Warning: To risk of personal injury, do not bend the blade arms (also referred to as flanges) or the brackets while

balancing the blades or cleaning the fan. Do not insert foreign objects between rotating fan blades.

Warning:

for fan support” with the screws provided with the outlet box.

To reduce the risk of fire, electric shock, and personal injury, mount fan to outletbox marked ”acceptable

Safety Rules – Read and Save These Instructions

before beginning.

2. All wiring must be in accordance with the national and local electrical codes. Electrical installation should

be performed by a qualified licensed electrician.

3. WARNING: To reduce the risk of electric shock or fire, do not use this fan with any solid-state fan-speed

control device. It will permanently damage the electronic circuitry.

4. CAUTION: To reduce the risk of personal injury, use only the screws provided with the outlet box.

5. The outlet box and support structure must be securely mounted and capable of reliably supporting a

minimum of 35 lb (15.9 kg). Use only UL listed outlet boxes marked “FOR FAN SUPPORT.”

6. The fan must be mounted with a minimum of 7' (2.13 m) from the trailing edge of the blades to the

floor.

7. Avoid placing objects in the path of the blades.

8. To avoid personal injury or damage to the fan and other items be cautious when working around or

cleaning the fan.

9. Do not use water or detergents when cleaning the fan or fan blades. A dry dust cloth will be suitable for

most cleaning.

10. After making electrical connections, spliced conductors should be turned upward and pushed carefully

up into the outlet box. The wires should be spread apart with the grounded conductor and the

equipment-grounding conductor on one side of the outlet box and the ungrounded conductor on the

other side of the outlet box.

11. All set screws must be checked and retightened where necessary

before installation.

Warning: To reduce the risk of fire, electric shock, or personal injury, mount to outlet box marked "acceptable for

fan support of 35 lb (15.9 kg) or less" and use mounting screws provided with the outlet box. Most outlet boxes

commonly used for the support of light fixtures are not acceptable for fan support and may need to be replaced.

Due to the complexity of this fan, a qualified licensed electrician is strongly recommended.

!

!

!

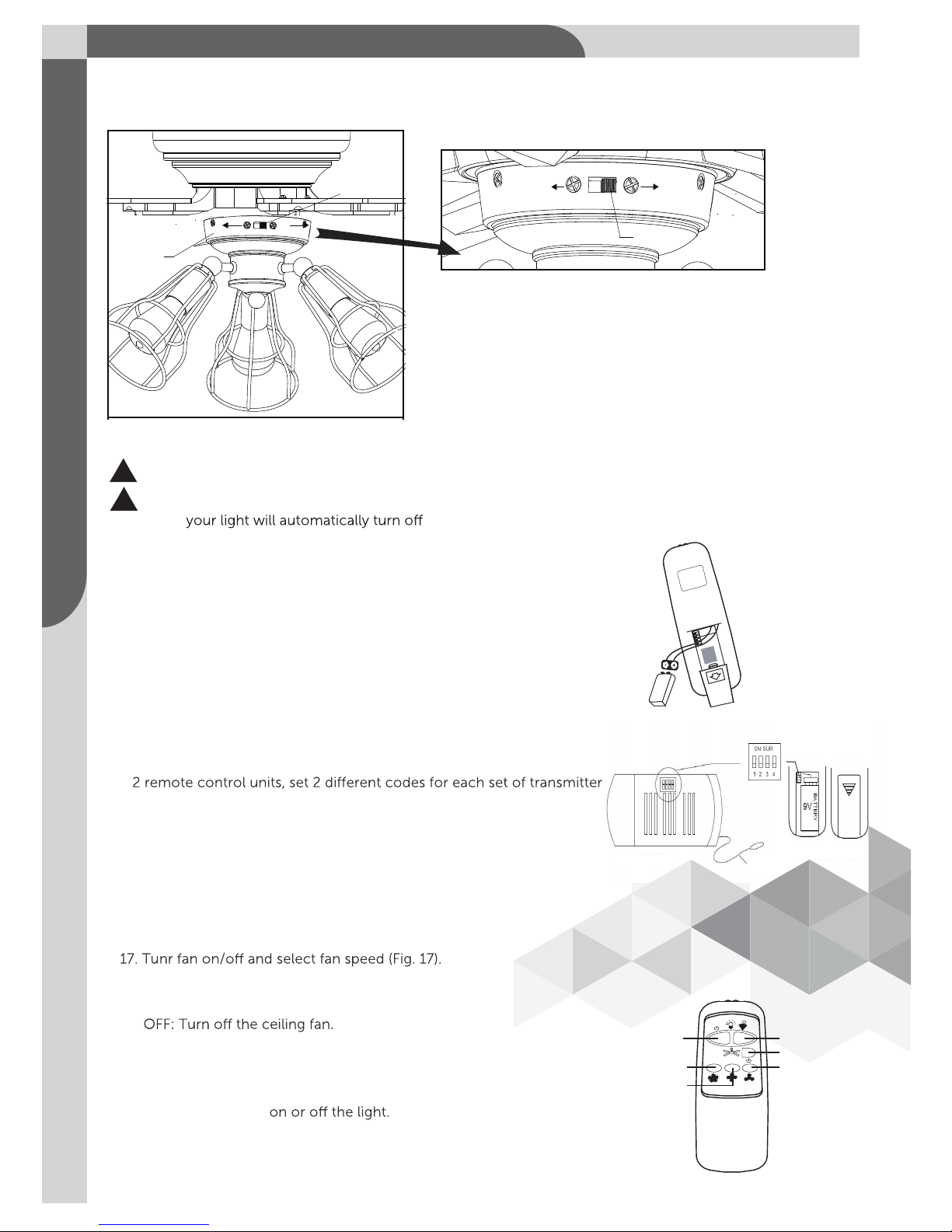

Attention: This product is equipped with a 190 W limiting device. If lamping exceeds 190 W the light kit will shut

bulbs with the correct wattage, and then turning the light kit back on.

!

IMPORTANT: RETAIN FOR FUTURE REFERENCE, AND READ CAREFULLY.

Toll Free 1-866-827-4985 model no. 052-8687-4