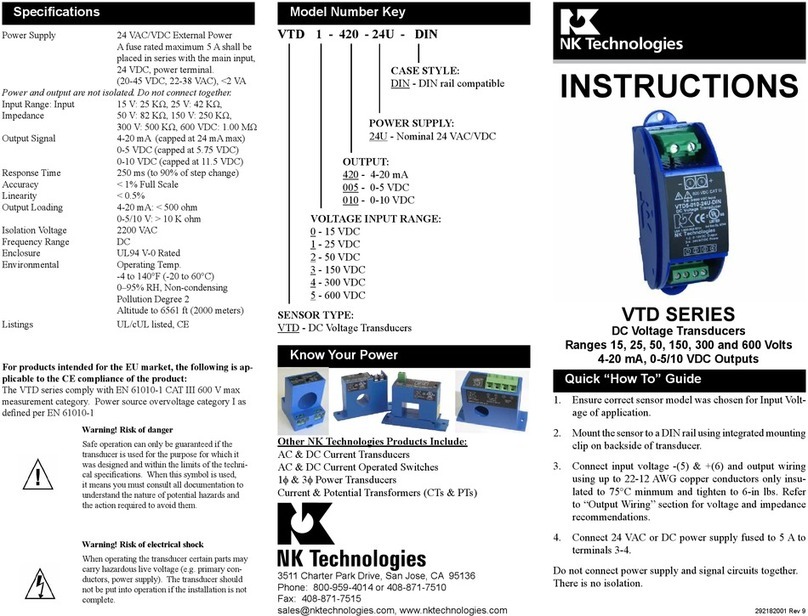

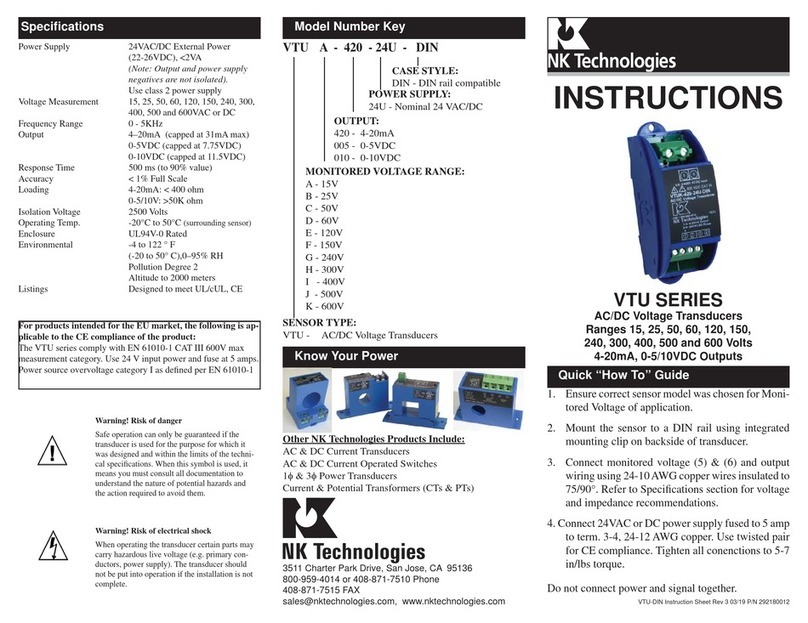

VTR transducers feature a slim DIN rail compatible enclo-

sure and are typically located in the same environment as

motors, contactors, heaters, pull-boxes, and other electrical

enclosures.

To mount on DIN rail: Orient transducer so that line volt-

age terminals L1 and L2 are upright/on top of unit and snap

securely onto DIN rail. To remove, insert small screwdriver

into the lower mounting hole of the spring loaded clip, and

push the handle end of the screwdriver toward the sensor

base to release the tension on the rail.

Description

Installation

Output Wiring

Connect control or monitoring wires to the sensor. Use

30-12 AWG copper wire, insulated to 75°C minimum

and tighten terminals to 6 inch-pounds torque. Be sure

the output load or loop power requirements are met (see

diagram below).

VTR Series Voltage Transducers are designed to monitor

AC voltage and detect conditions where supply voltage is

above or below normal. Detecting such conditions helps

users to avoid problems commonly associated with voltage

irregularities such as motor overheating, damage to drives

due to regeneration, loss of phase and the like.

The VTR is available with a 4-20 mA “True RMS” output

as standard, making them suitable for use in applications

where the monitored voltage is laden with harmonic current

components.

1. Transducer has no output

A. Power supply is not properly sized. Check power

supply voltage and current rating.

B. Polarity is not properly matched. Check and correct

wiring polarity.

2. Output Signal Too Low or Too High

Transducer model improperly sized for application. De-

termine the normal operating voltage of your monitored

circuit and ensure transducer selected is equal to or

slightly higher than the normal operating voltage.

3. Sensor is always at 4 mA

Monitored load is not AC or is not on. Check that the

monitored load is AC and that it is actually on.

Troubleshooting Tips

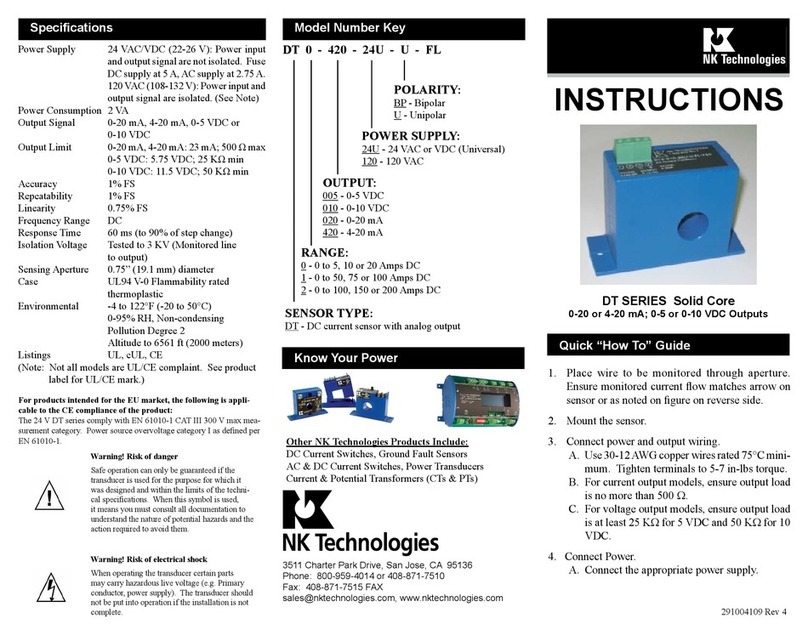

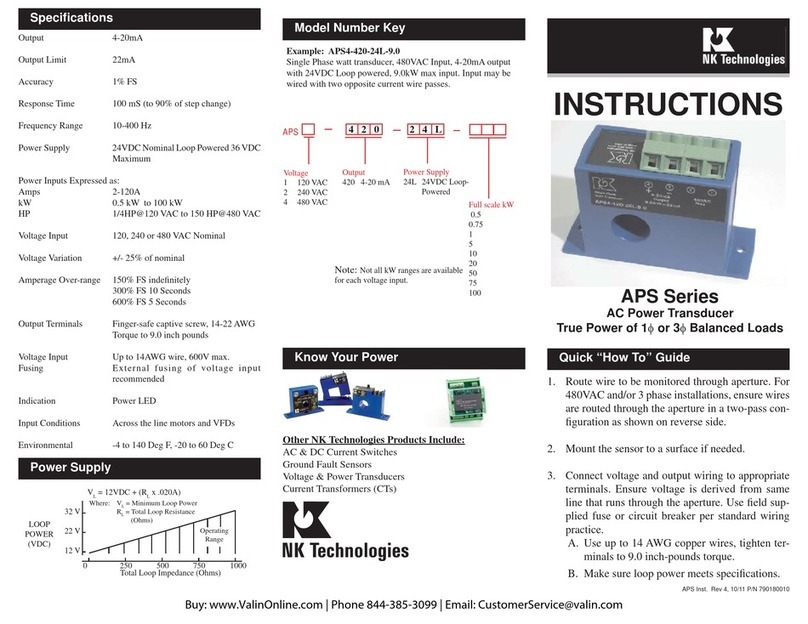

Loop Voltage Requirements:

LV = 12 V + (LR X 20 mA)

Where: LV = Min. Loop voltage

LR = Loop Resistance

500 Ω maximum impedance

Line Voltage Wiring Connection

CAUTION: TO AVOID ANY POTENTIAL FOR SHOCK OR

SAFETY HAZARD, ENSURE LINE VOLTAGE IS DISCON-

NECTED AT SOURCE BEFORE WIRING TO UNIT.

Connect input voltage to be monitored to terminals L1 and

L2 on transducer using 30-12 AWG copper wires and tighten

terminals to 6 inch-pounds torque. For multiple transducer

applications on separate phases, ensure all phase relationships

between L1 and L2 are consistent.

Fusing of the primary voltage inputs is recommended. Use

a 1/2 amp, 600 V rated fast acting fuse.

To mount using screws: Insert screws and mount to back

plane or other suitably fl at surface.

292180001 Rev 7