LogBox-DA Datalogger

NOVUS AUTOMATION 3/7

Tag: Set of up to 8 characters that allows you to identify the variable.

Input Type:Allows you to define how the pulses applied to input 1

will be measured. The list presents the following options: NPN, PNP

and Dry Contact.

Sensor Factor: Allows you to set the quantity per pulse received. It

is optimized for measuring liquid flow (liters per pulse). It can assume

any value between 0.000001 and 16383.

Decimal Digits: Allows you to set the number of decimal places of

the sensor factor.

Unity: Allows you to define the unit to be used for the measured

variable. The options are optimized for measuring flow rate. Still, you

can define other units.

Scale Factor: Field to measure flow rate. Allows you to define the

connections between the different flow measurement units. It can

assume any value between 0.000001 and 65535. For variables other

than flow rate, you should configure it with a value of 1.

Decimal Digits: Allows you to set the number of decimal places for

alarm values.

Alarm: Allows you to define limit values for the measured variable.

Once they are exceeded, the alarm will be triggered. In this case,

even if the alarm condition no longer occurs, the alarm indicator will

remain blinking.

The "Lower Alarm" parameter allows you to define the value

below which the alarm will be triggered.

The "Upper Alarm" parameter allows you to define the value

above which the alarm will be triggered.

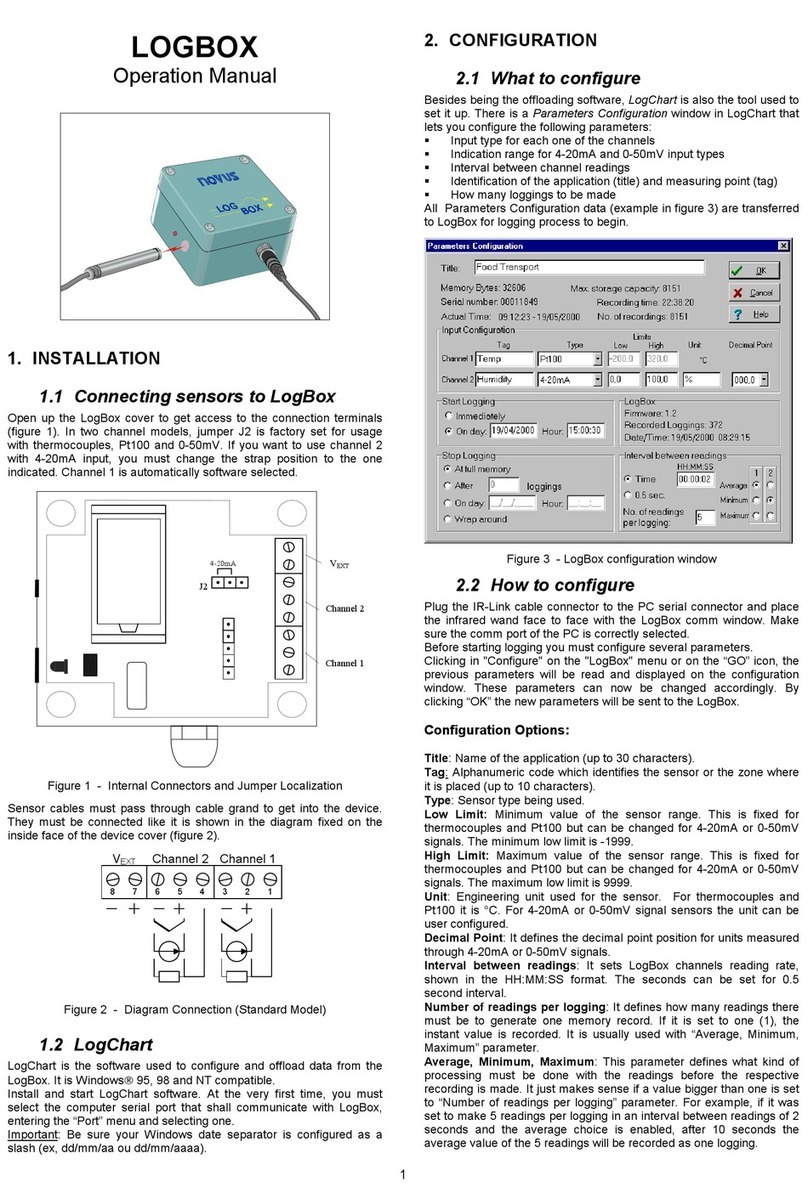

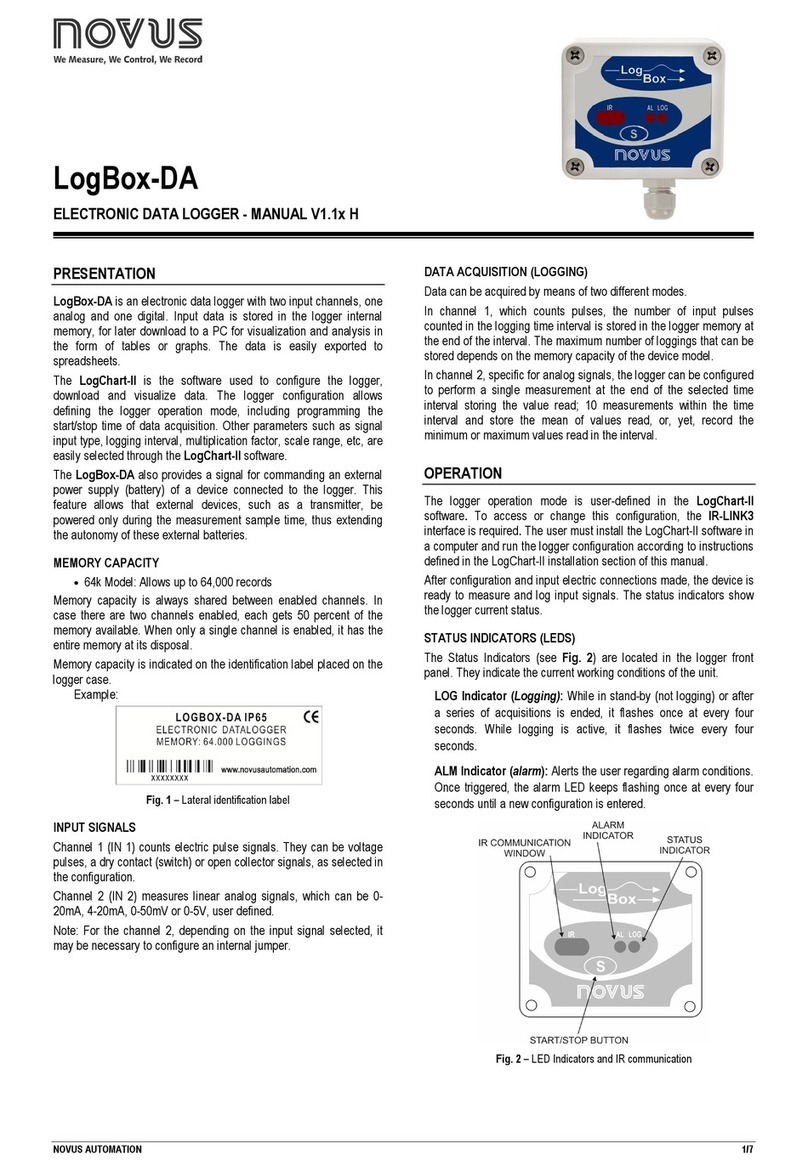

ANALOG CHANNEL – ANALOG SIGNAL

Figure 8 –Analog channel

The configuration fields for the Analog Channel are the following:

Tag:Set of up to 8 characters that allows you to identify the variable.

Input Mode:Allows you to define the signal applied to the analog

input: 4-20 mA, 0-20 mA, 0-50 mV, 0-10 V. The option used must be

according to the jumper configuration (see INPUT CONNECTIONS −

ANALOG CHANNEL item).

Unit: Allows you to define the unit to be used for the measured

variable.

Mode: Allows you to define the recording mode of the acquired data:

Instant:The device performs a measurement. The value is

recorded at each acquisition "Interval".

Medium:The device periodically takes ten measurements over

each acquisition "Interval". The recorded value is the average of

these measurements.

Minimum:The device periodically takes ten measurements over

each acquisition "Interval". The recorded value corresponds to the

smallest measurement.

Maximum:The device periodically takes ten measurements over

each acquisition "Interval". The recorded value corresponds to the

largest measure.

Decimal Digits: Allows you to define how many decimal places after

the comma will be displayed in the Lower and Upper Limits, Upper

and Lower Alarms and Offset parameters.

Lower Limit and Upper Limit:Allows you to define upper and lower

limit values for the inputs.

Alarm: Allows you to define limit values for the measured variable.

Once they are exceeded, the alarm will be triggered. In this case,

even if the alarm condition no longer occurs, the alarm indicator will

remain blinking.

The "Lower Alarm" parameter allows you to define the value

below which the alarm will be triggered.

The "Upper Alarm" parameter allows you to define the value

above which the alarm will be triggered.

Offset: Allows you to correct small errors presented by the input

signal. Errors that occur, for example, when changing a sensor or

replacing a transmitter.

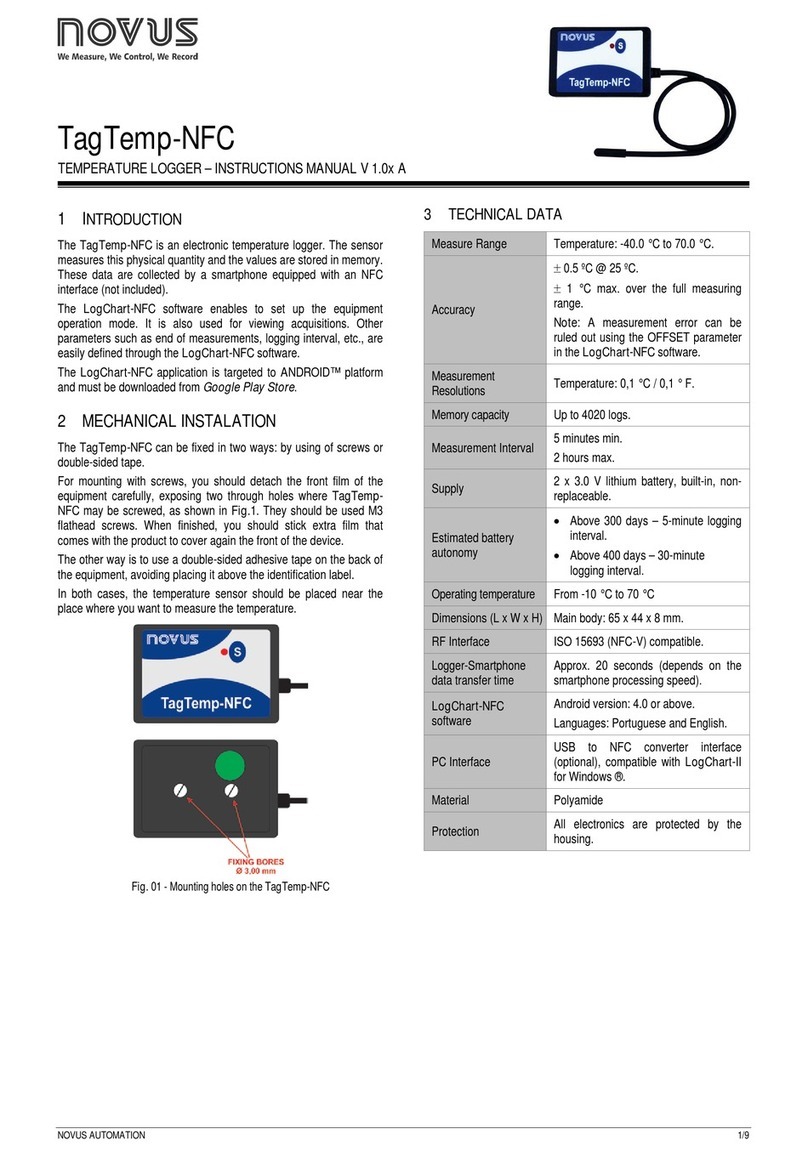

LOG REGISTER

By clicking the button, you can access the configuration fields of

the logger data:

Figure 9 –Log register

LOG

Log Interval: Allows you to determine the time interval (hh:mm:ss)

between acquisitions. At the end of this period, the data will be saved

in the memory of the logger.

Estimated Time: Based on the "Interval" of the acquisitions and the

number of programmed acquisitions, it informs you how long it

should take the logger to perform all the programmed acquisitions.

Available if the Memory Mode is set to "Full Memory" mode.

External Battery Switch: Allows you to set the time interval that the

logger takes to turn on the electronic switch before each

measurement. This time cannot exceed half the time between

measurements (limited to 10 seconds).

MEMORY MODE

Circular Memory: The logger performs acquisitions continuously.

Once the logger reaches maximum memory capacity, the oldest data

will be overwritten.

Full Memory: The logger performs acquisitions until the available

memory capacity of the logger is reached.

START MODE

Immediate Start: Allows to start the acquisition process right after

sending the configuration to the logger.

Date/Time: Allows to start the acquisitions at a defined date and

time.

Digital Input: Allows to perform acquisitions while the digital input is

triggered (closed) and to stop acquisitions when the digital input is

disabled (open).

Start Button:Allows to start the acquisitions using the Start button.

Daily:Allows to start the acquisitions daily and at a previously

defined time.