Novis Premium9 User manual

user guide

9 digital

Important Notice

Before operating this medical equipment, it is

important to read this User Guide and understand

the operating instructions and safety precautions.

Failure to do so could result in patient injury and/or

damage to the product.

page

Safety Precautions 4-6

Product Overview 7

Installation & Operation 8-15

Troubleshooting 16 - 17

Cleaning 18-19

Maintenance 20

Technical Specifications 21-26

Warranty Information 27

4

safety precautions

The purpose of the following safety precautions are to

direct your attention to possible dangers. The safety

symbols and their explanations, require your careful

attention and understanding.

The safety warnings by themselves do not eliminate any

danger. The instructions or warnings they give are not

substitutes for proper accident prevention measures.

The following symbols may appear in this User Guide,

on the Control Unit, or on its accessories. Some of

the symbols represent standards and compliances

associated with its use.

SAFETY ALERT SYMBOL: Indicates caution or

warning.

WARNING: Failure to obey a safety warning can

result in serious injury to yourself or to others.

Always follow the safety precautions to reduce

the risk of fire, electric shock and personal injury.

DOUBLE INSULATION

Double insulation is a safety concept of electrical

equipment which eliminates the need for earth

grounding. Whenever there is electric current

in the Control Unit there are two complete sets

of insulation to protect the user. All exposed

metal parts are isolated from the internal metal

components with protecting insulation.

WARNING: The double insulated system is

intended to protect the user from shock resulting

from a break in the Control Unit’s internal wiring.

Observe all normal safety precautions related to

avoiding electrical shock.

WARNING: Servicing a Control Unit with double

insulation requires extreme care and knowledge

of the system and should only be performed by

a qualified service technician. For service we

recommend you return the Control Unit to your

nearest Novis Healthcare Authorised Service

Centre for repair. When servicing, use only

identical replacement parts.

OPERATING INSTRUCTIONS

WARNING: Do not attempt to operate this

product until you have thoroughly read and

completely understand the safety precautions

contained in this User Guide. Failure to comply

can result in accidents involving fire, electric

shock or serious personal injury. Save the User

Guide and review frequently for continual safe

operation and for instructing others who may use

this product.

Maximum recommended patient weight for this

system is 180 kg.

Only use the combination of Control Unit and

Mattress as specified by Novis Healthcare,

otherwise the correct function of this product

cannot be guaranteed.

5

safety precautions

WARNING: This device is not suitable for use

in the presence of a flammable anaesthetic

mixture with air, or in the presence of a

flammable anaesthetic mixture with oxygen

or nitrous oxide.

WARNING: Bed frames used with the

systems can vary greatly depending on the

specific health care setting (ie hospitals,

nursing homes, home care, etc). It is the

responsibility of the caregiver to take the

necessary precautions to ensure the safety

of the patient. This includes, but is not

limited to, the appropriate use of side rails to

prevent falls and/or patient entrapment.

IMPORTANT: Minimise articles between

the system surface and patient, and secure

bed sheets loosely so as not to affect the

alternating cell movement.

WARNING: Significant risks of reciprocal

interference may be posed by the Control

Unit during specific investigations or

treatments. Potential electromagnetic or

other interference between the Control Unit

and other devices may occur. If interference

is suspected, move equipment from sensitive

devices or contact Novis Healthcare.

Only plug into a grounded power outlet

using the power cord supplied with the

system.

Exposure of the electronic Control Unit to

any liquid while it is plugged in could result

in a severe electrical hazard.

Preventive inspection and calibration is not

required.

Do not modify this equipment without

authorisation of the manufacturer.

The Mattress is treated as the applied part of

a medical electrical (ME) system.

Do not position the system so that it is

difficult to disconnect.

Keep the equipment away from children and

animals.

Long power cord and air hose. To avoid

strangulation and entanglement, keep cable

and hoses out of reach of young children and

animals.

Novis Healthcare recommends running the

cord through the cord retention loops on

the mattress and attaching it to an electrical

outlet by the head of the bed.

The power cord to the Control Unit should be

positioned to avoid a tripping hazard and/or

damage to the cord.

control unitin general

6

Unplug the Control Unit from the mains power

supply to disconnect the power when not in use.

The Control Unit is tested and approved

according to ISO-EN 60601-1 Rev.3 & EMC

Repairs and service should be conducted by

the manufacturer or authorised personnel. If

the Control Unit is not functioning properly, or

has been damaged, unplug the unit and take

it out of service immediately. (See contact

information on cover for repair and service

information).

Do not place any objects or items, such as

blankets, on or over the Control Unit.

The electronic Control Unit is a precision

product. Use care when handling or

transporting. Dropping or other sudden impacts

may result in damage to the unit. Before

attaching the Control Unit to the foot board

of the bed, ensure the mounting surface is

sufficiently robust and free of damage.

WARNING: Risk of electrical shock: do not

open and/or attempt to repair or service the

Control Unit. If parts need to be repaired, circuit

diagrams and parts lists can be provided by

Novis Healthcare to suitably qualified service

personnel.

WARNING: Only use fuses that have the same

specified rating (see Technical Specifications).

Using fuses with higher ratings could result in

damage and/or injury.

NOTE: No special skills, training or knowledge are

required to operate the Control Unit.

safety precautions

7

The 9 Digital is an Alternating Mattress System

providing pressure application and relief for patients

with, or vulnerable to pressure injuries. It is designed

to be used on either standard or profiling single bed

frames.

The 9 Digital Alternating Mattress System consists of

the following:

• Control Unit

• Mattress

• Power Cord

• User Guide

• Carry Bag

The Control Unit provides the air supply to the

Mattress. It is controlled by a digital touch membrane

on the front panel which controls eight comfort

settings, Alternating or Static Mode for treatment

or transfers respectively, and Max Inflate function

to facilitate quick Mattress inflation. The Alarm LED

indicator and Alarm Mute completes the profile.

The visible and audible alarm function has a number of

indications depending on the cause of the failure.

On the side of the Control Unit are four male air

connectors for quick connection of air hoses. The

connectors include a locking lever on the handle for

safety and ease of use.

The mains supply to the Control Unit can be easily

disconnected and is designed to detach if pulled too

firmly – protecting the internal wiring of the unit.

The mattress comprises 19 air cells including 3

static head cells to provide static ‘pillow’ support

for optimum comfort. Air pressure in the other 16

cells including the heel zone is alternated over a

12 minute cycle. This provides regular periods of

pressure reduction to aid blood and lymphatic flow to

vulnerable tissues.

The system includes a rapid release CPR tag for

emergency deflation.

product overview

8

unpacking & inspection

NOTE: It is recommended that all packing materials

and instructions be kept in the carry bag provided,

in the event the product has to be shipped to an

approved Novis Healthcare Service Centre.

Carefully remove the Control Unit, Mattress and

accessories from the shipping cartons. Inspect all

items for any damage that may have occurred during

shipping. Any damage or missing components

should be reported to a Novis Healthcare Service

Centre as soon as possible.

The box should contain the following items:

• Completely assembled 9 Digital Mattress System

• Carry Bag

• Digital Control Unit

• Medical Grade Power Cord

• User Guide

The Mattress is treated as an applied part of this

Medical Electrical (ME) system.

installation & operation

9

installation & operation

A. power button

Turns system power on and off by pressing the power

button for at least three seconds.

B. alarm LED

This red light flashes, and an audible alarm sounds, to

alert when Control Unit or Mattress pressure fails. The

alarm has five different signals to indicate the cause of

the failure.

The audible alarm also sounds when power is

disconnected – press Alarm Mute to silence. Refer to

Alarm Function [page 14] and Troubleshooting [page

16-17], or Alarm Indication Guide on the right side of

Control Unit for cause of alarm and resolution

C. alarm mute button

Silences the audible alarm. Audible alarm will resume

after 20 minutes if cause of error is not resolved.

D. mode button

Once initialisation is complete, press to toggle

between Alternation Mode (alternative cells cyclically

inflating and deflating) and Static Mode (all cells fully

inflated with no dynamic alternation). Static mode

will automatically revert to Alternation Mode after 20

minutes for patient safety.

E. comfort setting buttons

Press arrows to increase or decrease pressure setting.

Eight pressure settings from soft to hard are available

(18mmHg to 60mmHg; 6mmHg per step). The green

LEDs illuminate to indicate which of the eight settings is

selected. Press the right arrow to increase firmness, left

arrow to decrease firmness.

F. max inflate button

Press to facilitate rapid inflation to maximum pressure

setting (60mmHg). After 20 minutes, the system

automatically reverts back to the previous pressure

setting for patient safety.

G. control unit lock/unlock button

To prevent tampering and unintended operation,

press for at least three seconds to lock the Control

Unit settings – a beep sounds and the amber LED

illuminates to indicate system is locked. When locked,

only the Alarm Mute and Lock/Unlock buttons remain

operational.

Press again for at least three seconds to unlock (beep sounds

and amber LED turns off).

The Control Unit will automatically unlock in the

event of a power failure.

control unit panel D AE FB CG

10

installation & operation

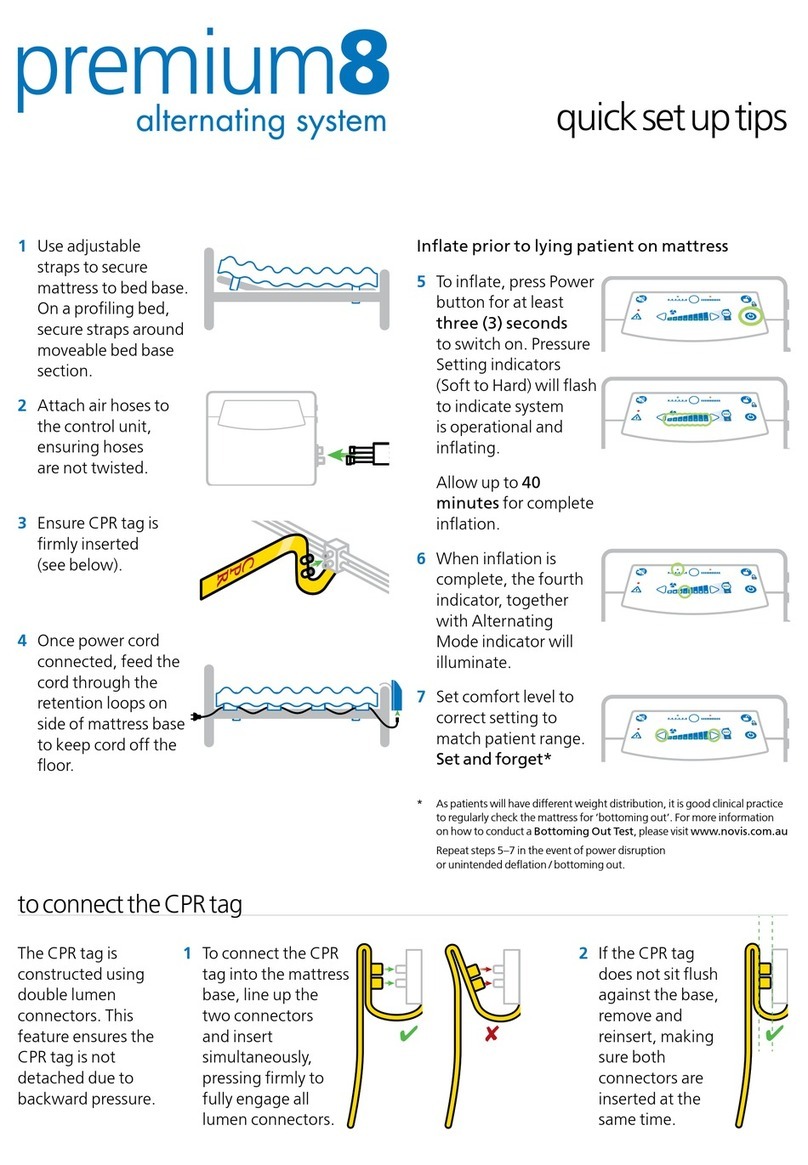

The following describes the procedures to follow when

setting up the system for the first time.

a) Remove all blankets, bedding, sheets and mattress

from the existing bed.

b) Position Mattress Replacement, with its top cover,

on top of bed frame and position hose ends at foot

of bed for Control Unit. The feet symbol on the

Mattress Replacement indicates location of the foot

end.

c) In a profiling bed, secure the side straps around the

moveable sections of the bed base. DO NOT SECURE

TO THE SIDE RAILS – THE STRAPS WILL TEAR OFF!

d) Unzip top cover and check CPR sealing plugs are

pushed fully onto the connectors.

[for details see page 13]

e) Confirm there are no sharp objects in the immediate

area which may cause damage to the Mattress

Replacement.

IMPORTANT: Make sure that the attachment of the

Mattress Replacement does not interfere with the

movement or operation of the bed.

The system is designed to operate in a controlled

environment free from extreme temperatures, high

humidity and/or excessive amounts of airborne particles,

such as dust and smoke.

setting up mattress replacement

a) Position Control Unit by its hanging hooks over foot

board of the bed or on the floor under the bed.

b) i. Depress the lever on the top of the handle.

ii. Aligning the connectors on the handle with those

on the Control Unit, firmly push the handle into

position.

iii. Release the lever, ensuring this has engaged onto

the catch connected to the Control Unit.

iv. Ensure air hoses do not kink between bed frame

and Control Unit.

c) Position the power cord through the cord retention

loops along the side of the Mattress base and insert

power cord into Control Unit, then into a grounded

240 V AC 50 Hz electrical outlet.

1

23

setting up control unit

11

installation & operation

d) Press the power button for more than three seconds

to activate Control Unit. The pressure LEDs will flash in

sequence indicating that the system has activated.

Allow up to 40 minutes for initialisation, alarm will

sound if mattress fails to reach operating pressure

after 50 minutes.

e) Once ready, the fourth pressure LED as well as

the alternating LED will illuminate to indicate that

the system is ready for use (system automatically

defaults to alternation mode after initialisation).

f) Once the Mattress Replacement is fully inflated,

bedding can be placed. Secure sheets loosely

enough to ensure they do not interfere with cell

alternation. Do not use thick mattress covers or

blankets which will interfere with cell alternation.

g) Transfer the patient to the Mattress Replacement

and perform a ‘Bottoming Out’ test to ensure that

the patient is properly suspended. Refer to page 12

for more details.

12

installation & operation

Establishing Pressure (supine patient)

With the patient lying supine (on his/her back, face

upwards), use the comfort arrows to cycle through the

eight available pressure settings.

Based on patient weight and comfort requirements,

establish the best setting for effective alternation,

support and comfort.

Before changing or lowering the pressure, ensure

the system is working effectively by performing a

‘Bottoming Out’ test:

a. Ensure system is in alternation mode but is not

undergoing an alternation (cells inflating or

deflating).

b. With the patient lying supine, unzip one side of the

top cover just past sacral region (lower spine).

c. Slide your hand underneath the patient and feel for

a deflated cell under the patient’s lower spine. The

inner static cell will remain inflated, however your

hand should easily slide between patient and base.

d. If a hand can pass under patient then the patient

is adequately suspended and pressure can be

lowered if desired.

e. Repeat Bottoming Out test at least 12 minutes

after pressure has been adjusted.

After approximately 20 minutes, reassess system

function and patient comfort. In the event of a system

error, the alarm will activate and pressure LEDs will

flash indicating a fault.

For quick reference, a comfort setting guide can

be found on the right side of the Control Unit, with

indicative settings according to the approximate

weight of the patient.

Establishing Pressure (inclined patient)

When moving the patient to a sitting or more upright

position, pressure may need to be increased (by

approximately 20% or up to two levels on the comfort

setting) to provide added support and to avoid

‘Bottoming Out’.

IMPORTANT: It is important to return to the original

pressure setting when the patient returns to the supine

position.

IMPORTANT: Wait a minimum of 12 minutes between

pressure adjustment and patient assessment, as it may

take a full cycle for the system to adjust.

CPR function

Rapid deflation of the Mattress Replacement may be

required for emergency treatment or to decommission

the unit. The CPR tag located at mattress head should

be used in the event that patient CPR or emergency

treatment is required.

1.Firmly pull the CPR tag outwards and upwards to

rapidly deflate the entire system, ensuring all four

sealing plugs are fully detached from the connectors.

mattress function

13

2. Remove patient prior to re-inflation. Power off

Control Unit. To re-inflate the system after the CPR

tag has been pulled, unzip the top cover to reveal

the CPR connectors, undo the air cell press studs

above the CPR connectors to gain access. Align the

CPR seals with the corresponding connectors.

3. Press firmly to ensure an airtight seal.

IMPORTANT: Do not position the system to make it

difficult to operate the CPR Tag. Perform a Bottoming

Out test after re-inflating the mattress following rapid

deflation (see page 12).

4. Ensure the CPR tag is correctly fed through

the opening in the left side bolster and through

the zippered opening in the mattress base when

reattaching. Zip up the opening when done.

5. Power on Control Unit. Wait for initialisation to

complete before placing patient back on Mattress

Replacement.

installation & operation

14

Initialisation Mattress has failed to reach minimum

Failure operational pressure within 50 minutes

Low Pressure Pressure has fallen 5mmHg or more

below the setting minimum

High Pressure Pressure has exceeded the setting

maximum by 10mmHg or more

Alternating Mattress has failed to commence alternation

Mode failure

AC power failure No pressure output due to mains power failure

alarm function

The red Alarm LED flashes, and an audible alert

sounds, to indicate the Control Unit or Mattress is

experiencing a fault. The LED will remain illuminated

until the fault is cleared. The audible alarm

can be silenced for 20 minutes by pressing the

Alarm Mute button.

The system has five different alarm signals, identified

by five different Pressure Setting illumination

sequences. The signals and corresponding Pressure

Setting LED displays are illustrated below.

If alarm activates and the system fails to inflate or

loses pressure, refer to Troubleshooting on

page 16-17.

display alarm/fault

installation & operation

15

transport function

1. Before patient transport, press the Max Inflate

button and wait at least five minutes for all cells to

inflate to maximum pressure.

2. Once Mattress pressure has reached maximum

inflation, press the Power button for at least three

seconds to switch off the Control Unit. Switch off

the mains supply and unplug the

power cord.

3. Remove the ‘D’ handle from the

Control Unit and seal with the attached handle

cap. The length of time the air

is retained in the Mattress will depend on the

weight and height of the individual patient.

If the patient is responsive, check

comfort level based on current pressure and adjust

accordingly.

IMPORTANT: Always perform a ‘bottoming out’ test

(see page 12) to ensure the patient is adequately

supported and not touching bed base.

mattress deflation and storage

1. Press the power button for at least three seconds

to switch off the Control Unit. Switch off the mains

supply and unplug the power cord.

WARNING: Unplug the Control Unit from the

mains power supply to disconnect the power.

2. Pull the handle to disconnect air hoses from the

Control Unit. This will deflate all cells except the

three static head cells.

3. To deflate the head cells, firmly pull the CPR tag to

disconnect the sealing plugs from the connectors.

4. Place Control Unit and power cord on top of the

Mattress and detach Mattress from bed.

5. Once fully deflated, roll up the Mattress and return

all items to Carry Bag for safe keeping.

IMPORTANT: Prior to re-starting the system, ensure

the CPR tag is reattached and connectors are fully

resealed.

installation & operationC

16

troubleshooting

alarm/fault display solution

Control Unit does not

operate; no display lights

illuminate

The Control Unit may

not be attached to a

power source or a fuse

may need replacing

1. Check the Control Unit is connected to mains

power outlet with the correct voltage.

2. Check the Control Unit is switched on. Switch off

and unplug the unit before restarting.

3. Check the Control Unit fuse (1 AMP) – fuse can be

released using a screwdriver to push and turn.

(see page 20)

WARNING: Do not try to open the Control

Unit. Opening the unit could cause personal injury or

equipment damage.

Alarm LED Initial failure 1. Reset the alarm – turn off Power and press the

Alarm Mute button.

2. Check all air hoses along the inside of the Mattress

– each should be firmly connected. Check each air

cell is securely attached to its connecting air pipe.

3. Check all cells, pipes and hoses for any air leakage.

4. Switch on Power.

+ audible alarm

Alarm LED Pressure too low 1. Reset the alarm – turn off Power and press the

Alarm Mute button.

2. Check the CPR tag is intact, ensuring the sealing

plugs are firmly fitted to the connectors.

3. Check all air hoses along the inside of the Mattress

– each should be firmly connected. Check each air

cell is securely attached to its connecting air hose.

4. Check all cells, pipes and hoses for any air leakage.

5. Check that the air filter cover is correctly secured

and the air filter is clean.

6. Switch on Power.

+ audible alarm

17

troubleshooting

Alarm LED AC power failure 1. Press the Alarm Mute button to silence the audible

alarm.

2. Check the power cord is firmly plugged into the

mains outlet and the Control Unit; and check the

mains power is switched on.

3. Check the Control Unit fuse (1 AMP) – fuse can be

released using a screwdriver to push and turn.

+ audible alarm

Patient is sinking or

‘bottoming out’

whilst lying flat

on the Mattress

The pressure maybe

set too low for the

patient’s weight

1. Increase the pressure setting by pressing up the

Pressure arrow.

2. To check effective system performance, conduct a

‘bottoming out’ test as described on page 12.

NOTE: If the problem is not resolved, please contact

an authorised Novis Healthcare Service Centre.

alarm/fault display solution

Alarm LED Pressure too high 1. Reset the alarm – turn off Power and press the

Alarm Mute button.

2. Detach the handle from Control Unit to reduce

pressure – reconnect when pressure

has decreased.

3. Check for twists in the air hoses between Mattress

and Control Unit.

4. Switch on Power.

+ audible alarm

Alarm LED Alternating

Mode Failure

(no alternation)

1. Reset the alarm – turn off Power and press the

Alarm Mute button.

2. Disconnect the air hoses to reduce pressure –

reconnect when pressure

has decreased.

+ audible alarm

18

cleaning

Infection Control and routine cleaning must be carried

out in accordance with your local Infection Control

Policy.

It is suggested that all disinfection be done with a high

grade disinfectant in accordance with manufacturer’s

instructions.

NOTE: The top cover seams are sealed to help prevent

moisture ingress and bacterial growth in the seam

stitching.

WARNING: Do not use high temperature

autoclave, or use phenolic based products for cleaning.

IMPORTANT: It is recommended the system is cleaned

between patients and every two weeks if in constant

use.

mattress base

Swab the mattress base and cells with a solution of

Sodium Hypochlorite or similar (up to 10,000ppm

available chlorine). Dry thoroughly before refastening.

CAUTION: Do not machine wash or dry the air cells or

Mattress base.

IMPORTANT: Do not disassemble the Mattress unless

cleaning is required. If cleaning or disinfecting is

required, do not disconnect the hoses from the air cells.

Never or allow fluid and moisture to enter air cells and

air hoses.

NOTE: Refer to the top cover wash tag for cleaning

instructions.

If there are visible signs of body fluids or other

substances, the top cover should be washed. The top

cover can be machine washed (up to 70°C) using

disinfectant according to manufacturer’s instructions.

Some surface wrinkling may result from cleaning

procedures. This has no adverse effect on the fabric’s

properties.

In washing machines, it may be difficult to wet out full

covers. Correspondingly, spinning and tumbling may not

remove water trapped between layers. It may be helpful

to interrupt the washing or drying cycles to alleviate

this.

Corrosive or abrasive cleaning agents must not be used.

CAUTION: Do not dry the top cover using the heat cycle

or a dryer. Air dry or select a non heat dry cycle.

If there are no visible signs of body fluids or other

substances, the top cover should be sanitised.

top cover: machine laundering

19

cleaning

light soilage

Superficial dirt on the coating may be removed

by wiping with a soft cloth moistened with water

containing a neutral detergent. More persistent

contamination may be treated by wiping with alcohols

or turpentine substitute, followed by hot water and

detergent.

Routine cleaning and disinfection in situ may be

carried out on the cover with warm water and a

neutral detergent or with a sodium hypochlorite

solution (0.1% or 1,000 parts per million available

chlorine).

Decontamination: For the decontamination of blood

spills or heavy soilage

The material is compatible with 10,000 ppm available

chlorine in solution. After the 2 minute required dwell,

excess solution must be removed and the surface

thoroughly rinsed and dried prior to reuse or storage.

Proprietary disinfectants may be used provided

manufacturer’s instructions are followed.

All cleaning agents, and disinfectants, must be

thoroughly rinsed off and the item dried before

storage. Failure to do this may result in the

accumulation of reagent that could damage the

polyurethane coating, react with the bed frame, or

negate the biocompatibility properties of the fabric.

storage

Store in a cool, dry area. Avoid excessive pressure and

contact with non-colourfast materials.

control unit

WARNING: Ensure the Control Unit is

disconnected from the mains electricity supply before

cleaning.

WARNING: Do not spray disinfectant directly on

to the Control Unit, or immerse the Control Unit in any

type of fluid. This could pose a severe electrical hazard

as this equipment has no protection against ingress

of water.

Wipe down Control Unit with warm water containing

detergent (or with a solution up to 10,000 ppm of

Sodium Hypochlorite or similar) and dry thoroughly

before use.

top cover: wiping by hand and disinfection

20

air filter

1. Switch off the power supply to the Control Unit.

2. Disconnect the power cord and

air hoses.

3. Place the Control Unit on a flat surface with back

panel uppermost (place soft cloth under unit to

prevent scratches).

4. Carefully remove air filter cover, remove and

discard the filter material and fit new filter (there

may be a small locking screw – use a small small

flat head screwdriver to remove}.

5. Refit the air filter cover to the Control Unit. The

Control Unit is now ready for re-connection.

NOTE: Good filter maintenance is critical

to maintain your system in optimal operating

condition. Failure to keep the filters clean will result in

system downtime and increase repair costs.

It is recommended that the air filter be replaced

annually. Air filters are available from a Novis

Healthcare Service Centre. Preventative inspection and

calibration is not required.

fuse

1. Switch off the power supply to the Control Unit.

2. Remove the power cord from the electrical socket

on the side of the base of the Control Unit.

3. Insert a small flat head screwdriver into the groove

and turn anti-clockwise (quarter turn).

4. Remove the “blown” fuse from the fuse holder clip

and discard.

5. Insert a new fuse into the plug.

Push against the force of the spring and turn

clockwise with the screwdriver (quarter turn).

maintenance

This manual suits for next models

1

Table of contents

Other Novis Medical Equipment manuals

Popular Medical Equipment manuals by other brands

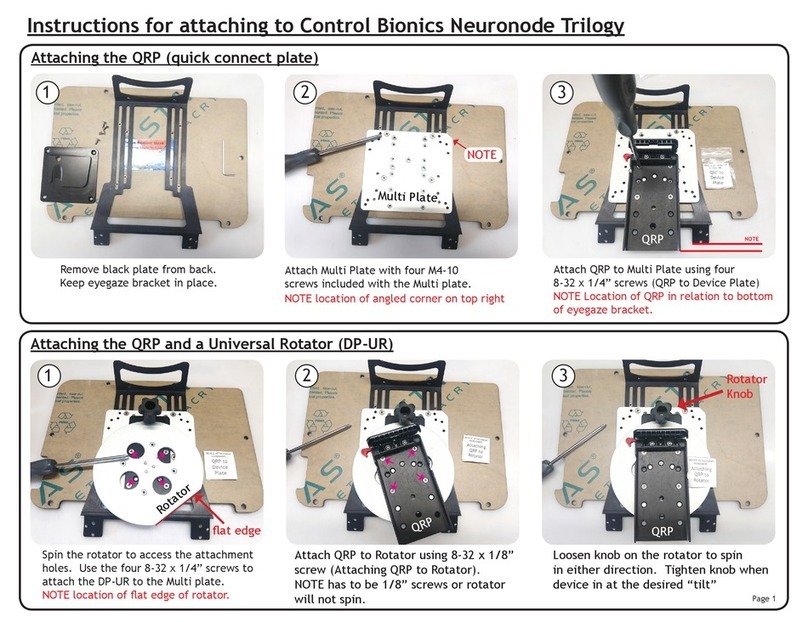

Control Bionics

Control Bionics Neuronode Trilogy Attachment instructions

fasciotens

fasciotens Carrier Instructions for use

Direct Healthcare Services

Direct Healthcare Services Dyna-Form Mercury Safety 7 user manual

Enraf Nonius

Enraf Nonius TensMed 911 user manual

3M

3M Littmann 3200 manual

ITC

ITC HEMOCHRON Signature Elite Operator's manual