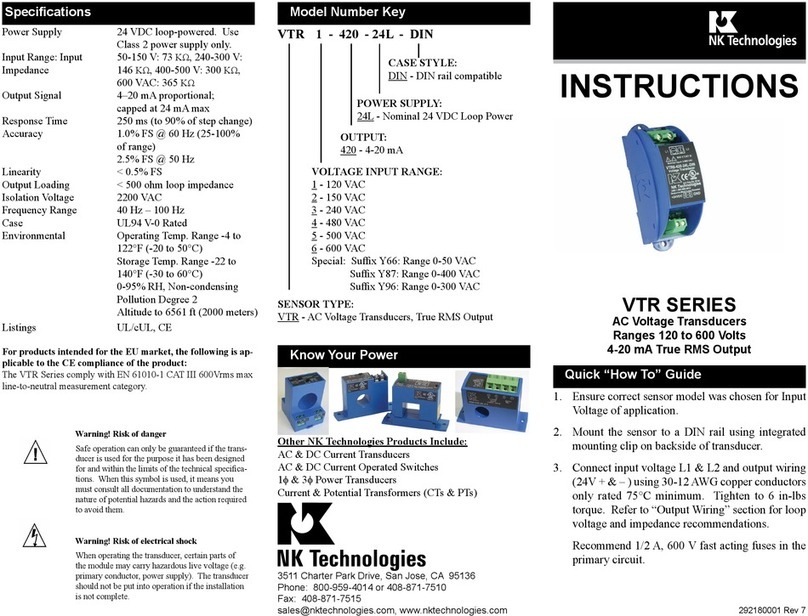

NK TECHNOLOGIES VTR Series User manual

NK TECHNOLOGIES

NK TECHNOLOGIES DT Series User manual

NK TECHNOLOGIES

NK TECHNOLOGIES APS Series User manual

NK TECHNOLOGIES

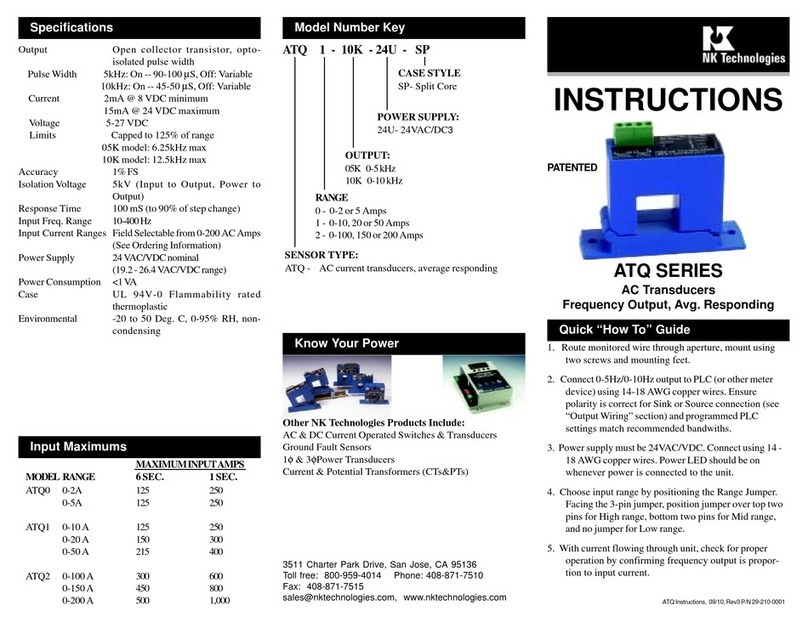

NK TECHNOLOGIES ATQ Series User manual

NK TECHNOLOGIES

NK TECHNOLOGIES VTU Series User manual

Popular Transducer manuals by other brands

ITR

ITR SEM SC11 User manual and technical documentation

Balluff

Balluff BIW1-A310-M -P1-S115 Series user guide

Faget

Faget EM2020 Installation and start-up instructions

WIKA

WIKA WUD-2x-E operating instructions

TR-Electronic

TR-Electronic LMP-30-300 PB manual

controlair

controlair 2000 Installation, operation and maintenance instructions

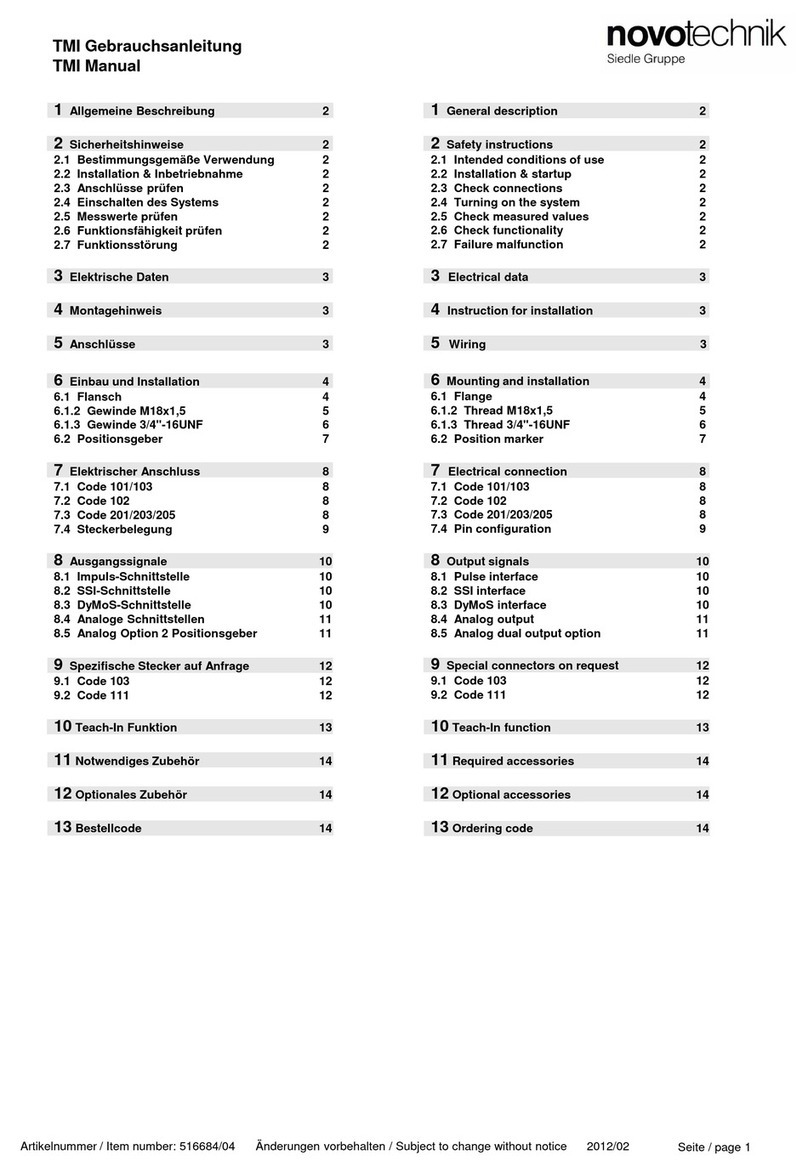

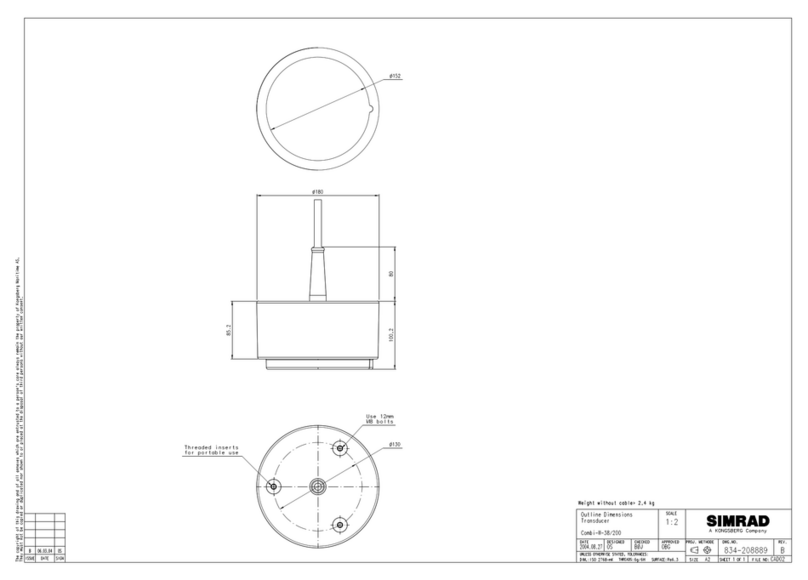

Simrad

Simrad OUTLINE DIMENSIONS - SCHEMA REV B Dimensions

domat

domat PREMASGARD SHD Operating Instructions, Mounting & Installation

Hontzsch

Hontzsch UVA-AS102 operating instructions

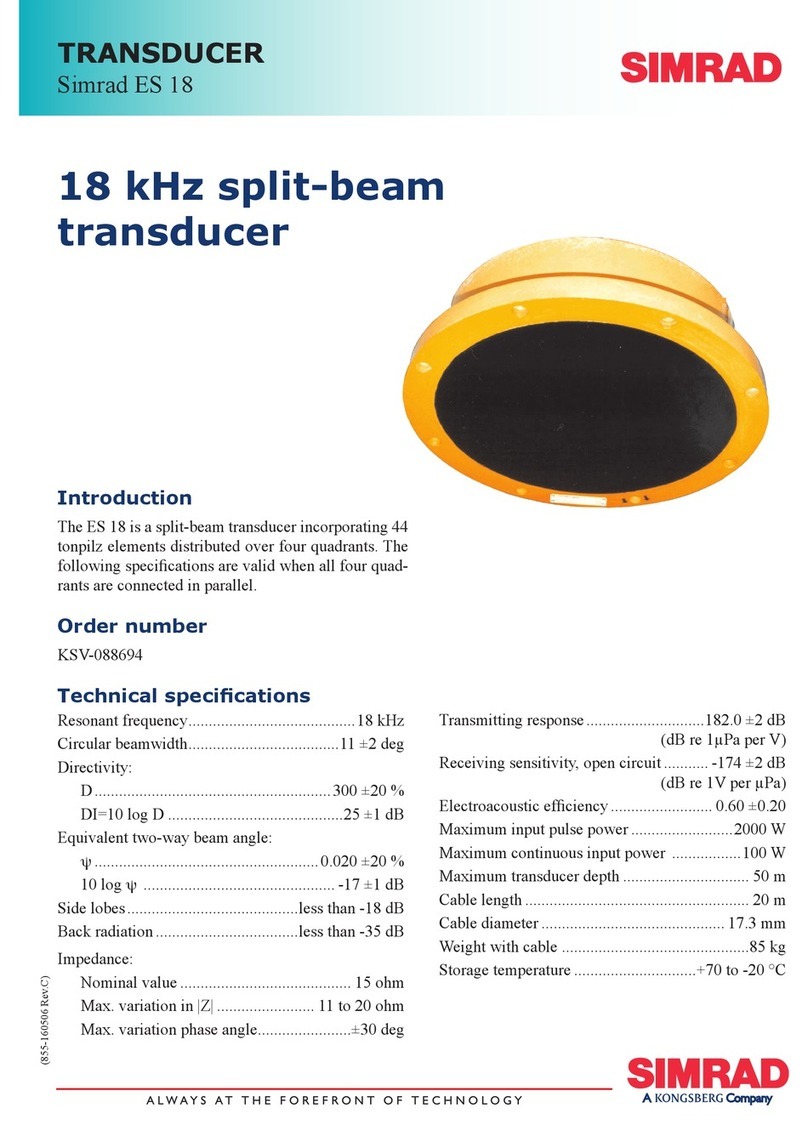

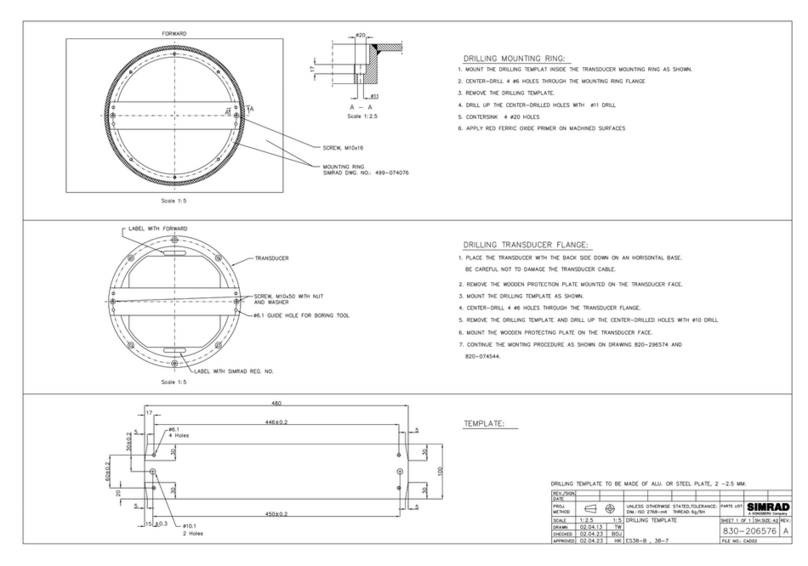

Simrad

Simrad SUPPORT BEAM DRILLING TEMPLATE - SCHEMA REV... Template

Induction Dynamics

Induction Dynamics SolidDrive SD1 Installation & use guide

Balluff

Balluff BTL7-V50T-M P-C003 Series user guide