2

Start Logging: Two modes can be selected.

→Immediately: LogBox will start logging as soon as configuration is

finished.

→On day __/__/__ hour __:__:__ : LogBox will start logging on the

day and time defined by the user.

Stop Logging: Four modes can be selected.

→At Full Memory: LogBox will stop logging when its available memory

is full.

→After __ readings: LogBox will stop logging after the number of

readings here defined.

→On day __/__/__ hour __:__:__ : LogBox will stop logging on the day

and time defined by the user.

→Wrap around: LogBox will keep on recording the readings and when

the memory is full it will overwrite the oldest logging in a circular (FIFO)

or wrap around manner. The time stamped is kept updated accordingly.

Input Type Range

None -

Thermocouple J -50 to 760oC

Thermocouple K -90 to 1370oC

Thermocouple T -100 to 400oC

Thermocouple E -40 to 720oC

Thermocouple N -90 to 1300oC

Thermocouple R 0 to 1760oC

Thermocouple S 0 to 1760oC

Thermocouple B 150 to 1820oC

Pt100 -200.0 to 320.0oC

4-20mA Programmable linear indication from -2000 to

9999

0-50mV Programmable linear indication from -2000 to

9999

Figure 4 - Available Input Types Table

3. OFFLOADING DATA

Acquired data can be transferred to a PC with LogChart and be viewed

in a chart and a table way. After data are offloaded, they can be saved

in files for future analysis.

For data offloading, click on the corresponding icon or select the

appropriate item of the LogBox menu. The infrared wand must be face

to face with LogBox communication window. While in offloading

process, a progress bar will be displayed. The offloading time is

proportional to the amount of data logged.

Important: When you offload data, recordings are stopped. To restart

the logging process, you must re-enter in the Parameters Configuration

window.

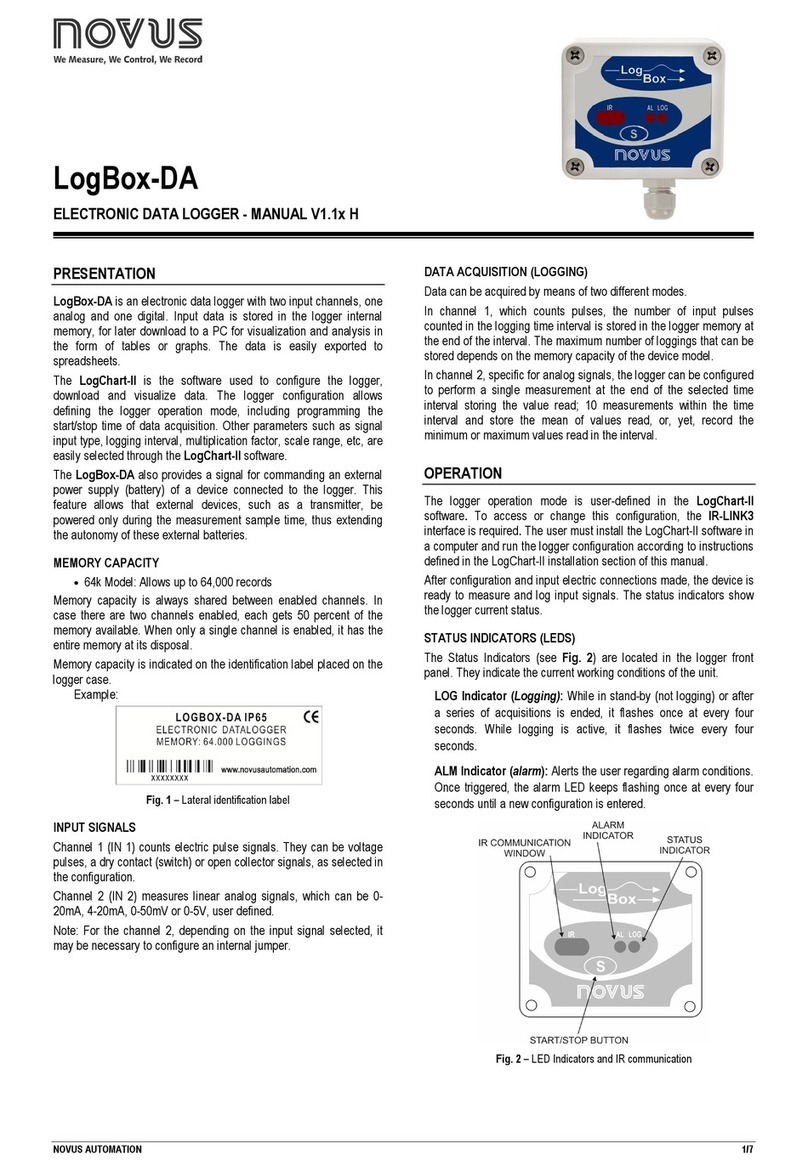

4. SOME OTHER FEATURES

An external LED is used to indicate the device operating status. It

usually blinks once each four seconds. When it starts to record (enters

logging time), the LED blink is doubled. After loggings are finished, it

again blinks a single time in a period of four seconds.

There is in LogBox a battery consumption projection for 0,95Ah

batteries. This projection is available in LogBox menu (Battery option)

and it requires communication with the device. Each time you get the

battery out of the device (as in a battery change), this consumption

indicator will consider that the new battery is full-charge. This feature

was not created to try to use a battery untill it is almost empty. Novus

will not be responsible for data losses because of earlier battery

discharge.

There is an option for little calibration corrections to be made in

LogBox. You can individually adjust the offset of the channels entering

LogBox menu and then Offset Adjust. It is a good practice to check it

out if the adjust was well succeeded by monitoring the input signals in

the monitoring window. Important: every time you change the input type

of one channel the offset of that channel will be reset to zero.

It is recommended to take a good look at LogChart’s on-line help to see

how to operate all the software features.

5. ADDITIONAL INFORMATION

If you have any doubt about this or other NOVUS products, you can

www.novus.com.br

6. LOGBOX TUTORIAL

1. Connect the sensors to LogBox. If no sensors are connected to the

logger any recorded value will have no meaning at all.

2. Connect the IR Link wand to the PC serial port, approach the tip to

the IR window and click "GO" in the tool bar menu. A message "Trying

Communication" will appear in the lower left corner of the screen. If

necessary try turning the wand to help IR communication. (Notice that

the apparently weak IR signal is meant to be so in order to extend

battery life)

3. After a few seconds the configuration window will be active. To start

configuration follow the steps below:

3.1. Select input type for channel 1. By selecting "none" you will

exclude this channel. For the "Temp" and "RHT" loggers the input type

is fixed and cannot be changed. If this is your case go to item 3.3.

3.2. For 4-20mA or 0-50mV input types, the fields Low Limit and

Upper Limit, Measuring Unit and Decimal Point can be edited. Choose

the measuring range to be displayed. Example: If channel 1 is

connected to a pressure sensor in the 0 to 30 bar range with 4 to 20mA

output you can have the logger record directly in pressure scale unit by

configuring:

· Decimal Point: 00,00

· Lower Limit: 0

· Upper Limit: 30,00

· Unit: bar

For all other input types (thermocouple, Pt100, ...), the limits and the

scale unit is fixed (°C) and the decimal point option is not available.

3.3. Each channel can have a tag name which will be displayed

on the graph identifying the channel.

3.4. A title for the application can be written which will describe

the application or location.

3.5. Select the interval between readings. Choose a sampling

time fast enough to have a good graph resolution but be ware that

memory space is scarce. A compromise between logging interval and

total logging time must be considered.

Two parameters must be configured: "Interval between readings" which

defines the time between measurements, and Number of readings per

logging which defines how many readings will generate one logging.

The latter can be selected to record the average, the maximum or the

minimum value measured within so many readings.

3.6. At last, configure the start logging time and stop logging

time. Immediately will make the logger start logging right after sending

the instructions. Start logging On day...and hour... will make the logger

do so on that day and hour.

The field "Stop Logging " has the following options:

· At Full Memory: The logger will only stop when the memory is full.

· After __ loggings: the logger wil stop when completing that many

loggings. This is helpful when the user knows the application and wants

to save battery.

· On day: __/__/__ Hour: __:__:__ : The user can select the exact date

and time for the logger to start working.

· Wrap Around (circular memory): The logger will keep on working

indefinitely by overwriting the older recordings (first in, first out) thus

keeping the data recorded for the full memory capacity.

3.7. Steps 3.1 to 3.3 must be applied to channel 2 when available.

Channel 2 will have the same logging interval selected for channel 1, as

well as start and stop time.

4. After all options selected click "OK" and send the new configuration

to LogBox by pointing the IR Link to the IR Window. Confirm that you

want to "Replace configuration of LogBox".

5. It is highly recommended that you perform some recordings after a

new configuration to make sure that all sensors are well connected. To

do so, point the IR Link to the IR Window and click on the LogBox

menu and then on the Monitor option (or click on the "On-Line Monitor".

6. Data download can be performed at any time but this will stop the

recording procedure. The data in memory can be downloaded as many

times as necessary and they will not be erased. After doing a new

configuration all data kept in memory from a previous logging will be

erased.