NOEL NM-620 User manual

Handbook version no. 20190903

1st floor, 220 Zhongxing Road, Dalingshan Town, Dongguan City, Guangdong Province, China

Dongguan Easytech Automation Mechanical and Electrical Equipment Co., Ltd.

Tel: +86 135 3727 1735

NOEL MACHINERY

Manual of Hydraulic Riveting Machine ETJSTY-818

Industrial Shed, No.6/5, MSREC Road, Gokula, Mathikere, Bangalore-560054.

www.noelmachinery.in

Handbook version no. 20190903

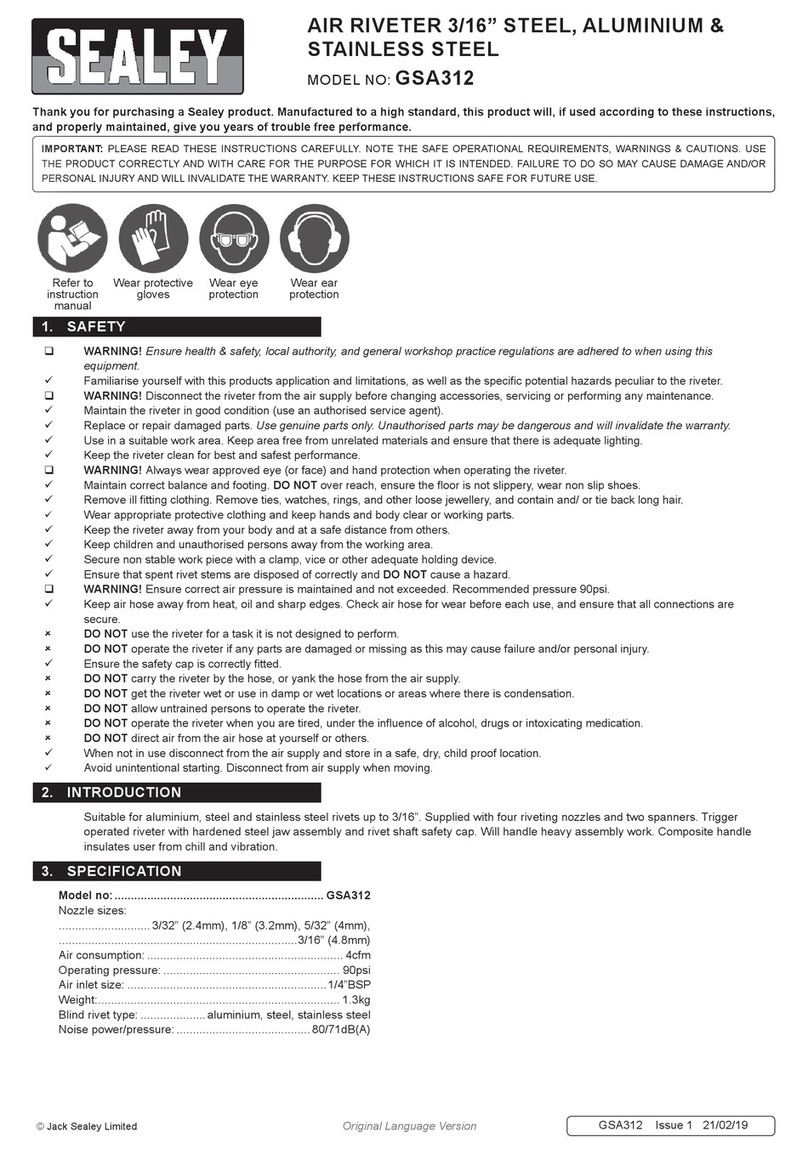

Brief description:

Detail parameters and functions:

-YY- full hydraulic drive

- Maximum output pressure

-500C-C frame throat depth 500mm (Standard)

-650C-C frame throat depth 650mm (Optional)

Detail parameters and functions:

* throat high 380 mm

* working stroke 110mm, adjustable stroke 60mm

* upper die is with guider to prevent the upper die from rotating

* upper die descending speed of 60mm/s

* position of upper die can be adjusted

* maximum pressure holding time 5s

* output pressure is not adjustable

* oil pressure system repeat accuracy +/-1%

* safety protection (conductive/non-conductive testing)

* tap mode (rhythmic tap/continuous tap)

* auxiliary positioning

* motor power 3.75kw (380V/ three-phase)

* dimensions 840*1100*2020mm (standard one, 500mm depth throat)

* equipment weight (about 600Kg) (standard one, 500mm depth throat)

Model No.: ETJSTY-818

www.noelmachinery.in

Handbook version no. 20190903

www.noelmachinery.in

NM-620 NM-826

6 ton 500 mm throat depth 8 ton 650mm throat

Main Motor 2.2Kw Main motor 3.7kw

Handbook version no. 20190903

=====================================

安全警告

客户如需自制上模时,上模的安装部位尺寸一定要按图纸要求做,否则安全

防护会失效或损坏安全开关。

压铆机上模建议选用材料Cr12加工,加工后需热处理55°-60°

Safety Warning

If customers make the upper die by themselves, the size of the mounting

part of the upper die must be made according to the drawing. Otherwise

the safety protection will fail or damage the safety switch.

It is recommended to use material Cr12 to process the die on the riveting

press. After processing, 55°-60° heat treatment is required

==========================================================================

加油说明

打开左上盖板,就可以进行对油箱的加油。

请加46#抗磨液压油,油量为55-60升。

透过前盖板的透明视窗可以观察油位高度,

最小油位大概在刻度60以上(小桶4桶)

www.noelmachinery.in

Handbook version no. 20190903

Oil Supplement

Open the upper left cover to refuel the tank.

Please add 46# anti-wear hydraulic oil. The capacity is 55-60L.

The oil level can be seen through the transparent window of the front

cover.

The minimum oil level is about above the mark 60 (4 small barrels)

upper left

cover

transparent

window

www.noelmachinery.in

Handbook version no. 20190903

==========================================================================

接总电源说明

本款机型电机功率为3.75KW

请使用(3+1; 三根相线,一根地线)2.5平方线电源线

当相序接错时,旋转总电源开关接通电源,电控箱内的相序控制器工作指示

灯不亮,按下启动按钮设备不能启动,这时需更换相序(更换任意两根相线

就可以调换相序)。

当相序接正确时,旋转总电源开关接通电源,电控箱内的相序控制器工作指

示灯会亮红灯,按下启动按钮设备就可以启动。

Main Power Connection

The motor power is 3.75kw

-Please use (3 + 1, three phase lines, one ground line)2.5 square power

line

-If the phase sequence is misconnected, when you turn the main power

switch to connect the power, the working indicator light of the phase

sequence controller in the electric cabinet won’t be on, and the device

cannot start when press the start button. At this time, the phase sequence

should be switched (switching any two phase lines will do).

-When the phase sequence is correctly connected, rotate the main power

switch to connect the power, and the working indicator light of the phase

sequence controller in the electric cabinet will turn red. Press the start

button to start the device.

www.noelmachinery.in

Handbook version no. 20190903

Power on/off

1. Turn on the main power switch, and the corresponding power indicator

will be lit.

2. Check whether the oil pump stop button is in a reset state. If there is no

reset, please reset first.

3. Press the start oil pump button, and the electric machine will start.

4. Press the stop oil pump button, the electric machine will stop.

5. If it does not work for a long time, please turn off the main power.

脚踏操作说明

脚踏操作模式有两种,可以根据实际操作需要,在制面板上进行选择。

一、 持续踩模式

工作时,脚必需一直踩住向下脚踏,整个压铆过程才能完成。

任意位置松开向下脚踏,上模具就会立即停止动作。如需继续工作,脚必需

www.noelmachinery.in

Handbook version no. 20190903

再次一直踩住向下脚踏,整个压铆过程才能完成。

工作时,如果需要模具向上运动,请踩住向上脚踏开关。

二、 点踩模式

工作时,脚只需踩一下向下脚踏,整个压铆过程会自动完成。

工作时,如果需要模具向上运动,请踩住向上脚踏开关。

Pedal Operation

There are two tap operation modes, which can be selected on the panel

according to the actual operation needs.

1. Continuous pedal mode

When working, step on the downward pedal so that the whole process of

riveting can be completed.

Release the downward pedal at any position and the upper mold will stop

immediately.If you want to continue working, step on the downward pedal

again, then the whole process of riveting can be completed.

When working, if you need the mold to move upward, please step on the

upward pedal switch.

2. Rhythmic pedal mode

When working the whole riveting process will be completed automatically

with only one step on the downward pedal.

When working, if you need the mold to move upward, please step on the

upward foot switch.

www.noelmachinery.in

Handbook version no. 20190903

Safety Protection

(Safety warning: please do not place any part of your body between the

upper and lower molds when operating the machine.

1. Conductive mode (please refer to tap operating instruction for pedals)

1). When the workpiece is conductive, turn the switch to conductive mode.

2). In the conductive mode, when the upper mold presses on a

non-conductive object, it will return immediately; when it presses on a

conductive object, it will continue to work.

2. Non-conductive mode (please refer to tap operating instruction for

pedals)

1). When the workpiece is non-conductive, please rotate the switch to the

non-conductive mode.

2). In the non-conductive mode, when the upper mold presses on a

non-conductive object, it will stop immediately. If you need to continue

working, please step on the pedal again.

=====================================================================================

保压时间说明

参照控制面板,顺时针增大保压时间,逆时针减小保压时间。

当上下模具压紧工件时,可以根据需要对工件进行1-5秒的保压时间设置,

当上下模具达到保压时间,会自动返回。

Pressure Holding

www.noelmachinery.in

Handbook version no. 20190903

Referring to the control panel, turn clockwise to increase the pressure

holding time and turn counterclockwise to reduce the pressure holding

time.

When upper mold and lower mold press the workpiece, 1-5 seconds of

pressure holding time can be set according to the need. When the upper

mold and lower mold reach the pressure holding time, it will return

automatically.

返回位置说明

参照控制面板,顺时针增大上下模具之间的高度。

逆时针减小上下模具之间的高度

警告:当返回位置过高时,在返回时,压力表会有压力指示(因为返回行程

已走到极限,造成油缸活塞与端盖接触),这时要适当减小返回位置高度。

Return Position Setting

Referring to the control panel, turn clockwise to increase the distance

between the upper mold and lower mold.

Turn counterclockwise to reduce the distance between the upper mold

and lower mold.

Warning: when the return position is too high, the pressure gauge will

have pressure indication on return (because the return stroke has reached

the limit, resulting in the contact between the cylinder piston and the end

www.noelmachinery.in

Handbook version no. 20190903

cover). At this time, the return position should be reduced appropriately.

压力调整说明

参照压力调整面板,松开锁紧螺母,顺时针加大压力,逆时针减小压力;

压力调整完成后请锁紧螺母。

调压手柄后面的锁紧螺母不能卸下。当压力调整的太小时,有可能会造成调

压手柄掉落,请立即安装上。本机型建议最大使用压力在175以内。

(客户进行抽牙时,压力调到0-50之间,把保压时间尽量调小)

Pressure Adjustment

Referring to the pressure adjustment panel, loosen the lock nut, turn

clockwise increase the pressure, and turn counterclockwise to decrease

the pressure. Lock the nut when the pressure is adjusted.

The lock nut at the back of the pressure regulating handle cannot be

removed.When the pressure is adjustedtoo low, the pressure regulating

handle may fall off. Please install it back immediately.The recommended

maximum operating pressure of this model is within 175.

(When flaring, the pressure shall be set between 0 and 50, and the

pressure holding time shall be adjusted to be as short as possible)

www.noelmachinery.in

Handbook version no. 20190903

Stroke Limit Adjustment

Tip: use only when necessary.(Press rather soft materials or for other use)

Note: when using limit, the pressure should be controlled below 100.

1. Loosen the lock nut and the limit nut can be rotated to adjust the

downward position. Lock the lock nut after adjustment. Otherwise, the

screw will be damaged.

2. When adjusting the height limit and the device cannot automatically

return, it means the limit is exceeded. Please step on the upward pedal to

let the device return and then reset the height limit.

Lock nut

Limit nut

www.noelmachinery.in

Handbook version no. 20190903

主电路控制原理图

安全警告:当需检查或维修电路时,请先关闭总电源

Main Circuit Control Schematic Diagram

Safety warning: when you check or repair the circuit, please turn off the

main power.

www.noelmachinery.in

Handbook version no. 20190903

Control panel instruction

Press-hand preventing switch

(when the equipment is only powered on, not running, the upper mold and

lower mold doesn’t contact, the machine will not work when the light is on. Push

up the mold with hand, release,and see whether the light will be off.If the light is

off, fault can be eliminated.The fault is that the safety switch is not reset.)

Solenoid valve upward

(mold upward solenoid valve working indicator)

Solenoid valve downward

(mold downward solenoid valve working indicator)

Pedal downward switch

(step on pedal switch, this light will be on. If not, check the pedal switch or

pedal switch control line.)

Pedal upward switch

(step on pedal switch, this light will be on. If the light is not on, check the pedal

switch or the pedal switch control line. In any case, step on the pedal switch

and the upper die will return.)

Laser LED

15 pin positive electrode (red) 16 pin negative electrode (black)

Upper and lower mold switch

(If the upper and lower mold are not in contact, the light will notbe on. If the

light is on, there’s an equipment failure and the machine won’t work.)

www.noelmachinery.in

Handbook version no. 20190903

Counter

Laser switch

Conductive/non-conductive switch

(Please refer to “Safety protection instruction”)

Rhythmic tap/continuous tap (Please refer to “Tap operation mode

instruction”)

AC 24V input

www.noelmachinery.in

This manual suits for next models

1

Table of contents

Popular Rivet Tools manuals by other brands

LOBSTER

LOBSTER N1A2 instruction manual

Gesipa

Gesipa taurus 1 Operating manual with spare parts list

Chicago Pneumatic

Chicago Pneumatic CP4281 Operator's manual

Powerfix

Powerfix Profi+ PBNZ 4 B3 quick start guide

TKR Group

TKR Group PNP 90 SNW-RIV instruction manual

Worcraft PROFESSIONAL

Worcraft PROFESSIONAL CRG-S20Li instruction manual