5

air handler and the return air opening. If no part of the

return air opening is directly adjacent to the unit no

clearance is required.

• In applications where the supply ducts carry heated

air to areas outside the space where the furnace is

installed,thereturn airmustbedeliveredtothefurnace

by duct(s) secured to the furnace casing, running full

size and without interruption.

Supply Air Connections

• The supply duct system must be designed so that the

static pressure measured external to the furnace does

not exceed the listed static pressure shown on the

furnace rating plate.The supply air must be delivered

to the heated space by duct(s) secured to the furnace

casing, running full length and without interruption.

Unconditioned Spaces

All duct work passing through unconditioned space must

beproperlyinsulatedtominimizeductlossesandprevent

condensation.Use insulation with an outer vapor barrier.

Refer to local codes for insulation material requirements.

Acoustical DuctWork

• Certain installations may require the use of acoustical

lininginside thesupply duct work.Acoustical insulation

must be in accordance with the current revision of the

Sheet Metal and Air Conditioning Contractors National

Association (SMACNA) application standard for duct

liners.DuctliningmustbeULclassifiedbattsorblankets

with a fire hazard classification of FHC-25/50 or less.

• Fiberductworkmaybeusedinplaceofinternalduct

liners if the fiber duct work is in accordance with the

current revision of the SMACNA construction standard

on fibrous glass ducts. Fibrous duct work and internal

acoustical lining must be NFPA Class 1 air ducts when

tested per UL Standard 181 for Class 1 ducts.

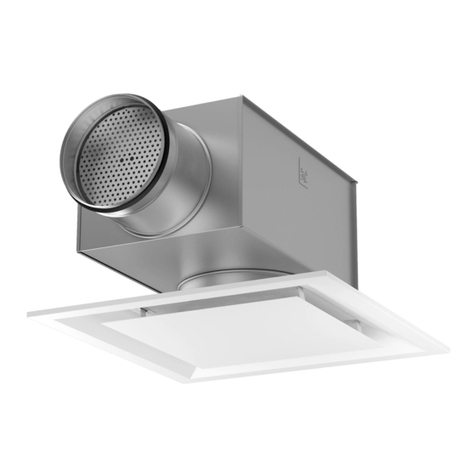

• Damping ducts, flexible vibration isolators, or pleated

media-style filters on the return air inlet of the air

handler may be used to reduce the transmission of

equipment noise eminating from the air handler.These

treatmentscanproduceaquieterinstallation,particularly

in the heated space. However, they can increase the

pressure drop in the duct system. Care must be taken

to maintain the proper maximum pressure rise across

the air handler, temperature rise and flow rate. This

may mean increasing theduct sizeand/or reducing the

blower speed.These treatments must be constructed

and installed in accordance with NFPA and SMACNA

construction standards. Consult with local codes for

special requirements.For best sound performance, be

sure to install all the needed gaskets and grommets

around penetrations into the air handler, such as for

electrical wiring.

Air Filters

B6BVseriesair handlers arenotsuppliedwithanairfilter

whenshipped fromthe factory.The installer mustprovide

ahighvelocityfilterthatisappropriatelysizedtothereturn

airflow rating. Refer to the rating plate or Tables 6, 7a

& 7b (page 14) for proper circulating airflow data.

• Use transition ttings if the supply and/or return air

openings of the unit do not match the duct openings.

Thesetransitionsshouldbedimensionedinaccordance

with standard practice as specified in the ASHRAE

recommendations for duct transitions.

• Flexibleconnectorsmaybeusedbetweentheunitand

the ductwork to prevent transmission of vibration from

the unit to the structure. Heat resistant material must

be used for the flexible connector at the supply air end

of the unit.

• It is good practice to seal all connections and joints

with industrial grade sealing tape or liquid sealant.

Requirements for sealing ducts vary from region to

region.Consultwithlocalcodesforrequirementsspecific

to your area.

Return Air Connections

For each application in the USA, the home manufacturer

shall comply with all of the following conditions to have

acceptable return air systems for closet installed forced

air heating appliances:

• Regardlessofthelocation,thereturnairopeningintothe

closetshallnotbelessthanspecifiedintheappliance’s

listing.

• Meansshallbeprovidedtopreventinadvertentclosure

by a flat object placed over the return air opening when

it is located in the floor of the closet (versus the vertical

front or side wall).

• The cross-sectional area of the return duct system

leading into the closet shall not be less than 390 in2.

• Thetotalfreeareaofopeningsintheoororceiling

registers serving the return air duct system must be at

least 352 in2. At least one register should be located

where it is not likely to be covered by carpeting, boxes

and other objects.

• Materialslocatedinthereturnductsystemmusthavea

flamespread classificationof 200 or less.Thisincludes

a closet door if the air handler is in a closet.

• Test thenegativepressure inthecloset withthe air-

circulating fan operating at high speed and the closet

closed.Thenegativepressureistobenomorenegative

than minus 0.05 inch water column.

• For oor return systems, the manufactured home

manufacturer shall affix a prominent marking on or

near the appliance where it can be easily read when

the closet door is open.The marking shall read:

CAUTION:

HAZARD OF ASPHYXIATION: Do not cover or

restrict return air opening.

• Thereturnairopeningcanbelocatedinaclosetdooror

a sidewall. If the return air opening is directly adjacent

to the side (or front) of the air handler, 6” minimum

clearance must be provided between the side of the