Kinetic 1S (#1741)

#55-1740-1 Rev.2

2-2011

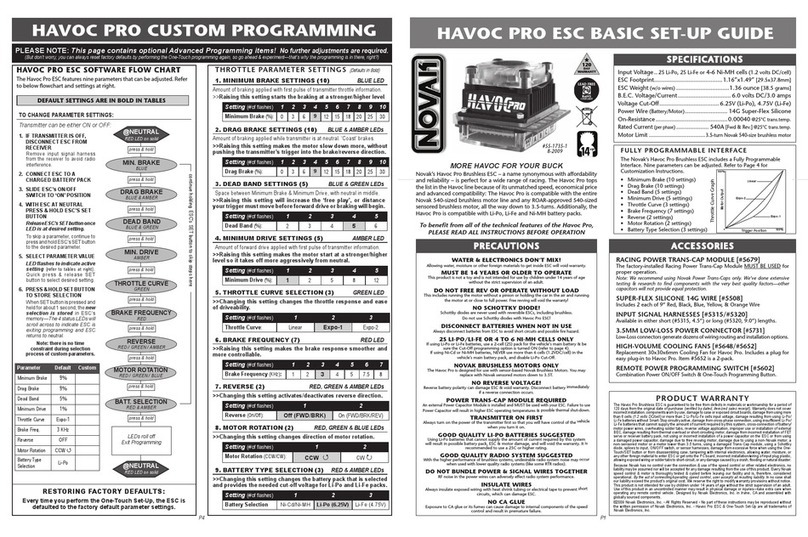

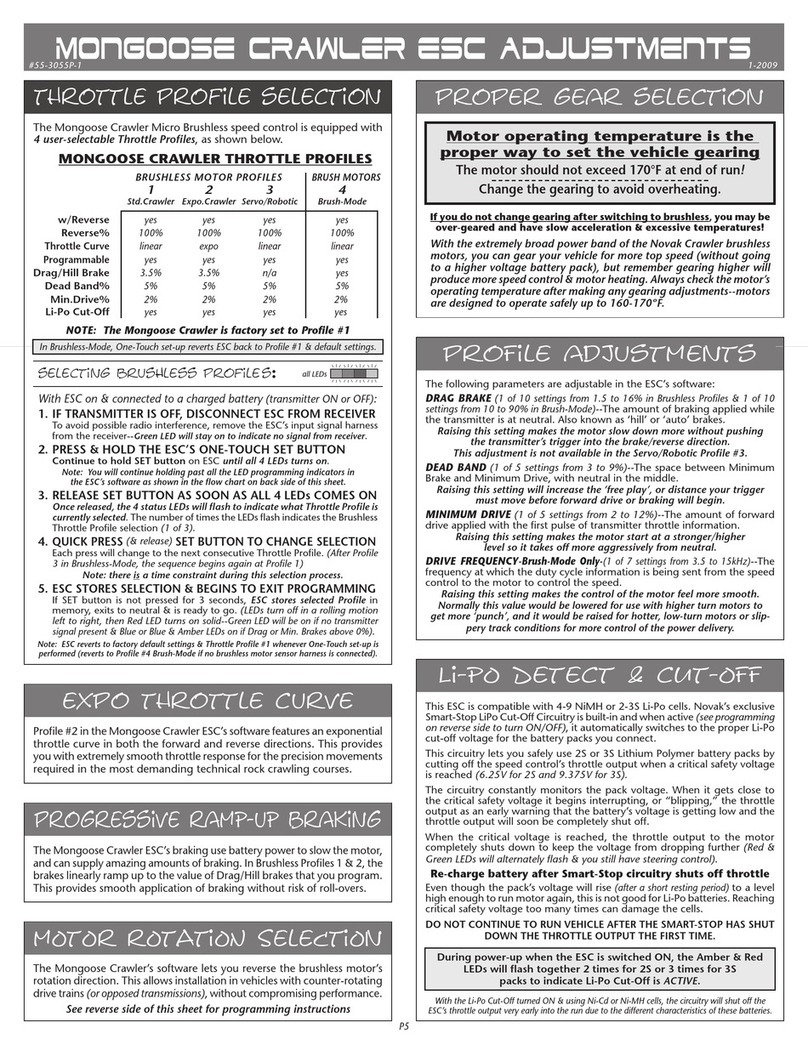

SPECIFICATIONS

Input Voltage

–1S ESC

.........................................................1S LiPo

Input Voltage

–2S ESC

..................... 1-2S LiPo/LiFe cells, 4-6 NiMH

ESC Footprint .......................................

1.16”x1.47” (29.5 x 37.3mm)

ESC Weight

–1S

(w/o wires) .......................... 1.15 ounce (32.6 grams)

ESC Weight

–2S

(w/o wires) .......................... 1.29 ounce (36.6 grams)

B.E.C. Voltage/Current (built-in) .................... 6.0 volts DC / 3 amps

Power Wire (Battery/Motor) ......................... 14G Super-Flex Silicone

On-Resistance .................0.00040 ohm per phase

@25°C trans.temp.

PC interface ........................... NovaLink™ Programming Interface

Compatibility ....................................... Sensored Brushless Motors

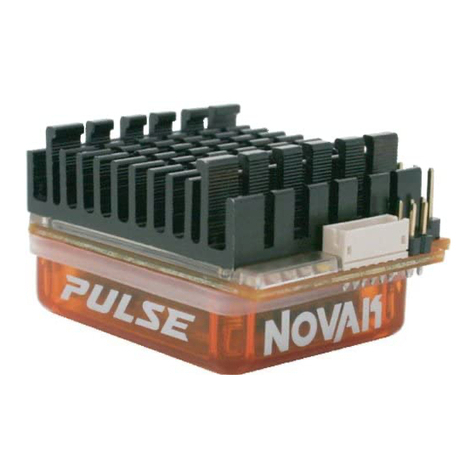

The Most Advanced Racing Speed Controller

The Kinetic Racing Brushless ESC (#1740) includes Novak’s Dynamic Timing

Advance™ electronic motor timing, NovaBrakes™, Electronic Power Control™

current limiting, on-board temperature monitoring, zero-timing Sportsman

Mode, complete on-board programmability and built-in PC interface.

The Kinetic ESC is loaded with 17 adjustable parameters,

sports a cross-cut heat sink, and includes everything

necessary including a cooling fan & power trans-cap module.

The Kinetic 1S ESC is optimized for 1S racing and features

a low-profile heat sink and 2S LiPo receiver pack harness.

For informative product videos, visit the Team

Novak Channel on YouTube®.

Join Novak’s e-mail list to receive updates about the Kinetic.

To benefit from all of the technical features of the Kinetic,

PLEASE READ ALL INSTRUCTIONS BEFORE OPERATION

NOVALINK™ PROGRAMMING INTERFACE [Novak kit #5440]

Optional fully adjustable PC interface, which includes a USB cord and software disk.

PLUG-IN INPUT SIGNAL HARNESS (MINI-JST) [Novak kits #5304 & #5309]

Includes input signal harness with 2mm mini plug on ESC end for use with Kinetic.

4.5” in Novak kit #5304, and 9” in Novak kit #5309.

BRUSHLESS SENSOR HARNESSES [Novak kit #5351-#5353]

Shielded sensor harness protects sensor wires and provides multiple installation options.

4”/100mm (Novak #5351), 6”/150mm (Novak #5352) & 9”/230mm (Novak #5353).

SUPER-FLEX SILICONE 14GA WIRE SET [Novak kit #5508]

Two each of 9” length black, red, blue, yellow and orange 14GA wire.

SUPER-FLEX SILICONE 12GA WIRE SET [Novak kit #5512]

Two each of 3 ft. length black, red and blue 12GA wire. Optional wire set is perfect for

low-resistance connections.

BRUSHLESS MOTOR CONNECTOR WIRE SET [Novak kit #5332]

Flexible 14GA wire with gold-plated connectors for low-resistance connections.

LOW-PROFILE HEAT SINK [Novak kit #S5431]

For Kinetic/GTB 2/Havoc Pro SC ESCs with 8.5T or higher motor. Includes thermal gap pad.

REMOTE POWER PROGRAMMING SWITCH [Novak kits #5602 & 5604]

Includes ON/OFF Power Switch and Programming Button harness. #5604 for Kinetic 1S.

2-PIN JST HARNESS SET--MALE & FEMALE PIGTAILS [Novak kit #5612]

Includes 1 male & 1 female harness with 22GA silicone wire and 2-pin JST connector on 1 end.

COOLING FANS--25x25x10mm [Novak kits #5649 & #5653]

Cooling fans fit the ESC’s heat sink perfectly & has the Kinetic’s 2mm mini plug for easy

power connection. Single fan in Novak kit #5649, and 2-pack of fans in Novak kit #5653.

POWER TRANS-CAP MODULE [Novak kits #5679 & 5687]

Replacement Power Trans-Cap provides improved efficiency and lowers operating

temperatures. #5679 for 2S LiPo and #5687 for 1S LiPo usage.

POWER CONNECTORS–3.5 & 4mm [Novak kit #5731 & #5741]

Low-Loss connectors generate dozens of wiring routing and installation options.

LEAD-FREE SILVER SOLDER [Novak kit #5831-#5833]

Novak solder contains 3% Silver for high-conductivity and is available in three sizes.

6g in Novak kit #5831, 15g in Novak kit #5832, and 100g in Novak kit #5833.

DOUBLE-SIDED MOUNTING TAPE [Novak kit #5840 & #5841]

Includes cushioned, double-sided tape to secure electronics in vehicles.

10 pieces in Novak kit #5840, and 100 pieces in Novak kit #5841.

HEAT SHRINK TUBING [Novak kit #5850 & #5851]

Novak heat shrink tubing is 6” long and available in six sizes: 1/16” - 3/8”.

6 piece assortment in Novak kit #5850, and 24 piece assortment in Novak kit #5851.

WATER & ELECTRONICS DON’T MIX!

Allowing water, moisture or other foreign materials to get inside ESC will void warranty.

MUST BE 14 YEARS OR OLDER TO OPERATE

This product is not a toy and is not intended for use by children under 14 years of age

without the strict supervision of an adult.

TIMING INCREASES ELECTRONICS’ TEMPERATURES

Use extreme caution when setting up and testing your application to avoid overloading and

overheating the Kinetic ESC and brushless motor. Excessive overheating will void warranty!

SENSOR-BASED BRUSHLESS MOTORS ONLY

The Kinetic ESC is designed for optimal use with Novak sensor-based brushless motors. Motor

may be replaced with sensor-based brushless motors down to 3.5T (540-size) or 4.5T (550-size).

TIMING PRODUCES DANGEROUSLY HIGH SPEEDS

When Novak’s advanced timing is activated, the resulting vehicle speed can be

dangerously high. It is important to take extra precautions.

NO SCHOTTKY DIODES!

Schottky diodes are never to be used with brushless ESCs.

Do not use Schottky diodes with Kinetic ESC!

DO NOT FREE REV OR OPERATE WITHOUT LOAD!

This includes running the motor without a pinion or holding the car in the air and running

the motor at or close to full power. Free revving will void the warranty!

DISCONNECT BATTERIES WHEN NOT IN USE

Always disconnect batteries from ESC to avoid short circuits and possible fire hazard.

1-2S LiPo/LiFe OR 4-6 NiMH CELLS ONLY

If using LiPo or LiFe battery packs, use 1 or 2-cell (1-2S) batteries for the vehicle’s main

battery & be sure the Voltage Cut-Off programming option is turned ON

(refer to Track Guide)

.

If using NiCd or NiMH batteries, NEVER use more than 6 cells (1.2VDC/cell) in the vehicle’s

main battery pack, and disable Voltage Cut-Off Circuitry (refer to Track Guide).

NO REVERSE VOLTAGE!

Reverse battery polarity can damage ESC & void warranty. Disconnect battery immediately

if a reverse connection occurs.

POWER TRANS-CAP MODULE REQUIRED

An external Power Trans-Cap module is installed on ESC & MUST be used at all times.

Failure to use a Novak Trans-Cap module with proper cell rating (1S or 2S, depending on

ESC) will result in higher ESC temperatures & possible thermal shut-down or damage.

TRANSMITTER ON FIRST

Always turn on the power of the transmitter first so that you will have control of the

vehicle when you turn on the electronics.

GOOD QUALITY LiPo/LiFe BATTERIES SUGGESTED

Using batteries that cannot supply the amount of current required by this brushless system

will result in possible battery pack, ESC, and/or motor damage, and will void the warranty.

It is recommended to use cells with a 25C or higher rating.

GOOD QUALITY RADIO SYSTEM SUGGESTED

With the higher performance of brushless systems, undesirable radio system noise may

occur when used with lower quality radio systems. 2.4GHz radio system use is best. An

FM system is acceptable, as long as it is high quality. AM systems are NOT recommended.

DO NOT BUNDLE POWER & SIGNAL WIRES TOGETHER

RF noise in the power wires can adversely effect radio system performance.

INSULATE WIRES

Always insulate exposed wiring with heat shrink tubing or electrical tape to prevent short

circuits, which can damage the ESC.

NO CA GLUE

Exposure to CA glue or its fumes can cause damage to internal components of the ESC

and result in premature failure.

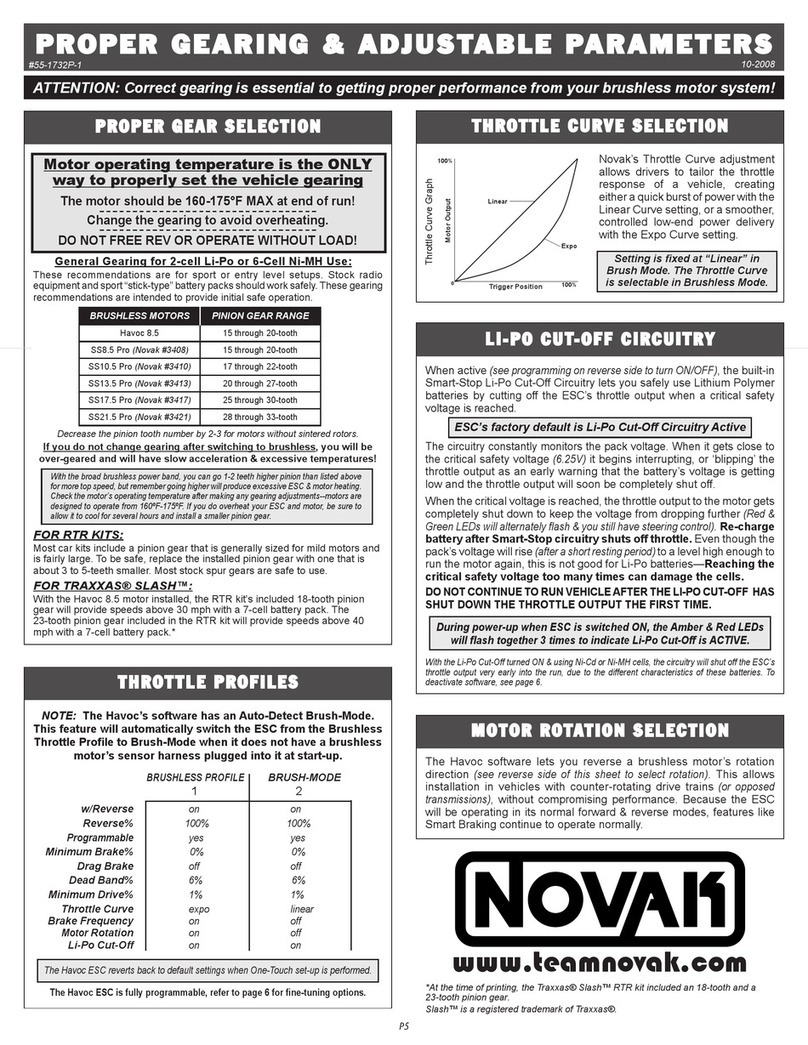

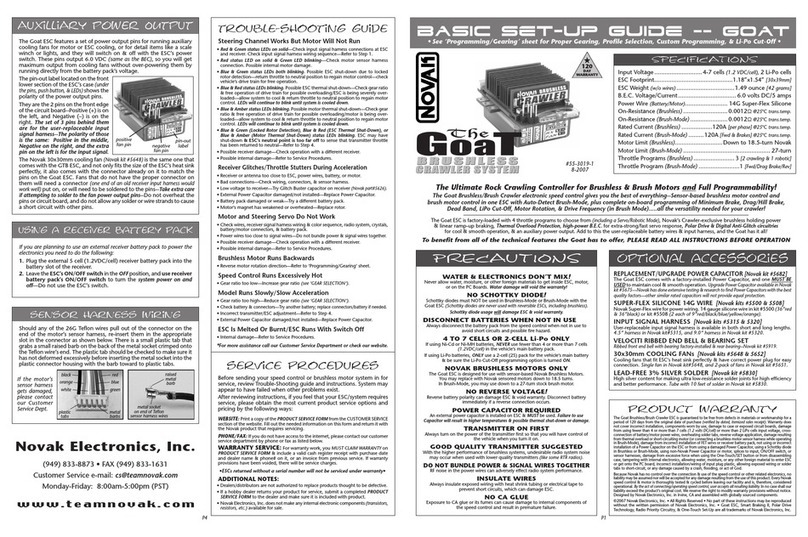

BASIC SET-UP GUIDE – KINEtic

• See “Track Guide” sheet for Proper Gearing, Profile Selection, Custom Programming & One-Touch Set-Up •

PRECAUTIONS

ACCESSORIES

P1P4

product warranty

The Kinetic Racing Brushless ESC (1S or 2S) is guaranteed to be free from defects in materials

or workmanship for a period of 120 days from the original date of purchase (verified by dated,

itemized sales receipt). Warranty does not cover incorrect installation, components worn by

use, damage to case or exposed circuit boards, damage from using more than 6 cells (1.2 volts

DC/cell) or more than 2 LiPo/LiFe cells input voltage, damage due to timing, damage due to

turning off Thermal Overload Protection (via NovaLink™), damage resulting from using LiPo/LiFe

batteries without Smart-Stop circuitry active,

using insufficient LiPo/LiFe batteries that cannot

supply the amount of current required by this system,

cross-connection of battery/motor

power wires, overheating solder tabs, reverse voltage application, improper use or installation of

external BEC, damage resulting from thermal overload or short-circuiting motor, damage from

incorrect installation of FET servo or receiver battery pack,

damage due to free revving motor,

damage due to using a non-Novak motor or a non-sensored motor,

not using or incorrect

installation of a Power Trans-Cap module on the ESC or from using a damaged or incorrect cell-

rating Power Trans-Cap module, using a Schottky diode, splices to input, ON/OFF switch, or

sensor harnesses, damage from excessive force when using the One-Touch/SET button or from

disassembling case, tampering with internal electronics, allowing water, moisture, or any other

foreign material to enter ESC or get onto the PC board, incorrect installation/wiring of input plug

plastic, allowing exposed wiring or solder tabs to short-circuit, or any damage caused by a crash,

flooding, or natural disaster. Melted speed controls or motors are not covered by the warranty.

Because Novak has no control over the connection & use of the speed control or other related

electronics, no liability may be assumed nor will be accepted for any damage resulting from the

use of this product. Every Novak speed control & motor is thoroughly tested & cycled before

leaving our facility and is, therefore, considered operational. By the act of connecting/operating

speed control, user accepts all resulting liability. In no case shall our liability exceed the product’s

original cost. We reserve the right to modify warranty provisions without notice. This product is

not intended for use by children under 14 years of age without the strict supervision of an adult.

Use of this product in an uncontrolled manner may result in physical damage or injuries—take

extra care when operating any remote control vehicle. Designed by Novak Electronics, Inc. in

Irvine, CA and assembled with globally sourced components.

©2011 Novak Electronics, Inc. • All Rights Reserved • No part of these instructions may be

reproduced without the written permission of Novak Electronics, Inc.

Kinetic 2S Racing Brushless ESC, Kinetic 1S Racing Brushless ESC, Dynamic Timing Advance,

Electronic Power Control, NovaBrakes, Smart Braking II, Polar Drive Technology, Radio Priority

Circuitry, & One-Touch Set-Up are all trademarks of Novak Electronics, Inc.

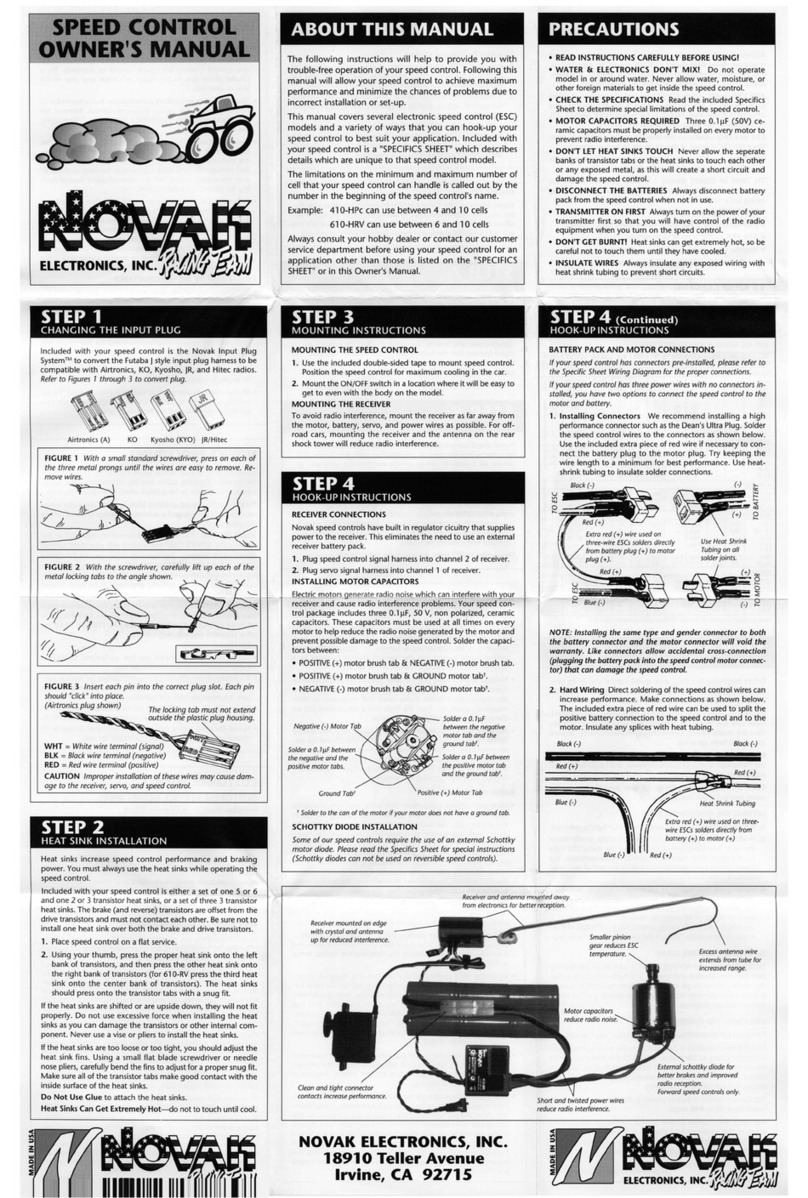

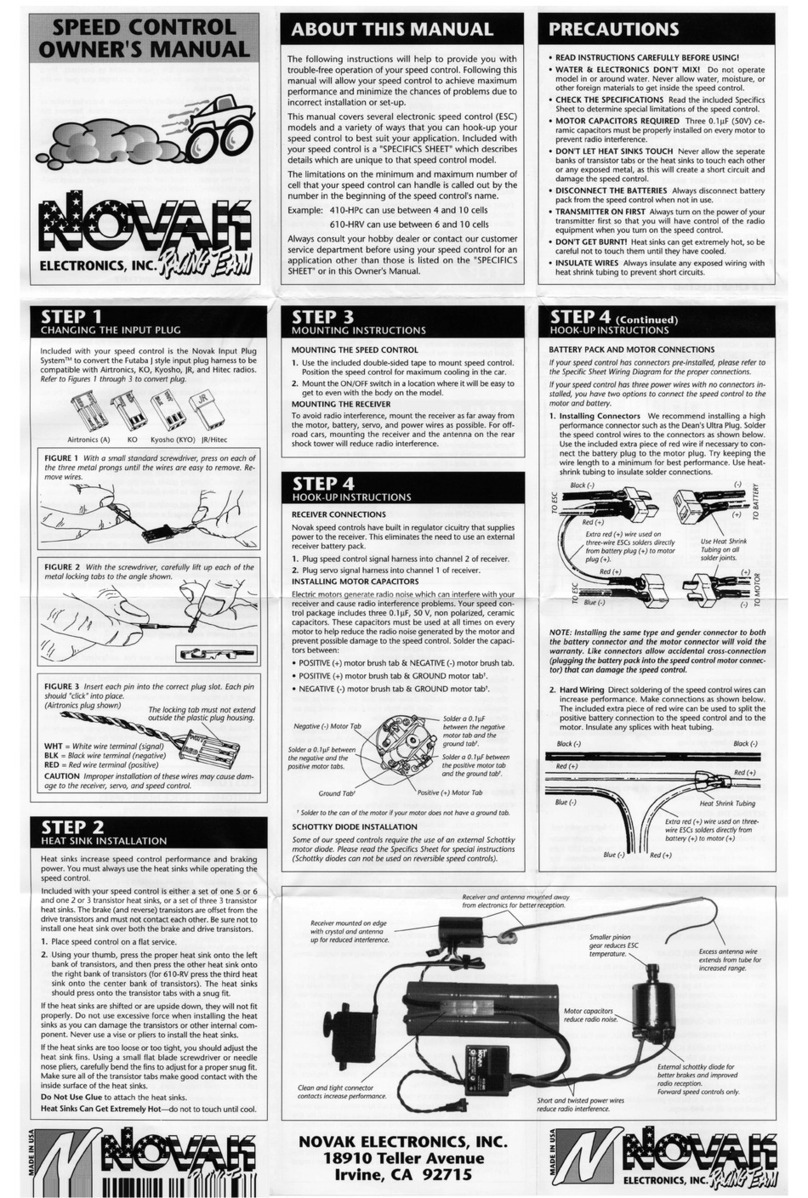

This section shows the polarity of the Kinetic’s output pins. The included receiver

harness (Novak #5309) has a 2mm mini plug on the end that is plugged into the

ESC and a standard JST plug on the receiver end. The included ON/OFF switch on

the Kinetic 2S (Novak #5602) has a standard JST plug on it. Before connecting,

note the wiring sequence of the installed harness connectors as shown here.

The Kinetic 2S’s heat sink is designed to accept a 25x25mm cooling fan, and

comes with nylon 4-40x5/8” screws to secure it. To install, simply center the

fan on the ESC and push the nylon screws down into the cross cuts of the heat

sink. If using metal screws, thread them into the heat sink. Install the fan’s power

connector onto the fan output pins on the ESC--note polarity as shown below.

NOVAK ELECTRONICS, INC.

17032 Armstrong Ave. Irvine, CA 92614

PHONE: (949) 833-8873 • FAX: (949) 833-1631

www.teamnovak.com

service procedures

Before sending your speed control in for service, review the Trouble-Shooting

Guide (in Track Guide). The ESC may appear to have failed when other problems exist.

After reviewing instructions, if you feel that your ESC requires service, please ob-

tain the most current product service options and pricing by the following ways:

WEB SITE: Print a copy of the PRODUCT SERVICE FORM from the CUSTOMER

SERVICE

section of the Web site. Fill out the needed information on this form and

return it with the Novak product that requires servicing.

PHONE/FAX: If you do not have access to the internet, please contact our

customer service department by phone or fax.

WARRANTY SERVICE: For warranty work, you MUST CLAIM WARRANTY

on PRODUCT

SERVICE FORM & include a valid cash register receipt with purchase

date and dealer name & phone # on it, or an invoice from previous service. If

warranty provisions have been voided, there will be service charges.

• ESCs returned without a serial number will not be serviced under warranty •

TRADE-IN PROGRAM: For non-warranty work, Novak offers a trade-in

program for current and discontinued products. You can replace, exchange or

upgrade any Novak speed control to any available speed control listed within the

trade-in program. You must complete a Non-Warranty Service Form to be eligible.

ADDITIONAL NOTES:

•

Dealers/distributors aren’t authorized to replace products thought to be defective.

• If a hobby dealer returns your product for service, submit a completed PRODUCT

SERVICE FORM to the dealer and make sure it is included with product.

• Novak Electronics, Inc. does not make any internal electronic components

(transistors, resistors, etc.) available for sale.

CONTACT:

When active (see Track Guide to turn ON/OFF), the built-in Novak Smart-Stop

Voltage Cut-Off Circuitry lets you safely use 1S or 2S Lithium Polymer (LiPo) or

Lithium Iron Phosphate (LiFe) battery packs by cutting off the speed control’s

throttle output when the critical safety voltages are reached.

The circuitry constantly monitors the pack voltage and automatically selects a 1S

or 2S cut-off voltage

[3.125V (1S), 6.25V (2S) Li-Po; 2.375V (1S), 4.75V (2S) Li-Fe]

.

When the ESC detects that the critical safety voltage will soon be reached, it begins

interrupting, or “blipping,” the throttle output as an early warning that the battery’s

voltage is getting low and the throttle output will soon be completely shut off.

When the critical voltage is reached, the throttle output to the motor gets

completely shut down to keep the voltage from dropping further (Red & Green

LEDs will alternately flash & you still have steering control).

Re-charge battery after Smart-Stop circuitry shuts off throttle

Even though the pack’s voltage will rise

(after a short resting period)

to a level high

enough to run motor again, this is not good for LiPo or LiFe batteries.

Reaching critical safety voltage too many times can damage the cells.

DO NOT CONTINUE TO RUN VEHICLE AFTER THE SMART-STOP HAS SHUT

DOWN THE THROTTLE OUTPUT THE FIRST TIME.

When the ESC is switched ON, the Yellow & Red LEDs will flash

together 3 times to indicate LiPo/LiFe Cut-Off is ACTIVE.

With the Voltage Cut-Off Circuitry turned ON & using NiCd or NiMH cells, the circuitry will

shut off the ESC’s throttle output very early into the run, due to the different characteristics of

these batteries. Change the ESC’s Voltage Cut-Off Circuitry mode to OFF to use these batteries.

See CUSTOM PROGRAMMING options on the Track Guide to properly adjust this setting.

With the ESC connected to (at least) a charged battery pack, the receiver, and the

brushless motor’s sensor harness:

1. TURN ON THE TRANSMITTER’S POWER

2. PRESS & HOLD ESC’S ONE-TOUCH/SET BUTTON

3. TURN ON THE SPEED CONTROL’S POWER

With transmitter throttle at neutral, and still pressing the

SET button, slide the ESC’s

ON/OFF switch to ON position.

4.

CONTINUE HOLDING SET BUTTON UNTIL RED LED COMES ON

5. RELEASE SET BUTTON AS SOON AS LED TURNS RED

6.

PULL TRANSMITTER THROTTLE TO FULL-ON POSITION

Hold it there until the green status LED turns solid green.

Note: Motor will not run during programming even if connected.

7. PUSH TRANSMITTER THROTTLE TO FULL-BRAKE/REVERSE

Hold it there until the green status LED blinks green.

8. RETURN TRANSMITTER THROTTLE TO NEUTRAL

The red status LED will turn solid red, indicating that speed control is at neutral

and that proper programming has been completed.

Blue & yellow LEDs will also be

on indicating Minimum Brake (blue) & Drag Brake (yellow) settings are at levels above 0%.

If transmitter settings are changed, the One-Touch Programming must be repeated.

If you experience any problems, turn off ESC and repeat One-Touch.

NOTE: Whenever the One-Touch Programming set-up is performed, the

speed control will automatically revert back to the factory-default settings.

If you are planning to use an external receiver battery pack with the Kinetic 2S ESC

to power the electronics you need to do the following:

1. Plug the external 5 cell (1.2VDC/cell) receiver battery pack into the battery

slot of the receiver.

2. To turn the vehicle ON, switch the receiver pack ON. Then, turn the ESC’s

switch ON, then OFF to allow the ESC to be powered by an external source.

3. To turn the vehicle OFF, turn the receiver pack’s switch OFF.

ALTERNATIVE METHOD

1. Plug the external 5 cell (1.2 VDC/Cell) receiver battery pack into the battery

slot of the receiver.

2. Unplug the ESC’s red wire from the input harness going to the receiver. Insulate

the red wire to keep it from shorting.

3. To turn the vehicle ON, switch the receiver pack ON, then turn the ESC’s switch ON.

4.

To turn vehicle OFF, turn ESC’s switch OFF, then turn receiver pack’s switch OFF.

OPTIONAL RECEIVER PACK USAGE

STEP 6-one-touch programming

VOLTAGE cUt-OFF circuitry

Wiring and cooling fan

standard

JST plug

2mm

Mini plug

Sensor harness

FIGURE 5

Receiver harness

ON/OFF

switch

black wire

(negative)

red wire

(positive)

white wire

(signal)

Fan power

output pins

black wire

(negative)

positive

fan pin

negative

fan pin

Novak

#5649

installed

FIGURE 4

www.teamnovak.com