Nordbo Robotics NAC-S20-15 User manual

1 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

Copyright

Copyright © 2021 Nordbo Robotics. All Rights Reserved. No part of this manual may be reproduced

or transmitted in any form or by any means, electronic or mechanical, including photocopying and

recording, for any purpose without the written permission of Nordbo Robotics.

Disclaimer

The information provided in this documentation contains general descriptions of the use, of one or

more of Nordbo Robotics’ products. Following this document's instruction for installation and use

must not be considered a substitute for making a risk assessment and testing the specific application

and setup. Neither Nordbo Robotics nor any of our affiliates or subsidiaries shall be held responsible

for the consequences that arise from misuse of – or misunderstanding of – any information stated in

this document.

If any instructions are considered unclear it is the user’s responsibility to contact Nordbo Robotics

for clarification of the issue(s) before making use of said unclear instructions.

If the user has any suggestions for improvements, amendments, or if errors have been found in this

release, please notify Nordbo Robotics.

Nordbo Robotics reserves the right to make refinements or changes without notice.

Warranty

Warranty void if products are opened. The warranty further excludes failure resulting from improper

use or installation, normal wear and tear, abuse, accidents, neglect, fire, water, lightning, or other acts

of nature, causes external to the product, or other factors beyond Nordbo’s control.

Contact

Nordbo Robotics A/S

Noatunvej 2

5000 Odense, Denmark

Phone: +45 81 81 98 81

Mail: info@nordbo-robotics.com

2 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

Table of Contents

1. Introduction 4

1.1. Intended Use 4

1.2. Prerequisites 4

1.3. Safety Warnings 4

2. Product information 5

2.1. Included in the Package 6

2.2. Technical Specifications 7

2.3. Mechanical Dimensions 8

2.4. NAC-S20-15 Overview 9

2.5. NAC-CTRL Interfaces 10

3. Web Interface & Configuration 12

3.1. Overview of Web Interface 13

3.2. How to Access the Web Interface 14

4. Configuring the NAC Using Web Interface 18

4.1. Enable/Disable Digital IO Interface Control 18

4.2. Configure Force Registers 19

4.3. Configure “Is moving” 20

4.4. Configuring Static IP 21

4.5. Configure DHCP Client 22

4.6. Updating the Firmware 23

5. Installing the NAC-S20-15 25

5.1. Connection Scheme, robots 26

5.2. Connection Scheme, PLC/IPC 27

5.3. Pneumatic Installation 28

5.4. Electrical Installation 29

6. Controller Functions 32

6.1. Idle 32

6.2. Active Force Control 32

6.3. Retract 33

6.4. Load Calibration 33

3 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

7. Control via Digital IO Interface 34

7.1. Logic Status of Input and Outputs 34

7.2. Determine Unit is Ready 34

7.3. Active Force Control 35

7.4. Initiate Calibration 35

7.5. Monitor NAC-S20-15 Motion and Error 36

8. Control via Ethernet TCP/IP Interface 37

9. Troubleshooting 41

9.1. Unable to Connect to the Controller 41

9.2. Reset Controller to Factory Defaults 42

9.3. Support Requests 42

10. Technical Appendix 43

10.1. Connection Specifications 43

4 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

1. Introduction

1.1. Intended Use

This document serves as a guide for the installation of Nordbo Robotics’ Active Compensation unit

(NAC) on a manipulator. This guide does not provide any information about risk assessment which

must be carried out before initiating any robot movements.

1.2. Prerequisites

This documentation is intended for people who have experience in installation, commissioning,

programming, and diagnostics of automation systems. Furthermore, it is expected that the person

using this manual understands the risks related to working with industrial robots. It is recommended

reader should also have basic knowledge in using a computer and configuration of network settings.

1.3. Safety Warnings

Following instructions must be read thoroughly by anyone intending to use this product.

Warning! This symbol indicates that potentially hazardous, dangerous, or

unwanted situations can arise from not following the instructions correctly. If

safety instructions are not followed properly it may result in death, personnel

injury, or equipment damage.

Before attempting to connect the NAC to a robot, it is important to ensure that the robot cannot

move unintentionally. The robot must therefore be powered off before attempting to connect the

equipment to the robot.

Robots must always be powered off before attempting to connect wires to the robot’s controller,

or when connecting cables between any of Nordbo Robotics’ products. Only switch the supply

voltage and pneumatics on when installation is fully complete.

The product may be damaged if dropped on hard surfaces. Be aware that connectors can break if

the user pulls or overtightens the cables. Do not perform any repairs on the product(s). In the event

of a defect: replace the control unit or/and tool unit.

The product can only be used within the specified range. Using the product outside of its specified

range may create unexpected results. Nordbo Robotics is not liable for any damage or injury resulting

from the use of the product.

5 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

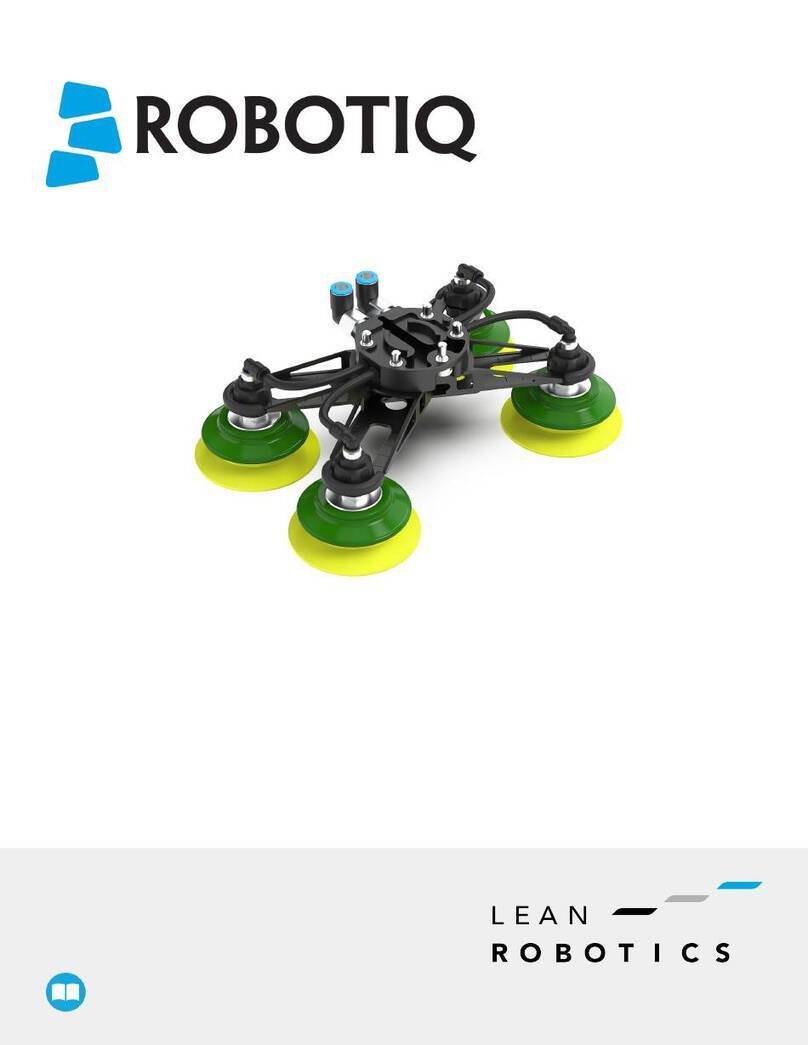

2. Product information

The Nordbo Active Compensation unit (NAC) is a solution for applications with where a constant,

specifiable force between tool and workpiece is required. The NAC consist of two parts, a tool unit,

and a controller. The force can be specified through the controller using IO or ethernet, and the

integrated sensors ensure that high contact forces are prevented during initial part contact.

Figure 1 – Tool Unit

Figure 2 - Controller

Figure 3

6 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

2.1. Included in the Package

Picture

Code

Description

NAC-CTRL

Controller for the NAC-S20-15

controllable by IO or ethernet.

NAC-S20-15

Tool unit with a stroke of 20 mm

and a maximum payload capacity

of 15 kg.

Ethernet cable RJ45

Ethernet cable for connecting the

NAC-CTRL.

NAC Cable

Communication cable to connect

the NAC-CTRL and the NAC-S20-

15.

IO modules

IO modules that can be used directly

with most common robot brands.

Table 1

7 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

2.2. Technical Specifications

General specifications

Maximum force (push/pull)

150 N / 110 N

Maximum allowed external moment

16 Nm

Stroke length

20 mm

Control Interface

Ethernet TCP/IP

Digital IO ports

Parameterization Interface

Web interface

Pneumatic specifications

The NAC tool needs to be connected to a supply of compressed air through an air-regulator to

regulate push/pull force

Maximum supply pressure

1.0 MPa

Minimum supply pressure

0.1 MPa1

Nominal supply pressure

0.7 MPa

Maximum flow rate

0.6 L/min

Electrical specifications

Power supply voltage

24VDC ±10%

Power supply current consumption

Typical 0.30A, Up to 2A

Digital IO interface

Switch logic

IO logic voltage ratings

Maximum output current

NPN

5 to 48V

0.22A

Ambient specifications

Operating ambient temperature

0° to +50°

Storage ambient temperature

-10° to +75°

Cooling

Passive

Operating humidity (at 25° C)

0% to 85%, No condensation

Degree of protection

NAC-S20-15: IP67 with full pin and fitting allocation

NAC-CTRL: IP40 with full pin allocations

Table 2

1Maximum possibly actuated force will be reduced when supply pressure is under nominal. At 0.1MPa the maximum

actuated force is 25N

8 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

2.3. Mechanical Dimensions

Unit

NAC-S20-15

NAC-CTRL

Weight

2.6 Kg

1.2 Kg

Dimensions

Height

Width

Depth

121-141 mm

110 mm

110 mm

56.26 mm

106.13 mm

226 mm

Mounting Tool Side

Bolts

Flange Diameter

M5-10

Ø60mm

-

Mounting Fixation Site

Bolts

Flange Diameter

M5-10

Ø60mm

-

Table 3

Figure 4

Figure 5

Mounting Fixation Side

Mounting Tool Side

9 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

2.4. NAC-S20-15 Overview

Figure 6

ID

Description

Functionality

1

Mounting hole pattern, fixation

site

Used when mounting the tool unit on a stable surface or

on a robot flange.

2

Air, in

Connect tube to supply air to the tool unit.

3

Interface for NAC control Unit

Use the supplied cable to connect the tool unit and the

controller.

4

Air, out

Connect tube for exhaust air

5

Mounting hole pattern, tool

side

Used when mounting a tool on the tool unit.

Table 4

5

1

2

3

4

10 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

2.5. NAC-CTRL Interfaces

NAC-CTRL Interface, Front

Figure 7

ID

Description

Functionality

A

Ethernet Connection

For connecting the controller to a PC.

B

Interface to NAC tool unit

For connecting the controller to the NAC.

1

LED status indicator

Ready for operation indicator. Is turned “On” when the

NAC is ready for operation.

2

LED status indicator

Ethernet session indicator. The LED is only turned “On”

when there is a connection using the Ethernet TCP/IP

connection.

3

LED status indicator

System state indicator. The LED is “Off” when the system is

in idle state, “On” when system is in active force control

state. The LED is blinking when an error has occurred, and

the device is in error state.

4

LED status indicator

Power indicator. The LED is “On” when the NAC-CTRL is

powered on.

RES

Reset button

Hold to reset the controller to the default settings.

Table 5

A

B

1

2

3

4

RES

11 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

NAC-CTRL Interface, Back

Figure 8

ID

Description

Functionality

C

Power supply input

Use to power the NAC controller.

D

IO interface

Use to connect and control the NAC using inputs/outputs.

Table 6

C

D

12 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

3. Web Interface & Configuration

The NAC can be reconfigured by accessing its integrated web interface. The web interface is

accessible by connecting the NAC-CTRL to a PC via ethernet link. Input the NAC-CTRL’s IP address

in a web browser e.g., Internet Explorer or Google Chrome to access the settings.

The integrated web interface of the NAC supports:

•Diagnostics of NAC

•Parameterization target forces selectable when using the IO interfaces

•Updating the NAC-CTRL and NAC-S20-15

•Configuring Network settings for the NAC

Figure 9

13 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

3.1. Overview of Web Interface

The NAC web interface contains the tabs listed in the following table.

Figure 10 - NAC web interface

Tab

Functions

Configuration

•

Configuration IO Interface

oEnable disable control using IO interface

oSetting predefined target forces and ramp time for each of the

16 preset registers which can be selected using the 4-bit IO

register indexing

oIs moving parameterization

Timeout of is moving signal. How long the actuator

should stand still before it is considered not moving

Distance threshold of how far the actuator should move

before it is considered being in motion

Network

•Enable/Disable DHCP.

Note: If enabled the NAC will gain an IP address from the networks

DHCP provider

•Static address, subnet mask and default gateway if DHCP is disabled

Update

•Update firmware on NAC control unit and Tool unit

About

•Firmware version number

•Serial number

Table 7: Website tab functions for NAC web interface

14 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

3.2. How to Access the Web Interface

Before the controller can be accessed through an internet browser by typing in the IP address of the

controller, the network settings may need to be configured. The following section explains how to

connect to the controller using a Windows 10 PC.

Note: Default settings for the NAC-CTRL is having a static IP address of 192.168.1.100. Adding the

device to a network with an existing device having the same IP address can cause network faults. For

initial commissioning, connect the control unit directly to a PC via the Ethernet interface.

Step 1

Connect the controller's power supply and connect to a PC using an ethernet cable.

Step 2

Open Network & Internet settings by right-clicking on the Wi-Fi/LAN icon in the menu.

Figure 11

15 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

Step 3

Click ”Change adapter options”.

Figure 12

Step 4

Right-click on ”Ethernet 3” and select “Properties.”

Note: Ethernet number may vary from system to system

Figure 13

16 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

Step 5

Select Internet Protocol Version 4 (TCP/IPv4) and click “Properties”.

Figure 14

17 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

Step 6

Set the IP address to 192.168.1.42

Set the Subnet mask to 255.255.255.0

Figure 15

Step 7

Access the real-time view using a browser by typing the IP address 192.168.1.42.

Figure 16

18 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

4. Configuring the NAC Using Web Interface

4.1. Enable/Disable Digital IO Interface Control

Step 1

Click the checkbox “Enable IO Interface”

Figure 17

Step 2

Navigate to the bottom of the configuration page and click “Save”.

Step 3

Apply the new settings by rebooting the NAC-CTRL by powering it off and on again.

19 of 44

NAC-S20-15 Active Compensation Unit - User Manual – Ver. 1.0

4.2. Configure Force Registers

Force registers enables the user to control the actuated force the NAC-S20-15 is applying by indexing

to one of the 16 registers using the 4-force register selection digital input pins.

Figure 18

Step 1

Edit each row in the Force register table

•Assign your target force.

oPositive values correspond to a push force.

oNegative values correspond to a pull force.

•Assign a ramp time.

Step 2

Navigate to the bottom of the configuration page and click “save”.

Step 3

Apply the new settings by rebooting the NAC-CTRL by powering it off and then on again

(pull the power supply).

Table of contents

Other Nordbo Robotics Robotics manuals

Popular Robotics manuals by other brands

Generation Robots

Generation Robots Nao Presenter user guide

adept technology

adept technology Cobra s600 user guide

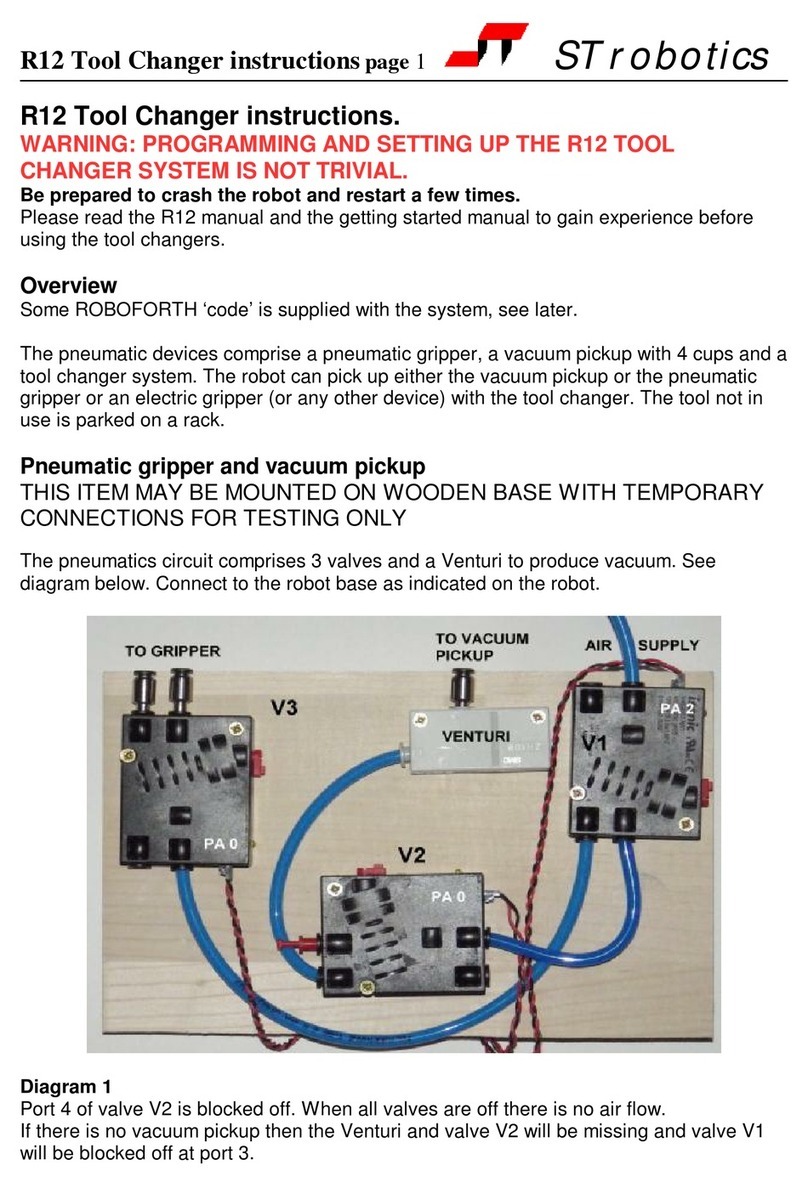

ST Robotics

ST Robotics R12 instructions

Pro's Kit

Pro's Kit GE-634 Assembly & instruction manual

Pro's Kit

Pro's Kit Probbie II Assembly & installation manual

Pro's Kit

Pro's Kit GE-896 Assembly & instruction manual