For All Versions

Run wire to be monitored through opening in the sensor.

ATQ Series transducers work in the same environment as

motors, contactors, heaters, pull-boxes, and other electrical

enclosures. They can be mounted in any position or hung

directly on wires with a wire tie. Just leave at least one inch

(25mm) distance between sensor and other magnetic de-

vices.

Split-Core Versions (SP Suffix)

Press the tab in the direction as shown to open the sensor.

After placing the wire in the opening, press the hinged por-

tion firmly downward until a definite click is heard and the

tab pops out fully.

KEEP SPLIT-CORE SENSORS CLEAN.

Silicone grease is factory applied on the mating surfaces to prevent

rust and improve performance. Be careful not to allow grit or dirt

onto the grease in the contact area. Operation can be impaired if

the mating surfaces do not have good contact. Check visually

before closing.

Description

Installation

Output Wiring

Range Select

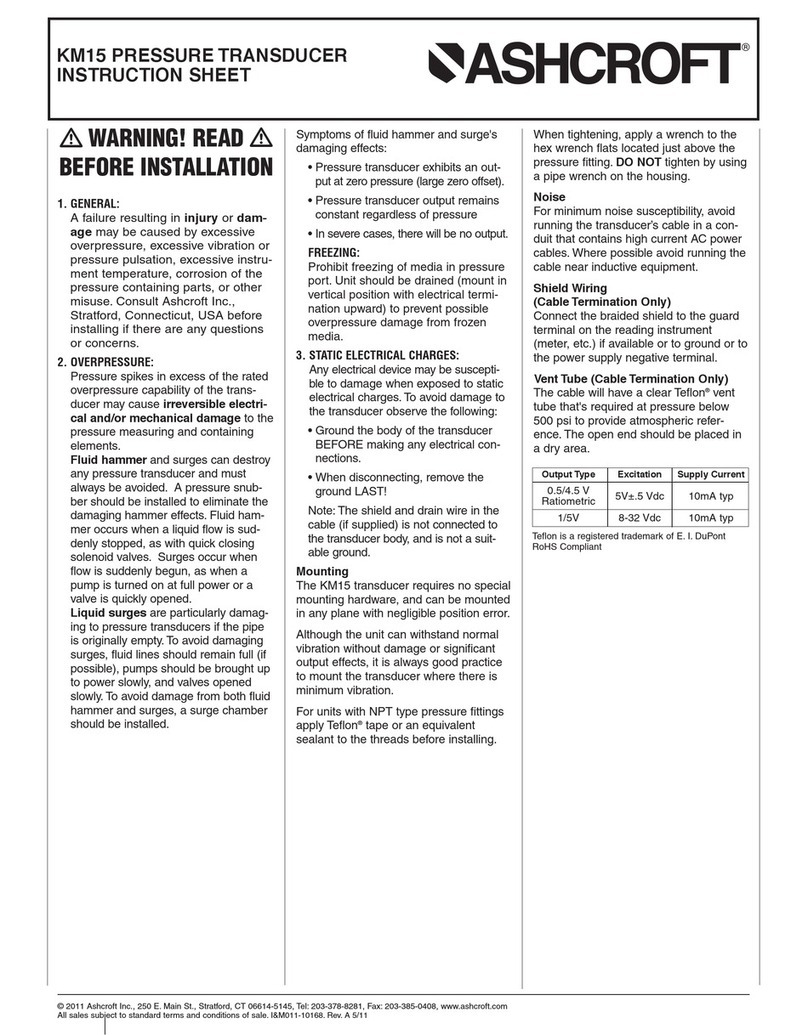

Connect output wiring from PLC or other meter device to

the sensor. Use 14 to 18 AWG copper wire and tighten

terminals to 4 inch-pounds torque. Terminals are desig-

nated as follows: terminal 3 “C” for collector, terminal 4

“E” for emitter. Be sure to observe output polarity for a

SINK or SOURCE connection (diagrams below).

ATQ Series transducers feature field selectable ranges.

These ranges are factory calibrated, eliminating time con-

suming and inaccurate field setting of zero or span.

1. Determine the normal operating amperage of your moni-

tored circuit

ATQ Series transducers combine a current transformer and

a signal conditioner into a single package. This provides

higher accuracy, lower wiring costs, easier installation and

save valuable panel space. The frequency output is com-

patible with high speed counter inputs. This allows an au-

tomation system equipped with only Digital Inputs (DIs) to

accept and process an analog value.

ATQ Series provide an “Average Responding” output. Se-

lect ATQ Series for constant speed motors or On/Off loads

such as lamps or heaters.

2. Select the range that is equal to or slightly higher than

the normal operating amperage.

3. Place the range jumper in the appropriate position

(note: ATQ0 has only two ranges corresponding to

“High” or “Low” jumper positions.

.

1. Sensor has no output

A. Control Power is not connected or the right voltage Check

power supply voltage and connections.

B. Output Polarity is not properly matched. Check and cor-

rect wiring polarity

C. Split Core models: The core contact area may be dirty.

Open the sensor and clean the contact area.

2. Output Signal Too Low

A. The jumper may be set in a range that is too high for cur-

rent being monitored. Move jumper to the correct range.

B. The load current is not sinusoidal.

C. Monitored current is below minimum required.

Loop the monitored wire several times through the aper-

tureuntil the “sensed” currentrisesabove minimum. Sensed

Amps = (Actual Amps) x (Number of Loops). Count loops

on the inside of the aperture.

3. Sensor is always at 0 Hz

A. Monitored load is not AC or is not on. Check that the

monitored load is AC and that it is actually on.

4. Output Signal is always at maximum Hz

A. The jumper may be set in a range that is too low for cur-

rent being monitored. Move jumper to the correct range.

Trouble Shooting

OutputConnectionNotes:

• Captive screw terminals, 14-18 AWG solid or stranded.

•Open Collector transitor output, opto-isolated.

•See label for ranges & jumper positions

•Observe Polarity

SINK Connection SOURCE Connection

Power Wiring

Connect the power wires to Terminals 1 & 2. Use 14-18

AWG copper wire and tighten terminals to 4 inch-pounds

torque. The power input is not polarity sensitive. The

POWER LED should be lit to indicate whenever control

power is supplied to the unit.

PowerConnectionNote:

Be sure that the power applied matches the nominal volt-

ageshown on thelabel (24VAC/VDC)! Highervoltages may

cause damage to the unit.