Norac UC4+ Raptor Pro 1200 User manual

Table of contents

Other Norac Controllers manuals

Norac

Norac UC4+ User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4 Plus Rogator 1286C User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ 1200/1600 User manual

Norac

Norac UC4+ Hardi OEM User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac Case AFS Pro 600 User manual

Norac

Norac UC4 Plus Rogator 64 Series User manual

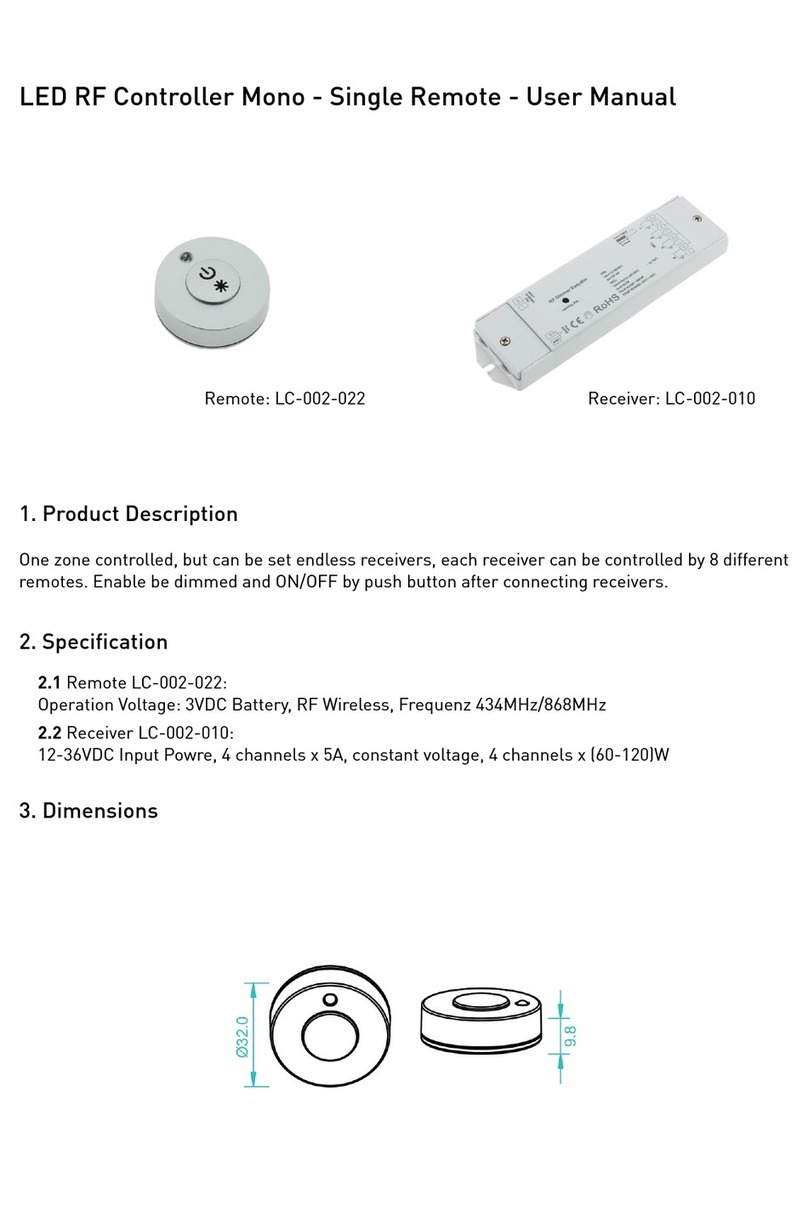

Popular Controllers manuals by other brands

Denali

Denali CANsmart DNL.WHS.24700 instruction manual

Real-El

Real-El STAB-300 Operation manual

Nordson EFD

Nordson EFD ValveMate 9000 quick start guide

Simplex

Simplex RTL-TH DIGITAL Installation and operating instructions

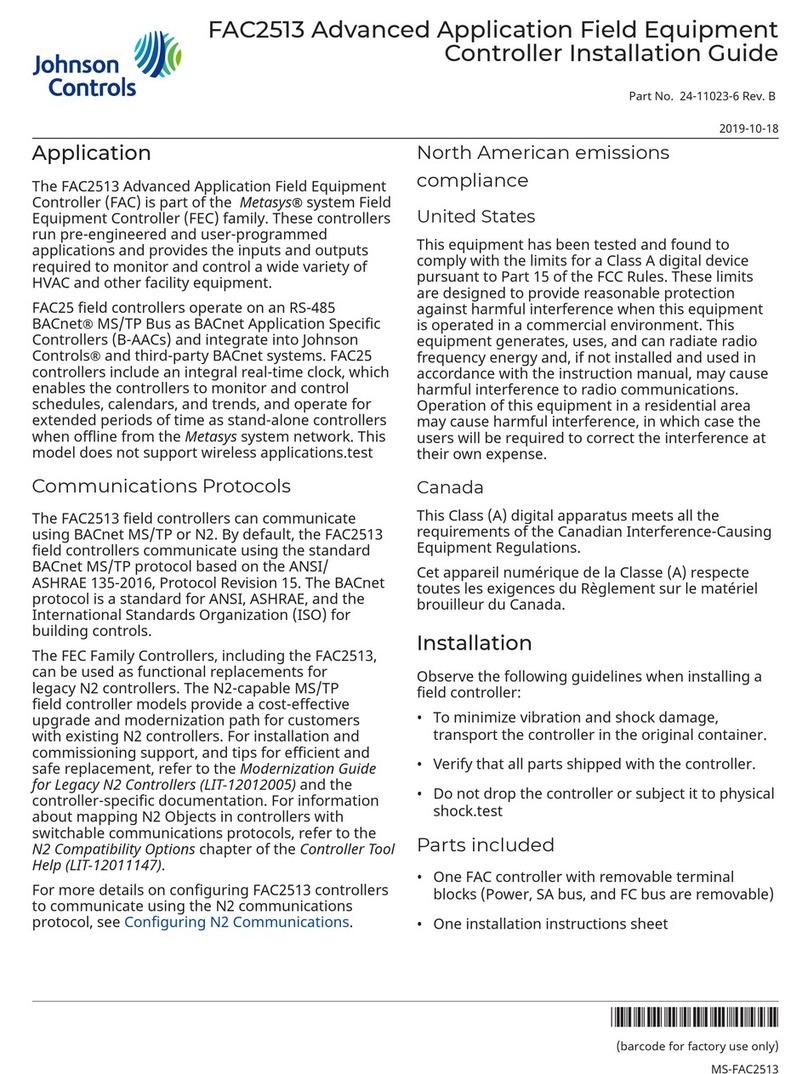

Tyco Security Products

Tyco Security Products DSC TL8803GI-IL2 manual

Crestron

Crestron onCue BPC-8 Supplemental guide

Heateflex

Heateflex PF2000 manual

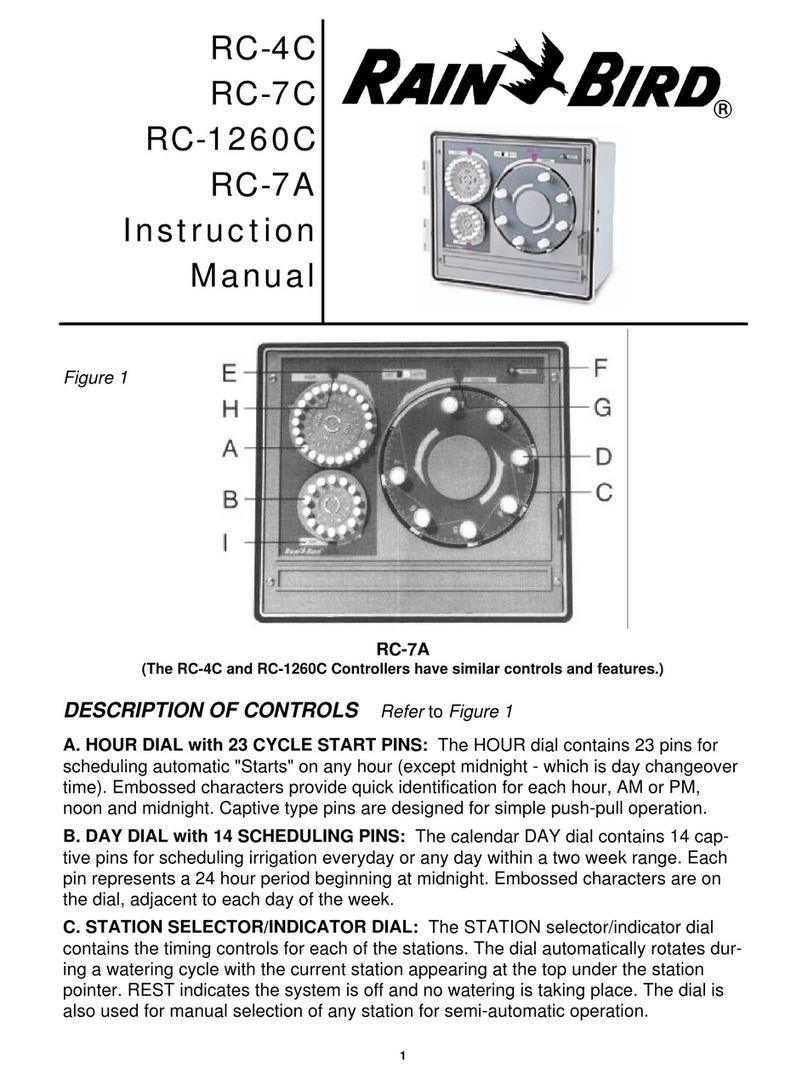

Rain Bird

Rain Bird RC-4C instruction manual

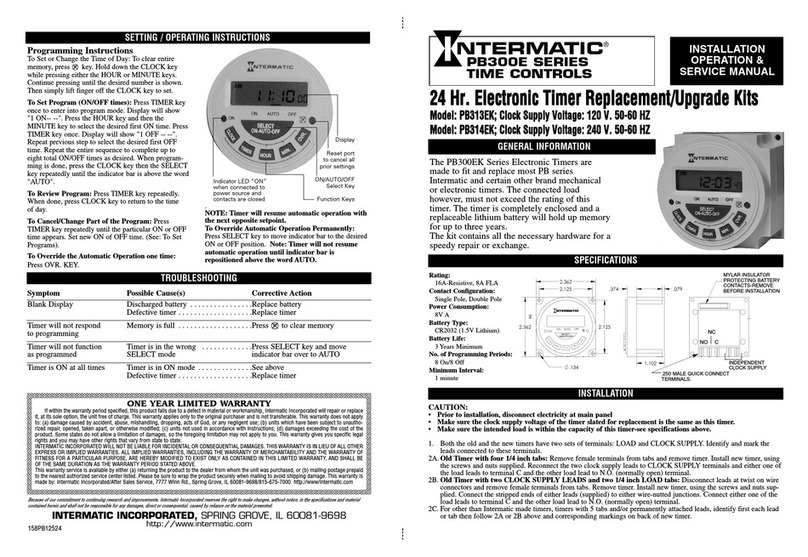

Intermatic

Intermatic PB313EK Installation, operating & service manual

Phasetronics

Phasetronics 1P1 Series Operation and service manual

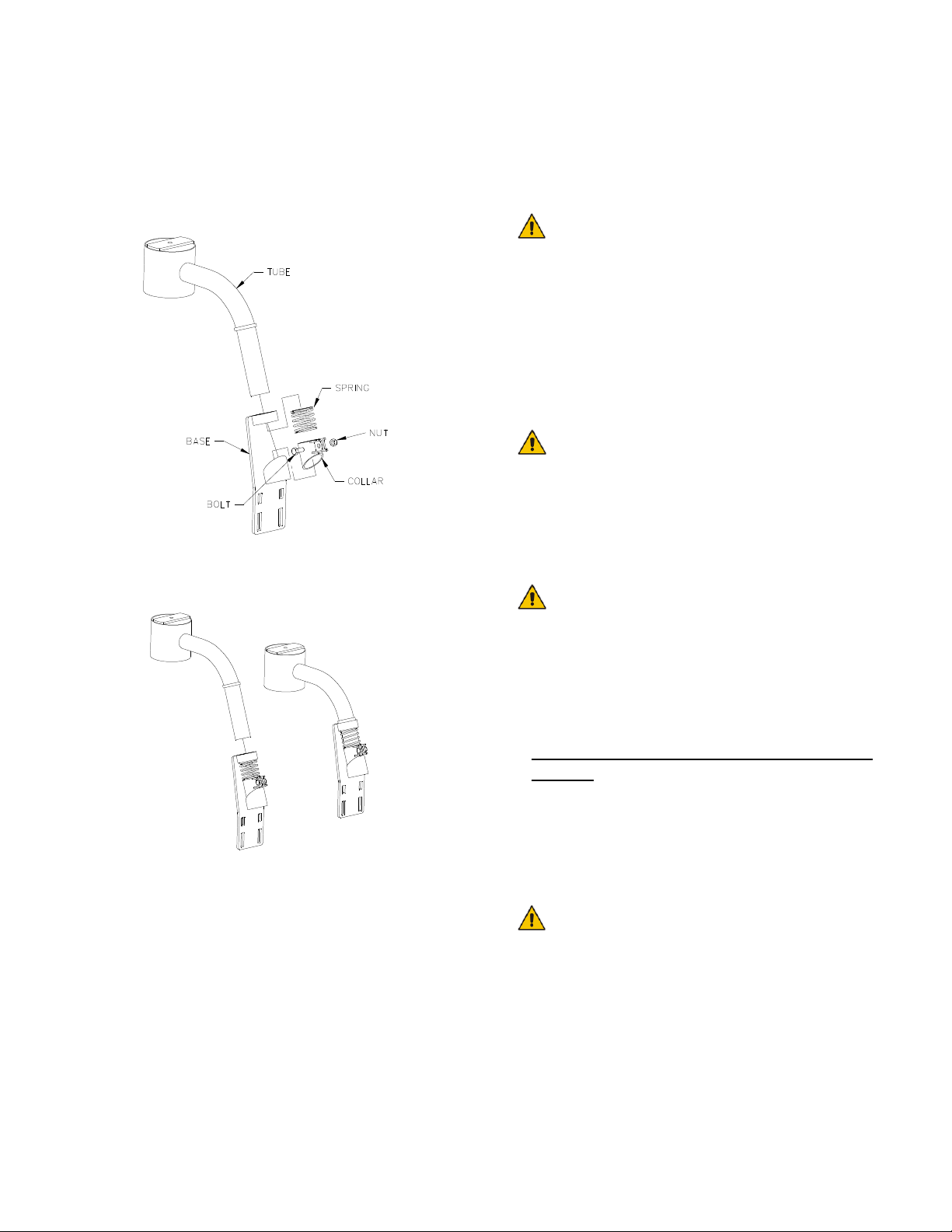

Alcor

Alcor AU9381 Technical reference manual

MEDENUS

MEDENUS RSP 254 Operating and maintenance instructions