TEMPERATURE CONTROLLER

N322PID

OPERATING MANUAL - V1.7x A

Man 5001266

The N322-PID is a 2- utput digital electr nic c ntr ller with PID c ntr l alg rithm, intended f r

heating and c ling applicati ns. The input sens rs available are NTC thermist r, Pt100 r

J/K/T type therm c uples. Sens r ffset c rrecti n is pr vided. The 2 independent utputs

can be used as c ntr l r alarm.

The features f a particular m del (input sens r type, sens r range, mains supply, etc) are

identified by the label placed n the c ntr ller b dy.

SPECIFICATIONS

INPUT SENSOR: The input sens r type can be ch sen f rm the 4 pti ns bel w (specified

when placing the rder):

NTC Thermist r, 10 kΩ @ 25 °C; range: –50 t 120 °C (-58 t 248 °F); Accuracy: 1,0 °C

(1,1 °F), with riginal sens r;

Sens r interchangeability: 1 °C (1.35 °F). This err r can be c mpensated by the offset

parameter in the c ntr ller.

Pt100 (α= 385); Range: –50 t 300 °C (-58 t 572 °F); Accuracy: 0,7 °C (1.3 °F);

Type J T/C; Range: 0 t 600 °C (32 t 1112 °F); Accuracy: 3 °C (5.4 °F);

Type K T/C; Range: -50 t 1000 °C (-58 t 1832 °F); Accuracy: 3 °C (5.4 °F);

Type T T/C; Range: -50 t 400 °C (-58 t 752 °F); Accuracy: 3 °C (5.4 °F);

Note: In the c ntr ller with NTC input, a 3 m-sens r cable is bundled with the instrument.

The cable can be extended up t 200 m.

ARM-UP: 15 minutes

MEASUREMENT RESOLUTION:

0.1 °C: fr m –19.9 t 199.9 °C (-3.8 t 391.8 °F) With NTC, Pt100.

1°C: elsewhere

OUTPUT1: Relay: 16 A / 250 Vac, SPDT

OUTPUT2: L gic pulse f r SSR drive: 5 V max / 25 mA

PO ER SUPPLY: 100~240 Vac ( ± 10 %, 50~60 Hz)

P wer c nsumpti n: 5 VA

Cauti n: check the p wer supply specificati n bef re energizing the c ntr ller.

DIMENSIONS: Width x Height x Depth: 74 x 32 x 75 mm

Panel cut- ut: 70 x 29 mm; Weight: 100 g

ENVIRONMENT: Operating temperature: 0 t 40 °C (32 t 122 °F)

St rage temperature: -20 t 60 °C(-4 t 140 °F)

Relative humidity: 20 t 85 % n n c ndensing

CASE: P lycarb nate UL94 V-2; Pr tecti n: Fr nt panel: IP65, B x: IP42

Suitable wiring: Up t 4,0 mm²

Serial interface isolated from input circuitry.

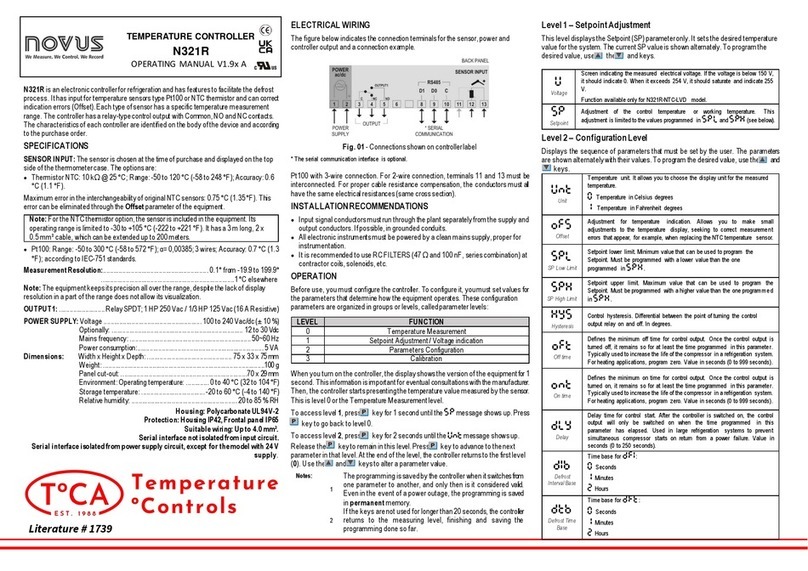

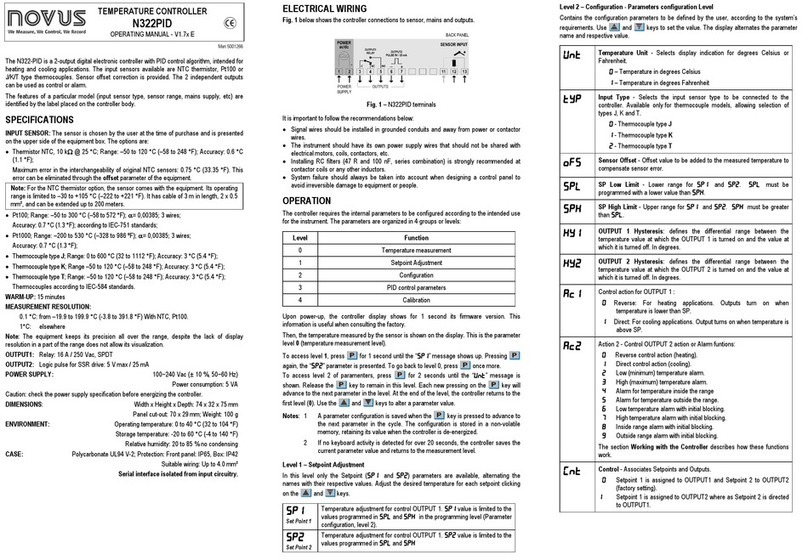

ELECTRICAL IRING

Figure 1 bel w sh ws the c ntr ller c nnecti ns t sens r, mains and utputs.

Figure 1 – N322PID terminals

It is imp rtant t f ll w the rec mmendati ns bel w:

• Signal wires sh uld be installed in gr unded c nduits and away fr m p wer r c ntact r

wires.

• The instrument sh uld have its wn p wer supply wires that sh uld n t be shared with

electrical m t rs, c ils, c ntact rs, etc.

• Installing RC filters (47 R and 100 nF, series c mbinati n) is str ngly rec mmended at

c ntact r c ils r any ther induct rs.

• System failure sh uld always be taken int acc unt when designing a c ntr l panel t

av id irreversible damage t equipment r pe ple.

OPERATION

The c ntr ller requires the internal parameters t be c nfigured acc rding t the intended use

f r the instrument. The parameters are rganized in 4 gr ups r levels:

Level Function

0 Temperature measurement

1 Setp int Adjustment

2 C nfigurati n

3 PID c ntr l parameters

4 Calibrati n

Up n p wer-up, the c ntr ller display sh ws f r 1 sec nd its firmware versi n. This

inf rmati n is useful when c nsulting the fact ry.

Then, the temperature measured by the sens r is sh wn n the display. This is the parameter

level 0 (temperature measurement level).

T access level 1, press f r 1 sec nd until the “SP1

SP1SP1

SP1” message sh ws up. Pressing

again, the “SP2

SP2SP2

SP2” parameter is presented. T g back t level 0, press nce m re.

T access level 2 f paramenters, press f r 2 sec nds until the “uNT

uNTuNT

uNT” message is

sh wn. Release the key t remain in this level. Each new pressing n the key will

advance t the next parameter in the level. At the end f the level, the c ntr ller returns t the

first level (0). Use the and keys t alter a parameter value.

Notes: 1 A parameter c nfigurati n is saved when the key is pressed t advance t

the next parameter in the cycle. The c nfigurati n is st red in a n n-v latile

mem ry, retaining its value when the c ntr ller is de-energized.

2If n keyb ard activity is detected f r ver 20 sec nds, the c ntr ller saves the

current parameter value and returns t the measurement level.

Level 1 – Setpoint Adjustment

In this level nly the Setp int (SP1

SP1 SP1

SP1 and SP2

SP2SP2

SP2) parameters are available, alternating the

names with their respective values. Adjust the desired temperature f r each setp int clicking

n the and keys.

SP1

SP1SP1

SP1

Set Point 1

Temperature adjustment f r c ntr l OUTPUT 1. SP1

SP1SP1

SP1 value is limited t the

values pr grammed in SPL

SPLSPL

SPL and SPk

SPk SPk

SPk in the pr gramming level (Parameter

c nfigurati n, level 2).

SP2

SP2SP2

SP2

Set Point 2

Temperature adjustment f r c ntr l OUTPUT 1. SP2

SP2SP2

SP2 value is limited t the

values pr grammed in SPL

SPLSPL

SPL and SPk

SPk SPk

SPk

Level 2 – Configuration - Parameters configuration Level

C ntains the c nfigurati n parameters t be defined by the user, acc rding t the system’s

requirements. Use and keys t set the value. The display alternates the parameter

name and respective value.

Unt

UntUnt

Unt

Temperature Unit - Selects display indicati n f r degrees Celsius r

Fahrenheit.

0

00

0 – Temperature in degrees Celsius

1

11

1 – Temperature in degrees Fahrenheit

typ

typtyp

typ

Input Type - Selects the input sens r type t be c nnected t the

c ntr ller. Available nly f r therm c uple m dels, all wing selecti n f

types J, K and T.

0

00

0 - Therm c uple type J

1

11

1 - Therm c uple type K

2

22

2 - Therm c uple type T

ofs

ofsofs

ofs

Sensor Offset - Offset value t be added t the measured temperature t

c mpensate sens r err r.

spl

splspl

spl

SP Low Limit - L wer range f r SP1

SP1 SP1

SP1 and SP2

SP2SP2

SP2. SPL

SPL SPL

SPL must be

pr grammed with a l wer value than spK

spKspK

spK.

spK

spKspK

spK

SP High Limit - Upper range f r SP1

SP1 SP1

SP1 and SP2

SP2SP2

SP2. SPx

SPx SPx

SPx must be greater

than spl

splspl

spl.

ky1

ky1ky1

ky1

OUTPUT 1 Hysteresis: defines the differential range between the

temperature value at which the OUTPUT 1 is turned n and the value at

which it is turned ff. In degrees.

ky2

ky2ky2

ky2

OUTPUT 2 Hysteresis: defines the differential range between the

temperature value at which the OUTPUT 2 is turned n and the value at

which it is turned ff. In degrees.

Ac1

Ac1Ac1

Ac1

C ntr l acti n f r OUTPUT 1 :

0

00

0 Reverse: F r heating applicati ns. Outputs turn n when

temperature is l wer than SP.

1

11

1 Direct: F r c ling applicati ns. Output turns n when temperature is

ab ve SP.

Ac2

Ac2Ac2

Ac2

Acti n 2 - C ntr l OUTPUT 2 acti n r Alarm funti ns:

0

00

0 Reverse c ntr l acti n (heating).

1

11

1Direct c ntr l acti n (c ling).

2

22

2L w (minimum) temperature alarm.

3

33

3High (maximum) temperature alarm.

4

44

4Alarm f r temperature inside the range

5

55

5Alarm f r temperature utside the range.

6

66

6L w temperature alarm with initial bl cking.

7

77

7High temperature alarm with initial bl cking.

8

88

8Inside range alarm with initial bl cking.

9

99

9Outside range alarm with initial bl cking.

The secti n orking with the Controller describes h w these functi ns

w rk.

nt

ntnt

nt

Control - Ass ciates Setp ints and Outputs.

0

00

0 Setp int 1 is assigned t OUTPUT1 and Setp int 2 t OUTPUT2

(fact ry setting).

1

11

1 Setp int 1 is assigned t OUTPUT2 where as Setp int 2 is directed

t OUTPUT1.