Norac UC4+ Case 44 Series User manual

Table of contents

Other Norac Controllers manuals

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ Apache 1010 2005+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ New Navigator 2007+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4 Plus Rogator 64 Series User manual

Norac

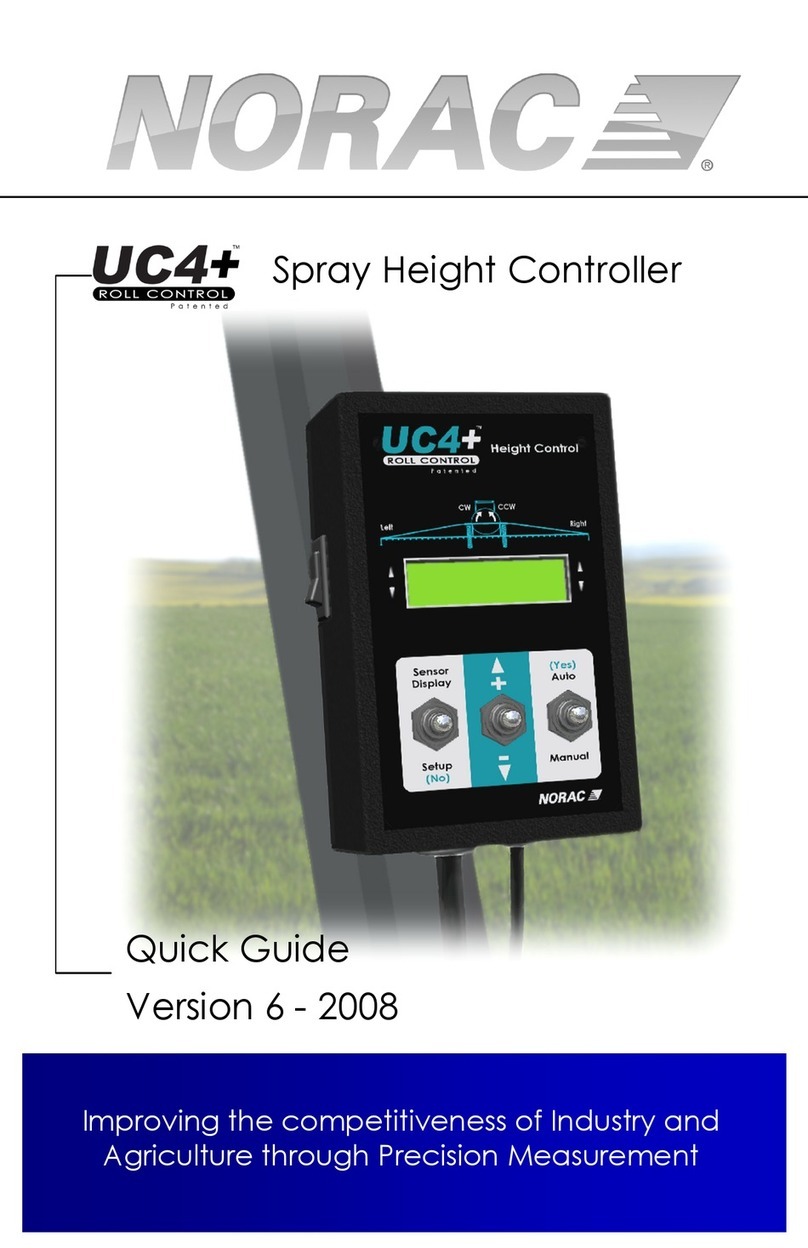

Norac UC4+ User manual

Norac

Norac UC4 Plus Rogator 74 Series User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac CS02 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Popular Controllers manuals by other brands

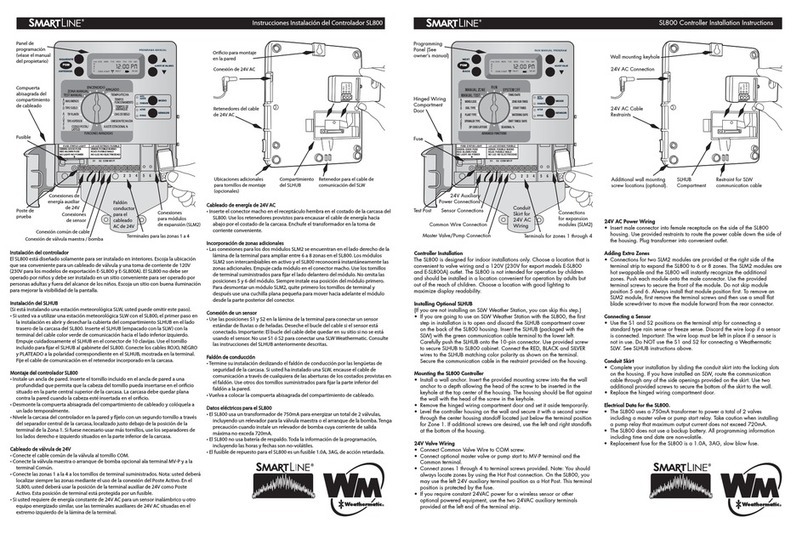

SmartLine

SmartLine SL800 installation instructions

Miura

Miura MP1-200 Operation manual

Osram

Osram Regiolux CUA 2 Series instructions

Roger

Roger CPR32-SE v3.0 user manual

Shenzhen FeiCan Technology Co.

Shenzhen FeiCan Technology Co. FC-PB-WIFI03 user manual

Samson

Samson BR 31a Series Operating, Assembly and Maintenance Instructions

ICP DAS USA

ICP DAS USA I-7188E3D-232 quick start guide

Siemens

Siemens TIM 1531 IRC operating instructions

Jordan Valve

Jordan Valve STERIFLOW Mark 95LL Series Installation & maintenance instructions

IAI

IAI X-SEL Operation manual

APV

APV 5.2 operating manual

DURAVIT

DURAVIT DuraSystem WD5001 Series Mounting instructions