Controller N480

Novus Produtos Eletrônicos Ltda. Tel.:+55-51-3323-3600 2/3

After the last parameter in one level is reached the controller returns

to operation level and the display will indicate the measured

temperature.

The display will also go back to the measured temperature whenever

the display is inactive for 20 seconds or more.

When a parameter value is changed via keyboard the controller will

only accept the new value after the user presses the INDEX key to

go to next prompt or if the keyboard is left inactive for 20 seconds.

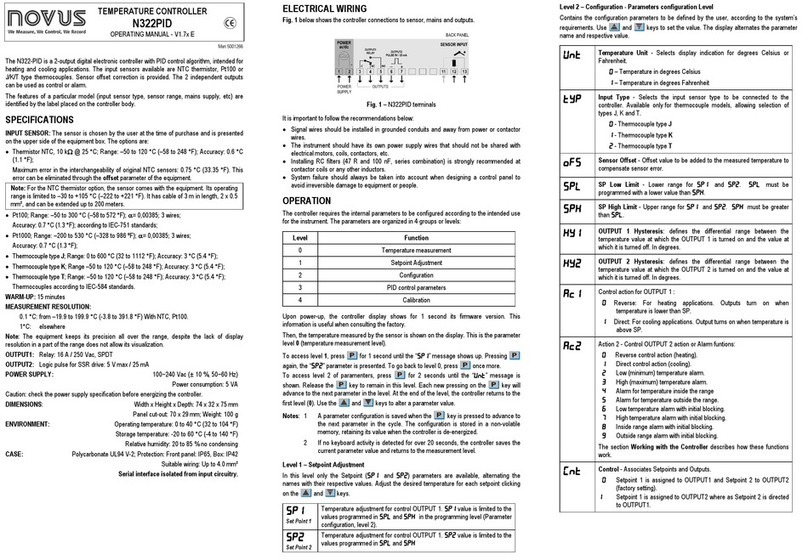

For disabling the keyboard, move the internal strap to the position

KEY DISABLE. All parameters will be protected, accept the SP

parameter.

KEY

DISABLE

KEY

DISABLE

Figure 2 – Strap in normal operating

position (enabled) Figura 3 – Strap position for inhibiting the

keyboard

3.2. OPERATION LEVEL

TEMPERATURE

INDICATION

END

SP

Set Point

TEMPERATURE measured by the sensor.

At power up, the upper display shows the process

temperature value. It also shows the messages

described in chapter 5 of this manual.

The lower displays shows the set point value which

is the temperature value desired for the process.

rAte

rAtE

TEMPERATURE RATE OF RISE: The user defines

the rate of temperature rise from the starting

temperature to the value set in “ SP

SPSP

SP ”.

Rate is defined in °C / minute.

T Sp

time for soak

TIME FOR SOAK: Time in minutes which the

temperature will remain at the selected “ SP

SPSP

SP “.

Refer to item 4.

Rvn

run

RUN: At this prompt the user sets the control output

and alarms to active or to inactive.

0

00

0- inactive outputs; 1

11

1- active outputs;

3.3. TUNING AND ALARMS LEVEL

Atvn

Auto tune

AUTO-TUNE: Activates the auto-tuning of PID

parameters.

0

00

0- Auto-tune is off;

1

11

1- Auto-tune is on;

Pb

Proportional

band

PROPORTIONAL BAND: percentage of maximum

input span.

When set ot zero (0), control action is ON/OFF.

Ir

integral rate

INTEGRAL RATE: Integral time constant in

repetitions per minute (Reset). This constant is not

used when controller is set to ON/OFF action

(Pb=0).

Dt

derivative

time

DERIVATIVE TIME: Derivative time constant in

seconds. This constant is not used when controller

is set to ON/OFF action (Pb=0).

(t

Cycle time

CYCLE TIME: Pulse Width Modulation (PWM)

period in seconds. This term is not used when

controller is set to ON/OFF action (Pb=0).

KySt

HYSterisis

CONTROL HYSTERESIS: Is the hysteresis for

ON/OFF control (set in temperature units).

This parameter is only used when the controller is

in ON/OFF mode (Pb=0).

A1SP

SP Alarm 1

SETPOINT for Alarm 1: Tripingpoint for alarm 1

A2SP

SP Alarm 2

SETPOINT for Alarm 2: Triping point for alarm 2

3.4. CONFIGURATION LEVEL

Type

tYPE

INPUT TYPE: Selects the input sensor type to be

connected to the controller. This is the first

parameter to be set.

0

00

0- Thermocouple type J;

1

11

1- Thermocouple type K;

2

22

2- Thermocouple type S;

3

33

3- Pt100 with 0,1° resolution;

4

44

4- Pt100 with 1° resolution;

5

55

5- Thermocouple type T;

6

66

6- Thermocouple type E;

7

77

7- Termopar tipo N;

8

88

8- Termopar tipo R;

Vnit

unit

TEMPERATURE UNIT: Selects display indication

for degrees Celsius or Farenheit.

0

00

0- degrees Celsius ( °C );

1

11

1- degrees Farenheit ( °F );

A(t

ACtion

CONTROL ACTION:

0

00

0- reverse action. Generally used for heating.

1

11

1- direct action. Generally used for cooling.

(ntr

Control

CONTROL OUTPUT:

0

00

0- Sets control output to terminals OUT A.

1

11

1- Sets control output to terminals OUT B.

As control output is defined to terminals OUT A,

alarm output is automatically set to OUT B.

If control output is defined to OUT B alarm 1 will

then be automatically set to OUT A.

spll

SP Low Limit

SET POINT LOW LIMIT: sets the lower range for

SV

spKl

SP High Limit

SET POINT HIGH LIMIT: Sets the upper range for SV.

A1fv

Alarm 1 Function

FUNCTION OF ALARM 1: Refer to table 2 for

function description and respective codes to set at

this prompt.

A2fv

Alarm 2 Function

FUNCTION OF ALARM 2: Refer to table 2 for

function description and respective codes to set at

this prompt.

Aiky

A2ky

AlarmHYsteresis

ALARM 1 AND ALARM 2 HYSTERESIS: Defines

the differential range between the PV value at

which the alarm is turned on and the value at which

it is turned off (in engineering units).

3.5. CALIBRATION LEVEL

A T E N T I O N

These parameters are used to calibrate the temperature

measurement and should only be dealt with by experienced and well

equipped personnel.

Inl(

Input Low

Calibration

SENSOR OFFSET CALIBRATION. Sets the

temperature sensor low calibration (offset). The

display shows only the corrected temperature and

not the offset added. A signal simulator should be

used to inject a low value signal to properly adjust

the offset.

InK(

Input High

Calibration

INPUT HIGH CALIBRATION. Sets the sensor input

circuit gain or high calibration.

A signal simulator should be used to inject a high

value signal to properly adjust the offset.

(j L

Cold Junction Low

Calibration

COLD JUNCTION OFFSET CALIBRATION: Sets

the cold junction offset calibration. A good

thermometer or a temperature simulator should be

used to properly adjust this parameter.