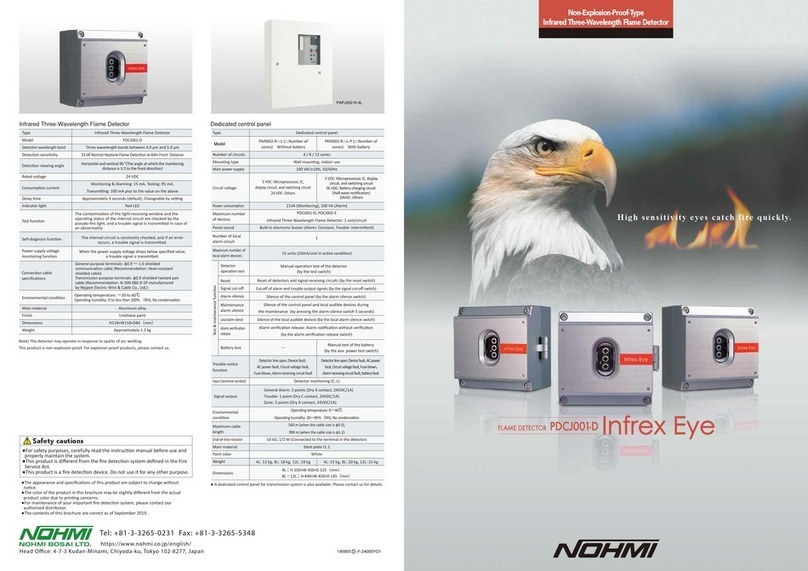

NOHMI FDGJ103-D-X/XHT User manual

5mー100m

OPERATING MANUAL

Projected Beam Type Smoke Detector

Models FDGJ103/203-D-X/XHT

TN51541e-1

CAUTION Be sure to read this manual before use of this product. In addition,

carefully read and understand all the warning/cautions/notes in this

manual to use/operate this product.

● Please keep this operating manual in place so that it may be available at all

the times.

● Be sure to conduct the regular inspection and maintenance for this product.

INTRODUCTION

CONTENTS

Thank you for purchasing our projected beam type smoke detector. This detector

has passed various tests in accordance with the standards of the Japanese Fire

Service Law and is approved as the national type approval product.

Be sure to read this manual carefully before use of this product to properly

use/operate this product in case of fire. Please keep this operating manual in

place so that it may be available at all the times.

1. FEATURES OF THIS PRODUCT• • • • • • • • • • • • • • • • • • • • • • • • • •

2. BEFORE USE• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

3. CAUTIONS FOR USE • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

4. CAUTIONS ON INSTALLATION WORK AND OPERAION • • • • • • • •

5. ITEMS REQUIRED FOR INSTALLATION• • • • • • • • • • • • • • • • • • • •

6. NAME OF EACH PART • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

7. WORK FLOW• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

8. CONNECTION WITH FIRE CONTROL PANEL• • • • • • • • • • • • • • • •

9. INSTALLATION/CONNECTION/SETTING • • • • • • • • • • • • • • • • • • •

10. CONNECTION OF HEATER (HEATER TYPE ONLY)• • • • • • • • • • •

11. LIGHT AXIS ADJUSTING METHOD• • • • • • • • • • • • • • • • • • • • • • •

12. LIGHT AXIS ADJUSTING METHOD (FLICKERING PATTERN)• • • •

13. TROUBLESHOOTING• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

14. REGULAR MAINTENANCE & INSPECTION • • • • • • • • • • • • • • • •

15. SPECIFICATIONS• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

1

2

3

4

5

7

8

9

11

12

17

19

22

23

- 1 -

1. FEATURES OF THIS PRODUCT

2. BEFORE USE

WARNING

CAUTION

● Sensitivity Compensation Function to Keep Stable Function

: The detector sensitivity is automatically compensated and adjusted even in

case that the level of the light received by the light receiver is decreased due

to contamination on the detector lens surface.

● Light Axis Adjustment without Voltmeter (Tester)

: Light output can be checked by means of the light emitting pattern of the

indicator lamps, without using a voltmeter.

● Easy Installation

: This product can be installed as an unit with the assembled state by

changing the assembling Combination of the base, the cover and the body

depending on the installation site conditions.

● To use this product safely, this operating manual contains various cautions.

Before using this product, understand the following caution markings together

with the statements and read this manual. When using this product, be sure to

bring this manual at all times.

Mishandling may result in the user exposed to serious injuries or damage.

Failure to observe these guidelines may also cause serious damages to a part

of the fire protection function of the product.

Mishandling may result in the user injuries. Failure to observe these guidelines

may also have an adverse effect on the fire protection function of the product.

It is important to observe these guidelines at all times in order to effectively

utilize the fire protection functions over long-term use.

This mark shows a matter related to Danger, Warning or Caution.

■ CAUTION Markings

This mark shows an action to be taken or the instructions on

actions.

This mark shows the prohibition of actions.

- 2 -

3. CAUTIONS FOR USE

● Where it is directly exposed to rain or water.

● Where smoke or mist is usually generated.

● Where the light receiver is subjected to direct sunlight or strong

illumination light.

● Where the ambient temperature is lowered below -10°C or

exceeds 50°C.

● Where the mounting position of the detector is subjected to

vibration or strain. (Install the detector on a rigid position such as a

support/pillar of the main structure.)

● Where it is difficult to perform maintenance and inspection.(Space

of 50cm in vertical and horizontal directions (50cm each in

left/right/up/down directions) is required for surrounding of the

detector. In case that the ceiling height is 2.5 m or lower, pay

attention to the upper space. Example: If the ceiling height is

2.1m, the upper space is to be 42cm.)

● Where the light axis (between the light transmitter and receiver)

may be interrupted due to transportation of objects or a

transparent obstacle such as glass.

● In a place where a ball or a bar is usually used, such as

gymnasium, apply the protective cover (Model FZP014).

As this product is not of outdoor type, DO NOT install it in any of the following

places. (If installed, it may cause a malfunction or abnormal operation.)

Space for a screwdriver is required in the

above of the detector.

Prohi-

bition

Installation Standard :

The detector shall be installed so

that the height of the light axis

exceeds 80% of the ceiling

WARNING

- 3 -

4. CAUTIONS ON INSTALLATION WORK

AND OPERATION

● Be sure to arrange a secure scaffold.

● Make sure that nobody is located under the worker installing the

detector.

● Turn OFF the power supply of the fire control panel and remove

the battery provided in the panel as the auxiliary power. (Excl. the

case for light axis adjustment after installation work)

● Ensure that this product is not damaged due to drop, impact or

handling of a tool.

● DO NOT touch the front plate nor the lens. (If touched, the front

plate or the lens may contaminated, causing an adverse effect on

the detector function.)

● The Models FDGJ103/203-D-XHT are equipped with a heater.

As the heater becomes hot, NEVER touch. If touched, you may

get burnt.

(Position of heater Refer to 6. NAME OF EACH PART on

Page 6.)

● NEVER apply any vibration or impact/shock to the product,

disassemble/modify the product, or insert any foreign material into

the product, as these actions may cause a fault in the product.

● As this product is a component device of the automatic fire alarm

system stipulated in the Japanese Fire Service Law, do not use it

for any other applications.

When installing and operating this product, pay attention to the following matters.

Prohi-

bition

WARNING

INSTRUC-

TIONS

- 4 -

5. ITEMS REQUIRED FOR INSTALLATION

To install this product, the following items are used.

Arrange them according to the necessity.

No.

1

DESCRIPTION

Phillips type screwdriver For M4 and M5 screws

Test filter set (Model FXG012C)

REMARK

2

Battery connector for detector

test

If the auxiliary battery (for test) (24V,

with connector) is used, arrange it.

3

4

Solderless tool and terminals

(with heater type)

Auxiliary battery (for test)

(24V, with connector)

The light axis of this detector can be

adjusted with the auxiliary power

supply (Battery, 0.225AH to 3.5AH ).

In case of the detector with heater,

connection of the heater power is

made with solderless method.

(AWG22(0.3mm2) and AWG20

(0.5mm2) wires one each)

5

- 5 -

Light transmitter

Left :Power lamp

(Green)

Right:Test lamp

(Red)

6. NAME OF EACH PART

Cover Body fixing screwFront plate

Cover fixing screw

Light axis adjusting

screw (Vertical)

Collimation

hole

Light receiver

Left :Fire alarm lamp

(Red)

Right:Trouble lamp

(Yellow) Lens

Body

Indicator lamp

Cover hook

Viewing hole

Light axis adjusting

screw (Horizontal)

MONITOR/ADJUST.

Switch

Body fixing screw

- 6 -

Heater (Heater type only)

Battery connector

Tarminal base

Name plate Name plate

Light receiver

Light transmitter

Bottom view

Right side viewLeft side view

Range setting switch

(Light receiver only)

Sensor output jack

(Light transmitter only)

Light axis adjusting

screw (Horizontal)

Light axis adjusting

screw (Vertical)

- 7 -

7. WORK FLOW

Install this product according to the following work flow.

We recommend to install the light receiver first.

Light Receiver

①Installation • • • • • • • • • • • • • • • • • • • • • • • • • • • •

②Connection • • • • • • • • • • • • • • • • • • • • • • • • • • • •

③Setting • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

④Adjustment (Coarse adjustment) • • • • • • • • • • • • •

※Fine adjustment is not required for the light receiver.

Light Transmitter

⑤Installation • • • • • • • • • • • • • • • • • • • • • • • • • • • •

⑥Connection • • • • • • • • • • • • • • • • • • • • • • • • • • • •

※Setting is not required for the light transmitter.

⑦Adjustment (Coarse adjustment) • • • • • • • • • • • • •

⑧Adjustment (Fine adjustment) • • • • • • • • • • • • • • •

Page9 to Page10

Page8 and Page10

Page11 (Heater type only)

Page10 to Page11

Page12

Page9 to Page10

Page8 and Page10

Page11 (Heater type only)

Page12

Page13 to Page18

- 8 -

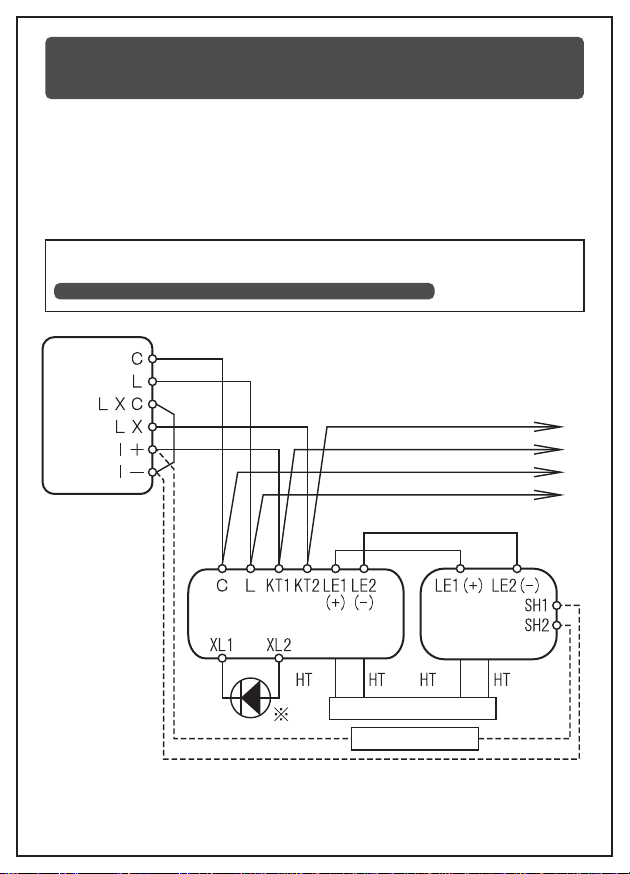

Connection shall be made as shown below.(Applicable wire for the terminal

base of the detector is a single line, φ0.4 to φ1.6.)

● Line resistance between the fire control panel and the light receiver of the

detector (C-L, KT1-KT2) shall be 50Ω or less.

● Line resistance between the light transmitter and the light receiver of the

detector (LE1, LE2) shall be 30Ω or less.

※As the remote indicator lamp FLL061 and the signal transmission adaptors

FRL014,pay attention to the polarities of the terminals XL1 and XL2.

As the synchronization lines(LE1(+), LE2(-))has the polarities, pay attention to

their connection. As for connection of the heater, refer to

10. CONNECTION OF HEATER (HEATER TYPE ONLY) on Page11.

8. CONNECTION WITH FIRE CONTROL

PANEL

Power supply for heater

Test push button

Light receiver Light transmitter

Next detector

P- type

(conventional)

fire

control

panel

- 9 -

9. INSTALLATION/CONNECTION/SETTING

As fine adjustment is to be performed on the light transmitter, install the light

receiver and adjust the light axis of the light receiver first, and then, install the

light transmitter and adjust the light axis of the light transmitter.

When installing and operating this product, pay attention to the following matters.

● Be sure to arrange a secure scaffold.If not, an installation worker

may fall down the scaffold and be injured.

● Mount the light transmitter and receiver of the detector on the rigid

wall and the like. If installed on an unstable location, the detector

may not perform normal monitoring.

①Loosen

②Open

④Remove

③Loosen

⑤Fix

⑥Tighten

Body

If loosen the cover fixing screw,

the cover moves toward you.

INSTALLATION

WARNING

CAUTION

Make sure that the cover is

secured to the cover hooks on

both sides of the detector base.

If not, the cover may drop.

Cover

INSTRUC-

TIONS

- 10 -

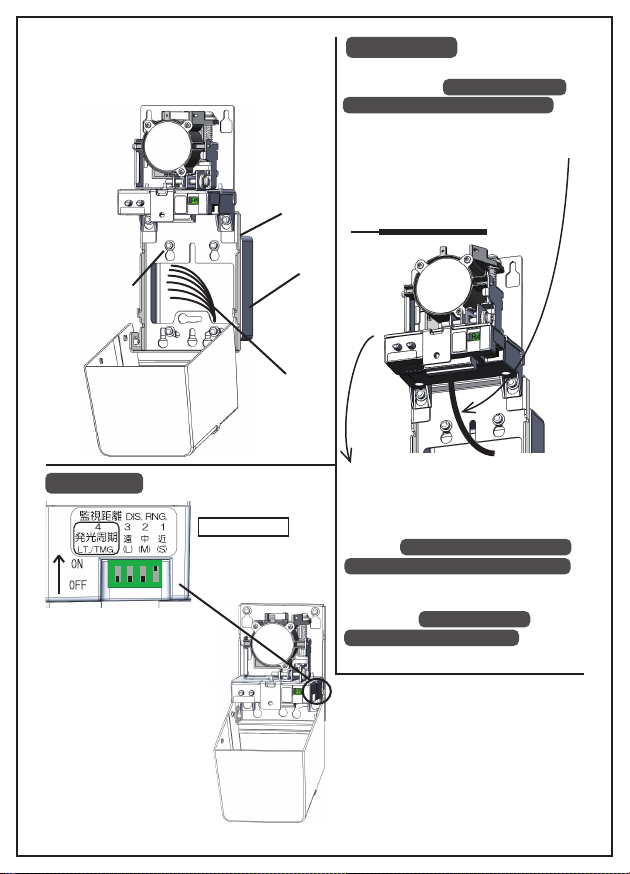

Securely fix the detector to the switch

box with four M4 screws

In case of the

light receiver , set

the monitoring

range and the light

emission cycle.

S:(ON)Short range

(5-20m)

M:(ON)Medium range

(20-40m)

L:(ON)Long range

(40-100m)

CONNECTION

SETTING

Base

Switch box

Wire

⑧Insert the wire into the terminal

base. Refer to 8. CONNECTION

WITH FIRE CONTROL PANEL on

Page 8.

As the terminals LE1(+) and LE2(-)

have the polarities, pay attention

when connecting the wire.

Applicable wire : φ0.4 to 1.6mm

Strip gage : 10mm

⑨Remove the body and mount it

again to the original position and

tighten the two screws.

As for connection of the heater,

refer to 10. CONNECTION OF

HEATER (HEATER TYPE ONLY)

on Page 11.

After installing the light transmitter,

proceed to 11. LIGHT AXIS

ADJUSTMENT METHOD

on Page 12.

⑦Tighten

⑩Select

LT. / TMG.:

The light emission cycle:

(ON) 2.8 second / (OFF) 3.0 second

Please refer to next page for details.

- 11 -

10. CONNECTION OF HEATER

(HEATER TYPE ONLY)

To prevent interference, set the light emission cycle No.4 of

the adjoining detectors to ON and OFF alternately.

To install the heater type (Models FDGJ103-D-XHT and 203-D-XHT), connect

the heater with the power supply for heater.

Connect the heater with the power lines of

heater by means of insulated open-end

connectors and apply waterproof treatment

to the connection by means of self-fusing

tape and the like.

Setting of Monitoring Range and Light Emission Cycle

S:(ON) Short range (5-20m)

1:(ON)

M:(ON) Medium range (20-40m)

2:(ON)

L:(ON) Long range (40-100m)

3:(ON)

INSTRUC-

TIONS

- 12 -

11. LIGHT AXIS ADJUSTING METHOD

11.1. Coarse Adjustment with Collimation Hole (Common to Light

Transmitter and Receiver)

View the mirror through the viewing hole, and turn the light axis adjusting

screw(s) (vertically and/or horizontally) so that opposing light receiver

(viewed from the transmitter) and the opposing JIS box (viewed from the

receiver) may be located in the viewing hole.

Image Viewed through Viewing Hole

Light Receiver: Opposing JIS Box

Light Transmitter : Opposing Light Receiver

When the heater (for preventing dew condensation) is energized,

it becomes hot (about 60°C). Therefore, pay attention not to

touch it during the installation work. If touched, it may cause you

to be burnt.

HIGH

TEMP.

After adjusting the light axis, set the cover again and tighten the

screw. In case of the light transmitter, proceed to the installation

of the light transmitter (Paragraph 9 on Page 9) and in case of

the light transmitter, proceed to Para.11.2 on the next page.

INSTRUC-

TIONS

Viewing hole

Heater

Collimation

hole

Mirror

Light axis adjusting

screw (Vertical)

Light axis adjusting

screw (Horizontal)

- 13 -

INSTRUC-

TIONS

CAUTION

11.2. Power Energization (Recommend to energize to Light Transmitter)

Connect the battery connector for detector test to the connector on the left

side of the detector (when viewed from the front of the detector), and next,

connect the battery connector for detector test to the auxiliary battery. In

this case, the Adjustment Mode alone is effective. (In case that no battery

is available, turn ON the power of the fire control panel.)

11.3. Switchover of Adjustment Mode

(Recommend to switch over Adjustment Mode on Light Transmitter)

At a lapse of about 10 seconds after power

ON, the detector

becomes operational.(In case that the power is

fed through the battery connector of the light

receiver, the green LED of the receiver lights

every 3 seconds. When the power is fed to the

light transmitter, the green LED of the receiver

does not light.

Stand at a position so that you may not

interrupt the light axis (You can see the

detector as shown on the left figure.).

Press MONITOR/ADJUST. Switch for one

second and then, release the switch, and the

indicator lamps emit lights as follows ;

※In case of the light receiver, operate the

MONITOR/ADJUST. Switch in the same way.

(Light Transmitter : Green and red LEDs light at

the same time and then, flicker alternately.)(Light

Receiver : Yellow LED flickers every one

sec.)Wait (about 4 sec.) until alternate

flickering of the indicator lamps is finished.

The power can be supplied through the battery connector of the

light transmitter or light receiver or the terminals C and L of the

light receiver. To avoid a malfunction, ensure that the power is

supplied via one route.

No adjustment can be made when the Fire Alarm Lamp on the

light receiver is lighting. In case that the power is supplied

through the battery connector of the light receiver, pull out the

battery connector and wait for about 15 seconds. Then, connect

the battery connector again.

Auxiliary battery

Battery connector for detector test

- 14 -

Image of the Paragraphs 11.4 and 11.5 on Page 15 and Paragraph 12 on Page

17 is shown below.

The relationship between the light emission pattern and output of the light

transmitter in case of the light axis adjustment is as follows.

To ensure stable monitoring of the detector for long period, set the light

output to the peak as possible as you can according to the following steps

①→② (Allowance for imperfect alignment of light axis generated after

installation).

①Turn the Light Axis Adjusting Screw until green flickering of the indicator lamp

(Power Lamp) of the light transmitter becomes red on the left and right side

ends. Then, set the light axis to the center within the green flickering range.

②Adjust the light axis in the vertical direction in the same manner as stated in

the above ①

①②

The relationship between

the light axis and flickering

pattern of the indicator

lamp :

Flickering pattern of the

indicator lamp may change

due to light axis adjustment

on the light transmitter.

GreenGreen

Red

Red

Image of Fine Adjustment of Light Trnsmitter

Turn the light axis adjusting

screw.

Turn the light axis adjusting

screw oppositely.

- 15 -

11.4. Fine Adjustment of Light Transmitter (in Horizontal Direction)

Turn the Light Axis Adjusting Screw (Horizontal), and the flickering pattern

of the green indicator lamp changes according to the condition of the

received light output.

11.6 Switchover of Monitoring Mode

If the green indicator lamp flickers after

adjusting the light axis in the vertical

and horizontal directions, press the

MONITOR/ADJUST. Switch for two

seconds or over and then,release it.

(Both the green and red indicator

lamps light at the same time.)

Adjust the light axis in the vertical

direction in the same manner as

described in the above 11.4.

11.5 Fine Adjustment of Light Transmitter (in Vertical Direction)

CAUTION

DO NOT use a motor-driven

screwdriver. If used, it may

cause the screw to be

damaged.

DO NOT interrupt the light axis during the switchover of the

Adjustment and Monitoring Modes.

Normally, the indicator lamp flickers in

green first. Turn the screw clockwise or

counterclockwise to flicker it in red.

Change flickering of the lamp in the

order of “red→green→red” and check

the range of green flickering and align

the light axis to the center of it.

Make the fine adjustment of the light axis by means of the Light Axis Adjusting

Screw so that the indicator lamp (Power Lamp) of the light transmitter flickers

only in green.

After green flickering of the indicator lamp goes out, pull out the battery

connector for detector test. In case that the power is fed through the

terminals C and L, it is not necessary to cut off the power supply of the fire

control panel.

Image of light emission pattern in

Horizontal direction (Viewed from

the top.)

Image of light emission pattern in

Vertical direction

(Viewed from the side.)

INSTRUC-

TIONS

Refer to Para.12 LIGHT AXIS ADJUSTMENT METHOD

(FLICKERRING PATERN)

Red

Red

Green

Red

Green

Red

- 16 -

11.7. Mounting of Cover (Completion of Adjustment)

Close the cover and tighten the screw. If tightened,

the cover, is fixed to the detector body.

Indicator Lamp

Red

Red (quick

flickering)

Green

Green (quick

flickering)

Green/Red

(simultane-

ous

flickering)

In case of

Trouble

①

②

③

④

Flickering Pattern Status/Operation

In case that the power is fed from the fire control panel, be sure

to close the cover within one minute after green flickering of

the indicator lamp goes out.(If the cover is closed after a lapse

of more than one minute, the detector may fail to monitor fire

properly.

If the status of the indicator lamp (②RED, quick flickering) in the

above table does not change, chek the setting of monitoring range

of the light receiver and press the MONITOR/ADJUST. Switch.

INSTRUC-

TIONS

Initial stage of adjustment

:Turn the Light Axis Adjusting Screw

clockwise or counterclockwise.

Insufficient output of received light

:Turn the Light Axis Adjusting Screw in

the reverse direction of the above ①.

Sufficient monitoring output

:Set the light axis in the center of this

range (In case that the indicator lamp

does not flickers quickly.).

Increase in output of received light

: Set the light axis in the center of this

range.

Check for the request of switch

operation (output saturation and the

like) and status of light receiver/

transmitter, and press the MONITOR/

ADJUST. Switch.

In this case, NEVER touch the front plate (black) as the

light output may lower due to contamination of the front plate.

INSTRUC-

TIONS

11.8. List of Flickering Patterns

- 17 -

Flow of Fine Adjustment

1

2

3

4

Flickering Pattern of Indicator

Lamps on Light Transmitter

Green and red

indicator lamps

flicker at the same

time.(one time)

Green and red indicator lamps

flicker alternately.

Green indicator lamp starts

flickering.

Green indicator lamp flickers.

Red indicator lamp flickers.

Operation and flickering pattern of the indicator lamps on the light transmitter

during light axis adjustment are as shown in table below.

Adjustment

Press the MONITOR/ADJUST. Switch for

one second and then, release it.

Wait for about four seconds, without

interrupting the light axis by your hand or

body and the like.

Turn the Light Axis Adjusting Screw

clockwise to the point that the green

indicator lamp stops flickering and the red

one starts flickering.

Then, the green indicator lamp alone starts

flickering. As it means that you are ready

for light axis adjustment, perform the steps

4 to 6 below in every four directions

(UP/DOWN/LEFT/RIGHT) respectively to

align the light axis to the center.

(If the light axis is interrupted by your hand

or body and the like, the red indicator starts

flickering. In this case, repeat the same

operation from the above step 1 again.)

12. LIGHT AXIS ADJUSTING METHOD

(FLICKERING PATTERN)

- 18 -

6

7

Flickering Pattern of Indicator

Lamps on Light Transmitter

Red indicator lamp flickers.

Green indi cator lamp flickers.

Green indicator lamp flickers.

Green indicator lamp flickers

quickly.

Green indicator lamp flickers.

Green and red indicator lamps

flicker at the same time.

Green indicator lamp flickers.

Green indicator lamp goes out.

Adjustment

Set the light axis to the center of green

flickering range.

(Turn the screw clockwise by the half

volume turned counterclockwise at the

above step 5.)

When the Light Axis Adjusting Screw is

turned, flickering of the green indicator

lamp may turn into quick flickering. In this

case, set the light axis to the center of

green quick flickering range (Turning

volume of the screw can be reduced.)

Press the MONITOR/ADJUST. Switch for

2 seconds, and release it, and the green

and the green and red indicator lamps

flicker at he same time. Then, the green

lamp alone flickering and finally it goes out.

After the green indicator lamp goes out,

mount the cover.

Supplement

Red indicator lamp flickers.

Green indicator lamp flickers.

Red indicator lamp flickers.

5

Turn the Light Axis Adjusting Screw

counterclockwise to the point that the red

indicator lamp stops flickering and the

green one starts flickering and next, the

green indicator lamp stops flickering and

the red one starts flickering again.

This manual suits for next models

1

Table of contents

Other NOHMI Security Sensor manuals

Popular Security Sensor manuals by other brands

SKF

SKF TKSU 10 Instructions for use

IFM Electronic

IFM Electronic efector300 SM8001 operating instructions

B.E.G.

B.E.G. LUXOMAT PD4-S-K manual

PCB Piezotronics

PCB Piezotronics 109C11/PCS-2AF Installation and operating manual

Korno

Korno GT-1000 SERIES user manual

Antec Scientific

Antec Scientific FlexCell user manual

Versahaul

Versahaul VH-SR quick start guide

Niko

Niko 25421 quick start guide

TOOLCRAFT

TOOLCRAFT OG08 operating instructions

Autronica

Autronica AutroSense 75 Installation & Commissioning Handbook

Elenco Electronics

Elenco Electronics AK-510 Assembly and instruction manual

AJAX Systems

AJAX Systems DoorProtect user manual