12

номер

ПОРЯДОК КОД

КОЛИЧЕСТВО

номер

ПОРЯДОК КОД

КОЛИЧЕСТВО

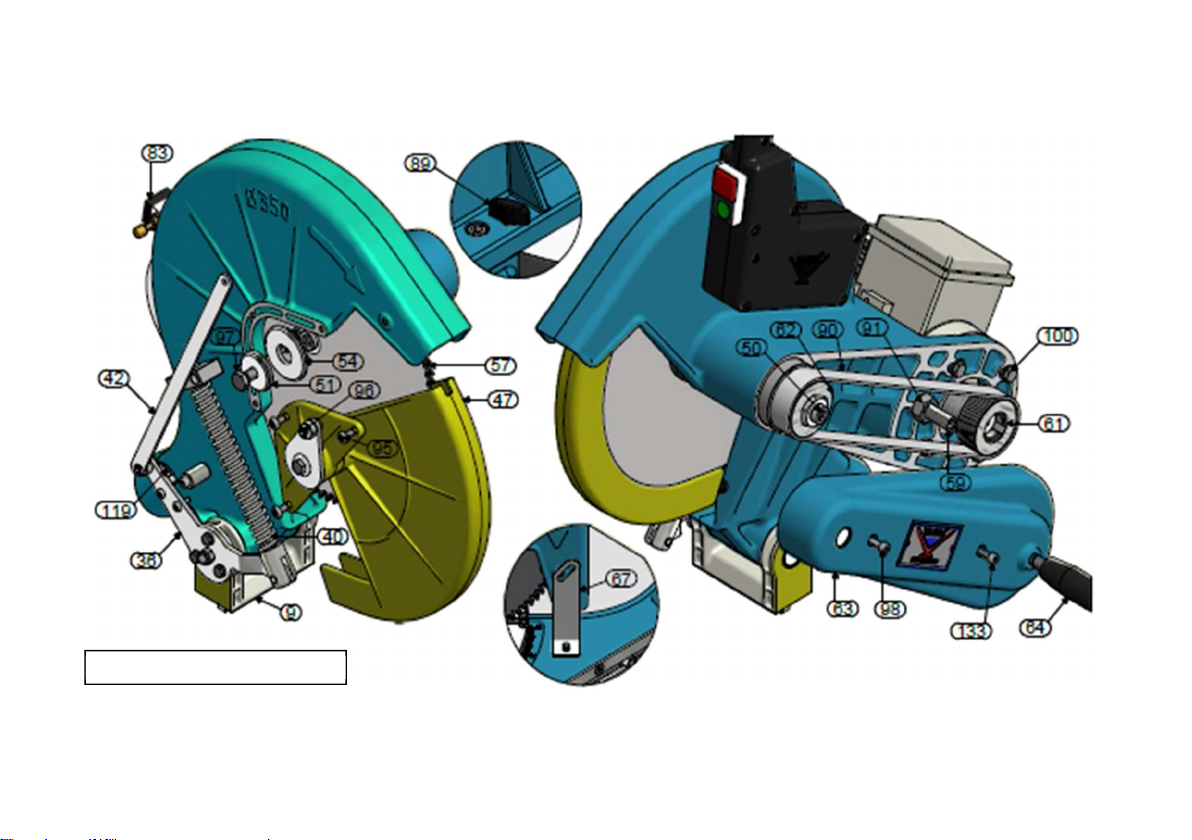

1 1SA010000-0060 1 57 1SK010000-0003 (KD 350) 1

5 2TU012610-0094 1 57 1SK010000-0004 (KD 400) 1

6 1PL030000-0017 2 59 2TU011110-1018 1

8 2TU011610-0009 1 60 1EL070001-0002 (230 V) 1

9 2TU012610-0102 1 60 1EL070001-0001 (400 V) 1

17 2TU011441-0043 1 61 2TU012110-0029 1

23 3UA030030-0003 1 62 2TU012110-0030 1

25 2TU012610-0100 1 63 2TU012610-0097 (KD 350) 1

33 2TU012710-0007 (KD 350) 1 63 2TU012610-0099 (KD 400) 1

33 2TU012710-0008 (KD 400) 1 64 1PL010000-0076 1

36 2TU011441-0905 (KD 350) 1 66 1PL010000-0042 1

36 2TU011441-0906 (KD 400) 1 66-1 1EL010000-0080 1

40 1YY011000-0023 (KD 350) 1 67 2TU011441-0305 1

40 1YY011000-0025 (KD 400) 1 71 1PN010000-0087 1

42 2TU011210-0073 (KD 350) 1 74 2TU012610-0010 1

42 2TU011210-0100 (KD 400) 1 75 3UA060030-0013 2

47 2TU012610-0096 (KD 350) 1 77 3UA040030-0007 2

47 2TU012610-0098 (KD 400) 1 78 3UA040030-0002 2

50 2TU011110-0135 1 79 3UA110030-0020 1

51 2TU011110-0857 1 83 1PN010000-0012 1

54 2TU011441-0651 1 86 4UN300030-0001 1