NORTHERN ELECTRIC QSD300A User manual

NORTHERN ELECTRIC PRACTICES SECTION 506-3211-200

Issued: 19 November 1973

Standard

PANEL COIN TELEPHONE SETS

QSD300A AND QSD2300A TYPES

PREPAY

IDENTIFICATION AND INSTALLATION

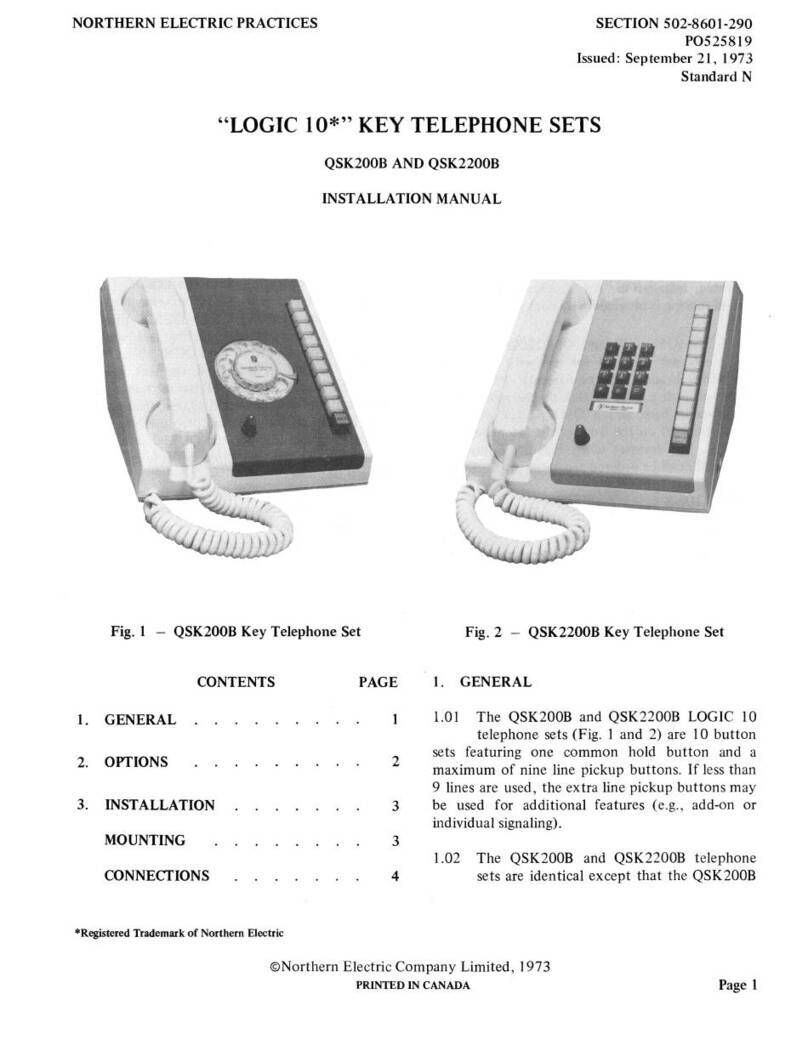

(a) QSD300A Type (b) QSD2300AType

Fig. 1 -

Front

View

of

QSD300A and QSD2300A Coin Telephone Sets

©Northern Electric Company Limited, 1973

PRINTED IN

CANADA

Page 1

SECTION 506-3211-200

CONTENTS PAGE

L GENERAL 2

2. DESCRIPTION 2

3. CIRCUIT DESCRIPTION 3

4.

ORDERING INFORMATION 4

5.

INSTALLATION 8

INSTALLATION REQUIREMENTS 8

MOUNTING INSTRUCTIONS 9

CONNECTIONS AND OPTION

SELECTION 10

6. OPERATION TESTS

22

1.

GENERAL

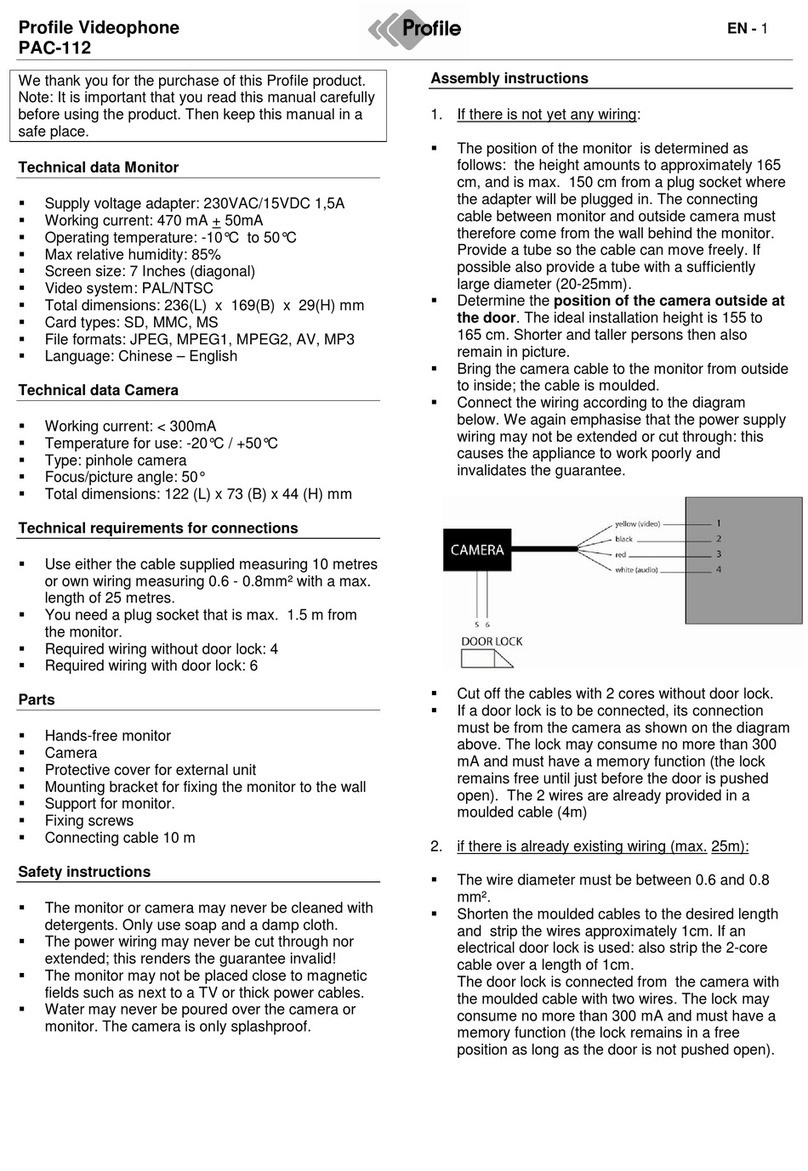

1.01 This section describes the QSD300A and

QSD2300A prepay, single coin slot, panel

coin telephone sets. Dismantling and assembling

information

is

given to facilitate installation

of

the

coin telephone sets. Station wiring and option

connections are also provided.

2. DESCRIPTION

2.01 The QSD300A and QSD2300A coin

telephone sets are single -slot, prepay type

panel coin tel.ephones. The QSD300A, equipped

with a rotary dial, and QSD2300A, equipped with

a DIGITONE* dial, are shown in Fig.

1.

The sets

can be converted from rotary dial

to

DIGITONE

dial by interchanging the door assembly.

2.02

The

panel coin telephone set components

are contained within a sheet steel housing

which is fabricated by a combination

of

welding

and bolt fasteners for maximum security.

*A trademark

of

Northern Electric.

Page2

2.03 The front

of

the set features a brushed

chrome center panel which contains the

coin slot, coin release lever, handset hook, dial,

instruction and number card windows, coin return,

and cash compartment door. Decorator panels

of

brushed stainless steel

or

. panels with a painted

finish are inserted on each side

of

the center panel.

2.04 The QSD300A and QSD2300A coin

telephone sets are equipped with

mechanical and electronic initial rate totalizers

which inhibit dialing from the coin telephone until

a preselected amount in coins has been deposited.

2.05 When shipped froin the factory, the

QSD300A and QSD2300A sets are arranged

to operate on the mechanical totalizer at a 10-cent

initial rate. With this arrangement the set may be

used on either ground-start

or

loop-start central

office (CO) lines.

2.06 The electronic variable initial rate (VIR)

totalizer on the printed circuit board (PCB)

assembly in the coin telephone set can be modified

to

change the initial rate from 5-cents

to

40-cents

inclusive in increments

of

5-cents.

2.07 The free access to selected numbers (FASN)

feature permits coinless calling to special ·

preselected numbers. The

CO

must be equipped for

FASN and the line must have a loop-start line

circuit.

2.08 Ground isolation (GI) disconnects the

grounding circuit from the transmission

path to minimize line induced noise during voice

transmission. This feature requires that the

CO

line

is equipped with a loop-start line circuit.

2.09 The coin identification signals are

transmitted to the operator by a solid state

tone generator when the required coins are

deposited in the coin telephone set.

'

2.10 The transmission qualities

of

the QSD300A

and QSD2300A coin telephone sets are

similar to those

of

the NE-500 type telephone set.

2.11 The maximum loop resistance for

satisfactory operation

of

the set

is

determined by such parameters as minimum CO

battery voltage, feeding-bridge resistance, ringing

cut-off current, etc. To ensure reliable operation

it

is recommended that the following conditions be

met.

(a) With the handset off-hook the de voltage

at

the ring and tip terminals

of

the set must

not

be l

ess

than 4.4 volts.

(b) The current in the ring side

of

the line

shou

ld

not

be less than 23.0 milliamperes

with the hopper trigger switch in the normal

position (i.e.,

not

tripped).

Example

of

long loop:

CO

battery

Feeding-Bridge

Resistance

Current

Loop resistance

45.0 volts

200 ohms X 200 ohms

23.0 millfumperes

1365 ohms

Note: Other factors associated with the

CO

SECTION 506-3211-200

coin switch module.

As

the coin passes through the

coin switch module, a switch is activated which

in

turn energizes the solid-state tone generator. The

generator sends bursts

of

tone appropriate

to

the

coin deposited

to

permit operatorrecognition. The

signals are

not

heard in the receiver

of

the coin

telephone set. The number

of

tone bursts for each

coin deposited are:

• one burst for a 5-cent coin

• two bursts for a 10-cent coin

•

five

bursts for a 25-cent coin (transmitted

at twice the.rate

of

the 5-cent and

10

-cent

coin tone bursts).

may limit the loop resistance to less than

23-l/

4

1365 ohms.

For

higher loop resistance a long

line circuit should be used.

2.12 The coin telephone set weighs

approximately

55

pounds (25 kilograms).

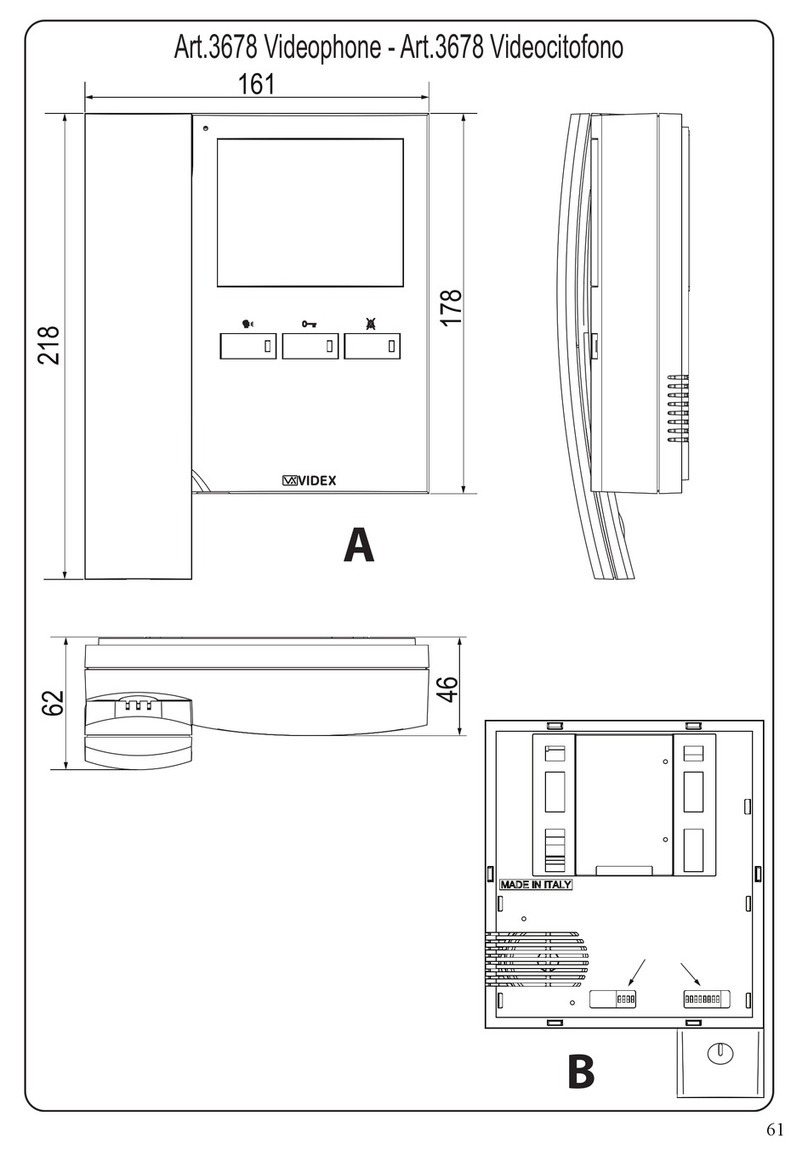

2.13 The dimensions

of

the QSD300A and

QSD2300A coin telephone sets are shown

in Fig. 2.

3. CIRCUIT DESCRIPTION

Coin Signaling

3.01 Coins inserted in the single slot and

accepted

by

the chute are sorted into the

appropriate channel before passing through the

'12-7/16

ALL

DIMENSIONS

SHOWN

ARE

IN

INCHES

Fig. 2 - Rear View ofQSD300A and

QSD2300ATelephone Sets,

Showing Physical Dimensions

Page

3

SECTION 506-3211-200

Mechanical Totalizer

3.

02

The

mechanical totalizer detects the total

number

of

5-cent coins deposited for

I0-cent initial rate calls.

3.03

The

first 5-c

ent

coin is trapped in the switch

module.

The

5-cent coin in the trapped

position holds a switch operated. This switch

provides a connection to ground which

is

necessary

for central offices having ground

start

line circuits.

The

second 5-cent coin

is

deflected by the first

5-cent coin (which is trapped) and passes

on

through the switch module i

nto

the coin relay

hopper.

On

entering the hopper,

it

trips the hopper

trigger switch.

The

operated hopper trigger switch

removes a

short

circuit from the dial and the user

can now dial.

3.04 A deposited 10-cent coin

or

25-cent coin is

segregated by the coin chute and passes

through the coin switch module.

The

tone

generator monitors the switches

on

the switch

module and generates the appropriate coin signals.

The

coin then drops into the coin hopper, tripping

the

hopper

trigger which allows the call to proceed.

The

mechanical totalizer is

not

operated by the

deposit

of

these coins.

ElectronicTotalizer (VIR)

3.05

The

electronic

tota

lizer

is

used to inhibit

dialing

(or

continuity

to

ground for FASN

operation) in the same manner as

the

mechanical

totalizer.

The

electronic totalizer receives its

input

signa

ls

from the same switches

on

the switch

module which provide inputs

to

the coin signal

tone generator.

The

electronic totalizer can be

strapped

(on

the PCB assembly) so

that

it enables

dialing

(or

continuity to ground for FASN

operation) when the total value

of

the coins

deposited equals

or

exceeds

the

preset initial rate.

The initial rate

may

be preset by appropriate

strapped connections

on

the PCB assembly.

FASN Operation

3.06 When the coin telephone

set

is used with a

CO which

is

equipped

to

psovide FASN

service the user receives dial tone

by

lifting the

Page 4

handset and may complete a call to any free access

number without depositing coins.

3.07 When a non-FASN call

is

made, ground

identification

is

detected· by the

CO

when

the initial rate

is

deposited.

GI Feature

3.08

The

GI feature provides a means

of

disconnecting the station ground from the

transmission network whenever line current is

flowing. This feature achieves a substantial

reduction in transmission circuit noise caused by

induced voltages on the line.

3.09 GI

is

activated by current

on

the ring side

of

the line. When this feature

is

used, ground

tests

or

coin collect/return functions, which

require an electrical continuity to ground, must be

made

on

the tip side

of

the line only.

Coin Rejection

3.10 Slugs, washers, tokens

or

foreign coins

inserted through the coin entry slot are

directed

to

the loin chute and rejected to the coin

return assembly

or

held up.

The

coin-return lever

when operated, has a positive clearing action,

which releases the slugs, washers, etc., into the coin

return assembly.

4. ORDERING INFORMATION

4.01

The

panel coin telephone sets are ordered as

follows:

COIN TELEPHONE SET QSD300A

COIN TELEPHONE SET QSD2300A

4.02

To

provide a complete installation the

following components must be ordered

separately.

• Cash compartment

doorNE-lA-30

• Cash compartment lock, NE-22QC

• Upper housing lock, NE-22QD (keys must

be ordered separately)

• Cash receptacle, NE-IB

• Cash receptacle cover, NE-IC

4.03 The QSD300A and QSD2300A are available

with the following decorator panels.

(a) Stainless steel decorator panels

P0502663

are supplied with all panel coin telephone

sets.

(b) Black decorator panels

P050266

2 are

available

but

have to be ordered separately.

(c) Zinc plated decorator panels

P050266

I are

supplied on a special order basis only (for

special paint finishes applied by the customer).

4.04 Instruction and number cards should be

supplied locally and must be in accordance

with the dimensions given in Table B.

4.05 The QSD300A and QSD2300A coin

telephone sets may be mounted

as

follows.

• Recessed into a wall so that the front panel

is

flush with the surface

of

the wall. The

Apparatus Box

QBM2A

(Fig. 3) is provided

to

fit into the wall prior

to

the installation

of

the coin telephone set. The customer

will be responsible for providing the recess

in the wall

of

the proper dimension

s.

Mounting screws are provided with the

Apparatus Box for the purpose

of

fastening

SECTION 506-3211-200

the coin telephone set to the Apparatus

Box. Dimensions and mounting screw holes

for the Apparatus Box are shown in Fig.

3.

See Table A for fasteners required.

• Mounted in a location where Burgess-Day

Type

101

Panel Coin Telephone mounted

in a Burgess-Day Type 1065-327 panel wall

mounting box

was

previously installed.

An

Adapter

QAA

l6A is available for this

purpose. Mounting screws are supplied with

this adapter.

• Mounted in furniture designed specifically

for this type

of

panel coin telephone.

4.06 The coin telephone set components that

may be substituted in the field are listed in

Table D.

4.07

If

the coin telephone set has been installed,

but

is

not

ready for service, place a QSWlA

out

of

service

sign

in the coin entry slot so that

customers cannot deposit coins. When service is

established, remove the

sign

or

arrange for the

agent

or

other responsible person

to

do so. The

QSW

IA sign, as shown in Fig. 4, is installed by

inserting the double pronged projection into the

coin entry slot and pressing firmly into place until

the

sign

is flush against the front surface. The

sign

may be removed

by

pulling

it

out

of

the coin entry

slot.

4.08 Installation accessories are listed in Table

C.

Page

5

SECTION

50

6-3211-200

TABLE A

FASTENERS USED IN MOUNTING APPARATUS BOX QBM2A

MOUNTING HOLE

SURFACES SIZE QUANTITY SIZE AND

TY

PE NOTES

REQUIRED

Softwood 1/8-inch

or

No. 30 8 1-3/4 inch No. 14 F.H. wood 1,2

screw

Hardwood 1/8-inch

or

No.

30

8

1-1

/4

inch No. 14 F.H. wood l,2

screw

Masonry Con- 5/16-inch 8 2-inch No. 14 F.H. wood 1,2

crete Brick screw in No.

16

plasticanchor

Cinder Block 3/4-inch 8 1/4 by 4-inch R.H. Toggle Bolt 1,2

Notes:

I. At least 4 screws must be placed in the sides

or

the

bottom

and top

of

the apparatus box.

2. Additional fasteners may be placed for added security.

WIRING

ACCESS

HOLE

lil.OUHTIHG

SCREW

HOLES

FOR

MOUNTING

PANEL

COI

NT

EL

EPHONE

Fig. 3 - Apparatus Box QBM2A

Page 6

SECTION 506-3211-200

Fig. 4 - QSWtA

Out

of

Service Sign

CARD

LOCATION

Instruction Cards

NumberCard

TABLEB

INSTRUCTION CARD SIZES

WIDTH HEIGHT

(±0.020) (±0.020)

7.580 in. 3.130 in.

1.800 in. 0.400 in.

TABLEC

THICKNESS

(MAX.)

0.020 in.

0.020 in.

INSTALLATION ACCESSORIES

FOR

QSD300A AND QSD2300A SETS

ORDERING USE

CODE

Apparatus Box QBM2A

For

installations recessed

into

a wall

AdapterQAA16A

For

installation

in

ADCO

type 1065-327

panel wall mounting box

Tool, P0896911

To

unlock the

door

assembly.

The tool

inhown

in Fig. 6.

Page 7

SECTION 506-3211-200

TABLED

COMPONENTS REPLACEABLE

IN

THE

FIELD

PART

NO.

NSQI016

LI

P0502569

P0521246

NE-DIQA

P0521209

POI

5E491

P0521213*

P0521214t

QDBIP*

~E-35Q3Kltt

NE-G3QF-52

P0521211*

P05212I

2t

P0896913

P0521260

P0502604

NE-22QD

P0896963

P0896334

P0892802

P0502663

P0502662

P0502661

ITEM

Coin

Chute

Coin Switch Module

Apparatus Module

Ringer

Coin Relay Assembly

Coin

Return

Assembly

Dial and Housing Assembly

Dial

and

Housing Assembly

Dial

Dial

Handset

Door

Assembly

Door

Assembly

Coin

Return

Chute

Assembly

Printed Circuit Board

Assembly

Coin Guide and Bracket

Assembly

Lock

(Upper

Housing Door)

Window (Instruction Card)

Window

(Number

Card)

Cord Retainer

Decorator

Panel

Kit

(Stainless Steel)

Decorator Panel Kit (Black

Simulated Vinyl)

Decorator Panel Kit, Blank

(For

Customer

Applied

Finish)

* QSD300A

Type

t QSD2300A

Type

t

The

NE-35Q3KI Dial is

not

available with

the

word

operator

printed

by

the

0.

Page 8

5.

INSTALLATION

INSTALLATION REQUIREMENTS

5.01 Information required

for

installation

of

the

QSD300A and QSD2300A coin telephone

sets is contained in the following charts.

Chart

I Opening and Removing

the

Door

Assembly

Chart

2 Removal and Replacement

of

Apparatus

Module

Chart

3 Removal and Replacement

of

Coin

Chute

Chart

4 Removal

and

Replacement

of

PCB

Assembly

Chart

5 Removal and Replacement

of

Coin

Return

Chute

Assembly

Chart

6 Removal and Replacement

of

Coin

Switch Module

Chart

7 Installation and Removal

of

Instruction

and Number Cards

Chart

8 Installation and Removal

of

Upper

Housing

Loc

k

Chart

9 Conversion

From

Mechanical to

ElectronicTotalizer

Chart

l0 FASN Conversion

Chart

11

G1 Conversion.

5.02

The

following factors should be considered

when

choosing a location

for

the

installation

of

the

panel coin telephone set:

• Accessible for public usage

• Adequate light

• Privacy

• Minimum noise or

vi

bra

ti

on

• Absence

of

grease, smoke or dust

• Clear

of

moving machinery, piled

merchandise, narrow aisles or stairways

• Check local installation practices before

mounting the coin telephone set on

surfaces

that

would

be

expensive to repair

if the set is removed.

• Telephone and wiring must be located at

least 6 inches from neon light fixtures,

transformers

or

other equipment likely

to

cause inductive effects.

• The QSD300A and QSD2300A coin

telephone sets must be mounted on a

vertical surface. A tilt greater than

1.5

degrees

in

any direction can cause chute

malfunction.

MOUNTING INSTRUCTIONS

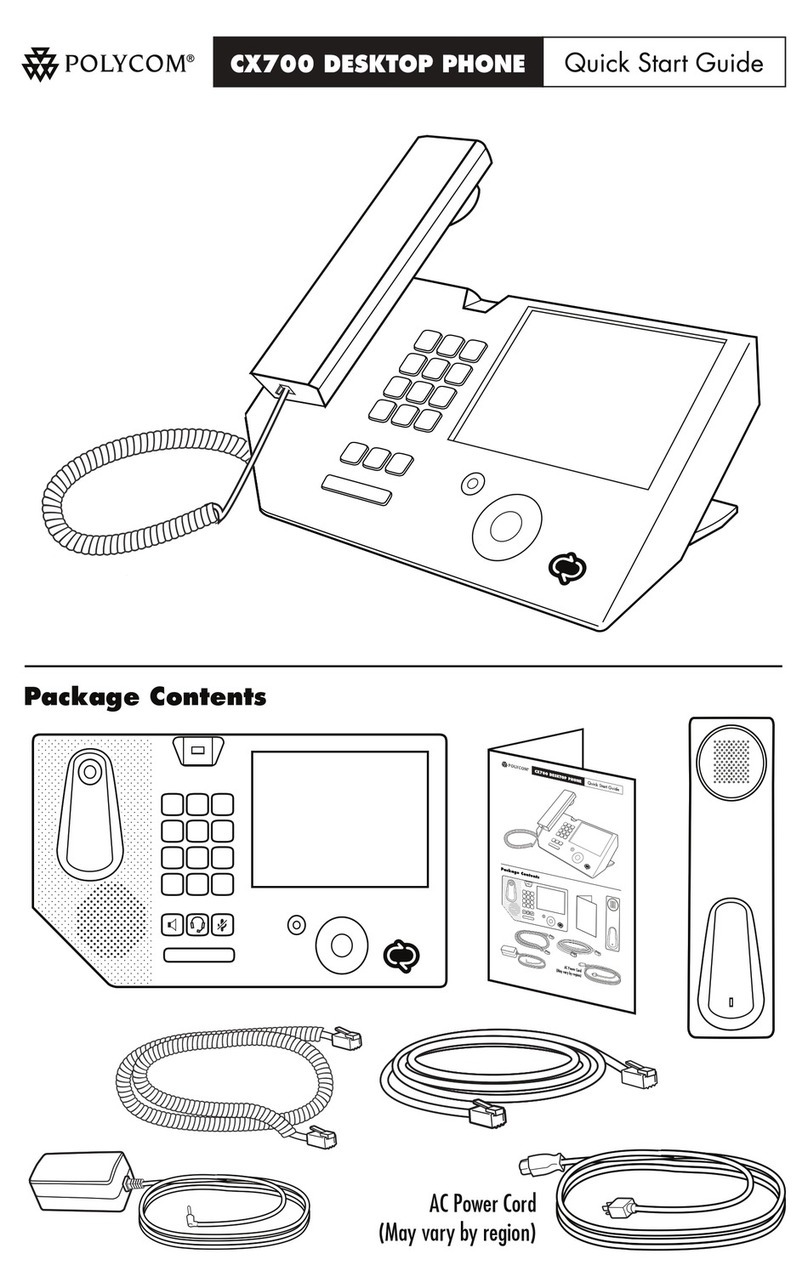

5.03 The QSD300A and QSD2300A coin

telephone sets have mounting screw holes

identical to those provided on the NE-233 type

coin collectors. Fig. 5 shows the arrangement

of

the mounting screw holes.

SECTION 506-3211-200

(I)

Coin Signal Printed Circuit Board (Chart 4).

(2) Coin Switch Module (Chart 6).

(3) Coin Chute (Chart 3).

(4) Coin Return Chute (Chart 5).

5.07 Wiring shall enter through the I-inch

diameter hole in the rear wall

of

housing

or

the 5/8-inch diameter hole on the side

of

the set.

5.08 The usual precautions for wiring

of

coin

telephones shall be observed:

• Conceal wiring near the telephone

or

use

approved moulding

or

tubing.

• Locate protectors and connecting blocks

where they will be inaccessible

to

the coin

telephone set user.

5.09 Provision is made for adding four security

studs

(PO

IOE070) (Fig. 5). Security studs

cannot be used in most enclosures since vertical

movement

of

the set

is

necessary

to

engage the

stud in the keyhole slot.

MOUNTING

SCREW

HOLES

P010E070

~---

WIRING

HOLES

5.04 The mounting surface for the panel coin

~~~~~ITY

telephone must be vertical. A tilt in any

direction may cause malfunction

of

the coin chute.

5.05 The suggested mounting height

of

the panel

~g~;:ING

coin telephone set

is

63 inches from the top

HOLES

of

housing to the floor.

5.06

To

provide access to all mounting screw

holes

it

will

be

necessary

to

remove

assemblies listed below in the following sequence.

AUXILIARY

MOUNTING

SCREW

HOLES

(10)

Fig. 5 -Arrangement

of

Mounting

and

Wiring Holes

Page9

SECTION

506-3211-200

CONNECTIONS

AND

OPTION

SELECTION

5.10

Connect

the

station wiring leads, tip, ring,

and ground,

to

the

T,

R, and G connections

on TB

I.

5.

11

When shipped from

the

factory

the

QSD300A

and

QSD2300A coin telephone

sets are wired for 10-cent mechanical totaliz

er

operation. The mechanical totalizer permits

connection

to

loop-start

or

ground-start CO lines.

5.12

To

convert

the

QSD300A and QSD2300A

sets from

the

mechanical totalizer

to

the

electronic totalizer (VIR) proceed as described in

Chart

9.

5.13

To

use the sets

with

a CO which is equipped

for FASN service convert as described in

Chart 10.

Page

10

5.14

To

convert

the

QSD300A and QSD2300A '

Sets for GI proceed as described in

Chart

11.

5.15

The

door

is removed from

the

housing

assembly as described in Chart

1.

The

P08969

11

tool

(Fig. 6) is used

to

unlock the door.

Fig. 6 - P089691 l Tool

SECTION

506-3211-

200

CHART

1 - OPENING AND REMOVING

THE

DOOR ASSEMBLY

STEP

PROCEDURE

OPENING

THE

DOOR

ASSEMBLY

1 Unlock NE-22QD Lock (rotate key clockwise)

2 Insert P089691 I Tool (Fig. 6) in keyhole on right side. Rotate tool 1/8 turn clockwise to

release right-hand bolt.

3

Mov

e key from right-side

to

left-side keyhole. Rotate tool 1/8 turn counterclockwise

to

release left-hand bolt.

4 Remove handset from hook.

5 Door is hinged

at

the bottom. Open d

oo

r by pulli

ng

outward

at

the top.

6 Adjust position

of

open

door

by moving the supporting chain

to

a new position in the notch

at

the upper end

of

the l

eft

hand lock strike.

7 Close the door by reversing the above procedure.

REMOVING

THE

DOOR

ASSEMBLY

8 Disengage plug 3 from jack 3 on the connector bracket assembly.

9 Support the door and unhook the chain from the notch

at

the top

of

the lock strike.

l0 With the

door

open nearly 90°, lift the hinge end

of

the door upward until

it

is clear

of

the

flange on the front

of

the housing.

11

Replace the

door

by reversing the above procedures. (Check that cords

or

restraining chain

are

not

trapped in the hinge area.)

Page

11

SECTION

506-3211-200

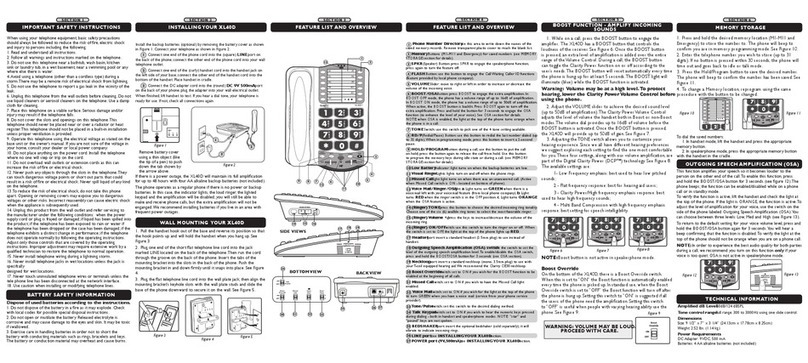

CHART

2 -

REMOVAL

AND

REPLACEMENT

OF

APPARATUS

MODULE

(Fig.

7)

STEP

2

3

4

5

6

7

8

Page

12

PROCEDURE

Open

the

door

assembly as described in

Chart

1.

Disengage

coin

release linkage

from

coin

chute

(Fig. 8).

Loosen fastening screw

for

coin guide assembly as

shown

in

Fig. 8. Swing the coin guide

assembly

outward

on

its

hinge.

Disconnect

plugs I

and

2 from

jacks

1

and

2.

Remove

PCB assembly as described

in

Chart

4.

Loosen

the

fastening screw

for

the

apparatus

module

(Fig.

8).

Lift

the

module

upward

until

lower

end

clears

the

housing

bracket.

Replace

the

apparatus

module

by

reversing

the

above

procedure.

NE-425QE1 NETWORK

Fig.

7 -

Apparatus

Module

SECTION

506-3211-200

CHART

3 -

REMOVAL

AND REPLACEMENT

OF

COIN

CHUTE

NSQ1016

LI

STEP

PROCEDURE

1

Open

door

assembly as described

in

Chart

1.

2 Disengage coin release linkage from coin

chute

(Fig. 8).

3 Disengage coin

chute

retainer

on

upper

left

side

of

chute

bracket

(Fig. 8).

4

Lift

chute

upward

until

lower

end

can

be

pulled

outward,

then

pull

upper

end

upward

and

forward

to

clear

mounting

bracket.

5 Replace

the

coin

chute

by

reversing above procedure.

CHART

4 -

REMOVAL

AND

REPLACEMENT

OF

PRINTED

CIRCUIT BOARD ASSEMBLY

STEP

PROCEDURE

1

Open

door

assembly as described in

Chart

1.

2

Disconnect

plug 2 from

jack

2.

3 Grasp

front

edge

of

PCB assembly

at

top

and

bottom.

Do

not

apply

pressure

on

components

of

PCB assembly.

4 Pull PCB assembly

outward,

away from

connector.

PCB

should

be pulled

out

carefully

to

avoid damage

to

the

components

on

the

PCB.

5

Insert

PCB

with

component

side

adjacent

to

the

right

hand

lock strike

and

outside wall

of

housing.

6

Reconnect

plug 2 to

jack

2.

Page

13

SECTION 506-3211-200

COIN GUIDE

COIN CHUTE

RETAINER

COIN

CHUTE

COIN CHUTE

GATES

CO

IN SWITCH

MODU

LE

CO

IN RETURN

CHUTE

COIN

RELAY

RETAINING SPRING COIN RELEASE

LINKAGE

COIN GUIDE

BRACKET ASSEMBLY

-

-

--

-.

"

5

06

-005

CO

IN GUIDE

RETA

INING

SCREW

APPARATUS MODULE

RETA

INING

SCREW

PRINTED CIRCUIT

BOARD ASSEMBLY

Pl

- Sl

COIN

SWITCH

MODULE LOCKING

ASSEMBLY

TBl

P2-S2

CONNECTOR

BRACKET

ASSEMBLY

. Fig. 8 - QSD300A and QSD2300A Coin Telephone Set Door Assembly Removed

Page 14

SECTION 506-3211-200

CHART 5 -REMOVAL

AN

D REPLACEMENT

OF

COIN RETURN CHUTE ASSEMBLY (Fig. 9)

STEP

1

2

3

4

5

6

PROCEDURE .

Open

doo

r assembly as

de

scribed

in

Chart

1.

Remove coin chute

as

described in Chart 3.

Loosen retaining screw (Fig. 9).

Remove three mounting screws (Fig. 9).

Tilt assembly forward and li

ft

upward.

Re

place the assembly by reversing the above procedure.

RETAINING-

-

-==

SCREW

Fi

g.

9 - Mounting Arrangeme

nt

for Coin Return

Chute Assembly

Page

15

SECTION 506-3211-200

CHART 6 - REMOVAL AND REPLACEMENT

OF

THE

COIN SWITCH MODULE

STEP PROCEDURE

REMOVAL

OF

SWITCH MODULE

I Open door assembly

as

described in Chart

I.

2 Disconnect plug 1 from jack I.

3 Rotate the retaining·screw I

/4

turn counterclockwise

to

free right end

of

module.

4 Pull right

end

of

module forward until

it

clears the mounting bracket.

5 Move the whole module

to

the right until it clears the left side

of

the mounting bracket.

REPLACEMENT

OF

SWITCH MODULE

6 Align two locating tabs on left side

?f

module with two slots on the left side

of

chute

bracket.

7 Align locking assembly with oval slot

on

right side

of

bracket.

8 Press the right side

of

the module backwards against the mounting bracket.

9

Rotat

e the locking assembly 1/4 turn clockwise.

Page 16

SECTION 506-3211-200

CHART 7 - INSTALLATION

AND

REMOVAL

OF

INSTRUCTION

AND

NUMBER CARDS

STEP PROCEDURE

INSTRUCTION CARD (UPPER &

WWER)

1 Remove clear plastic window. Slide window upward using finger pressure friction on outer

surface

of

window. When lower edge

of

window

is

exposed the

bottom·of

the window may

be pried

out

and the window removed.

2 Insert instruction card.

3 Replace clear plastic window.

NUMBER CARD

4 Remove clear plastic window using

NS

-16750

L3

releaser.

5 Insert number card.

6 Replace clear plastic window.

CHART 8 - INSTALLATION AND REMOVAL

OF

UPPER HOUSING LOCK (NE-22QD)

STEP PROCEDURE

1 Open and remove the door assembly as described

in

Chart 1.

2 Remove the four hexagon nuts

but

do

not

remove the washer spacers from the lock

mounting studs (Fig. 10).

3 Place the key in the NE-22QD lock and operate the lock

to

fully withdraw the lock bolt.

4

Fit

the lock

to

the four mounting studs. (The key must remain in the lock and the lock

bolt

shall

be

withdrawn. The key handle must be inserted through the hole in the door.)

5 Replace the four hexagon nuts and tighten.

6 Replace and close the

door

assembly.

Page

17

SECTION 506-3211-200

TB2----

PLUG

Page

18

STAY

HOOK

Fig. 10 -

Door

Assembly

HANDSET

CORD

SECTION

506-3211-200

CHART

9 - CONVERSION

FROM

MECHANICAL

TO

ELECTRONIC

TOTALIZER

(VIR)

STEP

2

3

4

5

6

7

8

9

10

PROCEDURE

Ensure that

CO

line

is

wired for loop start. Dial tone is heard in handset before any coins are

deposited.

Open the

door

assembly

as

described in Chart

l.

Move

R-G

lead

on

TB

1 on connector bracket assembly from terminal 5

to

terminal G.

Disable the 5-cent coin trap on the switch module. (This may be done

by

wedging the

release magnet armature in the operated position. If there is

no

intention

of

reactivating the

mechanical totalizer, the release magnet armature assembly may be removed completel

y.

The protective cover plate should be replaced.)

Remove

PCB

assembly from apparatus module

as

described in Chart 4.

Move

R lead to required initial rate terminal (Fig.

11

).

Move

one G lead from terminal A

to

terminal

B.

Insert

PCB

assembly.

Close the

door

assembly.

Perform operation test described in Part 6, Chart

13.

Page

19

This manual suits for next models

1

Table of contents

Other NORTHERN ELECTRIC Telephone manuals