Novasina LabTouch-aw User manual

Operating Instructions

260 0775 Doc. : 004106.05

www.novasina.com

E

Leading the market thanks to INNOVATIVE solutions and sensor technology

aw-Messgerät / aw measuring instrument / Appareil de mesure aw

www.novasina.com

© 2019 by Novasina AG

Technische Änderungen vorbehalten

Technical data subject to modication

Sous réserve de modications techniques

English

www.novasina.com

INDEX

1. Introduction 4

1.1 You Are Awesome! 4

1.2 Important Notes 4

2. General Product Description 5

2.1 System Overview 5

2.2 System Architecture 6

2.3 Instrument Overview 6

2.4 Scope of Delivery 8

2.5 Optional Accessories 8

2.6 License Types 9

3. Putting into Operation 9

3.1 Installation 9

3.2 Putting into Operation 10

3.3 Basic Operations of the Instrument 10

4. Screens and Functions 12

4.1 Measurement Screen 12

4.2 Main Menu Screen 14

4.3 Navigation in Sub-Menus 16

4.4 Menu "Chamber Settings" 16

4.5 Menu "System Settings" 17

5. Temperature Control 18

5.1 Basics 18

5.2 Setting the Measurement Temperature 18

6. How to Perform Measurements 19

6.1 First Measurement 19

6.2 Stability System 20

7. Logging Functions 22

7.1 Automatic Logging of the Last 10 Measurements 22

7.2 Logging on SD-Card 22

8. Sensor Calibration 24

8.1 How to Handle SAL-T Standards Correctly 25

8.2 Values of SAL-T Standards 25

8.3 Factory Calibration, Delivery Status 25

8.4 Calibration and Verication 26

8.5. Deleting Calibration Points 27

8.6 Display Cal Points 27

8.7 Sensor Protection 28

8.8 Automatic Notication for Calibration 28

8.9 Automatic Notication for Filter Exchange 29

9. Additional Functions 29

9.1 Change Acoustic Signals 29

9.2 Reset to Default Values 29

9.3 Update of the System 30

9.4 Intensity of the Backlight 30

9.5 Touch Screen Calibration 30

9.6 Upgrade the LabTouch-aw 31

9.7 Communication Interface 31

10. Maintenance 31

10.1. Cleaning of the instrument 31

10.2. Cleaning of the aw-measurement cell „CM-2“ 32

10.3. Cleaning of the Infrared „IR“ sensor 32

10.4. Periodic Recalibration with Humidity Standards 32

10.5. Replacing Protective Filters 32

10.6. Replacing a CM-2 Sensor Unit 33

10.7. Important Notes About The Sensor 34

11. Error Codes, First Level Support 35

12. LabTouch Menu Structure 38

4

English

www.novasina.com

1. Introduction

1.1 You Are Awesome!

Thank you for having purchased a Novasina LabTouch-aw system for measuring

water activity. You have opted for a highly accurate and reliable instrument

representing the latest state-of-the-art in electronics and software design when

it comes to highest precision in aw (water activity) measuring.

To get the most out of all the possibilities of your Novasina LabTouch-aw and

to ensure safe and reliable operation, please read these operating instructions

carefully before setting the unit into operation.

Please keep this manual within reach of the installed instrument so that it will

be at hand whenever you need it. If you lose the manual, please contact your

Novasina representative for immediate replacement.

1.2 Important Notes

Intended use

The Novasina LabTouch-aw is intended to be used for measuring WATER

ACTIVITY under strict adherence to the information and notes given in this

manual. Any use beyond this scope is considered to be a violation of the

intended purpose and may endanger your safety or could result in irreversible

product damage and loss of all warranty claims. Any use of this Novasina

instrument other than intended is at the customer’s own risk and by no means

the manufacturer nor the supplier will be liable for any resulting damage.

Safety instructions

• The Novasina LabTouch-aw system should only be serviced, maintained

and repaired by qualied people who are familiar with the equipment.

• The LabTouch-aw system must not be used in hazardous zones or

similar areas. The design is made for the laboratory use only.

• No explosive materials and no highly inammable substances may be

measured in the measurement chamber system.

• Just use the original power adapter from Novasina (part number 2600505)

• Before connecting the unit to the mains, ensure that:

• The mains voltage is within 90...260V, at 50 or 60Hz.

Please check the type plate of the system!

• The power cable between the mains and the instrument is not

damaged.

• The Novasina LabTouch-aw system may only be used under the

specied operating conditions (see chapter 10).

• Observe and strictly adhere to the local regulations regarding the

handling of mains-powered devices.

• Use only genuine accessories and spare parts available from your

Novasina supplier or visit the homepage www.novasina.com.

• This instrument must not be modied in any way without the written

permission of the manufacturer.

• Never open the instrument without removing the mains power cable rst

This operating instructions is valid for software versions V2.21 or higher

5

English

www.novasina.com

2. General Product Description

2.1 System Overview

The LabTouch-aw system has been specically developed for determining the

water activity in a test sample like food, cosmetics or pharmaceuticals. Water

activity is dened as the availability of “free” water in a sample and should not

be directly compared with the water content (g water/ g sample). The water

activity is given as the aw – value and ranges between 0 (absolute dryness)

and 1 (100% relative humidity) and is a relative, sample-mass independent

measurement. Only this free water takes an active part in the exchange of

moisture with the ambient air and can possibly form the ideal medium for

microbiological growth on the surface and inuences the biological functions

of microorganisms which has an impact on the microbiological stability plus

chemical and physical properties of a product.

Special laboratory equipment is required for water activity (aw -value)

determination which quanties the air humidity over a sample in a closed

chamber after reaching the humidity equilibrium between free water in the

sample and water in the surrounding air.

The measured air humidity is directly proportional to the aw -value. An accurate

and reproducible measurement is only possible if the sample temperature is

kept constant (i.e. 25°C) and if the measurement is taken after reaching the

humidity equilibrium. It is obvious that the measurement of water activity always

take some time, means is not nished within a few seconds. The establishment

of the equilibrium is sample-dependent and can not be shortened anyhow due

to the fact that it is physics and chemistry.

An inevitable pre-requisite for determining water activity with extreme precision

is the use of an excellent humidity sensor that provides exact, reproducible

response over a very widerange (humidity from 0....100%rH), any hysteresis and

a good chemical robustness. Novasina has been developing special electrolytic

sensors that stand out for such unique properties for more than 50 years.

The integrated, resistive electrolytic LabTouch-aw sensor is based on the new

chemical substance the Novasina „Novalyte“, which achieves the required

accuracy and reproducibility for the daily sample measurement in the lab.

6

English

www.novasina.com

2.2 System Architecture

The LabTouch-aw consists of modular assemblies in combination with the

unique resistive-electrolytic Novasina measurement technology, which is part

of the aw-sensor. The aw-measurement signal is electronically processed tog-

ether with the IR (infrared)sample temperature measurement and an additional

temperature monitoring in the instrument's body. Recorded data can be stored

on an removable SD-card.

The touch screen allows intuitive programming of the instrument as well as

easy access to the various menus.

The LabTouch-aw comprises a semi-temperature stabilization of the measu-

rement chamber which allows heating but no cooling.

For checking and adjusting the instrument, humidity standards can be used.

2.3 Instrument Overview

Front view:

The measurement cell including infrared temperature measurement is located in the inner part of the

LabTouch-aw

Button to start-up the instrument

and open chamber

Touch screen

color display

Ventilation slits

(do not block)

Data storing slot

SD card reader

7

English

www.novasina.com

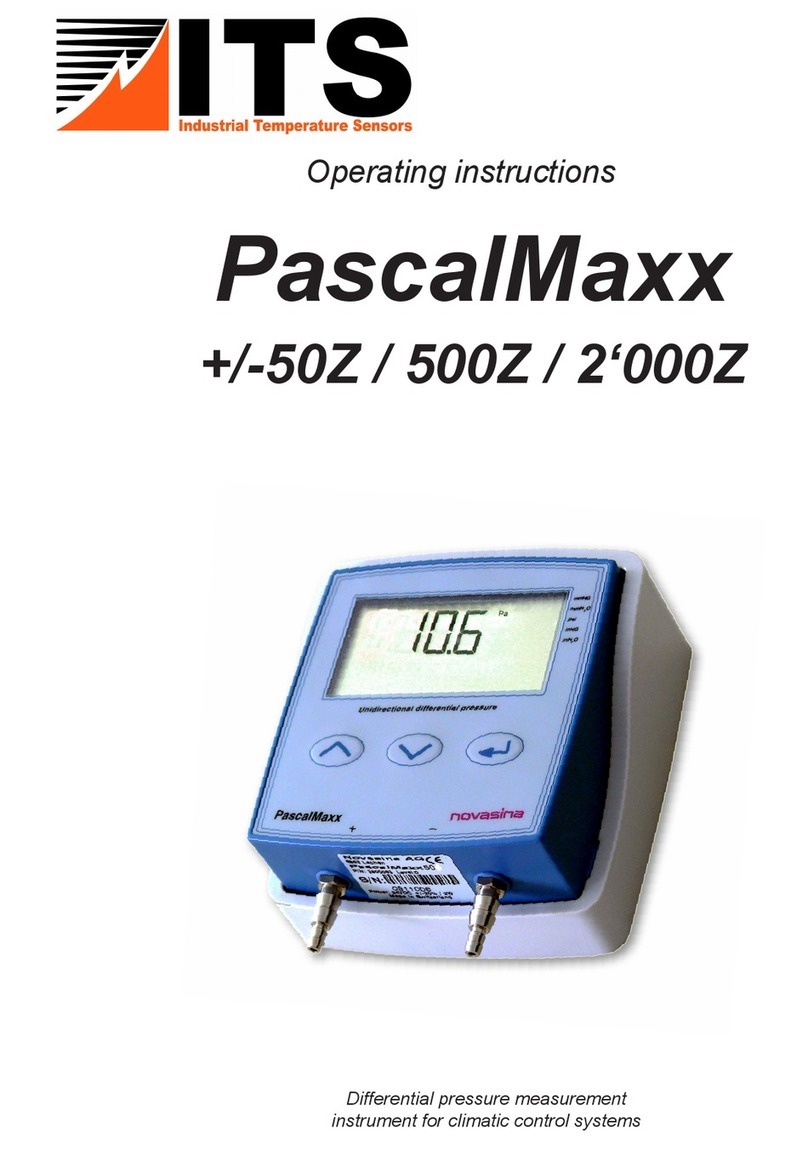

The inner part of the measurement chamber is equipped with all the characteristic sensors

White pre-lter in front

of the electrolytic

measurement cell (sensor)

Infrared temperature sensor

for sample surface temp.

measurement

Sealing to eliminate air ex-

change with environment

Metal indentation for lled

sample cup insertion

Power supply connector

USB connector for PC and Nova-

log MC communication

RS-232 interface for

connection to PC

8

English

www.novasina.com

2.4 Scope of Delivery

The LabTouch-aw instrument is delivered as followed:

LabTouch-aw:

• Instrument LabTouch

• Power supply with dierent insertion plugs

• 4 pcs of humidity standards : SAL-T: 33, 58, 75 and 84%rH

• 40 pcs standardized disposable sample dishes (ePW)

• Operating manual in English and German on a USB memory stick

• Factory calibration certicate

• SD-card 8 GB

• Tension ring

• 5 pcs pre-lter (white)

• USB and RS-232 cables

2.5 Optional Accessories

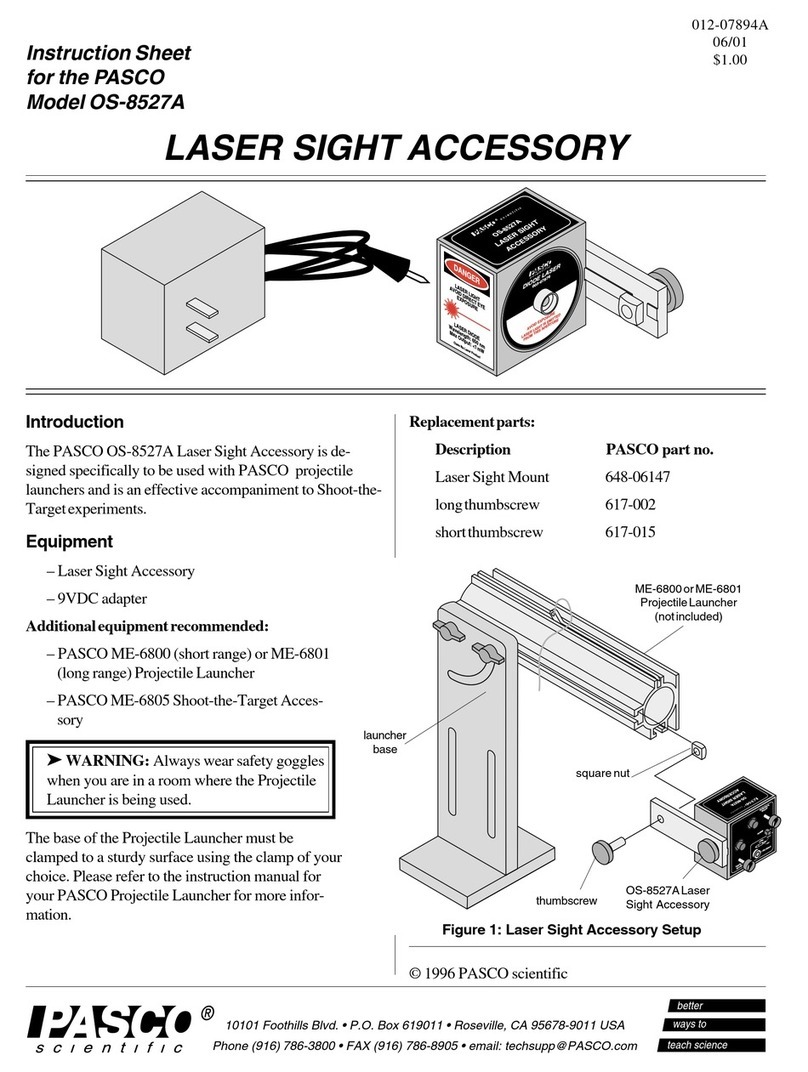

Mechanical lter

The white pre-lter provides mechanical protection of the measurement cell

e.g. in case the sample cup is overlled, sample will stick on the lter instead

of the measurement cell.

This lter should be replaced when it is dirty or at least on a yearly base,

otherwise it could inuence the measurement. 5 units are included in the

delivery of the instrument.

Chemical protection lter

Some samples do have volatiles components / ingredients thus the measuring

cell has to be protected from damaging, gaseous substances. This is done by

various lter systems which are provided by Novasina. To select an appropri-

ate lter system, consult the Novasina protection lter systems data sheet or

contact your local Novasina distribution partner.

Thanks to these lter systems, the lifetime of the measurement cell can be

extended considerably. As most of the lter material do absorb the volatile

component and get saturated by time, a regular check is mandatory to avoid

a contamination of the sensor by an ineective, saturated lter system

9

English

www.novasina.com

3. Putting into Operation

3.1 Installation

The LabTouch-aw measurement instrument is delivered with all necessary

accessories to operate the instrument properly. Upon receipt, please double-

check if everything is presentaccording to the scopeof delivery and immediately

notify your Novasina sales partner if anything is missing or broken. Do not put

damaged or incomplete measuring instruments into operation.

The equipment must be installed in a laboratory on an planar surface avoiding

vibrations, strong heat radiation, air ow, dust, direct sunlight exposure and

strong electromagnetic sources.

Make sure the power socket is not in too much distance to the instrument. It

is recommended to store the accessories in close proximity to the instrument.

3.2 Putting into Operation

• Use the Novasina power adapter only. Third party products can destroy

the instrument

• Check if the local mains voltage matches with the identication plate of

the supplied external power supply and plug it to the socket.

• Plug the external power supply cable to the instrument socket on the back

of the LabTouch-aw

Note:

The LabTouch-aw is very ecient and requires only little electrical power.

The power supply complies with the latest standard (fullls „energy star level

IV“) so the instrument can be switched-on permanently and kept ready for

measurements at any time. The LabTouch-aw should only be switched-o,

if no measurements are performed for a longer time period (i.e. more than

one week).

3.3 Basic Operations of the Instrument

This chapter describes the basic operations as starting-up and shutting-down

of the LabTouch-aw as well as other functions.

3.3.1 Start-up procedure

To start-up the instrument, proceed as follows:

• Close the instrument if it has been opened

• Power-up the instrument by hitting the black button in front of the instrument

which also can be used for opening the instrument. A beep indicates the

initialization of the starting sequence

• The system is started-up which is indicated by two dierent start-up screens

• The start-up sequence is nished after approx. 1 minute and the measu-

rement screen appears

10

English

www.novasina.com

• The current measurement values are displayed as soon as the sensor

is ready to measure

• The duration of the pre-heating phase depends on the existing humidity

and temperature in the measurement chamber. In general, it takes 2-3

minutes.

3.3.2 Shut-down procedure

To shut-down just press the red shut-down button on the main menu screen.

Conrm the shut-down process with "YES"

Important:

Always shut-down the instrument before you disconnect it from power other-

wise there might be a loss of data and settings.

4. Screens and Functions

This chapter describes the main screens which appear on the

display of the LabTouch-aw as well as the function of the symbols.

4.1 Measurement Screen

The measurement screen is displayed after the instrument has started up or

if a measurement has been started.

Status LED

Current values

(AW and surface

temperature)

Stable RESULTS

Information bar

Status of SD card

11

English

www.novasina.com

• The LED's (yellow or green) indicating the status of the measurement are

displayed in the rst line.

• If there is a ashing, yellow-coloured LED beside the "Analy.", a measu-

rement is on-going. If the green LED beside the "Stable" is activated,

measurement has been nished.

• If no measurement has been started, no LED is activated.

• The displayed temperature turn to red colour if temperature control has

been activated and the programmed temperature can not be reached.

• If a measurement has been started, the measurement time is displayed

in addition.

• The sample number is displayed as well below the measurement time if

the logging function is activated or if a protocol was stored. This allows an

allocation of the measured values to a specic sample.

• There is a stable indicator which changes its colour from yellow to green

and indicates the progress of the measurement. The greener the progress

bar, the closer the measurement is to be completed.

• After reaching a stable measurement value, the respective measurement

values at this point is displayed in green colour.

4.1.1 Information bar

The information bar is located in the footer of the measurement screen and

provides helpful information as operating conditions to the user.

The various information are displayed alternately.

Text or Symbol Description Remarks

Date / Time Current date and time

Please touch display to access the

menu!

Please touch display to access the

menu!

Press icon for more information! To gather more information about a

displayed symbol, press on it. Symbol

descriptions see further down

Press icon to abort beep! Press on the speaker symbol to stop

the beep

The beep appears once the mea-

surement is nished

SD Card is write protected! The SD card is write protected.

Please unlock the card by moving the

little bar on the left side of the SD card

This text is displayed in light red

colour

SD Card is not ready! The SD card is not ready for operation This text is displayed in light red

colour

Calibration validity expired The sensor of the respective chamber

needs to be recalibrated

This information appears only, if

a warning for next calibration has

been activated (see chapter 8.7).

This text is displayed in light red

colour

Filter exchange required The protection filter of the respective

chamber has to be exchanged

This text is displayed in light red

colour

Demo license expires in

XX:XX h

Demo license expires in

XX:XX h

The instrument will be rebooted

once the time has expired

12

English

www.novasina.com

4.1.2 Symbol SD-Card

The status of the SD card is displayed as a symbol on the right side of the

measurement screen footer

4.1.3 Symbols

Instead of the current measurement information in yellow colour, some symbols

might be displayed.

Those symbols have the following meaning:

Symbol Description Remarks

No symbol SD card is not inserted

SD card is inserted correctly

and ready for operation

It is allowed to remove the SD card in this status

SD card is accessed by the

system

SD card must no be removed, otherwise the le

system and structure could be damaged

-> loss of data

A problem with the SD card has

being recognized by the system

Remove SD card and re-insert the card after 10

sec. A re-initialization may solve the problem. If

not, replace the card

SD card has been write protec-

ted by the small bar on the left

side of the card

SD card can be removed without problems

Important:

Before a SD card is removed, always switch to the measurement screen and double-check, if it is safe to

remove the SD card. Please do not remove, if is displayed!

Symbol Description Remarks

The system detected a problem with

the respective chamber

Press on the symbol to gather more specic

information

Sensor will be put into operating condi-

tions

• Press on the symbol to gather more

specic information

• A measurement can be started even

if the symbol is present but data will

just be analyzed once the symbol has

disappeared

Based on a specic situation, no mea-

surement values can be established

(i.e. activated dew protection of the

sensor)

• Press on the symbol to gather more

specic information

• A dew protection can as well be activa-

ted, if the sensor has been calibrated

improperly and measures a much high-

er aw-value than the real one.

Danger of water condensation in the

chamber

• Remove the sample as soon as possi-

ble from the chamber

• In addition, there is a warning beep

which lasts till the opening of the cham-

ber or for 30 sec.

13

English

www.novasina.com

4.2 Main Menu Screen

The main menu screen provides easy access to programming and measurement

functions.

4.3 Navigation in Sub-Menus

Navigation through the sub-menus is simple and only 4 dierent icons are

available to do it:

Switch OFF

the instrument

Chamber

Status Settings

Start

functions

Switch

to measurement

screen

Symbol Description Remarks

Close a sub-menu and return to

the menu above

Close all sub-menus and return to

the measurement screen

Move one menu point upwards This icon is only displayed, if there are menu

points upwards the visible area

Move one menu point downwards This icon is only displayed, if there are menu

points downwards the visible area

14

English

www.novasina.com

Symbol Description Remarks

Start a measurement and switch automati-

cally to the measurement screen

If a measurement is on-going or nished

and the "Start" icon is pressed again, the

instrument will ask if you really want to start

a new one as the current data will no longer

be displayed

Abort a measurement and switch auto-

matically to the measurement screen

• A query is issued if the measurement

should really be stopped.

• Opening the chamber will immediately

stop an on-going measurement

Release a test protocol and switch auto-

matically to the measurement screen.

Adjustment of the way the chamber(s) are

displayed on the measurement screen

and switches to it afterwards:

- All chambers:

Multiple chambers will be

displayed.

Individual chamber view is changed au-

tomatically to all chambers view in case a

measurement has been nished in a non-

displayed chamber.

Switch from the main menu to the measu-

rement screen

This function is available in the sub-menus

as well

Access the submenu "system settings"

where all system parameters can be

programmed

Access can be restricted by setting pass-

word. Refer to chapter 9.8 for more

information

Access the sub-menu "chamber settings"

where all chamber parameters can be

programmed

Access can be restricted by setting pass-

word. Refer to chapter 9.8 for more

information

Shut-down / switch-o the instrument Please switch-o the instrument only by

using this function to avoid loss of data

(logging data etc.)

Status of chamber at a glance (ashing

LED's):

- Analyzing: Measurement is on-going

- Stable: Measurement is nished

This icon changes its size depending on

the number of connected chambers

15

English

www.novasina.com

4.4 Menu "Chamber Settings"

All chamber related settings as stable observation time or calibration can be

done in this menu.

Functions of the icons on the main menu screen once the icons are pressed:

The table below should give an overview about the available functions. Detailed

descriptions will be given thereafter.

Menu point Description Remark Factory default setting

Temperature

control

Setting of measurement tempera-

ture control (or switch o) Details see chapter 5.2. O

Stable mode Settings / Mode for stability obser-

vation time Details see chapter 6.2 A (Average)

Stability

observation time

Programmable stability time, only

available if stable mode "Manual"

and "Query" have been selected

Details see chapter 6.2.2 5 min

Stability check

temperature

Monitoring of adherence of nomi-

nal temperature, only available if

temperature control is activated

Details see chapter 6.2.2

available if temperature

control is switched on and

Stable Mode is not set

to"Quick"

On

Data logger Sub-menu for programming the

logger and/or logging functions. Details see chapter 7 Sample number: 0000

Interval recording: 10 sec

Sensor

calibration

Enter sub-menu for sensor

calibration Details see chapter 8

Menu point Description Remark Factory default

setting

Info

The following information will be displayed:

CHAMBER

Instrument:

Measurement chamber tag

Serial number:

Serial number of the measurement chamber

Firmware:

Firmware version

SENSOR

Version:

Sensor version

Serial number:

Serial number of the sensor

Firmware:

Info about the cability of the file system

Last calibration:

Date and time of the latest calibration.

PROTECTION FILTER

Last exchange:

Date of the last protection filter exchange if option activated

16

English

www.novasina.com

4.5 Menu "System Settings"

All system related settings as display settings, changing units etc can be done

in this menu.

5. Temperature Control

This chapter describes how the temperature control works on the LabTouch.

5.1 Basics

Most of the samples are signicantly inuenced by temperature. For this reason,

the instrument is equipped with a simple temperature-controlled measurement

chamber. As opposed to the LabMaster-aw, the LabTouch-aw does not oer

a cooling function which just allows measurement temperatures at least +2°C

but max. +10°C above environmental (lab) temperature

Furthermore, the instrument does not have an thoroughly isolated measurement

chamber. Thus the accuracy can get worse if the temperature inside the chamber

is signicantly higher than the environmental one, especially if the infrared

sensor is covered by an installed sensor protection lter.

5.2 Setting the Measurement Temperature

• Press "Chamber settings" on the main menu screen and select "Temperature

control afterwards, then enter the requested measurement temperature

there. If no value is entered, the temperature control is switched-o.

• A warning notice is displayed if the programmed temperature is less than

the required 2°C above the environmental one. In addition, the displayed

Menu point Description Remark Factory default setting

Date, Time Set current date and time

It is mandatory to set

the correct date and time,

otherwise the calibration

points management is

disturbed and reminders do

not work properly

aw, °C, DD.MM.YYYY

Units Sub-menu for changing units

(i.e. aw or %rH etc.).

Acoustic signals

Sub-menu for adjustments of

acoustic signals (as beep) for

end of measurement notica-

tion.

Printout protocol Sub-menu for protocol printout

conguration. see chapter 7.2 - 7.6

Maintenance Sub-menu to perform mainte-

nance tasks.

Info

Info about the rmware of the

instrument and display of the

license type

17

English

www.novasina.com

temperature in the measurement screen turns red in this case and the user

will be noticed in the status bar by a respective hint.

• Iftheenvironmentaltemperatureischangingduringanon-goingmeasurement

in a way that the programmed temperature can not be reached, the displayed

temperature turns red as well and the instrument will not reach stability,

means the measurement can not be nished.

The notice "retarded (temp)" appears below the stable indicator.

• Stability is foreclosed if nominal temperature cannot be reached plus if

"Stability check temperature" is activated . Retarded (temp) is displayed

in this case as well.

Note:

The programmed temperature must be between 15°C and 30°C!

6. How to Perform Measurements

Information about starting a measurement can be found in this chapter.

6.1 First Measurement

Prepare the sample by cutting it into small pieces and ll the sample cup till the

visible rst rim. This is approximately 2/3 of the sample cup. As the water activity

is a relative measurement, the amount of sample is negligible, means, it does

not matter how much sample is placed in the sample cup, the result will be the

same. Just note that the bottom of the sample cup should be covered at least

to achieve reasonable performance. Do not overll the sample cup, otherwise

some sample will be pressed into the white sensor protection lter which can

cause wrong measurements, thereby requires immediate lter replacement.

6.1.1 Insert a Sample

Place the prepared sample cup into the metal indentation of measurement

chamber and close it.

• If the sample is too hot (more than 4°C above environmental temperature),

an alarm is issued and the chamber has to be opened as soon as possible

to avoid condensation within the same. At the same time, a respective

symbol is displayed.

Condensation has to be avoided as water droplets are formed in the mea-

surement chamber and wrong measurement results for the current and the

following samples will be the consequence. The sensor itself is actively and

reliably protected by a dew protection as long as the instrument is switched on.

18

English

www.novasina.com

If the instrument is switched-o and hot sample is placed into the chamber,

the sensor might be destroyed, especially if additional vibrations are present.

Please do not place any sample into the measurement chamber while the

instrument is switched-o!

Note:

The condensation alarm does not work properly if the infrared temperature

sensor is blocked by an inserted, chemical sensor protection lter.

6.1.2 Start a Measurement

Program the respective stability parameters, depending on the sample proper-

ties (see chapter 6.2).

Start a measurement as follows:

• Switch to the main menu screen

• Press the "Start" button.

-> The measurement is started and the measurement screen is displayed

End of measurement :

If stability is reached, the instrument takes the reading which is as well the end

of the measurement. A "beep" indicates it acoustically.

Note:

• If the stability times are set in an inappropriate way, the readings might be

taken too early (stability not completely accomplished) or measurement

time is extended unnecessarily.

• Always remove the sample before shutting-down the instrument. The dew

protection is not active once the instrument is switched o and the sensor

might be damaged in this case. In addition, volatile substances in low

concentration can accumulate and deteriorate the sensor's performance.

To it, the warm-up phase is remarkably longer if a sample with high water

activity is not removed after nishing the measurement.

6.2 Stability System

The key to a successful and reliable water activity measurement is the fact

that the reading has to be taken once the equilibrium between the free water

in the sample and the surrounding air has been established. Even as dierent,

more or less successful approaches are present in the market, Novasina has

its own, unique equilibrium detecting system which is the most accurate and

reliable one, proven by hundreds of satised customers.

Theoretically, a full established equilibrium is reached after endless time period.

Of course, there must be a tradeo as the measurement results have to be

available within reasonable time. For that reason, the LabTouch-aw is equipped

with a so called stability indicator, which supports the user in nding the best

compromise between measurement duration and sucient accuracy.

19

English

www.novasina.com

6.2.1 Stable Indicator

What is a stable indicator? Well, it is not the same as a predictor which "predicts"

the residual measurement time in minutes and seconds. It is more a tool which

takes the previous measurement history of the sample into the account and

graphically outputs the progress. This can lead to the fact that the green bar is

getting smaller even if the measurement is developped if the establishment of

the equilibrium is interrupted by the evaporation of additional free water coming

from the inner part of the sample or if environmental temperature is changed

dramatically and temperature-control of the chamber is switched o.

How is it working? In simple terms, the system observes the change of the

measurement value within a programmable time. The maximal allowed deviation

in aw is 0.001aw. The programmable time is the one which can be set as "sta-

bility observation time" in minutes or which can be selected as "stability mode"

The progress bar indicates the already reached stability. The programed stability

parameters are displayed underneath the progress bar.

Thus, as closer the deviation comes to 0.001aw within the programmed stability

observation time frame, the greener the bar will get.

If the equilibrium has been established and thereby the values considered

as stable but questionable due to a remarkable temperature dierence bet-

ween sample surface (IR-sensor) and the second temperature sensor in the

instrument's body, the display of the stability values is retarded. A respective

notication below the stable indicator is shown.

A similar notication is issued if the values are considered as stable but the

programed temperature could not be reached and stability check temperature

has been activated.

If temperature control is switched-o, so will be "retarded (temp)".

6.2.2 Program Stability Time

The required stability time for a reliable water activity measurement is specic for

each product. To make your decision easier, you can nd some recommended

settings in the table below

Please feel free to contact the responsible Novasina distributor in your area

you need assistance in selecting an appropriate stability time for your sample.

Please provide as much information as possible about the ingredients, inclu-

ding volatiles.

You can choose from four pre-settings and two manual ones. To program the

stability time, respectively to select one of the predened stability settings, press

"chamber settings" on the main menu screen and select the menu "Stable mode

Pre-settings:

Quick Measurement is nished in maximum 10 minutes.

F Fast, stability observation time is set to approx. 2 minutes

A Average stability observation time is set to approx. 4 minutes

S Slow, stability observation time is set to approx. 6 minutes

20

English

www.novasina.com

Product Recommended settings

Production Line with reduced accuracy ex-

pectation but need for fast measurements

Quick

Powders, Jam, Tomato Sauce F

Dried Meat, Fruits, Cereals A

Chocolate, Fish, Cheese,

Bakery Products, Fresh Meat, Butter

S

The determination of the most appropriate stability time can be done as following

• Choose a suitable pre-set stability mode (F, A or S)

• Start a measurement with the sample which you want to optimize or nd out the

stability time.After stability is reached, do not open the chamber and take out

the sample, let it in for another 30-60 minutes. Now compare the stable value

with the current one (both values can be seen on the measurement screen)

• If the deviation is more than 0.005aw, choose the next higher stability

pre-setting level.

• If the measurement takes too long (more than 120 minutes), choose

the next lower stability pre-setting level.

Note:

Use Excel to display the stored measurement values on the SD-card on a

computer. With the help of the graph it is easier to nd the most appropriate

stability time for a specic product.

Manual setting and query

Beside the pre-settings, the instrument oers the ability to enter a stability time

manually. This feature should only be used by experienced users as the cor-

relation between water activity and product properties have to be understood.

• "Manual":

While selecting Manual in the menu "stable mode", an additional menu

"Stability observation time" appears right underneath. A stability time from

1-30min. can be entered there.

• "Query":

If "Query" is chosen in the stable mode menu, the user is asked every time

about the desired stability mode while starting a measurement. This option is

only useful, if various samples are measured with the instrument, so that the

operatordoes nothaveto change thisparametereverytime andadjustthe unit.

Other manuals for LabTouch-aw

1

Table of contents

Other Novasina Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Viavi

Viavi SmartClass Fiber OLP-87 NG-PON2 Quick Card User Guide

Bacharach

Bacharach Neutronics 7100P Operation manual

EINHELL

EINHELL TC-LD 50 operating instructions

TPI

TPI SP620 user manual

Keysight Technologies

Keysight Technologies MXA N9020A Instruction

Holaday Industries

Holaday Industries HI-3604 user manual