TAGTEMP logger

NOVUS

AUTOMATION

UK

TEL:

+

44

(0)

870

321

8522

FAX:

+

44

(0)

870

321

8523

web:

www.novusautomation.co.uk

email:

[email protected] |

6/7

In erval: Defines the interval between readings: hour, minutes

and seconds. When the logging mode is set to the

ins an aneous the minimum interval is 1 second. For maximum

and minimum values, the minimum interval is 10 seconds in

both models.

Misc: Shows the Logging Mode parameter that defines how

measured value will be logged. Options are:

Ins an aneous: The value logged will be exactly the value

measured at each interval. Measurement is taken at the end

of the defined interval. The minimum interval between

measurements is 1 second.

Minimum: The value logged will be the minimum value

found within ten consecutive measurements taken within an

interval. The minimum interval between measurements is 10

second.

Maximum: The value logged will be the maximum value

found within ten consecutive measurements taken within an

interval. The minimum interval between measurements is 10

second.

Alarms: Enables an alarm that is triggered according to user-

defined parameters. Values shown in the temperature unit

selected.

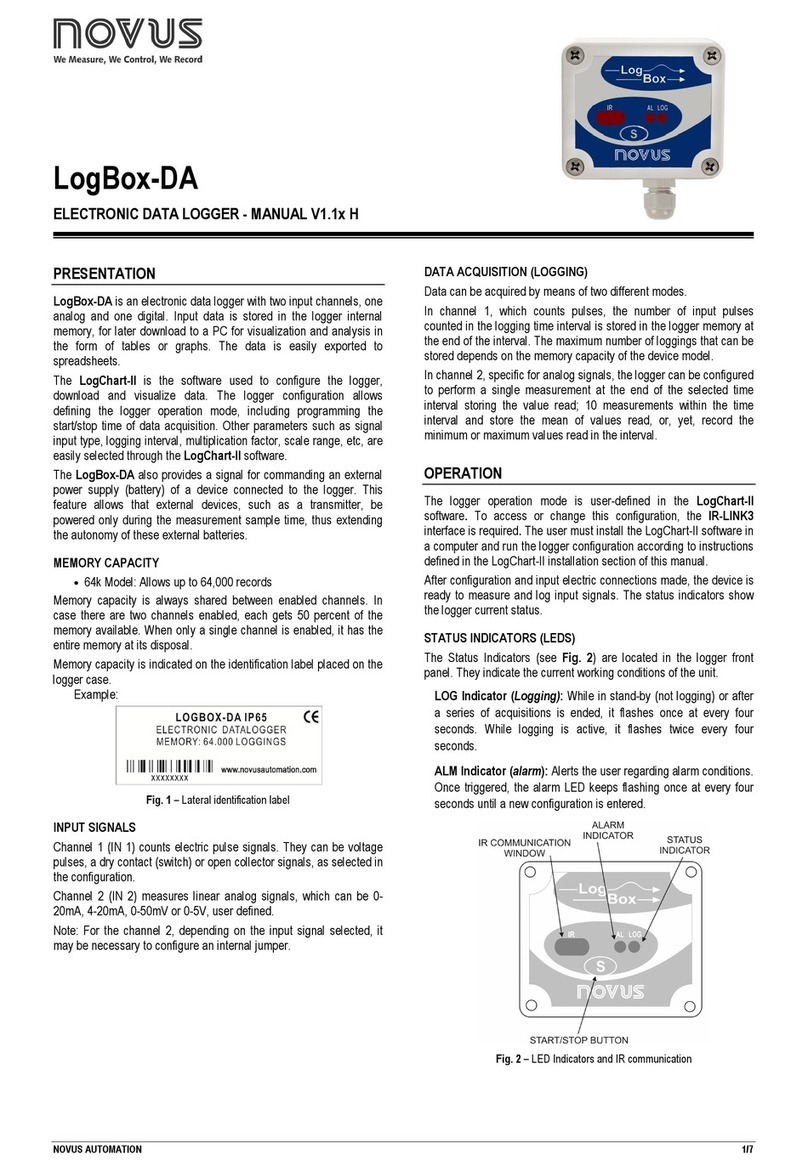

Figure 14 – PDA Alarm Settings screen

Clocks: Provides access to Logger and PDA clocks. When a

new configuration is sent to the logger, clocks are updated.

Offse : allows fine offset adjustment on the measured value. The

Rese button clears changes made and the logged values are

the measured values again.

Figure 15 – Offset adjust screen

After configuring clocks in the Se ings screen, click Apply to send

this configuration to the Logger, returning to the Moni oring screen.

Sending a new configuration implies the exclusion of all data

collected present in the logger memory.

7.3 DOWNLOADING DATA FROM THE LOGGER

In the Moni oring screen, the Download button performs the

transfer of the data from de LogBox to the PDA. Download can be

partial and it does not interfere in the ongoing acquisition process.

The data base of loggings is displayed in the Recorded Da a screen,

identified with the name assigned to the process (Da a Ti le) and the

date it was downloaded.

Should the PDA batteries be discharged, all readings will be lost.

7.4 FILE VISUALIZATION

The Recorded Da a screen lists the data base logged and stored in

the PDA. To access data, select the desired data base and press

De ails. Recorded Da a De ails screen shows several information

about the data base.

View Da a shows in table format the logged values and the date and

time they were performed.

Press Dele e to erase the selected data base.

7.5 TRANSFERRING DATA TO YOUR DESKTOP

HotSync of data stored in a PDA with the Desktop is performed

through a conduit installed together with the LogChart Palm-OS. The

conduit converts the data collected by the LogChart Palm-OS to a file

compatible with the LogChart-II software.

To access the conduit options, the Ho Sync Manager software must

be active. Click on the HotSync Manager in the Windows taskbar.

Select in the drop-down menu the option Custom. Select Novus

LogChar Condui and click Change. The following window will be

exhibited:

Figure 16 – LogChart Conduit options

Handheld overwri es Desk op: LogChar Palm-OS files are

transferred to the Desktop.

Save in: Choose a directory to record files generated during data

synchronization.

Leave Da a on Palm: Option to keep or delete the data in the PDA

after HotSync.

Do no hing: Data synchronization will not be performed;

Se as defaul : The same settings will be used in the next Ho Sync

processes.

8MOST FREQUENTLY FOUND PROBLEMS

The LED is no flashing: The LED flashing light is intentionally

weak, and it can be difficult to see it in clear environments, certify it is

really not flashing.

Communica ion wi h he logger fails:

Make sure the COM port is selected correctly and there is no other

program using the same port during communication attempts;

Make sure there is no physical obstacle blocking the infrared signal;

Make sure the cable is well connected to the PC port;

Make sure the port selected does not present any problem;

9SPECIAL CARE

When handling the device and its battery, observe the following:

•When the device is opened, avoid touching the electronic

components and the printed circuit board to avoid electrostatic

discharge damages.

•Pay close attention to battery polarity.

•When closing, the cover and its sealing must be mounted

correctly and carefully to ensure the enclosure sealing.